SCFT Study of Microphase Separation in Mixed Polymer Brushes Grafted on Cylindrical Surface

Received date: 2013-11-21

Online published: 2013-12-25

Supported by

Project supported by the National Basic Research Program of China (No. 2011CB605700) and the National Natural Science Foundation of China (No. 21320102005).

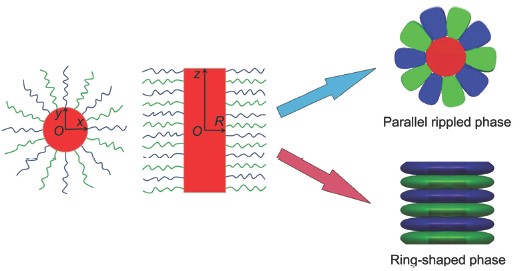

We report on microphase separation behaviors of mixed polymer brushes grafted onto an infinitely long cylindrical rod by performing polymer self-consistent field theory (SCFT) calculation with "masking" technique. The "masking" technique is especially suitable to deal with systems of confined polymers grafted onto curved surfaces. We have developed a method to solve the morphology of block copolymers confined into complicated topographic surfaces with SCFT. In this paper, this unique technique is extended to solve the SCFT for nanorod grafted by mixed polymer brushes. Furthermore, the use of simple Cartesian grids in a cubic computational cell with periodic boundary conditions makes it possible to solve diffusion equations in SCFT by utilizing an efficient and highly accurate pseudo-spectral method involving fast Fourier transform. Both parallel rippled phase and ring-shaped phase are predicted. We have investigated the influences of the cylinder radius, grafting density and interaction between the two incompatible grafting polymers on the stability of the two typical phases. Our results show that the system prefers the ring-shaped phase with the increase of the cylinder radius, grafting density and interaction between the two grafting polymers. Phase diagrams involving these parameters are constructed, and we explain the reason of the transition between the parallel rippled phase and ring-shaped phase in terms of the degree of phase segregation. Again, the degree of phase segregation is higher with larger cylinder radius, grafting density and interaction between the two grafting polymers. By comparing the degree of phase segregation and free energy of the parallel rippled and ring-shaped phases at the same condition, we found that the ring-shaped phase favors the entropic part of the free energy while the parallel rippled phase significantly reduces the enthalpy. Therefore, when the degree of phase segregation is low, the free energy of the system is dominated by the enthalpy, leading to the parallel rippled phase; when the degree of phase segregation is high, the free energy of the system is dominated by the entropic part and the ring-shaped phase is stable. We also found that the domain numbers of parallel rippled phase and the period of alternating ring-shaped phase vary with the radius of cylinder. These predictions are expected to be helpful in rational design and fabrication of such novel polymer brushes.

Ma Xin , Chen Cangyi , Tang Ping , Qiu Feng . SCFT Study of Microphase Separation in Mixed Polymer Brushes Grafted on Cylindrical Surface[J]. Acta Chimica Sinica, 2014 , 72(2) : 208 -214 . DOI: 10.6023/A13111179

[1] Zhao, B.; Brittain, W. J. Prog. Polym. Sci. 2000, 25(5), 677.

[2] Marko, J. F.; Witten, T. A. Phys. Rev. Lett. 1991, 66(11), 1541.

[3] Zhao, B.; Zhu, L. Macromolecules 2009, 42(24), 9369.

[4] Minko, S.; Müller, M.; Usov, D.; Scholl, A.; Froeck, C.; Stamm, M. Phys. Rev. Lett. 2002, 88(3), 5502.

[5] Lai, P. Y. J. Chem. Phys. 1994, 100(4), 3351.

[6] Matsen, M. W.; Schick, M. Phys. Rev. Lett. 1994, 72(16), 2660.

[7] Matsen, M. W. Phys. Rev. Lett. 1995, 74(21), 4225.

[8] Matsen, M. W. Macromolecules 1995, 28(17), 5765.

[9] Clayfiel.Ej; Lumb, E. C. J. Colloid Interface Sci. 1966, 22(3), 269.

[10] Clayfiel.Ej; Lumb, E. C. J. Colloid Interface Sci. 1966, 22(3), 285.

[11] Mackor, E. L. J. Colloid Sci. 1951, 6(5), 492.

[12] Mackor, E. L.; Vanderwaals, J. H. J. Colloid Sci. 1952, 7(5), 535.

[13] Vanderwaarden, M. J. Colloid Sci. 1950, 5(4), 317.

[14] Vanderwaarden, M. J. Colloid Sci. 1950, 5(5), 448.

[15] Vanderwaarden, M. J. Colloid Sci. 1951, 6(5), 443.

[16] Gross, N. A.; Zhulina, E.; Balazs, A. C. J. Chem. Phys. 1996, 104(2), 727.

[17] Szleifer, I.; Carignano, M. A. Adv. Chem. Phys., Vol Xciv 1996, 94, 165.

[18] Hong, J.; Degennes, P. G. Macromolecules 1993, 26(3), 520.

[19] Amiji, M.; Park, K. J. Biomater. Sci.-Polym. Ed. 1993, 4(3), 217.

[20] Vanzanten, J. H. Macromolecules 1994, 27(23), 6797.

[21] Joanny, J. F. Langmuir 1992, 8(3), 989.

[22] Milner, S. T. Science 1991, 251(4996), 905.

[23] Lai, P. Y. J. Chem. Phys. 1993, 98(1), 669.

[24] Lai, P. Y.; Binder, K. J. Chem. Phys. 1991, 95(12), 9288.

[25] Lai, P. Y.; Binder, K. J. Chem. Phys. 1993, 98(3), 2366.

[26] Lai, P. Y.; Halperin, A. Macromolecules 1991, 24(17), 4981.

[27] Marko, J. F.; Witten, T. A. Macromolecules 1992, 25(1), 296.

[28] Müller, M. Phys. Rev. E 2002, 65(3), 030802.

[29] Zhao, B.; Haasch, R. T.; MacLaren, S. J. Am. Chem. Soc. 2004, 126(19), 6124.

[30] Soga, K. G.; Zuckermann, M. J.; Guo, H. Macromolecules 1996, 29(6), 1998.

[31] Zhao, B.; Brittain, W. J.; Zhou, W. S.; Cheng, S. Z. D. Macromolecules 2000, 33(23), 8821.

[32] Zhao, B.; Brittain, W. J. Macromolecules 2000, 33(23), 8813.

[33] Zhao, B.; He, T. Macromolecules 2003, 36(23), 8599.

[34] Zhao, B. Langmuir 2004, 20(26), 11748.

[35] Ohno, K.; Koh, K.; Tsujii, Y.; Fukuda, T. Angew. Chem.-Int. Ed. 2003, 42(24), 2751.

[36] Wang, B. B.; Li, B.; Zhao, B.; Li, C. Y. J. Am. Chem. Soc. 2008, 130(35), 11594.

[37] Farmer, S. C.; Patten, T. E. Chem. Mater. 2001, 13(11), 3920.

[38] Sill, K.; Emrick, T. Chem. Mater. 2004, 16(7), 1240.

[39] Zhu, M. Q.; Wang, L. Q.; Exarhos, G. J.; Li, A. D. Q. J. Am. Chem. Soc. 2004, 126(9), 2656.

[40] Vestal, C. R.; Zhang, Z. J. J. Am. Chem. Soc. 2002, 124(48), 14312.

[41] Matsuno, R.; Yamamoto, K.; Otsuka, H.; Takahara, A. Macromolecules 2004, 37(6), 2203.

[42] Chanana, M.; Jahn, S.; Georgieva, R.; Lutz, J. F.; Baumler, H.; Wang, D. Y. Chem. Mater. 2009, 21(9), 1906.

[43] Papaphilippou, P.; Loizou, L.; Popa, N. C.; Han, A.; Vekas, L.; Odysseos, A.; Krasia-Christoforou, T. Biomacromolecules 2009, 10(9), 2662.

[44] Wang, B. B.; Li, B.; Dong, B.; Zhao, B.; Li, C. Y. Macromolecules 2010, 43(22), 9234.

[45] von Werne, T.; Patten, T. E. J. Am. Chem. Soc. 1999, 121(32), 7409.

[46] Prucker, O.; Ruhe, J. Macromolecules 1998, 31(3), 592.

[47] Prucker, O.; Ruhe, J. Macromolecules 1998, 31(3), 602.

[48] Wang, Y. Q.; Yang, G. A.; Tang, P.; Qiu, F.; Yang, Y. L.; Zhu, L. J. Chem. Phys. 2011, 134(13), 134903.

[49] Ma, X.; Yang, Y. Z.; Zhu, L.; Zhao, B.; Tang, P.; Qiu, F. J. Chem. Phys. 2013, 139, 214902.

[50] Egorov, S. A. Soft Matter 2012, 8(14), 3971.

[51] Egorov, S. A.; Binder, K. J. Chem. Phys. 2012, 137(9), 094901.

[52] Netz, R. R.; Schick, M. Macromolecules 1998, 31, 5105.

/

| 〈 |

|

〉 |