[1] Hong, G.; Diao, S.; Antaris, A. L.; Dai, H. Chem. Rev. 2015, 115, 10816.

[2] Ko, H. C.; Stoykovich, M. P.; Song, J.; Malyarchuk, V.; Choi, W. M.; Yu, C.-J.; Geddes III, J. B.; Xiao, J.; Wang, S.; Huang, Y.; Rogers, J. A. Nature 2008, 454, 748.

[3] Martyniuk, P.; Rogalski, A. Prog. Quantum Electron. 2008, 32, 89.

[4] Rauch, T.; Böberl, M.; Tedde, S. F.; Fürst, J.; Kovalenko, M. V.; Hesser, G.; Lemmer, U.; Heiss, W.; Hayden, O. Nat. Photonics 2009, 3, 332.

[5] Rogalski, A.; Chrzanowski, K. Metrol. Meas. Syst. 2014, 21, 565.

[6] Lv, J. T.; Yang, L. J.; Li, Z. G.; Wei, Y. T.; Zhang, B. J.; Liang, L. Q.; Wang, F. W.; Si, G. Y. Acta Chim. Sinica 2013, 71, 1275. (吕江涛, 杨琳娟, 李志刚, 魏永涛, 张宝健, 梁丽勤, 王凤文, 司光远, 化学学报, 2013, 71, 1275.)

[7] Zhou, J. P.; Wu, B. G.; Zhou, Z. K.; Tian, J. W.; Yuan, A. H. Chin. J. Org. Chem. 2019, 39, 406. (周建平, 吴保庚, 周志宽, 田蒋为, 袁爱华, 有机化学, 2019, 39, 406.)

[8] Juang, F.-S.; Su, Y.-K.; Yu, H. H.; Liu, K.-J. Mater. Chem. Phys. 2003, 78, 620.

[9] Xie, C.; Yan, F. Small 2017, 13, UNSP 1701822.

[10] Geim, A. K.; Novoselov, K. S. Nat. Mater. 2007, 6, 183.

[11] Wu, H.-Q.; Linghu, C.-Y.; Lu, H.-M.; Qian, H. Chin. Phys. B 2013, 22, 098106.

[12] Zhu, J.; Yang, X.; Fu, Z.; He, J.; Wang, C.; Wu, W.; Zhang, L. Chemistry 2016, 22, 2515.

[13] Gong, M.; Liu, Q.; Cook, B.; Kattel, B.; Wang, T.; Chan, W. L.; Ewing, D.; Casper, M.; Stramel, A.; Wu, J. Z. ACS Nano 2017, 11, 4114.

[14] Haider, G.; Roy, P.; Chiang, C.-W.; Tan, W.-C.; Liou, Y.-R.; Chang, H.-T.; Liang, C.-T.; Shih, W.-H.; Chen, Y.-F. Adv. Funct. Mater. 2016, 26, 620.

[15] Manga, K. K.; Wang, J.; Lin, M.; Zhang, J.; Nesladek, M.; Nalla, V.; Ji, W.; Loh, K. P. Adv. Mater. 2012, 24, 1697.

[16] Dang, V. Q.; Han, G.-S.; Trung, T. Q.; Duy, L. T.; Jin, Y.-U.; Hwang, B.-U.; Jung, H.-S.; Lee, N.-E. Carbon 2016, 105, 353.

[17] De Fazio, D.; Goykhman, I.; Yoon, D.; Bruna, M.; Eiden, A.; Milana, S.; Sassi, U.; Barbone, M.; Dumcenco, D.; Marinov, K.; Kis, A.; Ferrari, A. C. ACS Nano 2016, 10, 8252.

[18] Xu, H.; Wu, J.; Feng, Q.; Mao, N.; Wang, C.; Zhang, J. Small 2014, 10, 2300.

[19] Cai, J.; Ruffieux, P.; Jaafar, R.; Bieri, M.; Braun, T.; Blankenburg, S.; Muoth, M.; Seitsonen, A. P.; Saleh, M.; Feng, X.; Müllen, K.; Fasel, R. Nature 2010, 466, 470.

[20] Eda, G.; Mattevi, C.; Yamaguchi, H.; Kim, H.; Chhowalla, M. J. Phys. Chem. C 2009, 113, 15768.

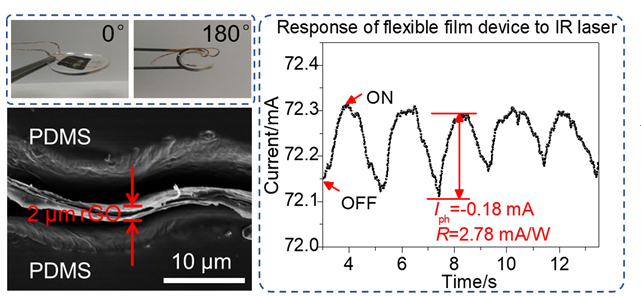

[21] Cao, Y.; Yang, H.; Zhao, Y.; Zhang, Y.; Ren, T.; Jin, B.; He, J.; Sun, J.-L. ACS Photonics 2017, 4, 2797.

[22] Cao, Y.; Zhu, J.; Xu, J.; He, J.; Sun, J. L.; Wang, Y.; Zhao, Z. Small 2014, 10, 2345.

[23] Yang, H.; Cao, Y.; He, J.; Zhang, Y.; Jin, B.; Sun, J.-L.; Wang, Y.; Zhao, Z. Carbon 2017, 115, 561.

[24] Huang, W.; Dong, X.; Cai, Y. Chin. Sci. Bull. 2016, 62, 635.

[25] Yan, S.; Zhang, G.; Jiang, H.; Li, F.; Zhang, L.; Xia, Y.; Wang, Z.; Wu, Y.; Li, H. ACS Appl. Mater. Interfaces 2019, 11, 10736.

[26] Sun, J.-L.; Zhang, W.; Zhu, J.-L.; Bao, Y. Opt. Express 2010, 18, 4066.

[27] Zheng, J.-G.; Sun, J.-L.; Xue, P. Chin. Phys. Lett. 2011, 28, 127302.

[28] Koppens, F. H.; Mueller, T.; Avouris, P.; Ferrari, A. C.; Vitiello, M. S.; Polini, M. Nat. Nanotech. 2014, 9, 780.

[29] Ito, Y.; Zhang, W.; Li, J.; Chang, H.; Liu, P.; Fujita, T.; Tan, Y.; Yan, F.; Chen, M. Adv. Funct. Mater. 2016, 26, 1271.

[30] Bae, J. J.; Yoon, J. H.; Jeong, S.; Moon, B. H.; Han, J. T.; Jeong, H. J.; Lee, G. W.; Hwang, H. R.; Lee, Y. H.; Jeong, S. Y.; Lim, S. C. Nanoscale 2015, 7, 15695.

[31] Jiang, F.; Zheng, X. L.; Chen, L.; Hu, N.; Yang, J.; Liao, Y. J. New Chem. Mater. 2016, 44, 7. (姜帆, 郑小林, 陈礼, 胡宁, 杨军, 廖彦剑, 化工新型材料, 2016, 44, 7.)

[32] Cao, Y.; Zhao, Y.; Wang, Y.; Zhang, Y.; Wen, J.; Zhao, Z.; Zhu, L. Carbon 2019, 144, 193.

[33] Hummers, W. S.; Offeman, R. E. J. Am. Chem. Soc. 1958, 80, 1339.