[1] Koros, W. J.; Zhang, C. Nat. Mater. 2017, 16, 289.

[2] Huang, A.-S.; Liang, F.-Y.; Steinbach, F.; Caro. J. J. Membr. Sci. 2010, 350, 5.

[3] Huang, A.-S.; Caro, J. J. Mater. Chem. 2011, 21, 11424.

[4] Shi, K.-Y.; Chi, Y.-J.; Jin, X.-Q.; Xu, M.; Yuan, F.-L.; Fu, H.-G. Acta Chim. Sinica 2005, 63, 885. (史克英, 池玉娟, 金效齐, 徐敏, 袁福龙, 付宏刚, 化学学报, 2005, 63, 885.)

[5] Huang, A.-S.; Wang, N.-Y.; Kong, C.-L.; Caro, J. Angew. Chem. Int. Ed. 2012, 51, 10551.

[6] Ben, T.; Lu, C.-J.; Pei, C.-Y.; Xu, S.-X.; Qiu, S.-L. Chem. Eur. J. 2012, 18, 10250.

[7] Liu, B.; Tang, L.-X.; Lian, Y.-H.; Li, Z.; Sun, C.-Y.; Chen, G.-J. Acta Chim. Sinica 2013, 71, 920. (刘蓓, 唐李兴, 廉源会, 李智, 孙长宇, 陈光进, 化学学报, 2013, 71, 920.)

[8] Guo, H.-L.; Zhu, G.-S.; Hewitt, I. J.; Qiu, S.-L. J. Am. Chem. Soc. 2009, 131, 1646.

[9] Budd, P. M.; Msayib, K. J.; Tattershall, C. E.; Ghanem, B. S.; Reynolds, K. J.; McKeown, N. B.; Fritsch, D. J. Membr. Sci. 2005, 251, 263.

[10] Diercks, C. S.; Yaghi, O. M. Science 2017, 355, 6328.

[11] Chen, Q.-D.; Tang, J.-J.; Fang, Q.-R. Chem. J. Chin. Univ. 2018, 39, 2357. (陈奇丹, 唐俊杰, 方千荣, 高等学校化学学报, 2018, 39, 2357.)

[12] Huang, N.; Wang, P.; Jiang, D.-L. Nat. Rev. Mater. 2016, 1, 16068.

[13] Wang, Z.-T.; Li, H.; Yan, S.-C.; Fang, Q.-R. Acta Chim. Sinica 2020, 78, 63. (王志涛, 李辉, 颜士臣, 方千荣, 化学学报, 2020, 78, 63.)

[14] Huang, W.; Li, Y.-G. Chin. J. Chem. 2019, 37, 1291.

[15] Peng, Z.-K.; Ding, H.-M.; Chen, R.-F.; Gao, C.; Wang, C. Acta Chim. Sinica 2019, 77, 681. (彭正康, 丁慧敏, 陈如凡, 高超, 汪成, 化学学报, 2019, 77, 681.)

[16] Dong, G.-X.; Lee, Y. M. J. Mater. Chem. A 2017, 5, 13294.

[17] Yuan, S.-S.; Li, X.; Zhu, J.-Y.; Zhang, G.; Puyvelde, P. V.; Bruggen, B. V. Chem. Soc. Rev. 2019, 48, 2665.

[18] Wang, J.; Zhu, J.-Y.; Zhang, Y.-T.; Liu, J.-D.; Bruggen, B. V. Nanoscale 2017, 9, 2942.

[19] Ding, S.-Y.; Wang, W. Chem. Soc. Rev. 2013, 42, 548.

[20] Uribe-Romo, F. J.; Doonan, C. J.; Furukawa, H.; Oisaki, K.; Yaghi, O. M. J. Am. Chem. Soc. 2011, 133, 11478.

[21] Kandambeth, Sharath.; Mallick, A.; Lukose, B.; Mane, M. V.; Heine, T.; Rahul, B. J. Am. Chem. Soc. 2012, 134, 19524.

[22] Zhou, H.-C.; Long, J.-R.; Yaghi, O. M. Chem. Rev. 2012, 112, 673.

[23] Chung, T. S.; Jiang, L.-Y.; Li, Y.; Kulprathipanja, S. Prog. Polym. Sci. 2007, 32, 483.

[24] Bunck, D. N.; Dichtel, W. R. J. Am. Chem. Soc. 2013, 135, 14952.

[25] Liu, X.-H.; Guan, C.-Z.; Ding, S.-Y.; Wang, W.; Yan, H.-Y.; Wang, D.; Wan, L.-J. J. Am. Chem. Soc. 2013, 135, 28, 10470.

[26] Dai, W.-Y.; Shao, F.; Szczerbiński, J.; McCaffrey, R.; Zenobi, R.; Jin, Y.-H.; Schlüter, D.; Zhang, W. Angew. Chem., Int. Ed. 2016, 55, 213.

[27] Dey, K.; Pal, M.; Rout, K. C.; Kunjattu-H, S.; Das, A.; Mukherjee, R.; Kharul, U. K.; Baneriee, R. J. Am. Chem. Soc. 2017, 139, 13083.

[28] Fu, J.-R.; Das, S.; Xing, G.-L.; Ben, T.; Valtchev, V.; Qiu, S.-L. J. Am. Chem. Soc. 2016, 138, 7673.

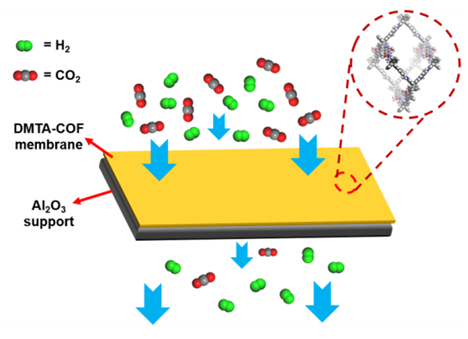

[29] Fan, H.-W.; Mundstock, A.; Feldhoff, A.; Knebel, A.; Gu, J.-H.; Meng, H.; Caro, J. J. Am. Chem. Soc. 2018, 140, 10094.

[30] Fan, H.-W.; Mundstock, A.; Gu, J.-H.; Meng, H.; Caro, J. J. Mater. Chem. A. 2018, 6, 16849.

[31] Segura, J. L.; Mancheo, M. J.; Zamora, F. Chem. Soc. Rev. 2016, 45, 5635.

[32] Ma, Y.-X.; Li, Z.-J.; Wei, L.; Ding, S.-Y.; Zhang, Y.-B.; Wang, W. J. Am. Chem. Soc. 2017, 139, 4995.

[33] Zhang, Y.-B.; Su, J.; Furukawa, H.; Yun, Y.-F.; Gándara, F.; Duong, A.; Zou, X.-D.; Yaghi, O. M. J. Am. Chem. Soc. 2013, 135, 16336.

[34] Bureekaew, S.; Sato, H.; Matsuda, R.; Kubota, Y.; Hirose, R.; Kim, J.; Kato, K.; Takata, M.; Kitagawa, S. Angew. Chem., Int. Ed. 2010, 49, 7660.

[35] Reichenbach, C.; Kalies, G.; Lincke, J.; Lässig, D,; Krautscheid, H.; Moellmer, J.; Thommes, M. Microporous Mesoporous Mater. 2011, 142, 592.

[36] Feng, S.-C.; Ren, J.-Z.; Li, H.; Hua, K.-S.; Li, X.-X.; Deng, M.-C. Membr. Sci. Technol. 2013, 33, 53. (冯世超, 任吉中, 李晖, 花开胜, 李新学, 邓麦村, 膜科学与技术, 2013, 33, 53)

[37] Lin, H.-Q.; Freeman, B. D. J. Mol. Struct. 2005, 739, 57.

[38] Lu, H.; Wang, C.; Chen, J.-J.; Ge, R.-L.; Leng, W.-G.; Dong, B.; Huang, J.; Gao, Y.-N. Chem. Commun. 2015, 51, 15562.

[39] Robeson, L. M. J. Membr. Sci. 2008, 320, 390.