Preparation and Performance Characterization of Flexible and Washable Zr-MOFs Composite Nanofiber Membrane

Received date: 2021-08-26

Online published: 2021-10-22

Supported by

National Natural Science Foundation of China(52170019); National Natural Science Foundation of China(51973015); Fundamental Research Funds for the Central Universities(06500100); Fundamental Research Funds for the Central Universities(FRF-TP-19-046AIZ)

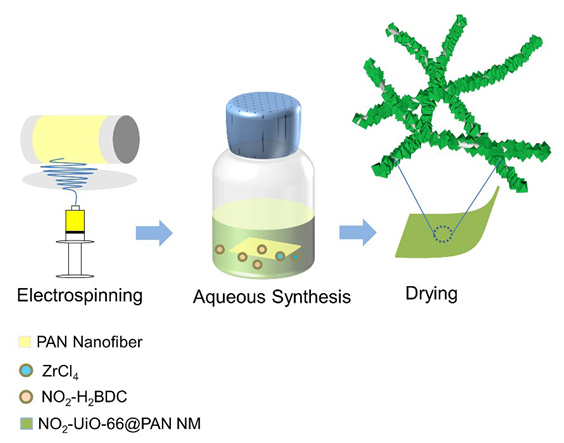

Flexible high adsorption materials play a key role in many fields such as wastewater and exhaust gas treatment, protective clothing manufacturing, toxic and harmful substance monitoring. In situ growth of NO2-UiO-66 on electrostatic spun nanofiber was obtained by aqueous synthesis using trifluoroacetic acid as regulator, and water as solvent. The effects of different ratio of trifluoroacetic acid (TFA)/deionized water, different metal salt and ligand proportions and hydrothermal growth time on NO2-UiO-66 morphology and load effects were studied. The add content of TFA was φTFA=30%, the molar ratio of metal salt and the ligand was 1∶1.5, and the hydrothermal growth time was maintained at 4 h, which proved to be the optimal synthetic conditions. The specific synthesis procedure of the NO2-UiO-66@polyacrylonitrile composite nanofiber membrane (NO2-UiO-66@PAN NM) was as follows: First, 10% (w) of PAN spinning liquid was woven into nanofiber membrane using the electrospinning method. Second, a solvent having a TFA content of 30% was prepared in a sealed glass bottle, followed by addition of metal salt (ZrCl4) and organic ligand (2-nitroterephthalic acid, NO2-H2BDC). Finally, the PAN nanofiber was immersed in the precursor mixture, and after 30 min of ultrasonic treatment, it was placed in an oven at 100 ℃ for 4 h to obtain the NO2-UiO-66@PAN NM. The structure of NO2-UiO-66@PAN NM was characterized by scanning electron microscope (SEM), X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FT-IR), thermogravimetry (TG) and nitrogen adsorption-desorption test. The characterization results showed that the NO2-UiO-66 were uniformly loaded on nanofibers. The load could reach 33.28%, the Brunner-Emmet-Teller measurements (BET) surface area was 504.16 m2/g, and the pore volume was 0.241 cm3/g. Further, the NO2-UiO-66@PAN nanofiber membrane still remained in the stability of the structure after being treated with high temperature (320 ℃), bending and washing with water, acid and alkali. Through the above characterization analysis, it was found that the NO2-UiO-66 loaded on the nanofibers, which enabled the membrane material excellent in physical and chemical stable properties, and has a large application potential under harsh conditions such as toxic and harmful.

Key words: electrospinning; nanofiber; metal-organic framework; NO2-UiO-66; aqueous synthesis

Xiaoke Hao , Zhenyu Zhai , Yaxin Sun , Congju Li . Preparation and Performance Characterization of Flexible and Washable Zr-MOFs Composite Nanofiber Membrane[J]. Acta Chimica Sinica, 2022 , 80(1) : 49 -55 . DOI: 10.6023/A21080402

| [1] | Hao, X. K.; Zhang, X. L.; Zhai, Z. Y.; Li, C. J. Fine Chem. 2021, 38, 249 ; (in Chinese) |

| [1] | ( 郝肖柯, 张秀玲, 翟振宇, 李从举, 精细化工 2021, 38, 249.) |

| [2] | Hu, M. L.; Masoomi, M. Y.; Morsali, A. Coord. Chem. Rev. 2019, 387, 415. |

| [3] | Georgiadis, A. G.; Charisiou, N.; Yentekakis, I. V.; Goula, M. A. Materials 2020, 13, 3640. |

| [4] | Lyu, L. X.; Zhao, Y. L.; Wei, Y. Y.; Wang, H. H. Acta Chim. Sinica 2021, 79, 869 ; (in Chinese) |

| [4] | ( 吕露茜, 赵娅俐, 魏嫣莹, 王海辉, 化学学报 2021, 79, 869.) |

| [5] | Zeng, J. Y.; Wang, X. S.; Zhang, X. Z.; Zhuo, R. X. Acta Chim. Sinica 2019, 77, 1156 ; (in Chinese) |

| [5] | ( 曾锦跃, 王小双, 张先正, 卓仁禧, 化学学报 2019, 77, 1156.) |

| [6] | Lazaro, I. A.; Wells, C. J. R.; Forgan, R. S. Angew. Chem. Int. Ed. 2020, 59, 5211. |

| [7] | He, P. C.; Zhou, J.; Zhou, A. W.; Dou, Y. B.; Li, J. R. Chem. J. Chin. Univ. 2019, 40, 855 ; (in Chinese) |

| [7] | ( 何鹏琛, 周健, 周阿武, 豆义波, 李建荣, 高等学校化学学报, 2019, 40, 855.) |

| [8] | Wang, D. K.; Li, Z. H. Res. Chem. Intermediat. 2017, 43, 5169. |

| [9] | Wang, Y.; Li, B. T.; Zhang, B. C.; Tian, S. Y.; Yang, X.; Ye, H.; Xia, Z. J.; Zheng, G. X. J. Electroanal. Chem. 2020, 878, 114576. |

| [10] | Hu, R.; Zhang, X.; Chi, K. N.; Yang, T.; Yang, Y. H. ACS Appl. Mater. Inter. 2020, 12, 30770. |

| [11] | Sule, R.; Mishra, A. K. Environ. Sci. Pollut. R. 2020, 27, 16004. |

| [12] | Wang, X. F.; Song, X. Z.; Sun, K. M.; Cheng, L.; Ma, W. Polyhedron 2018, 152, 155. |

| [13] | Cui, Y. J.; Li, B.; He, H. J.; Zhou, W.; Chen, B. L.; Qian, G. D. Acc. Chem. Res. 2016, 49, 483. |

| [14] | Jiao, L.; Seow, J. Y. R.; Skinner, W. S.; Wang, Z. U.; Jiang, H. L. Mater. Today 2019, 27, 43. |

| [15] | Falcaro, P.; Ricco, R.; Yazdi, A.; Imaz, I.; Furukawa, S.; Maspoch, D.; Ameloot, R.; Evans, J. D.; Doonan, C. J. Coord. Chem. Rev. 2016, 307, 237. |

| [16] | Zhang, H. B.; Nai, J. W.; Yu, L.; Lou, X. W. Joule 2017, 1, 77. |

| [17] | Liu, X. L. Front. Chem. Sci. Eng. 2020, 14, 216. |

| [18] | Ahmad, K.; Nazir, M. A.; Qureshi, A. K.; Hussain, E.; Najam, T.; Javed, M. S.; Shah, S. S. A.; Tufail, M. K.; Hussain, S.; Khan, N. A.; Shah, H. U. R.; Ashfaq, M. Mat. Sci. Eng. B-Adv. 2020, 262, 114766. |

| [19] | Rada, Z. H.; Abid, H. R.; Sun, H. Q.; Shang, J.; Li, J. Y.; He, Y. D.; Liu, S. M.; Wang, S. B. Prog. Nat. Sci. 2018, 28, 160. |

| [20] | Luu, C. L.; Nguyen, T. T. V.; Nguyen, T.; Hoang, T. C. 2015, 6, 025004. |

| [21] | Stassen, I.; Dou, J. H.; Hendon, C.; Dinca, M. ACS Central Sci. 2019, 5, 1425. |

| [22] | Taima-Mancera, I.; Rocio-Bautista, P.; Pasan, J.; Ayala, J. H.; Ruiz-Perez, C.; Afonso, A. M.; Lago, A. B.; Pino, V. Molecules 2018, 23, 2869. |

| [23] | Zhang, L. Y.; Chen, H.; Bai, X. J.; Wang, S.; Li, L. L.; Shao, L.; He, W. X.; Li, Y. N.; Wang, T. Q.; Zhang, X. M.; Chen, J. Y.; Fu, Y. Chem. Commun. 2019, 55, 8293. |

| [24] | Hong, Y.; Liu, C. Y.; Cao, X. C.; Chen, Y.; Chen, C.; Chen, Y.; Pan, Z. J. Polymers 2018, 10, 1386. |

| [25] | Wahiduzzaman |

| [26] | Wang, S. B.; Lin, Y.; Yang, J.; Shi, L.; Yang, G.; Zhuang, X. P.; Li, Z. H. Int. J. Hydrogen Energ. 2021, 46, 19106. |

| [27] | Zhai, Z. Y.; Zhang, X. L.; Wang, J. N.; Li, H. Y.; Sun, Y. X.; Hao, X. K.; Qin, Y.; Niu, B.; Li, C. J. Chem. Eng. J. 2021, 428, 131720. |

| [28] | Lu, A. X.; Ploskonka, A. M.; Tovar, T. M.; Peterson, G. W.; DeCoste, J. B. Ind. Eng. Chem. Res. 2017, 56, 14502. |

| [29] | Ma, K. K.; Islamoglu, T.; Chen, Z. J.; Li, P.; Wasson, M. C.; Chen, Y. W.; Wang, Y. F.; Peterson, G. W.; Xin, J. H.; Farha, O. K. J. Am. Chem. Soc. 2019, 141, 15626. |

| [30] | Diring, S.; Furukawa, S.; Takashima, Y.; Tsuruoka, T.; Kitagawa, S. Chem. Mater. 2010, 22, 4531. |

| [31] | Surya, S. G.; Bhanoth, S.; Majhi, S. M.; More, Y. D.; Teja, V. M.; Chappanda, K. N. CrystEngComm 2019, 21, 7303. |

| [32] | Zhang, Y. Q.; Chu, Q.; Shi, Y.; Gao, J. S.; Xiong, W.; Huang, L.; Ding, Y. Acta Chim. Sinica 2021, 79, 361 ( in Chinese); |

| [32] | ( 张雅祺, 楚奇, 石勇, 高金索, 熊巍, 黄磊, 丁越, 化学学报 2021, 79, 361.) |

| [33] | Shamsabadi, A. S.; Ranjbar, M.; Tavanai, H.; Farnood, A. Mater. Res. Express. 2019, 6, 055051. |

| [34] | Zhang, X. F.; Wang, Z. G.; Feng, Y.; Zhong, Y. X.; Liao, J. Q.; Wang, Y. Q.; Yao, J. F. Fuel 2018, 234, 256. |

| [35] | Ma, Y. L.; Liu, R. X.; Meng, S. Y.; Niu, L. T.; Yang, Z. W.; Lei, Z. Q. Acta Chim. Sinica 2019, 77, 153 ; (in Chinese) |

| [35] | ( 马亚丽, 刘茹雪, 孟双艳, 牛力同, 杨志旺, 雷自强, 化学学报 2019, 77, 153.) |

| [36] | Choi, J.; Yoo, K. S.; Kim, D.; Kim, J.; Othman, M. R. ACS Appl. Nano Mater. 2021, 4, 4895. |

| [37] | Woo, H. C.; Yoo, D. K.; Jhung, S. H. ACS Appl. Mater. Inter. 2020, 12, 28885. |

| [38] | Li, H.; Chu, H. J.; Ma, X. L.; Wang, G. R.; Liu, F. S.; Guo, M.; Lu, W. P.; Zhou, S. J.; Yu, M. Z. Chem. Eng. J. 2021, 408, 127277. |

| [39] | Piscopo, C. G.; Polyzoidis, A.; Schwarzer, M.; Loebbecke, S. Micropor. Mesopor. Mat. 2015, 208, 30. |

/

| 〈 |

|

〉 |