Research on Iron-Lead Semi-Flow Battery Based on 3D Solid Electrode

Received date: 2021-09-26

Online published: 2021-11-25

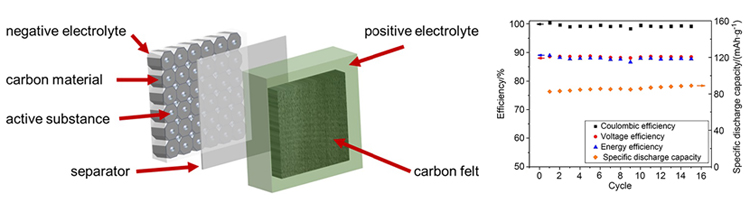

Low-cost large-scale electrochemical energy storage technology is of great significance for the efficient use of clean and renewable energy such as solar and wind energy. In this work, a 3D lead electrode is designed as a high-performance negative electrode, and an iron-lead (Fe-Pb) semi-flow battery is constructed on this basis. The positive and negative active materials of the battery are ferrous sulfate/iron sulfate and lead/lead sulfate respectively, and sulfuric acid aqueous solution is used as the supporting electrolyte. The negative electrode uses acetylene carbon black (ACET) as an effective additive to form a highly conductive network with a porous structure, and the performance of the battery can be significantly improved by adding ACET in the native electrode. Moreover, benefiting from the novel design of the battery, problems of metal dendrites, hydrogen evolution and irreversible sulfation of the Pb electrode can be avoided. The results show that the introduction of ACET in the negative electrode as a conductive agent can effectively improve the energy efficiency, the utilization rate of the active material of the negative electrode and the rate performance of the battery. The effect of the ACET content on the performance including the current efficiency, voltage efficiency and energy efficiency of the battery has been studied. It is illustrated that an ACET mass content of 12.5% over the active materials in the negative electrode is preferred. At a current density of 20 mA/cm2, the specific capacity of the negative electrode can reach 89.3 mAh/g, the battery current efficiency and energy efficiency can reach 99.3% and 88.6%, respectively. Cycling stability of the Fe-Pb semi-flow battery is also investigated in this work. The result shows that the designed battery has excellent cycling stability during the stability test. In addition, the estimated cost of the active material for this battery can be as low as 53.27 $/kWh, which is lower than most of the other energy storage battery systems. Therefore, as a low-cost large-scale electrochemical energy storage battery technology, the iron-lead semi-flow battery has a good research prospect.

Zhuhan Zhang , Fengjing Jiang , Keke Wu , Peng Shen . Research on Iron-Lead Semi-Flow Battery Based on 3D Solid Electrode[J]. Acta Chimica Sinica, 2022 , 80(1) : 56 -62 . DOI: 10.6023/A21090440

| [1] | May, G. J.; Davidson, A.; Monahov, B. J. Energy Storage 2018, 15, 145. |

| [2] | Divya, K. C.; Ostergaard, J. Electr. Power Syst. Res. 2009, 79, 511. |

| [3] | Wang, Y.; He, P.; Zhou, H. Energy Environ. Sci. 2011, 4, 805. |

| [4] | Deng, B.-W.; Sun, D.-M.; Wan, Q.; Wang, H.; Chen, T.; Li, X.; Qu, M.-Z.; Peng, G.-C. Acta Chim. Sinica 2018, 76, 259. (in Chinese) |

| [4] | ( 邓邦为, 孙大明, 万琦, 王昊, 陈滔, 李璇, 瞿美臻, 彭工厂, 化学学报 2018, 76, 259.) |

| [5] | Zhuang, R.; Xu, X.-S.; Qu, C.-Z.; Xu, S.-Q.; Yu, T.; Wang, H.-Q.; Xu, F. Acta Chim. Sinica 2021, 79, 378. (in Chinese) |

| [5] | ( 庄容, 许潇洒, 曲昌镇, 徐顺奇, 于涛, 王洪强, 徐飞, 化学学报 2021, 79, 378.) |

| [6] | Baker, J. Energy Policy 2008, 36, 4368. |

| [7] | Brost, R. D.. In Valve-Regulated Lead-Acid Batteries, Eds.: Rand, D. A. J.; Garche, J.; Moseley P. T.; Parker C. D., Elsevier, 2004, Chapter 11, p. 327. |

| [8] | Zogg, R.; Lawrence, T.; Oferl, D.; Brodrick, J. ASHRAE J. 2007, 49, 90. |

| [9] | Soloveichik, G. L. Chem. Rev. 2015, 115, 11533. |

| [10] | Han, P.-X.; Wang, H.-B.; Liu, Z.-H.; Chen, X.; Ma, W.; Yao, J.-H.; Zhu, Y.-W.; Cui, G.-L. Carbon 2011, 49, 693. |

| [11] | Han, P.-X.; Yue, Y.-H.; Liu, Z.-H.; Xu, W.; Zhang, L.-X.; Xu, H.-X.; Dong, S.-M.; Cui, G.-L. Energy Environ. Sci. 2011, 4, 4710. |

| [12] | Jiang, F.-J.; He, Z.-Q.; Guo, D.-Y.; Zhou, X.-J. J. Power Sources 2019, 440, 227114. |

| [13] | Wang, F.-R.; Jiang, F.-J. Acta Chim. Sinica 2021, 79, 1123. (in Chinese) |

| [13] | ( 王斐然, 蒋峰景, 化学学报 2021, 79, 1123.) |

| [14] | Feng, T. M.S. Thesis, Zhejiang University of Technology, Hangzhou, 2018. (in Chinese) |

| [14] | ( 冯天明, 硕士论文, 浙江工业大学, 杭州, 2018.) |

| [15] | Jayathilake, B. S.; Plichta, E. J.; Hendrickson, M. A.; Narayanan, S. R. J. Electrochem. Soc. 2018, 165, A1630. |

| [16] | Krista, L. H.; Tyler, J. P.; Mallory, A. M.; Jesse, S. W.; Robert, F. S. J. J. Electrochem. Soc. 2015, 162, 108. |

| [17] | Verde, M. G.; Carroll, K. J.; Wang, Z. Y.; Sathrum, A.; Meng, Y. S. Energy Environ. Sci. 2013, 6, 1573. |

| [18] | Zeng, Y.-K.; Zhao, T.-S.; Zhou, X.-L.; Wei, L.; Ren, Y.-X. J. Power Sources 2017, 346, 97. |

| [19] | Ruetschi, P. J. Power Sources 2003, 113, 363. |

| [20] | Pavlov, D.; Nikolov, P. J. Power Sources 2013, 242, 380. |

| [21] | Bullock, K. R. J. Power Sources 2010, 195, 4513. |

| [22] | Wei, H. M.S. Thesis, Southeast University, Nanjing, 2018. (in Chinese) |

| [22] | ( 魏会敏, 硕士论文, 东南大学, 南京, 2018.) |

| [23] | Karami, H.; Alipour, M. J. Power Sources 2009, 191, 653. |

| [24] | Pavlov, D.; Nikolov, P.; Rogachev, T. J. Power Sources 2010, 195, 4435. |

| [25] | Prochazka, J.; Prochazka, J.. EP2371019 A1 2011. |

| [26] | Krishna, M.; Fraser, E. J.; Wills, R. G. A. J. Energy Storage 2018, 15, 69. |

| [27] | Pavlov, D.; Nikolov, P.; Rogachev, T. J. Power Sources 2010, 195, 4470. |

| [28] | Huskinson, B.; Marshak, M. P.; Suh, C.; Er, S.; Gerhardt, M. R.; Galvin, C. J.; Chen, X. D.; Aspuru-Guzik, A.; Gordon, R. G.; Aziz, M. J. Nature 2014, 505, 195. |

| [29] | 硫酸亚铁采购价格, DB/OL, https://b2b.baidu.com.2021.11.8 |

| [30] | 铅粉价格, DB/OL, https://b2b.baidu.com.2021.11.8 |

/

| 〈 |

|

〉 |