Performance and Improvement of Ni-based Catalysts for Ethane Dehydrogenation

Received date: 2021-10-09

Online published: 2022-02-08

Supported by

National Natural Science Foundation of China(51972128); National Natural Science Foundation of China(U1910209)

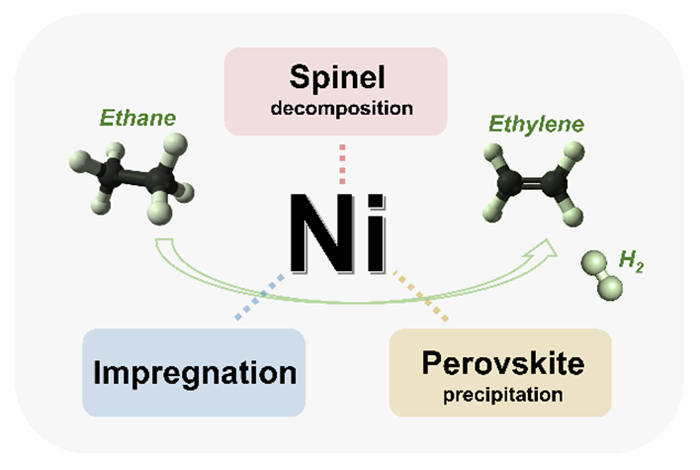

Ethylene is one of the largest chemical products in the world, and its global demand increases significantly every year. At present, ethylene is mainly produced commercially through steam cracking of naphtha or alkane feedstocks. Catalytic dehydrogenation of ethane can effectively reduce energy loss of steam cracking. The transition metal Ni is a metal element with abundant reserves on the earth. It is widely used in the catalytic fields of hydrodesulphurization and reforming hydrogen production. However, there are few studies on Ni-based catalysts in alkanes dehydrogenation; therefore, three kinds of Ni-based supported catalysts, namely spinel decomposition-type, impregnation-type and perovskite precipitation-type, were prepared by different methods and explored for their performance in ethane dehydrogenation at 700 ℃ in C2H6-N2 atmosphere at 50 mL•min-1. The results show that the spinel decomposition-type catalyst Ni1-xCuxCr2O4 prepared by glycine combustion method formed Ni-Cu alloy particles on the surface of Cr2O3 after reduction, which effectively passivated the C—C bond breaking activity of Ni and improved the selectivity of ethylene. The effect of Cu addition can be explained in geometric effect and electronic effect. When the Ni content was too high, the Ni particles could not be effectively dispersed, forming large metal clusters and resulting in excessive cracking of ethane and low ethylene selectivity. The impregnation-type catalyst NixMy/Al2O3 (M=Cu or Ag) had a large specific surface area and dispersed surface active sites, but the active metal particles were weakly interacted with the support and unstable at high temperatures; Cu or Ag forming an alloy with Ni effectively improved the selectivity of ethylene with Ag superior to Cu. The perovskite precipitation-type catalyst LaCr1-xNixO3 (LCNi-100x) precipitated uniform and fine Ni particles in a reducing atmosphere, which were strongly bonded to the support and demonstrated high carbon deposition resistance and high stability; the reduced LCNi-15 (R-LCNi-15 containing 15% Ni) showed the best catalytic performance with the highest ethylene yield (24%), and high carbon deposition resistance and stability compared to commercial 13% CrOx/Al2O3. Moreover, carbon-deposited R-LCNi-15 can restore catalytic activity by oxidation regeneration.

Jun Luo , Lichao Jia , Dong Yan , Jian Li . Performance and Improvement of Ni-based Catalysts for Ethane Dehydrogenation[J]. Acta Chimica Sinica, 2022 , 80(3) : 317 -326 . DOI: 10.6023/A21100451

| [1] | Zhang, Y.; Wang, L.; Li, M.; Feng, W. Z.; Zhang, Y. Contemp. Chem. Ind. 2018, 47, 113. (in Chinese) |

| [1] | 张阳, 王蕾, 李明, 冯伟忠, 张允, 当代化工, 2018, 47, 113.) |

| [2] | Zimmermann, H.; Walzl, R. Ullmann's Encyclopedia of Industrial Chemistry, Wiley, Weinheim, 2009, pp. 465-526. |

| [3] | Wang, F.; Luo, M.; Xiao, W. D.; Chen, X. W.; Long, Y. C. Petrkchem. Technol. 2011, 40, 12. (in Chinese) |

| [3] | (王飞, 罗漫, 肖文德, 程晓维, 龙英才, 石油化工, 2011, 40, 12.) |

| [4] | Research and Design Institute of Shengli Petrochemical Plant, Cracking of Petroleum Hydrocarbons to Ethylene, Fuel Chemical, Fuel Chemical Industry Press, Beijing, 1974. (in Chinese) |

| [4] | (胜利石油化工总厂科研设计所, 石油烃类裂解制乙烯, 燃料化学工业出版社, 北京, 1974.) |

| [5] | Liu, H. T.; Li, H. Q.; Yang, W. J.; Wang, X. R.; Zhang, Y. Acta Chim. Sinica 2009, 67, 1749. (in Chinese) |

| [5] | (柳海涛, 李会泉, 杨玮娇, 王兴瑞, 张懿, 化学学报, 2009, 67, 1749.) |

| [6] | Iglesias-Juez, A.; Beale, A. M.; Maaijen, K.; Weng, T. C.; Glatzel, P.; Weckhuysen, B. M. J. Catal. 2010, 276, 268. |

| [7] | Lieske, H.; Sárkány, A.; Völter, J. Appl. Catal. 1987, 30, 69. |

| [8] | Pham, H. N.; Sattler, J. J.; Weckhuysen, B. M.; Datye, A. K. ACS Catal. 2016, 6, 2257. |

| [9] | Childers, D. J.; Schweitzer, N. M.; Shahari, S. M. K.; Rioux, R. M.; Miller, J. T.; Meyer, R. J. J. Catal. 2014, 318, 75. |

| [10] | Kitchin, J. R.; Norskov, J. K.; Barteau, M. A.; Chen, J. G. J. Chem. Phys. 2004, 120, 10240. |

| [11] | Virnovskaia, A.; Morandi, S.; Rytter, E.; Ghiotti, G.; Olsbye, U. J. Phys. Chem. C 2007, 111, 14732. |

| [12] | Xia, Z. J.; Lu, H. F.; Liu, H. Y.; Zhang, Z. K.; Chen, Y. F. Catal. Commun. 2017, 90, 39. |

| [13] | Yao, Y.; Goodman, D. W. RSC Adv. 2015, 5, 43547. |

| [14] | He, D.; Zhang, Y.; Yang, S.; Mei, Y.; Luo, Y. ChemCatChem 2018, 10, 5434. |

| [15] | Liu, Y.; Zhao, J.; Feng, J.; He, Y.; Du, Y.; Li, D. J. Catal. 2018, 359, 251. |

| [16] | Khromova, S. A.; Smirnov, A. A.; Bulavchenko, O. A.; Saraev, A. A.; Kaichev, V. V.; Reshetnikov, S. I.; Yakovlev, V. A. Appl. Catal. A-Gen. 2014, 470, 261. |

| [17] | Vang, R. T.; Honkala, K.; Dahl, S.; Vestergaard, E. K.; Schnadt, J.; Laegsgaard, E.; Clausen, B. S.; Norskov, J. K.; Besenbacher, F. Nat. Mater. 2005, 4, 160. |

| [18] | Rovik, A. K.; Klitgaard, S. K.; Dahl, S.; Christensen, C. H.; Chorkendorff, I. Appl. Catal., A 2009, 358, 269. |

| [19] | Oh, T. S.; Rahani, E. K.; Neagu, D.; Irvine, J. T.; Shenoy, V. B.; Gorte, R. J.; Vohs, J. M. J. Phys. Chem. Lett. 2015, 6, 5106. |

| [20] | Kwon, O.; Sengodan, S.; Kim, K.; Kim, G.; Jeong, H. Y.; Shin, J.; Ju, Y. W.; Han, J. W.; Kim, G. Nat. Commun. 2017, 8, 15967. |

| [21] | Neagu, D.; Oh, T. S.; Miller, D. N.; Menard, H.; Bukhari, S. M.; Gamble, S. R.; Gorte, R. J.; Vohs, J. M.; Irvine, J. T. S. Nat. Commun. 2015, 6, 8120. |

| [22] | Sun, X.; Chen, H. J.; Yin, Y. M.; Curnan, M. T.; Han, J. W.; Chen, Y.; Ma, Z. F. Small 2021, 17, 2005383. |

| [23] | Wei, T.; Jia, L. C.; Zheng, H. Y.; Chi, B.; Pu, J.; Li, J. Appl. Catal., A 2018, 564, 199. |

| [24] | Abild-Pedersen, F.; Norskov, J. K.; Rostrup-Nielsen, J. R.; Sehested, J.; Helveg, S. Phys. Rev. B 2006, 73, 115419. |

| [25] | Wei, T.; Jia, L. C.; Luo, J. L.; Chi, B.; Pu, J.; Li, J. Appl. Surf. Sci. 2019, 506, 144699. |

/

| 〈 |

|

〉 |