Construction of Dendrite-free Lithium Metal Electrode Using Three-Dimensional Porous Copper and Zinc Coatings

Received date: 2021-11-23

Online published: 2022-03-10

Supported by

National Natural Science Foundation of China(22179011); International Scientific and Technological Cooperation Projects of Shaanxi Province of China(2020KW-024); Program for Graduate Research Innovation Practice of Chang'an University(300103714015)

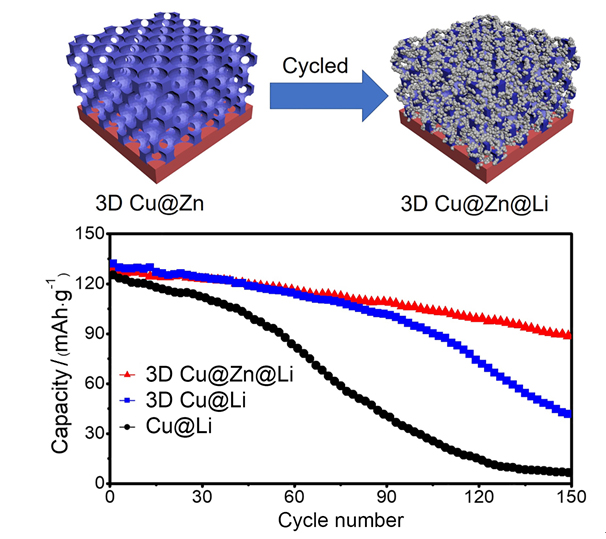

Metal Li has been considered as one promising anode due to its high theoretical capacity and the lowest redox potential, however its dendrites growth and volumetric changes during cycling easily cause battery failure and safety hazards. Here a three dimensional (3D) porous Cu with pore size of about 5 μm coated with Zn layer is used as current collector for Li deposition to construct dendrite-free metal Li electrode. The suitable pore size and high stability of 3D Cu is beneficial to decrease local current density and buffer volumetric changes, and the Zn layer can decrease the nucleation overpotential of Li, synergistically induce uniform deposition of Li and effectively suppress the growth of Li dendrites. There is no dendrite appears when the 3D Cu@Zn is used as the current collector even the depositing capacity increases to 4 mAh•cm–2, and displays smooth surface after Li stripping, however, the Li on Cu appears obvious dendrites and non-uniformity, Li on 3D Cu appears local non-uniformity and some dendrites. The semi-cell Li||3D Cu@Zn demonstrates stable coulombic efficiency at 0.5 and 1 mA•cm–2 with a capacity of 1 mAh•cm–2, the symmetrical cell Li||3D Cu@Zn@Li stably cycle for above 700 h at high current density of 2 mA•cm–2 with a capacity of 1 mAh•cm–2. The full cell with 3D Cu@Zn@Li as anode and LiFePO4 as cathode remains 88 mAh•g–1 after 150 cycles, which is much better than those using Cu@Li plate and 3D Cu@Li as the anodes.

Xiaoyong Fan , Shuai Zhang , Yongqiang Zhu , Maosen Jing , Kaixin Wang , Lulu Zhang , Julong Li , Lei Xu , Lei Gou , Donglin Li . Construction of Dendrite-free Lithium Metal Electrode Using Three-Dimensional Porous Copper and Zinc Coatings[J]. Acta Chimica Sinica, 2022 , 80(4) : 517 -525 . DOI: 10.6023/A21110529

| [1] | Balogun, M.-S.; Qiu, W.; Luo, Y.; Meng, H.; Mai, W.; Onasanya, A.; Olaniyi, T. K.; Tong, Y. Nano Res. 2016, 9, 2823. |

| [2] | Cheng, X. B.; Zhang, R.; Zhao, C. Z.; Zhang, Q. Chem. Rev. 2017, 117, 10403. |

| [3] | Winter, M.; Barnett, B.; Xu, K. Chem. Rev. 2018, 118, 11433. |

| [4] | Jin, L.; Shen, C.; Shellikeri, A.; Wu, Q.; Zheng, J.; Andrei, P.; Zhang, J.-G.; Zheng, J. P. Energy Environ. Sci. 2020, 13, 2341. |

| [5] | Liang, X.; Pang, Q.; Kochetkov, I. R.; Sempere, M. S.; Huang, H.; Sun, X.; Nazar, L. F. Nat. Energy 2017, 2, 17119. |

| [6] | Xu, F.; Wang, H.; Yu, T.; Xu, S.; Qu, C.; Xu, X.; Zhuang, R. Acta Chim. Sinica 2021, 79, 378. (in Chinese) |

| [6] | (徐飞, 王洪强, 于涛, 徐顺奇, 曲昌镇, 许潇洒, 庄容, 化学学报, 2021, 79, 378.) |

| [7] | Wang, Z.; Wang, J.; Mao, Q.; Yang, S.; Cheng, D.; Zhang, Z.; He, H.; Zhou, K. Chem. Eng. J. 2021, 407, 126861. |

| [8] | Chen, K.-H.; Wood, K. N.; Kazyak, E.; LePage, W. S.; Davis, A. L.; Sanchez, A. J.; Dasgupta, N. P. J. Mater. Chem. A 2017, 5, 11671. |

| [9] | Louli, A. J.; Eldesoky, A.; Weber, R.; Genovese, M.; Coon, M.; deGooyer, J.; Deng, Z.; White, R. T.; Lee, J.; Rodgers, T.; Petibon, R.; Hy, S.; Cheng, S. J. H.; Dahn, J. R. Nat. Energy 2020, 5, 693. |

| [10] | Wood, K. N.; Kazyak, E.; Chadwick, A. F.; Chen, K. H.; Zhang, J. G.; Thornton, K.; Dasgupta, N. P. ACS Cent. Sci. 2016, 2, 790. |

| [11] | Wang, Z.; Sun, Y.; Qian, Z.; Wang, R. Chem. J. Chin. Univ. 2020, 42, 1017. (in Chinese) |

| [11] | (王增强, 孙一翎, 钱正芳, 王任衡, 高等化学学报, 2020, 42, 1017.) |

| [12] | Zhou, H.; He, P.; Zhu, X.; Deng, H.; Yang, H.; Qiao, Y.; Chang, Z. Acta Chim. Sinica 2021, 79, 139. (in Chinese) |

| [12] | (周豪慎, 何平, 朱星宇, 邓瀚, 杨慧军, 乔羽, 常智, 化学学报, 2021, 79, 139.) |

| [13] | Chi, S. S.; Wang, Q.; Han, B.; Luo, C.; Jiang, Y.; Wang, J.; Wang, C.; Yu, Y.; Deng, Y. Nano Lett. 2020, 20, 2724. |

| [14] | Zhan, Y.; Shi, P.; Zhang, X.; Wei, J.; Zhang, Q.; Huang, J. Chem. J. Chin. Univ. 2021, 42, 1569. (in Chinese) |

| [14] | (詹迎新, 石鹏, 张学强, 魏俊宇, 张乾魁, 黄佳琦, 高等学校化学学报, 2021, 42, 1569.) |

| [15] | Zhang, D.; Dai, A.; Fan, B.; Li, Y.; Shen, K.; Xiao, T.; Hou, G.; Cao, H.; Tao, X.; Tang, Y. ACS Appl. Mater. Interfaces 2020, 12, 31542. |

| [16] | Liu, H.; Wang, E.; Zhang, Q.; Ren, Y.; Guo, X.; Wang, L.; Li, G.; Yu, H. Energy Storage Mater. 2019, 17, 253. |

| [17] | Lin, K.; Xu, X.; Qin, X.; Zhang, G.; Liu, M.; Lv, F.; Xia, Y.; Kang, F.; Chen, G.; Li, B. Energy Storage Mater. 2020, 26, 250. |

| [18] | Ke, X.; Liang, Y.; Ou, L.; Liu, H.; Chen, Y.; Wu, W.; Cheng, Y.; Guo, Z.; Lai, Y.; Liu, P.; Shi, Z. Energy Storage Mater. 2019, 23, 547. |

| [19] | Chi, S.-S.; Liu, Y.; Song, W.-L.; Fan, L.-Z.; Zhang, Q. Adv. Funct. Mater. 2017, 27, 1700348. |

| [20] | Ke, X.; Cheng, Y.; Liu, J.; Liu, L.; Wang, N.; Liu, J.; Zhi, C.; Shi, Z.; Guo, Z. ACS Appl. Mater. Interfaces 2018, 10, 13552. |

| [21] | Medvedev, A. Z.; Zherebilov, A. F.; Masliiy, A. I.; Poddubnyi, N. P. Russ. J. Electrochem. 2008, 44, 761. |

| [22] | Meng, X.; Song, Y.; Shu, T. J. Power Sources 2020, 27, 1069. |

| [23] | Singh, H.; Dheeraj, P. B.; Singh, Y. P.; Rathore, G.; Bhardwaj, M. J. Electroanal. Chem. 2017, 785, 1. |

| [24] | Wang, N.; Hu, W. C.; Lu, Y. H.; Deng, Y. F.; Wan, X. B.; Zhang, Y. W.; Du, K.; Zhang, L. Trans. IMF 2013, 89, 261. |

| [25] | Yun, Q.; He, Y.-B.; Lv, W.; Zhao, Y.; Li, B.; Kang, F.; Yang, Q.-H. Adv. Mater. 2016, 28, 6932. |

| [26] | Zhang, D.; Dai, A.; Wu, M.; Shen, K.; Xiao, T.; Hou, G.; Lu, J.; Tang, Y. ACS Energy. Lett. 2019, 5, 180. |

| [27] | Zhao, H.; Lei, D.; He, Y.-B.; Yuan, Y.; Yun, Q.; Ni, B.; Lv, W.; Li, B.; Yang, Q.-H.; Kang, F.; Lu, J. Adv. Energy Mater. 2018, 8, 1800266. |

| [28] | Qiu, H.; Tang, T.; Asif, M.; Huang, X.; Hou, Y. Adv. Funct. Mater. 2019, 29, 1808468. |

| [29] | Fan, X.; Sun, R.; Zhu, Y.; Zhang, S.; Gou, L.; Lu, L.; Li, D. Small 2021, 18, e2106161. |

| [30] | Fan, X.-Y.; Jiang, Z.; Huang, L.; Wang, X.; Han, J.; Sun, R.; Gou, L.; Li, D.-L.; Ding, Y.-L. ACS Appl. Mater. Interfaces 2020, 12, 20344. |

| [31] | Fan, X.-Y.; Han, J.; Ding, Y.-L.; Deng, Y.-P.; Luo, D.; Zeng, X.; Jiang, Z.; Gou, L.; Li, D.-L.; Chen, Z. Adv. Energy Mater. 2019, 9, 1900673. |

| [32] | Chi, S.-S.; Wang, Q.; Han, B.; Luo, C.; Jiang, Y.; Wang, J.; Wang, C.; Yu, Y.; Deng, Y. Nano Lett. 2020, 20, 2724. |

| [33] | Ye, Y.; Liu, Y.; Wu, J.; Yang, Y. J. Power Sources 2020, 472, 228520. |

| [34] | Zhao, F.; Zhou, X.; Deng, W.; Liu, Z. Nano Energy 2019, 62, 55. |

| [35] | Wang, G.; Xiong, X.; Zou, P.; Fu, X.; Lin, Z.; Li, Y.; Liu, Y.; Yang, C.; Liu, M. Chem. Eng. J. 2019, 378, 122243. |

| [36] | Fan, X.-Y.; Cui, Y.; Liu, P.; Gou, L.; Xu, L.; Li, D.-L. Phys. Chem. Chem. Phys. 2016, 18, 22224. |

| [37] | Zhang, Q.; Luan, J.; Tang, Y.; Ji, X.; Wang, S.; Wang, H. J. Mater. Chem. A 2018, 6, 18444. |

| [38] | Liu, J.; Ma, H.; Wen, Z.; Li, H.; Yang, J.; Pei, N.; Zhang, P.; Zhao, J. J. Energy. Chem. 2022, 64, 354. |

| [39] | Yang, T.; Qian, T.; Shen, X.; Wang, M.; Liu, S.; Zhong, J.; Yan, C.; Rosei, F. J. Mater. Chem. A 2019, 7, 14496. |

| [40] | Luo, N.; Ji, G.-J.; Wang, H.-F.; Li, F.; Liu, Q.-C.; Xu, J.-J. ACS Nano 2020, 14, 3281. |

| [41] | Huang, G.; Han, J.; Zhang, F.; Wang, Z.; Kashani, H.; Watanabe, K.; Chen, M. Adv. Mater. 2019, 31, e1805334. |

| [42] | Zhang, C.; Lyu, R.; Lv, W.; Li, H.; Jiang, W.; Li, J.; Gu, S.; Zhou, G.; Huang, Z.; Zhang, Y.; Wu, J.; Yang, Q. H.; Kang, F. Adv. Mater. 2019, 31, e1904991. |

| [43] | Domínguez-Ríos, C.; Moreno, M. V.; Torres-Sánchez, R.; Antúnez, W.; Aguilar-Elguézabal, A.; González-Hernández, J. Surf. Coat. Technol. 2008, 202, 4848. |

| [44] | Wang, R.; Shi, F.; He, X.; Shi, J.; Ma, T.; Jin, S.; Tao, Z. Sci. China Mater. 2020, 64, 1087. |

| [45] | Vinokurov, E. G.; Kandyrin, K. L.; Bondar', V. V. Russ. J. Appl. Chem. 2010, 83, 659. |

/

| 〈 |

|

〉 |