Study of Operating Conditions for High Efficiency and Anode Safety of Industrial-Size Solid Oxide Fuel Cell

Received date: 2022-01-22

Online published: 2022-04-06

Supported by

National Key Research and Development Program of China(2018YFB1502203)

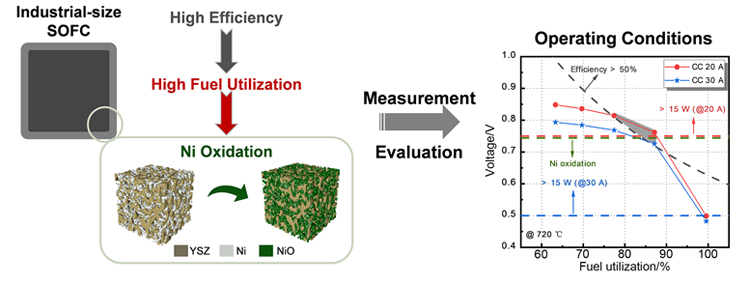

Solid oxide fuel cell (SOFC) has been regarded as one of the promising energy conversion technologies since it provides higher efficiency and lower pollution than conventional power systems. How to improve the SOFC efficiency is one of the focus issues in both industry and academia. Besides, when industrial-size SOFC is operated at high fuel utilization (Ufuel) to achieve high efficiency, the Ni anode in the downstream region may be locally oxidized due to the high oxygen partial pressure. Thus, operating conditions for both high efficiency and anode safety are required. In this work, a method for the measurement and evaluation of SOFC efficiency was established. By comparing the test results under different conditions (current, fuel flow rate, and temperature) with high fuel utilization, it was found that at the same fuel utilization, the voltage decreased as the current increased. Therefore, the lower current is beneficial for higher efficiency, while the higher current is beneficial for higher power. The relationship between voltage fluctuation and local oxidation of anode during operation at high fuel utilization was also studied. After analyzing the critical condition of Ni oxidation, the cell output voltage higher than the critical electromotive force of Ni oxidation was proposed as the safe operating condition to prevent local oxidation of anode. Based on the cell samples and test parameters used in this work, it was found a high efficiency of over 50% was corresponding to the fuel utilization range of 77% to 90%. And the maximum electrical efficiency was always corresponding to Ufuel=87.10%. Although the operating conditions corresponding to the maximum efficiency of SOFC cells or stacks with different materials, structures, and fabrication processes may vary, the measurement and evaluation methods, as well as the judgment of the safe operating condition proposed in this study, are still helpful. In practical application, the operating conditions could be determined based on such testing results according to the importance of efficiency, power and long-term stability.

Yige Wang , Hangyue Li , Zewei Lyu , Minfang Han , Kaihua Sun . Study of Operating Conditions for High Efficiency and Anode Safety of Industrial-Size Solid Oxide Fuel Cell[J]. Acta Chimica Sinica, 2022 , 80(8) : 1091 -1099 . DOI: 10.6023/A22010041

| [1] | Nakao, T.; Inoue, S.; Uenoyama, S.; Takuwa, Y.; Suzuki, M. ECS Trans. 2019, 91, 43. |

| [2] | Suzuki, M.; Inoue, S.; Shigehisa, T. ECS Trans. 2021, 103, 25. |

| [3] | Ballard, A.; Domanski, T.; Rees, L.; Nobbs, C.; Lawrence, N.; Heffer, K.; Harman, J.; Evans, C.; Barnard, P.; Mukerjee, S.; Selby, M. ECS Trans. 2019, 91, 117. |

| [4] | Sumi, H.; Nakabayashi, S.; Kawada, T.; Uchiyama, Y.; Uchiyama, N.; Ichihara, K. ECS Trans. 2019, 91, 149. |

| [5] | Vora, S. D.; Jesionowski, G.; Williams, M. C. ECS Trans. 2019, 91, 27. |

| [6] | Santhanam, S.; Ullmer, D.; Wuillemin, Z.; Varkaraki, E.; Beetschen, C.; Antonetti, Y.; Ansar, A. ECS Trans. 2019, 91, 159. |

| [7] | Hara, D. ECS Trans. 2019, 91, 3. |

| [8] | Horita, T. ECS Trans. 2021, 103, 1023. |

| [9] | Mai, A.; Grolig, J. G.; Dold, M.; Vandercruysse, F.; Denzler, R.; Schindler, B.; Schuler, A. ECS Trans. 2019, 91, 63. |

| [10] | Noponen, M.; Torri, P.; Göös, J.; Puranen, J.; Kaar, H.; Pylypko, S.; Roostar, M.; Õunpuu, E. ECS Trans. 2019, 91, 91. |

| [11] | Vora, S.; Williams, M.; Jesionowski, G. ECS Trans. 2021, 103, 3. |

| [12] | Fu, C.; Yan, D.; Jia, L.; Pu, J.; Chi, B.; Li, J. J. Ceram. 2020, 41, 869. |

| [13] | Futamura, S.; Tachikawa, Y.; Matsuda, J.; Lyth, S. M.; Shiratori, Y.; Taniguchi, S.; Sasaki, K. J. Electrochem. Soc. 2017, 164, F3055. |

| [14] | Min, G.; Park, Y. J.; Hong, J. Energy Convers. Manage. 2020, 209, 112614. |

| [15] | Li, H.; Cui, T.; Han, M. ECS Trans. 2021, 103, 831. |

| [16] | Fang, Q.; Blum, L.; Peters, R.; Peksen, M.; Batfalsky, P.; Stolten, D. Int. J. Hydrogen Energy 2015, 40, 1128. |

| [17] | Nehter, P. J. Power Sources 2007, 164, 252. |

| [18] | Klotz, D.; Weber, A.; Ivers-Tiffée, E. Electrochim. Acta 2017, 227, 110. |

| [19] | Brus, G.; Miyoshi, K.; Iwai, H.; Saito, M.; Yoshida, H. Int. J. Hydrogen Energy 2015, 40, 6927. |

| [20] | Kawasaki, T.; Matsuda, J.; Tachikawa, Y.; Lyth, S. M.; Shiratori, Y.; Taniguchi, S.; Sasaki, K. Int. J. Hydrogen Energy 2019, 44, 9386. |

| [21] | Feng, Y.; Ding, X.; Ma, Z.; Li, Y.; Zeng, F.; Zhou, J.; Wang, S. J. Ceram. 2021, 42, 360. |

| [22] | Wang, Y.; Shi, W.; Li, H.; Han, M.; Sun, Z. ECS Trans. 2019, 91, 707. |

| [23] | Heo, Y. H.; Lee, J. W.; Lee, S. B.; Lim, T. H.; Park, S. J.; Song, R. H.; Park, C. O.; Shin, D. R. Int. J. Hydrogen Energy 2011, 36, 797. |

| [24] | Lyu, Z.; Liu, S.; Wang, Y.; Li, H.; Liu, Z.; Sun, Z.; Sun, K.; Zhang, S.; Han, M. J. Power Sources 2021, 510, 230432. |

| [25] | Yang, B., Chen, Z., Qin, Z. Urban Gas 2019, 4. |

| [26] | Lyu, Z.; Meng, H.; Zhu, J.; Han, M.; Sun, Z.; Xue, H.; Zhao, Y.; Zhang, F. Appl. Energy 2020, 270, 115220. |

| [27] | Peters, R.; Deja, R.; Blum, L.; Pennanen, J.; Kiviaho, J.; Hakala, T. Int. J. Hydrogen Energy 2013, 38, 6809. |

| [28] | Calise, F.; Dentice d’Accadia, M.; Palombo, A.; Vanoli, L. Energy 2006, 31, 3278. |

| [29] | Nakamura, K.; Ide, T.; Kawabata, Y.; Nakajima, T.; Dohkoh, T.; Tsuji, M.; Akabane, S.; Hatae, T. J. Electrochem. Soc. 2020, 167, 114516. |

| [30] | Ramos, T.; Søgaard, M.; Mogensen, M. B. J. Electrochem. Soc. 2014, 161, F434. |

| [31] | Lang, M.; Bohn, C.; Henke, M.; Schiller, G.; Willich, C.; Hauler, F. J. Electrochem. Soc. 2017, 164, F1460. |

| [32] | Brus, G.; Iwai, H.; Sciazko, A.; Saito, M.; Yoshida, H.; Szmyd, J. S. J. Power Sources 2015, 288, 199. |

| [33] | Sugihara, S.; Iwai, H. Int. J. Hydrogen Energy 2020, 45, 25227. |

| [34] | Blum, L.; Fang, Q.; Groß-Barsnick, S. M.; de Haart, L. G. J. (Bert.; Malzbender, J.; Menzler, N. H.; Quadakkers, W. J. Int. J. Hydrogen Energy 2020, 45, 8955. |

| [35] | Lyu, Z.; Han, M.; Sun, Z.; Sun, K. Acta Chim. Sinica 2021, 79, 763. (in Chinese) |

| [35] | (吕泽伟, 韩敏芳, 孙再洪, 孙凯华, 化学学报, 2021, 79, 763.) |

| [36] | Wang, Y.; Lyu, Z.; Han, M.; Sun, Z.; Sun, K. ECS Trans. 2021, 103, 1261. |

| [37] | Cui, T.; Li, H.; Lyu, Z.; Wang, Y.; Han, M.; Sun, Z.; Sun, K. Acta Phys.-Chim. Sin. 2022, 38, 2011009. (in Chinese) |

| [37] | (崔同慧, 李航越, 吕泽伟, 王怡戈, 韩敏芳, 孙再洪, 孙凯华, 物理化学学报, 2022, 38, 2011009.) |

/

| 〈 |

|

〉 |