Temperature-controlled Dynamic Moisture-responsive Wrinkled Patterns★

Received date: 2023-04-01

Online published: 2023-05-12

Supported by

National Key R&D Program of China(2021YFB4001100); National Natural Science Foundation of China(52025032); National Natural Science Foundation of China(52103144)

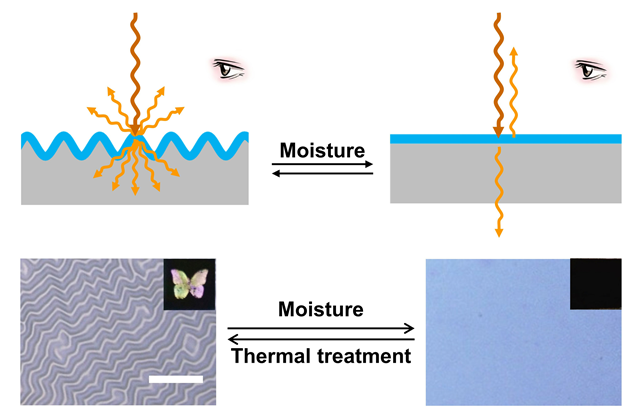

Here we reported temperature-controlled moisture responsive wrinkled patterns based on bilayer system, and explore its regulation mechanism and applications. The bilayer wrinkling system is comprising a copolymer P(IMAN-co-NIPAM-co-OEGMA) containing 1-vinyl-3-anthracenemethyl imidazolium chloride (IMAN), N-isopropylacrylamide (NIPAM) and poly(ethylene glycol) methyl ether methacrylate (OEGMA) as the skin layer and poly(dimethylsiloxane) (PDMS) as the substrate. After photodimerization of the AN group, the polymer network is crosslinked, and the modulus of the top film increases. According to the linear buckling theory, random wrinkles are formed under thermal treatment and subsequent cooling to room temperature owing to the mismatch in the moduli and thermal expansion coefficients between the stiff skin layer and the soft substrate. First, the photodimerization of AN group endows the system with the ability of region selective wrinkling. If the irradiation process is performed with a photomask, the exposed regions are rigid enough for wrinkles forming, while the unexposed areas are not. Furthermore, surface wrinkles caused strong light scattering while the flat surface limit it, which affects the visibility of an object. Thus, we could fabricate various images utilizing the selective wrinkled patterns. Second, the NIPAM-containing polymer chain endows the wrinkles with temperature-controlled moisture response. Under room temperature, the wrinkles can be eliminated by moisture, which is caused by the decreasing modulus and stress relaxation during absorbing moisture; while under a higher temperature, the wrinkles cannot be driven by moisture because the copolymer of top layer becomes hydrophobic, which is demonstrated by experimental results such as the laser scanning confocal microscope images. Furthermore, the wrinkled images and the transparence can be controlled by moisture and temperature during the switch between wrinkled and flat states. Besides, the poly(ethylene glycol) methyl ether methacrylate (OEGMA) is involved to tune the mechanical properties. The photosensitive and temperature- controlled moisture responsive wrinkled patterns may find potential applications in moisture sensing, smart display or smart windows.

Tianjiao Ma , Jin Li , Xiaodong Ma , Xuesong Jiang . Temperature-controlled Dynamic Moisture-responsive Wrinkled Patterns★[J]. Acta Chimica Sinica, 2023 , 81(7) : 749 -756 . DOI: 10.6023/A23040108

| [1] | Bowden N.; Brittain S.; Evans A. G.; Hutchinson J. W.; Whitesides G. M. Nature 1998, 393, 146. |

| [2] | Chung J. Y.; Nolte A. J.; Stafford C. M. Adv. Mater. 2011, 23, 349. |

| [3] | Khang D. Y.; Jiang H.; Huang Y.; Rogers J. A. Science 2006, 311, 208. |

| [4] | Jiang H.; Khang D. Y.; Song J.; Sun Y.; Huang Y.; Rogers J. A. Proc. Natl. Acad. Sci. U. S. A. 2007, 104, 15607. |

| [5] | Zhou L.; Hu K.; Zhang W.; Meng G.; Yin J.; Jiang X. Natl. Sci. Rev. 2020, 7, 1247. |

| [6] | Hou H.; Yin J.; Jiang X. Acc. Chem. Res. 2019, 52, 1025. |

| [7] | Chen S.; Yan S.; Yin J.; Jiang X. Acta Polym. Sin. 2021, 52, 1245. |

| [8] | Rodríguez-Hernández J. Prog. Polym. Sci. 2015, 42, 1. |

| [9] | Tan Y. L.; Hu B. R.; Song J.; Chu Z. Y.; Wu W. J. Nano-Micro Lett. 2020, 12, 101. |

| [10] | Wang Q. M.; Zhao X. H. MRS Bull. 2016, 41, 115. |

| [11] | Kong X.; Wang X.; Chen J.; Yao Y.; Lin S. J. Funct. Polym. 2017, 30, 259. |

| [12] | Xu Z.; Xie X.; Shen H.; Guo Y.; Yang L.; Ge D. Acta Materiae Compositae Sinica 2021, 38, 3151. |

| [13] | Lee S. G.; Lee D. Y.; Lim H. S.; Lee D. H.; Lee S.; Cho K. Adv. Mater. 2010, 22, 5013. |

| [14] | Wang J.; Zheng Y.; Li L.; Liu E.; Zong C.; Zhao J.; Xie J.; Xu F.; Konig T. A. F.; Grenzer Saphiannikova M.; Cao Y.; Fery A.; Lu C. ACS Appl. Mater. Interfaces 2019, 11, 25595. |

| [15] | Xu C.; Stiubianu G. T.; Gorodetsky A. A. Science 2018, 359, 1495. |

| [16] | Ma T.; Bai J.; Li T.; Chen S.; Ma X.; Yin J.; Jiang X. Proc. Natl. Acad. Sci. U. S. A. 2021, 118, e2114345118. |

| [17] | Ma T.; Zhou L.; Hua J.; Li J.; Ma X.; Qiao W.; Yin J.; Jiang X. ACS Appl. Mater. Interfaces 2022, 14, 16949. |

| [18] | Ma T.; Chen S.; Li J.; Yin J.; Jiang X. Mater. Horiz. 2022, 9, 2233. |

| [19] | Efimenko K.; Rackaitis M.; Manias E.; Vaziri A.; Mahadevan L.; Genzer J. Nat. Mater. 2005, 4, 293. |

| [20] | Kang J.; Wang C.; Xue Z.; Liu M.; Tan H. Appl. Phys. Lett. 2016, 109, 103503. |

| [21] | Huang X.; Sun Y.; Soh S. Adv. Mater. 2015, 27, 4062. |

| [22] | Chan E. P.; Smith E. J.; Hayward R. C.; Crosby A. J. Adv. Mater. 2008, 20, 711. |

| [23] | Lee H.; Lee B. P.; Messersmith P. B. Nature 2007, 448, 338. |

| [24] | Hou H.; Hu K.; Lin H.; Forth J.; Zhang W.; Russell T. P.; Yin J.; Jiang X. Adv. Mater. 2018, 30, 1803463. |

| [25] | Hou H.; Li F.; Su Z.; Yin J.; Jiang X. J. Mater. Chem. C 2017, 5, 8765. |

| [26] | Hou H.; Yin J.; Jiang X. Adv. Mater. 2016, 28, 9126. |

| [27] | Kim H. S.; Crosby A. J. Adv. Mater. 2011, 23, 4188. |

| [28] | Li F.; Hou H.; Yin J.; Jiang X. Sci. Adv. 2018, 4, eaar5762. |

| [29] | Li T.; Hu K.; Ma X.; Zhang W.; Yin J.; Jiang X. Adv. Mater. 2020, 32, 1906712. |

| [30] | Ma T.; Li T.; Zhou L.; Ma X.; Yin J.; Jiang X. Nat. Commun. 2020, 11, 1811. |

| [31] | Shou H.; Ma T.; Li T.; Chen S.; Ma X.; Yin J.; Jiang X. Chem. Eur. J. 2021, 27, 5810. |

| [32] | Zeng S.; Li R.; Freire S. G.; Garbellotto V. M. M.; Huang E. Y.; Smith A. T.; Hu C.; Tait W. R. T.; Bian Z.; Zheng G.; Zhang D.; Sun L. Adv. Mater. 2017, 29, 1700828. |

| [33] | Zhou L.; Yang L.; Liu Y.; Xu Z.; Yin J.; Ge D.; Jiang X. Adv. Optical Mater. 2020, 8, 2000234. |

| [34] | Zong C.; Zhao Y.; Ji H.; Han X.; Xie J.; Wang J.; Cao Y.; Jiang S.; Lu C. Angew. Chem. Int. Ed. 2016, 55, 3931. |

| [35] | Chen S.; Ma T.; Bai J.; Ma X.; Yin J.; Jiang X. Adv. Sci. 2020, 7, 2002372. |

| [36] | Li J.; Li T.; Ma X.; Su Z.; Yin J.; Jiang X. ACS Appl. Mater. Interfaces 2021, 13, 1704. |

| [37] | Chen S.; Hu K.; Yan S.; Ma T.; Deng X.; Zhang W.; Yin J.; Jiang X. Sci. Bull. 2022, 67, 2186. |

| [38] | Zhang Y.; Li T.; Ma X.; Yin J.; Jiang X. Acta Polym. Sin. 2021, 52, 61. |

| [39] | Mai Y. J. Funct. Polym. 2018, 31, 302. |

| [40] | Cakmak O.; El Tinay H. O.; Chen X.; Sahin O. Adv. Mater. Technol. 2019, 4, 1800596. |

| [41] | Zhang Y.; Jiang H.; Li F.; Xia Y.; Lei Y.; Jin X.; Zhang G.; Li H. J. Mater. Chem. A 2017, 5, 14604. |

| [42] | Han D. D.; Liu Y. Q.; Ma J. N.; Mao J. W.; Chen Z. D.; Zhang Y. L.; Sun H. B. Adv. Mater. Technol. 2018, 3, 1800258. |

| [43] | Ru J.; Zhu Z.; Wang Y.; Chen H.; Bian C.; Luo B.; Li D. Smart Mater. Struct. 2018, 27, 02lt01. |

| [44] | Sun Q.; Ayela C.; Thuau D. Adv. Mater. Interfaces 2022, 2201349. |

| [45] | Xue J.; Ge Y.; Liu Z.; Liu Z.; Jiang J.; Li G. ACS Appl. Mater. Interfaces 2022, 14, 10836. |

| [46] | Zain H. A.; Batumalay M.; Rahim H. R. A.; Yasin M.; Harun S. W. IEEE Sens. Lett. 2022, 6, 3500704. |

| [47] | Kumar P.; Sakla R.; Ghosh A.; Jose D. A. ACS Appl. Mater. Interfaces 2017, 9, 25600. |

| [48] | Lv X.; Li Y.; Li P.; Yang M. Sens. Actuators B Chem. 2009, 135, 581. |

| [49] | Cho M. Y.; Kim I. S.; Kim M. J.; Hyun D. E.; Koo S. M.; Sohn H.; Kim N. Y.; Kim S.; Ko S.; Oh J. M. Sensors 2022, 22, 5178. |

| [50] | Choi S. J.; Yu H.; Jang J. S.; Kim M. H.; Kim S. J.; Jeong H. S.; Kim I. D. Small 2018, 14, 1703934. |

| [51] | Borini S.; White R.; Wei D.; Astley M.; Haque S.; Spigone E.; Harris N.; Kivioja J.; Ryhanen T. ACS Nano 2013, 7, 11166. |

| [52] | Casalbore-Miceli G.; Yang M. J.; Li Y.; Zanelli A.; Martelli A.; Chen S.; She Y.; Camaioni N. Sens. Actuators B Chem. 2006, 114, 584. |

| [53] | Yeo T. L.; Sun T.; Grattan K. T. V.; Parry D.; Lade R.; Powell B. D. Sens. Actuators B Chem. 2005, 110, 148. |

/

| 〈 |

|

〉 |