Highly-Stable Two-Dimensional Bicarbazole-based sp2-Carbon-conjugated Covalent Organic Framework for Efficient Electrocatalytic Oxygen Reduction★

Received date: 2023-04-13

Online published: 2023-06-12

Supported by

National Key R&D Program of China(2022YFB3704900); National Key R&D Program of China(2021YFF0500500); National Natural Science Foundation of China(22025504); National Natural Science Foundation of China(21621001); National Natural Science Foundation of China(22105082); SINOPEC Research Institute of Petroleum Processing

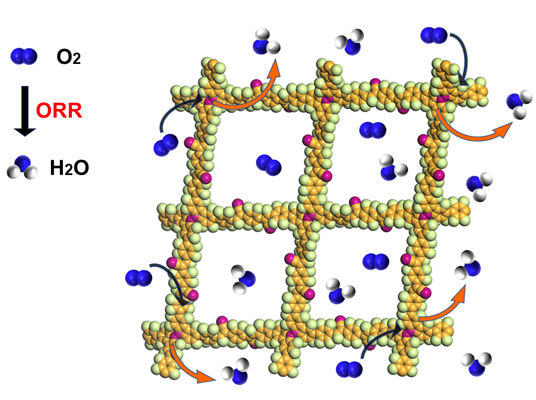

With the extensive utilization of fossil fuels in industrial development, the energy crisis and environmental issues have become crucial challenges for current scientific development. The development of sustainable and clean energy is of great importance for sustainable human progress. Fuel and metal-air batteries have emerged as promising alternatives to fossil fuels, providing environmentally friendly and sustainable clean energy. Improving the efficiency of the oxygen reduction reaction (ORR) is crucial for energy generation and storage processes of batteries. Therefore, the development of efficient and stable ORR electrocatalysts is a key task to improve battery performance. Noble metal-based materials are known for their excellent ORR catalytic performance, but their high cost and instability have limited their applications. Hence, it is essential to develop low-cost, low-pollution, and high-efficiency electrocatalysts as noble metal-based alternatives. Transition-metal (TM)-based materials, metal alloys, and metal-free carbon nanomaterials have been reported as alternatives, but their properties are not as good as those of noble metal-based materials. In addition, their complex processes and difficult-to-identify active sites make it challenging to elucidate the intrinsic mechanisms. Rational design and precise synthesis of electrochemical catalysts are critical strategies. Covalent organic frameworks (COFs) have several advantages, including high crystallinity, high specific surface area, high stability, and regular pore channels. Besides, the construction of COFs has the advantages of pre-design and precise synthesis. Reasonable design and construction unit is an important strategy to realize the functional application of COFs materials. Many new products with structural characteristics have been reported since the introduction of COFs, and they have demonstrated excellent performance in several fields. In this study, we investigated the application of a highly stable sp2-carbon-linked COF (JUC-557) based on a bicarbazole building block for electrocatalytic oxygen reduction. We performed various characterizations of JUC-557, which demonstrated its high crystallinity, high specific surface area (870.64 m2/g), and regular structure. Moreover, JUC-557 exhibited excellent thermal and chemical stability. In the ORR performance test, JUC-557 showed good ORR catalytic performance, with an onset potential of 0.80 V vs. RHE, a half-wave potential of 0.68 V vs. RHE, a Tafel slope of only 62.20 mA•cm-2, and a Cdl of 5.79 mF•cm-2. Moreover, the Zn-air battery assembled with JUC-557 as an air-cathode electrode catalyst has a stable open-circuit voltage of 1.29 V and can easily light up the “COF” LED board. In conclusion, the rational construction of COFs as ORR catalysts has great potential in energy device application.

Jianchuan Liu , Cuiyan Li , Yaozu Liu , Yujie Wang , Qianrong Fang . Highly-Stable Two-Dimensional Bicarbazole-based sp2-Carbon-conjugated Covalent Organic Framework for Efficient Electrocatalytic Oxygen Reduction★[J]. Acta Chimica Sinica, 2023 , 81(8) : 884 -890 . DOI: 10.6023/A23040132

| [1] | Zou X.; Zhang Y. Chem. Soc. Rev. 2015, 44, 5148. |

| [2] | Bu R.; Lu Y.; Zhang B. Chem. Res. Chin. Univ. 2022, 38, 1151. |

| [3] | Yang C.; Yang Z.-D.; Dong H.; Sun N.; Lu Y.; Zhang F.-M.; Zhang G. ACS Energy Lett. 2019, 4, 2251. |

| [4] | Tao S.; Jiang D. CCS Chem. 2021, 3, 2003. |

| [5] | Debe M. K. Nature 2012, 486, 43. |

| [6] | Zhang J.; Zhao Y.; Chen C.; Huang Y.-C.; Dong C.-L.; Chen C.-J.; Liu R.-S.; Wang C.; Yan K.; Li Y. J. Am. Chem. Soc. 2019, 141, 20118. |

| [7] | Lee Y.; Suntivich J.; May K. J.; Perry E. E.; Shao-Horn Y. J. Phys. Chem. Lett. 2012, 3, 399. |

| [8] | N?rskov J. K.; Rossmeisl J.; Logadottir A.; Lindqvist L.; Kitchin J. R.; Bligaard T.; Jonsson H. J. Phys. Chem. B 2004, 108, 17886. |

| [9] | Miles M. Electrochim. Acta 1978, 23, 521. |

| [10] | Gong K.; Du F.; Xia Z.; Durstock M.; Dai L. Science 2009, 323, 760. |

| [11] | Yang Z.; Xiang M.; Zhu Y.; Hui J.; Jiang Y.; Dong S.; Yu C.; Ou J.; Qin H. Chem. Eng. J. 2021, 426, 131347. |

| [12] | Wang J.; Cui W.; Liu Q.; Xing Z.; Asiri A. M.; Sun X. Adv. Mater. 2016, 28, 215. |

| [13] | Shao M.; Chang Q.; Dodelet J.-P.; Chenitz R. Chem. Rev. 2016, 116, 3594. |

| [14] | Cote A. P.; Benin A. I.; Ockwig N. W.; O'keeffe M.; Matzger A. J.; Yaghi O. M. Science 2005, 310, 1166. |

| [15] | Feng X.; Liu L.; Honsho Y.; Saeki A.; Seki S.; Irle S.; Dong Y.; Nagai A.; Jiang D. Angew. Chem., Int. Ed. 2012, 51, 2618. |

| [16] | Zhang Z.; Jiang F.; Wu K.; Shen P. Acta Chim. Sinica 2022, 80, 56. (in Chinese) |

| [16] | ( 张竹涵, 蒋峰景, 吴珂科, 申鹏, 化学学报, 2022, 80, 56.) |

| [17] | Zhuang R.; Xu X.; Qu C.; Xu S.; Yu T.; Wang H.; Xu F. Acta Chim. Sinica 2021, 79, 378. (in Chinese) |

| [17] | ( 庄容, 许潇洒, 曲昌镇, 徐顺奇, 于涛, 王洪强, 徐飞, 化学学报, 2021, 79, 378.) |

| [18] | Li J. L.; Xiao Y.; Shui F.; Yi M.; Zhang Z. Y.; Liu X. L.; Zhang L. Y.; You Z. F.; Yang R. F.; Yang S. Q.; Li B. Y.; Bu X. H. Chin. J. Chem. 2022, 40, 2445. |

| [19] | Yu C.; Li H.; Wang Y.; Suo J.; Guan X.; Wang R.; Valtchev V.; Yan Y.; Qiu S.; Fang Q. Angew. Chem., Int. Ed. 2022, 61, e202117101. |

| [20] | Song J.; Wang Z.; Liu Y.; Tuo C.; Wang Y.; Fang Q.; Qiu S.; Chem. Res. Chin. Univ. 2022, 38, 834. |

| [21] | Fang Q.; Wang J.; Gu S.; Kaspar R. B.; Zhuang Z.; Zheng J.; Guo H.; Qiu S.; Yan Y. J. Am. Chem. Soc. 2015, 137, 8352. |

| [22] | Wang T.; Zhao L.; Wang K.; Bai Y.; Feng F. Acta Chim. Sinica 2021, 79, 600. (in Chinese) |

| [22] | ( 王涛, 赵璐, 王科伟, 白云峰, 冯锋, 化学学报, 2021, 79, 600.) |

| [23] | Liao L.; Zhang Z. R.; Guan X. Y.; Li H.; Liu Y. Z.; Zhang M. H.; Tang B.; Valtchev V.; Yan Y. S.; Qiu S. L.; Yao X. D.; Fang Q. R. Chin. J. Chem. 2022, 40, 2081. |

| [24] | Li Z.; Zhang Y.; Xia H.; Mu Y.; Liu X. Chem. Commun. 2016, 52, 6613. |

| [25] | Xian W.; Zhang P.; Zhu C.; Zuo X.; Ma S.; Sun Q. CCS Chem. 2021, 3, 2464. |

| [26] | Haotian R.; Zhu Z.; Cai Y.; Wang W.; Wang Z.; Liang A.; Luo A. Acta Chim. Sinica 2022, 80, 1524. (in Chinese) |

| [26] | ( 浩天瑞霖, 朱子煜, 蔡艳慧, 王微, 王祯, 梁阿新, 罗爱芹, 化学学报, 2022, 80, 1524.) |

| [27] | Chandra S.; Kundu T.; Kandambeth S.; Babarao R.; Marathe Y.; Kunjir S. M.; Banerjee R. J. Am. Chem. Soc. 2014, 136, 6570. |

| [28] | Shao M. C.; Liu Y. Q.; Guo Y. L. Chin. J. Chem. 2023, 41, 1260. |

| [29] | Li D.; Li C.; Zhang L.; Li H.; Zhu L.; Yang D.; Fang Q.; Qiu S.; Yao X. J. Am. Chem. Soc. 2020, 142, 8104. |

| [30] | Chang S.; Li C.; Li H.; Zhu L.; Fang Q. Chem. Res. Chin. Univ. 2022, 38, 396. |

| [31] | Yu X.; Huang W.; Li Y. Acta Chim. Sinica 2022, 80, 1494. (in Chinese) |

| [31] | ( 于潇涵, 黄伟, 李彦光, 化学学报, 2022, 80, 1494.) |

| [32] | Chen Q.; Kuang Q.; Xie Z. Acta Chim. Sinica 2021, 79, 10. (in Chinese) |

| [32] | ( 陈钱, 匡勤, 谢兆雄, 化学学报, 2021, 79, 10.) |

| [33] | Chen Y.; Chen Q.; Zhang Z. Chin. J. Org. Chem. 2021, 41, 3826. (in Chinese) |

| [33] | ( 陈育萱, 陈奇, 张占辉, 有机化学, 2021, 41, 3826.) |

| [34] | Dong M.; Li W.; Zhou J.; You S. Q.; Sun C. Y.; Yao X. H.; Qin C.; Wang X. L.; Su Z. M. Chin. J. Chem. 2022, 40, 2678. |

| [35] | Ma L.; Wang S.; Feng X.; Wang B. Chin. Chem. Lett. 2016, 27, 1383. |

| [36] | Tang X.; Chen Z.; Xu Q.; Su Y.; Xu H.; Horike S.; Zhang H.; Li Y.; Gu C. CCS Chem. 2022, 4, 2842. |

| [37] | Nagai A.; Guo Z.; Feng X.; Jin S.; Chen X.; Ding X.; Jiang D. Nat. Commun. 2011, 2, 1. |

| [38] | Xiang Z.; Xue Y.; Cao D.; Huang L.; Chen J. F.; Dai L. Angew. Chem., Int. Ed. 2014, 53, 2433. |

| [39] | Bunck D. N.; Dichtel W. R. Angew. Chem., Int. Ed. 2012, 51, 1885. |

| [40] | Yu X.; Ma Y.; Li C.; Guan X.; Fang Q.; Qiu S. Chem. Res. Chin. Univ. 2022, 38, 167. |

| [41] | Liu Y.; Ren J.; Wang Y.; Zhu X.; Guan X.; Wang Z.; Zhou Y.; Zhu L.; Qiu S.; Xiao S.; Fang Q. CCS Chem. 2023, DOI: 10.31635/ccschem.022.202202352. |

| [42] | Materials Studio ver.7.0, Diego, S. Accelrys Inc, 2013. |

| [43] | El-Mahdy A. F.; Lai M.-Y.; Kuo S.-W. J. Mater. Chem. C 2020, 8, 9520. |

/

| 〈 |

|

〉 |