Research on Preparation of Nano-flake Sodium Vanadyl Phosphate

Received date: 2023-10-14

Online published: 2024-01-05

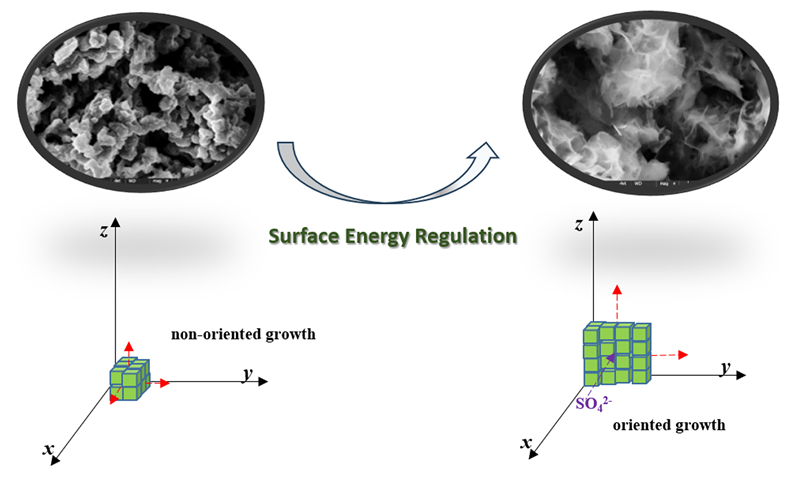

Based on the severe preparation conditions, large particle size and poor conductivity, a new method to prepare nano-flake sodium vanadyl phosphate is proposed. By the method of surface energy control technique under specific conditionsion, the controllable preparation of nano-flake sodium vanadyl phosphate was achieved. Through monitoring and analysis of the products under the different growth times, the formation process of nano-flake was studied, and the formation mechanism of sodium vanadyl phosphate was analyzed by density functional theory (DFT) simulation. The microstructure of sodium vanadyl phosphate is studied by adjusting the amount of sulfate radical, to verify the formation mechanism of unique nano-flake sodium vanadyl phosphate. The results show that the adsorption of $\text{SO}_{\text{4}}^{2}$ ions on different crystal faces changes the surface energy of different crystal faces, changes the dominant growth orientation of crystal nuclei, realizes directional growth and self-assembly, and finally gets the unique nano-flake sodium vanadyl phosphate. Because of the unique nano-flake micro-morphology, the prepared nano-flake sodium vanadyl phosphate has higher specific surface area and compaction density. The specific surface area of nano-flake sodium vanadyl phosphate is 16.2 m2/g, and the compaction density is 1.86 g/cm3, which is higher than that of the nano-particle sodium vanadyl phosphate, while 4.3 m2/g for the specific surface area and 1.77 g/cm3 for the compaction density of nano-particle sodium vanadyl phosphate. In addition, nano-flake sodium vanadyl phosphate also shows excellent sodium storage properties. Under the condition of current density at 0.1 C, the discharge specific capacity of nano-flake sodium vanadate phosphate reaches 93.76 mAh/g, which is larger than that of nano- particle sodium vanadyl phosphate (82.85 mAh/g) at the same discharge current density. At the same time, after 100 charge and discharge cycles at 10 C, 105% of the initial capacity can be maintained (in the same condition, only 92% of the initial capacity can be maintained for the nano-particle sodium vanadyl phosphate), showing good cycle stability.

Dongbin Zhang , Xinran Yuan , Yanan Xin , Tianhao Liu , Huiguo Han , Guangchao Du , Aijun Teng . Research on Preparation of Nano-flake Sodium Vanadyl Phosphate[J]. Acta Chimica Sinica, 2024 , 82(3) : 274 -280 . DOI: 10.6023/A23100449

| [1] | Chen, G. X.; Huang, Q.; Wu, T.; Lu, L. Adv. Funct. Mater. 2020, 2001289. |

| [2] | Zeng, X. G.; Peng, J.; Guo, Y.; Zhu, H. F.; Huang, X. Front. Chem. 2020, 8, 635. |

| [3] | Sun, C.; Deng, Z. R.; Jiang, N. B.; Zhang, L. L.; Fang, H.; Yang, X. L. Energy Storage Science and Technology 2022, 11, 1184 (in Chinese). |

| [3] | (孙畅, 邓泽荣, 江宁波, 张露露, Fang Hui, 杨学林, 储能科学与技术, 2022, 11, 1184.) |

| [4] | Liu, X. H.; Feng, G. L.; Wu, Z. G.; Wang, D.; Wu, C.; Yang, L.; Xiang, W.; Chen, Y. X.; Guo, X. D.; Zhong, B. H. J. Alloy. Compd. 2019, 815, 152430. |

| [5] | Jian, Z. L.; Zhao, L.; Pan, H. L.; Hu, Y. S.; Li, H.; Chen, W.; Chen, L. Q. Electrochem. Commun. 2012, 14, 86. |

| [6] | Shen, X.; Zhou, Q.; Han, M.; Qi, X. G.; Li, B.; Zhang, Q. Q.; Zhao, J. M.; Yang, C.; Liu, H. Z.; Hu, Y.-S. Nat. Commun. 2021, 12, 2848. |

| [7] | Yang, J.; Han, D.-W.; Jo, M. R.; Song, K.; Kim, Y.-I.; Chou, S.-L.; Liu, H.-K.; Kang, Y.-M. J. Mater. Chem. A 2015, 3, 1005. |

| [8] | Liu, Q.; Wang, D. X.; Yang, X.; Chen, N.; Wang, C. Z.; Bie, X. F.; Wei, Y. J.; Chen, G.; Du, F. J. Mater. Chem. A 2015, 3, 21478. |

| [9] | Wang, P. Y.; Zhang, X. L.; Xu, J. Q. New Chemical Materials 2007, 35, 14 (in Chinese). |

| [9] | (王培义, 张晓丽, 徐甲强, 化工新型材料, 2007, 35, 14.) |

| [10] | Xu, W. J.; Jia, J.; Wang, T.; Li, C.; He, B. W.; Zong, J. P.; Wang, Y. W.; Fan, H. J.; Xu, H. X.; Feng, Y. H.; Chen, H. Y. Angew. Chem., Int. Ed. 2020, 59, 22246. |

| [11] | Jia, J.; Liu, G. Y.; Xu, W. J.; Tian, X. L.; Li, S. B.; Han, F.; Feng, Y. H.; Dong, X. C.; Chen, H. Y. Angew. Chem., Int. Ed. 2020, 59, 14443. |

| [12] | Chen, T.; Yang, Y.; Zhao, W. Y.; Pan, D. Q.; Zhu, C. T.; Lin, F. Y.; Guo, X. Y. Acta Chim. Sinica 2019, 77, 447 (in Chinese). |

| [12] | (陈甜, 杨英, 赵婉玉, 潘德群, 朱从潭, 林飞宇, 郭学益, 化学学报, 2019, 77, 447.) |

| [13] | Wang, H. X.; Yang, G.; Cheng, T. S.; Wang, N.; Sun, R.; Wong, C.-P. Acta Chim. Sinica 2019, 77, 316 (in Chinese). |

| [13] | (王海旭, 杨光, 程天舒, 王宁, 孙蓉, 汪正平, 化学学报, 2019, 77, 316.) |

| [14] | Zhang, G. X.; Chen, Y. M.; He, Z.-N.; Lin, C.; Chen, Y.-G.; Guo, H.-B. Journal of Inorganic Materials 2018, 3, 289 (in Chinese). |

| [14] | (张国雄, 陈月梅, 何臻妮, 林川, 陈益钢, 郭海波, 无机材料学报, 2018, 3, 289.) |

| [15] | Fang, Y. J.; Liu, Q.; Xiao, L. F.; Rong, Y. C.; Liu, Y. D.; Chen, Z. X.; Ai, X. P.; Cao, Y. L.; Yang, H. X.; Xie, J.; Sun, C. J.; Zhang, X. Y.; Aoun, B.; Xing, X. R.; Xiao, X. H.; Ren, Y. Chem 2018, 4, 1. |

| [16] | Shen, X.; Han, M.; Li, X. W.; Zhang, P.; Yang, C.; Liu, H. Z.; Hu, Y.-S. ACS Appl. Mater. Interfaces 2022, 14, 6841. |

| [17] | Qi, Y. R.; Tong, Z. Z.; Zhao, J. M.; Ma, L.; Wu, T. P.; Liu, H. Z.; Yang, C.; Lu, J.; Hu, Y.-S. Joule. 2018, 2, 1. |

| [18] | Zhang, D. B.; Kong, X. G.; Jiang, M. H.; Lei, D. Q.; Lei, X. D. ACS Sustainable Chem. Eng. 2019, 7, 4420. |

/

| 〈 |

|

〉 |