Construction of ABC-Type Polypseudorotaxane and Its Responsive Membrane

Received date: 2024-04-09

Online published: 2024-05-08

Supported by

National Natural Science Foundation of China(52325308); National Natural Science Foundation of China(52073092); Natural Science Foundation of Shanghai(21ZR1415900)

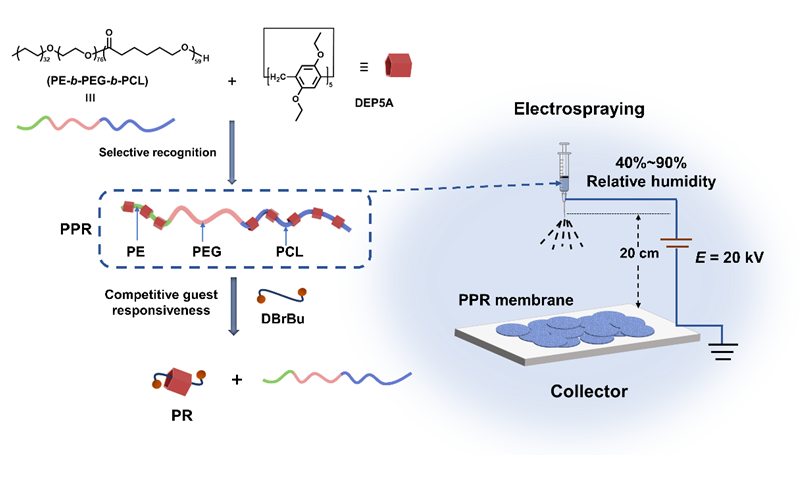

The surface microstructure and wettability of responsive membranes will change adaptively with changes in the external environment, which is significant in fields such as high-end manufacturing and biomedicine. However, it is still very challenging to precisely control the response of such films in an extensive range. Due to their incorporation of non-covalent bonds, polypseudorotaxanes exhibit distinctive reversibility and stimuli-responsiveness, rendering them a pivotal avenue in advancing smart materials, especially responsive membranes. Polypseudorotaxane membranes have the characteristics of easy control of structure and properties and multiple responses, which are of great significance in theoretical research and practical applications. This study capitalizes on the selective recognition property of 1,4-diethoxy pillar[5]arene (DEP5A) towards the polyethylene (PE) and polycaprolactone (PCL) segments within the polyethylene block polyethylene glycol block polycaprolactone (PE-b-PEG-b-PCL) copolymer, obtaining ABC-type polypseudorotaxane with competitive guest responsiveness. The successful assembly and competitive guest responsiveness to 1,4-dibromobutane is validated through 1H NMR spectroscopy. Additionally, a polypseudorotaxane membrane consisting of porous nanosheets and featuring superhydrophobicity is fabricated utilizing a novel technique combining electrospraying and the breath figure method. Notably, the polypseudorotaxane forms porous nanosheets during the membrane fabrication process, which then stack into a thin membrane. In addition, the polypseudorotaxane membrane's regular microstructure and superhydrophobicity can be achieved by controlling the molar ratio of DEP5A to polymer, polymer concentration, and relative humidity. Furthermore, the polypseudorotaxane membrane exhibits responsiveness to solvents and competing guest molecules, thus giving rise to different microstructure and hydrophobicity. Such responsive membranes hold immense promise for diverse applications, including catalyst supports and smart coatings.

Xiaoxuan Yin , Jinjie Li , Kexin Zhuo , Weixin Mou , Lingli Huang , Jianzhuang Chen , Shaoliang Lin . Construction of ABC-Type Polypseudorotaxane and Its Responsive Membrane[J]. Acta Chimica Sinica, 2024 , 82(7) : 790 -796 . DOI: 10.6023/A24040123

| [1] | Zhang Y. M.; Liu Y. H.; Liu Y. Adv. Mater. 2020, 32, 1806158. |

| [2] | Zeng C. Y.; Hu P.; Wang B. Q.; Fang W. Y.; Zhao K. Q.; Donnio B. Acta Chim. Sinica 2023, 81, 469 (in Chinese). |

| [2] | (曾崇洋, 胡平, 汪必琴, 方文彦, 赵可清, Donnio Bertrand, 化学学报, 2023, 81, 469.) |

| [3] | Zhang Z.; Lu S.; Cai R.; Tan W. Nano Today 2021, 38, 101202. |

| [4] | Tao X.; Liao M.; Wu F.; Jiang Y.; Sun J.; Shi S. Chem. Eng. J. 2022, 443, 136442. |

| [5] | Shin H.; Thanakkasaranee S.; Kambiz S.; Seo J. Food Packaging Shelf 2023, 40, 101188. |

| [6] | Fu B.; Liu Q.; Liu M.; Chen X.; Lin H.; Zheng Z.; Zhu J.; Dai C.; Dong X.; Yang D. Chinese Chem. Lett. 2022, 33, 4577. |

| [7] | Arunachalam M.; Gibson H. W. Prog. Polym. Sci. 2014, 39, 1043. |

| [8] | Su S.; Shi J. B.; Dong Y. B.; Hu X. Y.; Wang L. Y. Prog. Chem. 2014, 26, 1409 (in Chinese). |

| [8] | (孙书, 石建兵, 董宇平, 胡晓玉, 王乐勇, 化学进展, 2014, 26, 1409.) |

| [9] | Zhang M.; Yan X.; Huang F.; Niu Z.; Gibson H. Acc. Chem. Res. 2014, 47, 1995. |

| [10] | Feng W.; Zhou W.; Dai Z.; Yasin A.; Yang H. J. Mater. Chem. B 2016, 4, 1924. |

| [11] | Wang Z. Q.; Wang X.; Yang Y. W. Adv. Mater. 2023, 36, 2301721. |

| [12] | Li J.; Wang H.; Liu B.; Chen J.; Gu J.; Lin S. Adv. Funct. Mater. 2022, 32, 2201851. |

| [13] | Tang X.; Tang X. Z.; You Y. C.; Ren L. K.; Wang Y.; Yan L. J. Acta Chim. Sinica 2012, 70, 1565 (in Chinese). |

| [13] | (唐翔, 唐先忠, 游英才, 任立轲, 王洋, 严立京, 化学学报, 2012, 70, 1565.) |

| [14] | Cragg P. J.; Sharma K. Chem. Soc. Rev. 2012, 41, 597. |

| [15] | Wang Y.; Ping G.; Li C. Chem. Commun. 2016, 52, 9858. |

| [16] | Wu R. J.; Wu G.; Yang Y. W. Acc. Chem. Res. 2022, 55, 3191. |

| [17] | Li Q.; Zhu H.; Huang F. Trends Chem. 2020, 9, 850. |

| [18] | Ahmed E.; Womble C. T.; Weck M. Macromolecules 2020, 53, 9018. |

| [19] | Abetz V. Polymers 2020, 12, 794. |

| [20] | Huang J.; Tian Y.; Chen L.; Liao Y.; Miao T.; You X.; Wang R. Environ. Sci. Technol. 2020, 54, 7611. |

| [21] | Zhang A.; Bai H.; Li L. Chem. Rev. 2015, 115, 9801. |

| [22] | Li J.; Dong J.; Cui K.; Wang H.; Sun Y.; Yao Y.; Chen J.; Gu J.; Lin S. J. Mater. Chem. A 2020, 8, 10917. |

| [23] | Li J.; Dong J.; Wang H.; Yang X.; Chen J.; Gu J.; Lin S. Adv. Mater. Interfaces 2021, 8, 2101627. |

| [24] | Chen J.; Li N.; Gao Y.; Sun F.; He J.; Li Y. Soft Matter 2015, 11, 7835. |

| [25] | Liu K.; Yao X.; Jiang L. Chem. Soc. Rev. 2010, 39, 3240. |

| [26] | Dong J. H.; Li J. J.; Wang H.; Liu B. X.; Peng B.; Chen J. Z.; Lin S. L. Acta Chim. Sinica 2021, 79, 803 (in Chinese). |

| [26] | (董锦辉, 李进杰, 王赫, 刘彬秀, 彭博, 陈健壮, 林绍梁, 化学学报, 2021, 79, 803.) |

/

| 〈 |

|

〉 |