Efficient Preparation of Homogeneous Chromogenic Glucose-responsive Photonic Crystal Gels by Magnetic Assembly Method

Received date: 2024-03-11

Online published: 2024-05-17

Supported by

Sichuan Province Science and Technology Support Program(2019JDJQ0026)

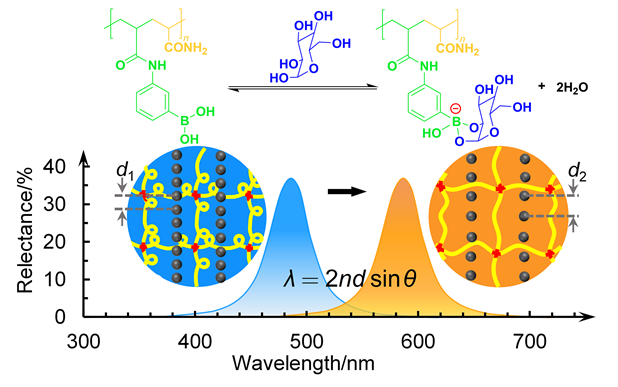

To efficiently prepare glucose-responsive photonic crystal gels with homogeneous coloration is still a challenge. A glucose-responsive gel embedded with ordered one-dimensional photonic crystal chains is fabricated by curing the precursors under both magnetic field and UV light. The chemically stable 3-acrylamidophenylboronic acid (3-APBA) is selected as the glucose-responsive co-monomer, which is negatively charged after recognizing glucose and makes the gel swelling. However, poly(vinylpyrrolidone)-coated magnetic colloidal nanoparticles (Fe3O4@PVP MCNCs) are prepared by solvothermal method and used as the magnetic assembly elements for the construction of the one-dimensional photonic crystal structure. MCNCs suspended in dimethyl sulfoxide/ethylene glycol (DMSO/EG) mixed solvent reach equilibrium by both spatial repulsion of PVP shell polymer and magnetic attraction along the direction of applied magnetic field, rapidly arranging into one-dimensional chain-like structures; while in the direction perpendicular to the magnetic field, magnetic particles repel each other and maintain the independent chains. When the total monomer concentration is 2.5 mol/L, the feeding molar ratio of 3-APBA and crosslinker to monomers are respectively 20% and 0.2%, the resultant hydrogel has satisfactory glucose-responsive swelling properties. The effects of MCNCs size, concentration, magnetic field strength and environmental pH on the glucose-responsive performance are investigated systematically. The diffraction wavelength of the photonic crystal gels will be red-shifted with the increase of the particle size and concentration of the MCNCs, the decrease of the applied magnetic field strength, and the enhancement of the test environment alkalinity. The results show that the photonic crystal gel, prepared by polymerizing the precursor solution containing MCNCs concentration of 4 g/L and a particle size of 181 nm at a moderate magnetic field strength of 8 mT, has the optimal glucose-responsive performance. It is able to change from blue to orange in glucose solutions from 0 to 50 mmol/L with satisfactory reusability, reaching a diffraction wavelength migration of nearly 100 nm. The glucose-responsive photonic crystal gel based on one-dimensional magnetic assembly chains has the advantages of facile preparation process, homogeneous structural color as well as stable and reversible responsiveness, and therefore, it has potential applications in the field of visual detection of glucose.

Key words: magnetic assembly; photonic crystal; glucose response; hydrogel; visualization

Yaqin Hu , Xiaojie Ju , Wei Wang , Zhuang Liu , Dawei Pan , Rui Xie , Liangyin Chu . Efficient Preparation of Homogeneous Chromogenic Glucose-responsive Photonic Crystal Gels by Magnetic Assembly Method[J]. Acta Chimica Sinica, 2024 , 82(7) : 782 -789 . DOI: 10.6023/A24030080

| [1] | Elsayed N. A.; Aleppo G.; Aroda V. R.; Bannuru R. R.; Brown F. M.; Bruemmer D.; Collins B. S.; Hilliard M. E.; Isaacs D.; Johnson E. L.; Kahan S.; Khunti K.; Leon J.; Lyons S. K.; Perry M. L.; Prahalad P.; Pratley R. E.; Seley J. J.; Stanton R. C.; Gabbay R. A. Diabetes Care 2023, 46, S19. |

| [2] | Liu Y.-T.; Zeng S.-Q.; Ji W.; Yao H.; Lin L.; Cui H.-Y.; Santos H. A.; Pan G.-Q. Adv. Sci. 2022, 9, 2102466. |

| [3] | Li Z.-Y.; Hu X.-Y.; Qiang J.-L.; Zhang D.-M.; Xiao S.-J.; Lin C.; Wang L.-Y. Chin. J. Org. Chem. 2018, 38, 29 (in Chinese). |

| [3] | (李臻益, 胡晓玉, 强琚莉, 张冬梅, 肖守军, 林晨, 王乐勇, 有机化学, 2018, 38, 29.) |

| [4] | Zou Y.-Y.; Chu Z.-K.; Guo J.-C.; Liu S.; Ma X.; Guo J.-H. Biosens. Bioelectron. 2023, 225, 115103. |

| [5] | Hu Y.-L.; Yang D.-S.; Zhang H.-B.; Gao Y.; Zhang W.-J.; Yin R.-X. Polymer 2023, 15, 1423. |

| [6] | Yoon H.; Nah J.; Kim H.; Ko S.; Sharifuzzaman M.; Barman S. C.; Xuan X.; Kim J.; Park J. Y. Sens. Actuators B 2020, 311, 127866. |

| [7] | Yang Y.; Shi W.-L.; Wu Q.-H.; Zhao Y.; Li C.; Song X.; Li Y.-C. Chem. Res. Application 2022, 34, 2221 (in Chinese). |

| [7] | (杨意, 石文龙, 吴青华, 赵野, 李超, 宋芯, 李宇春, 化学研究与应用, 2022, 34, 2221.) |

| [8] | Hajshahvaladi L.; Kaatuzian H.; Danaie M. Opt. Commun. 2022, 502, 127421. |

| [9] | Mostufa S.; Paul A. K.; Chakrabarti K. OSA Continuum 2021, 4, 2164. |

| [10] | Yan C.-F.; Yu S.-Y.; Jiang Y.; He Q.-H.; Chen H.-W. Acta Chim. Sinica 2014, 72, 1099 (in Chinese). |

| [10] | (严春芳, 余思扬, 蒋艳, 何巧红, 陈恒武, 化学学报, 2014, 72, 1099.) |

| [11] | Cho M. J.; Park S. Y. Sens. Actuators B 2019, 282, 719. |

| [12] | Huang X.-Y.; Zhou Y.-J.; Liu C.; Zhang R.-L.; Zhang L.-Y.; Du S.-H.; Liu B.-H.; Han M.-Y.; Zhang Z.-P. Biosens. Bioelectron. 2016, 86, 530. |

| [13] | Wang X.-X.; Zhong J.-Y.; Liu Y.; Wen A.-X.; Shan Z.; Yang W.-S. Acta Chim. Sinica 2010, 68, 2063 (in Chinese). |

| [13] | (王显祥, 钟娇懿, 刘怡, 温安祥, 单志, 杨婉身, 化学学报, 2010, 68, 2063.) |

| [14] | Wang M.-Y.; Cui X.-Y.; Cai W.-S.; Shao X.-G. Acta Chim. Sinica 2020, 78, 125 (in Chinese). |

| [14] | (汪明圆, 崔晓宇, 蔡文生, 邵学广, 化学学报, 2020, 78, 125.) |

| [15] | Hina A.; Saadeh W. Sensors 2022, 22, 4855. |

| [16] | Zhang X.-Y.; Song F.; Zhu H.-L.; Zheng C.-T.; Wang Y.-D. Anal. Chem. 2023, 51, 1571 (in Chinese). |

| [16] | (张馨予, 宋芳, 朱恒亮, 郑传涛, 王一丁, 分析化学, 2023, 51, 1571.) |

| [17] | Li Q.; Guan Y.; Zhang Y.-J. Sens. Actuators B 2018, 272, 243. |

| [18] | Hussain S.; Park S. Y. Sens. Actuators B 2020, 316, 128099. |

| [19] | Shi T.; Kou D.-H.; Xue Y.-N.; Zhang S.-F.; Ma W. Prog. Chem. 2024, 36, 106 (in Chinese). |

| [19] | (施坦, 寇东辉, 薛亚南, 张淑芬, 马威, 化学进展, 2024, 36, 106.) |

| [20] | Yan Z.-Q.; Xue M.; He Q.; Lu W.; Meng Z.-H.; Yan D.; Qiu L.-L.; Zhou L.; Yu Y. Anal. Bioanal. Chem. 2016, 408, 8317. |

| [21] | Liu D.-L.; Cai W.-P.; Marin M.; Yin Y.-D.; Li Y. Chem. Nano. Mat. 2019, 5, 1338. |

| [22] | Lan Y.-H.; Xue M.; Qiu L.-L.; Meng Z.-H. ChemistrySelect 2019, 4, 6547. |

| [23] | Hong X.-D.; Peng Y.; Bai J.-L.; Ning B.-A.; Liu Y.-Y.; Zhou Z.-J.; Gao Z.-X. Small 2014, 10, 1308. |

| [24] | Feng X.-Q.; Xu J.; Liu Y.-X.; Zhao W.-P. J. Mater. Chem. B 2019, 7, 3576. |

| [25] | Asher S. A.; Alexeev V. L.; Goponenko A. V.; Sharma A. C.; Lednev I. K.; Wilcox C. S.; Finegold D. N. J. Am. Chem. Soc. 2003, 125, 3322. |

| [26] | Zhang X.; Guan Y.; Zhang Y.-J. Biomacromolecules 2012, 13, 92. |

| [27] | Ayyub O. B.; Sekowski J. W.; Yang T.-I.; Zhang X.; Briber R. M.; Kofinas P. Biosens. Bioelectron. 2011, 28, 349. |

| [28] | Jiang N.; Butt H.; Montelongo Y.; Liu F.; Afewerki S.; Ying G.-L.; Dai Q.; Yun S.; Yetisen A. K. Adv. Funct. Mater. 2018, 28, 1702715. |

| [29] | Moghaddam G. K.; Margerison H.; Suzuki J.; Blyth J.; Lowe C. R. Sens. Actuators B 2018, 267, 1. |

| [30] | Kim Y. J.; Park S. Y. ACS Appl. Mater. Interfaces 2020, 12, 47342. |

| [31] | Munir S.; Hussain S.; Park S. Y. ACS Appl. Mater. Interfaces 2019, 11, 37434. |

| [32] | Jia Z.-H.; Xie R.; Qiu Y.; Lv X.-B.; Ju X.-J.; Wang W.; Liu Z.; Chu L.-Y. Macromol. Rapid Commun. 2021, 42, 2100200. |

| [33] | Wang W.-T.; Tang B.-T.; Ju B.-Z.; Zhang S.-F. RSC Adv. 2015, 5, 75292. |

| [34] | Luo W.; Ma H.-R.; Mou F.-Z.; Zhu M.-X.; Yan J.-D.; Guan J.-G. Adv. Mater. 2014, 26, 1058. |

| [35] | Jia Z.-H.; Xie R.; Hu Y.-Q.; Ju X.-J.; Wang W.; Liu Z.; Chu L.-Y. Macromol. Rapid Commun. 2023, 44, 2200800. |

| [36] | Jia Z.-H. Ph.D. Dissertation, Sichuan University, Chengdu, 2023 (in Chinese). |

| [36] | (贾智涵, 博士论文, 四川大学, 成都, 2023.) |

| [37] | Ge J.-P.; He L.; Hu Y.-X.; Yin Y.-D. Nanoscale 2011, 3, 177. |

| [38] | Zhang M.-J.; Wang W.; Xie R.; Ju X.-J.; Liu L.; Gu Y.-Y.; Chu L.-Y. Soft Matter 2013, 9, 4150. |

| [39] | Zhang S.-B.; Chu L.-Y.; Xu D.; Ju X.-J.; Wang W.; Liu Z.; Xie R. Polym. Adv. Technol. 2008, 19, 937. |

/

| 〈 |

|

〉 |