Bacterial Cellulose Separator with High Young's Modulus Effectively Inhibits Lithium Dendrites

Received date: 2024-04-22

Online published: 2024-06-26

Supported by

Key Scientific and Technological Innovation Project of Shandong(2022CXGC020301); National Natural Science Foundation of China(52073298); National Natural Science Foundation of China(52273221); Youth Innovation Promotion Association of CAS(2020217); Qingdao New Energy Shandong Laboratory Open Project(QNESL OP202312)

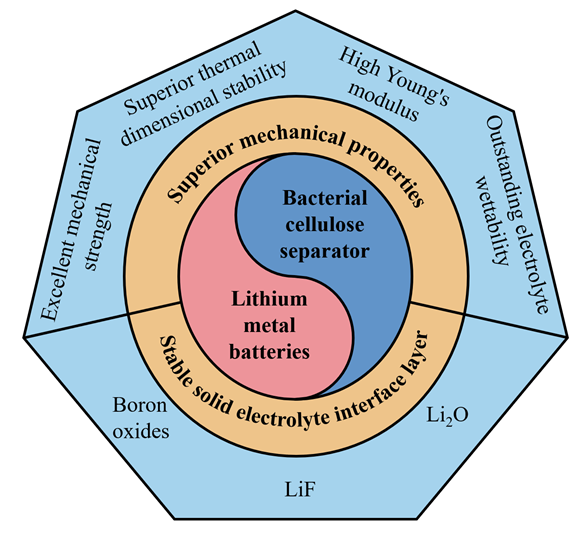

Separators play a critical role in isolating anodes and cathodes for lithium battery. However, commercialized polyolefin-based separators often suffered from poor electrolyte wettability, inferior dimentionally thermal stability, especially the low Young's modulus of polyolefin-based separators cannot effectively inhibit the growth of lithium dendrites, which limits their large-scale practical application in lithium metal batteries. Therefore, a novel separator with high Young's modulus which can be applied to lithium metal batteries is urgently needed. Bacterial cellulose is a porous, nanoscale biopolymer, which is synthesized mainly by micro-organisms such as bacillus xylosus. Compared with plant-derived cellulose, bacterial cellulose exhibits high crystallinity, high thermal stability, high electrolyte absorption, high porosity, and excellent mechanical strength. Considering the above advantages, bacterial cellulose-based bacterial cellulose separators have the potential to be effectively suited in lithium metal batteries. Herein, we demonstrate a novel kind of bacterial cellulose separator. Firstly, the structure of the prepared bacterial cellulose separator is characterized using scanning electron microscopy (SEM), atomic force microspocy (AFM) and X-ray diffraction (XRD), which shows a three-dimensional interpenetrating network structure, suggesting that it is favourable for achieving wetting of the electrolyte and providing more ionic conduction pathways. In addition, this bacterial cellulose separator with high Young's modulus, excellent dimentionally thermal stability and outstanding electrolyte wettability was prepared by a sample process. It is demonstrated that the resultant separator exhibits excellent mechanical strength (144 MPa), high Young's modulus (8.1 GPa) and superior thermal dimentionally stability (≥300 ℃). Meanwhile, Li/Li cells using this bacterial cellulose separator and conventional organic carbonate-based electrolyte can achieve a steady lithium plating/stripping behavior over 4000 h at a current rate of 0.52 mA•cm−2 and 1.56 mAh•cm−2. Such improved reliability is chiefly attributed to the high Young's modulus of bacterial cellulose separator and the formed stable solid electrolyte interphase (SEI) which rich in inorganic components such as boron oxides, LiF and Li2O. More intriguingly, this separator delivers an excellent cycling performance in LiFePO4/Li battery, stable cycling for 100 cycles with a low capacity loss at 1 C. These fascinating characteristics indicate this separator is a promising material for high-energy-density lithium metal batteries.

Zhixiang Yuan , Yalan Zhang , Hao Zhang , Shijie Zhang , duo Wang , Botao Zhang , Jianjun Zhang , Guanglei Cui . Bacterial Cellulose Separator with High Young's Modulus Effectively Inhibits Lithium Dendrites[J]. Acta Chimica Sinica, 2024 , 82(8) : 849 -855 . DOI: 10.6023/A24040141

| [1] | Etacheri, V.; Marom, R.; Elazari, R.; Salitra, G.; Aurbach, D. Energy Environ. Sci. 2011, 4, 3243. |

| [2] | Wakihara, M. Mater. Sci. Eng., R 2001, 33, 109. |

| [3] | Cao, C.; Zhong, Y.; Shao, Z. Chin. J. Chem. 2023, 41, 1119. |

| [4] | Teng, X.-G.; Zhang, L.-W.; Han, X.-Y.; Li, G.-W.; Dai, J.-C. Acta Chim. Sinica 2024, 82, 16 (in Chinese). |

| [4] | (滕祥国, 张良伟, 韩晓玉, 李郭威, 戴纪翠, 化学学报, 2024, 82, 16.) |

| [5] | Zhang, W.; Xia, H.; Cao, X.; Xu, B.-Y.; Li, Z.-Y. Chin. J. Org. Chem. 2024, 44, 148 (in Chinese). |

| [5] | (章炜, 夏欢, 曹昕, 徐彬瑜, 李峥沄, 有机化学, 2024, 44, 148.) |

| [6] | Liu, G.; Wan, W.; Nie, Q.; Zhang, C.; Chen, X.; Lin, W.; Wei, X.; Huang, Y.; Li, J.; Wang, C. Energy Environ. Sci. 2024, 17, 1163. |

| [7] | Gu, Q.; Liu, X.-X.; Zhou, X.-Y.; Li, J.; Lin, X.-J.; Ma, Y.-W. Acta Chim. Sinica 2024, 82, 449 (in Chinese). |

| [7] | (谷琪, 刘夏夏, 周鑫宇, 李江, 林秀婧, 马延文, 化学学报, 2024, 82, 449.) |

| [8] | Shi, K.; Dutta, A.; Hao, Y.; Zhu, M.; He, L.; Pan, Y.; Xin, X.; Huang, L. F.; Yao, X.; Wu, J. Adv. Funct. Mater. 2022, 32, 202203652. |

| [9] | Liang, J.; Chen, Q.; Liao, X.; Yao, P.; Zhu, B.; Lv, G.; Wang, X.; Chen, X.; Zhu, J. Angew. Chem. Int. Ed. 2020, 59, 6561. |

| [10] | Lingappan, N.; Lee, W.; Passerini, S.; Pecht, M. Renewable Sustainable Energy Rev. 2023, 187, 113726. |

| [11] | Francis, C. F. J.; Kyratzis, I. L.; Best, A. S. Adv. Mater. 2020, 32, e1904205. |

| [12] | Lagadec, M. F.; Zahn, R.; Wood, V. Nat. Energy. 2019, 4, 16. |

| [13] | Miranda, D.; Gon?alves, R.; Wuttke, S.; Costa, C. M.; Lanceros- Méndez, S. Adv. Energy Mater. 2023, 13, 2203874. |

| [14] | Huang, J.-Q.; Sun, Y.-Z.; Wang, Y.-F.; Zhang, Q. Acta Chim. Sinica 2017, 75, 173 (in Chinese). |

| [14] | (黄佳琦, 孙滢智, 王云飞, 张强, 化学学报, 2017, 75, 173.) |

| [15] | Wu, W.-L.; Xu, Y.-T.; Ke, X.; Chen, Y.-M.; Cheng, Y.-F.; Lin, G.-D.; Fan, M.-P.; Liu, L.-Y.; Shi, Z.-C. Energy Storage Mater. 2021, 37, 387. |

| [16] | Li, H.; Wu, D.; Wu, J.; Dong, L. Y.; Zhu, Y. J.; Hu, X. Adv. Mater. 2017, 29, 1703548. |

| [17] | Zhang, T. W.; Chen, J. L.; Tian, T.; Shen, B.; Peng, Y. D.; Song, Y. H.; Jiang, B.; Lu, L. L.; Yao, H. B.; Yu, S. H. Adv. Funct. Mater. 2019, 29, 1902023. |

| [18] | Uddin, M.-J.; Alaboina, P. K.; Zhang, L.; Cho, S.-J. Mater. Sci. Eng., B 2017, 223, 84. |

| [19] | Hu, L.; Wu, H.; La Mantia, F.; Yang, Y.; Cui, Y. ACS Nano 2010, 4, 5843. |

| [20] | Zhang, J.; Yue, L.; Hu, P.; Liu, Z.; Qin, B.; Zhang, B.; Wang, Q.; Ding, G.; Zhang, C.; Zhou, X.; Yao, J.; Cui, G.; Chen, L. Sci. Rep. 2014, 4, 6272. |

| [21] | Hao, X.; Zhu, J.; Jiang, X.; Wu, H.; Qiao, J.; Sun, W.; Wang, Z.; Sun, K. Nano Lett. 2016, 16, 2981. |

| [22] | Zheng, Z.; Guo, S.; Yan, M.; Luo, Y.; Cao, F. Adv. Mater. 2023, 35, e2304667. |

| [23] | Gregory, D. A.; Tripathi, L.; Fricker, A. T. R.; Asare, E.; Orlando, I.; Raghavendran, V.; Roy, I. Mater. Sci. Eng., R 2021, 145, 100623. |

| [24] | Cheng, C.; Yang, R.; Wang, Y.; Fu, D.; Sheng, J.; Guo, X. Carbohydr. Polym. 2023, 304, 120489. |

| [25] | Yang, Y.; Huang, C.; Gao, G.; Hu, C.; Luo, L.; Xu, J. Carbohydr. Polym. 2020, 247, 116702. |

| [26] | Cabras, L.; Serpelloni, M.; Salvadori, A. Front. Mater. 2022, 9, 12. |

| [27] | Orendorff, C. J.; Lambert, T. N.; Chavez, C. A.; Bencomo, M.; Fenton, K. R. Adv. Energy Mater. 2012, 3, 314. |

| [28] | Wu, H.; Huang, H.; Xu, Y.; Xu, F.; Zhang, X. Chem. Eng. J. 2023, 470, 144089. |

| [29] | Chang, L.; Wang, D.; Cao, Z.; Zhang, X.; Yang, J.; Liu, H.; Jiang, L. Chem. Eng. J. 2024, 484, 149416. |

| [30] | Zeng, W.; Wang, L.; Peng, X.; Liu, T.; Jiang, Y.; Qin, F.; Hu, L.; Chu, P. K.; Huo, K.; Zhou, Y. Adv. Energy Mater. 2018, 8, 1702314. |

| [31] | Li, Y.; Cui, L.; Tan, C.; Fan, X.; Pan, Q.; Chu, Y.; Hu, S.; Zheng, F.; Wang, H.; Li, Q. Chem. Eng. J. 2022, 430, 132985. |

| [32] | Ye, M.; Xiao, Y.; Cheng, Z.; Cui, L.; Jiang, L.; Qu, L. Nano Energy. 2018, 49, 403. |

| [33] | Liu, Y.; Lin, D.; Liang, Z.; Zhao, J.; Yan, K.; Cui, Y. Nat. Commun. 2016, 7, 10992. |

| [34] | Wu, R.; Du, X.; Liu, T.; Zhuang, X.; Guan, P.; Zhang, B.; Zhang, S.; Gao, C.; Xu, G.; Zhou, X.; Cui, G. Adv. Energy Mater. 2023, 14, 2302899. |

| [35] | Zhao, Z.; Zhou, X.; Zhang, B.; Huang, F.; Wang, Y.; Ma, Z.; Liu, J. Angew. Chem. Int. Ed. 2023, 62, e202308738. |

/

| 〈 |

|

〉 |