1 引言

2 结果与讨论

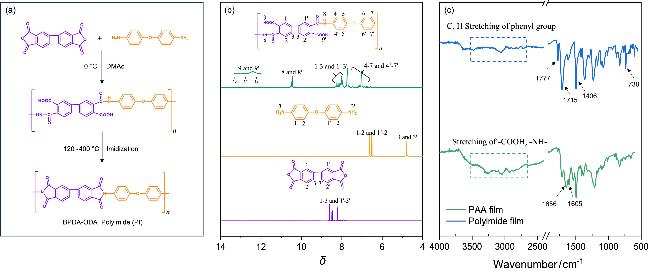

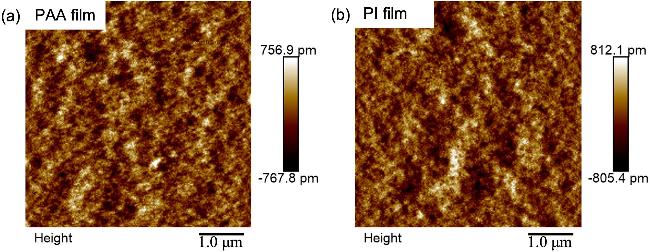

2.1 聚酰亚胺膜的合成与结构表征

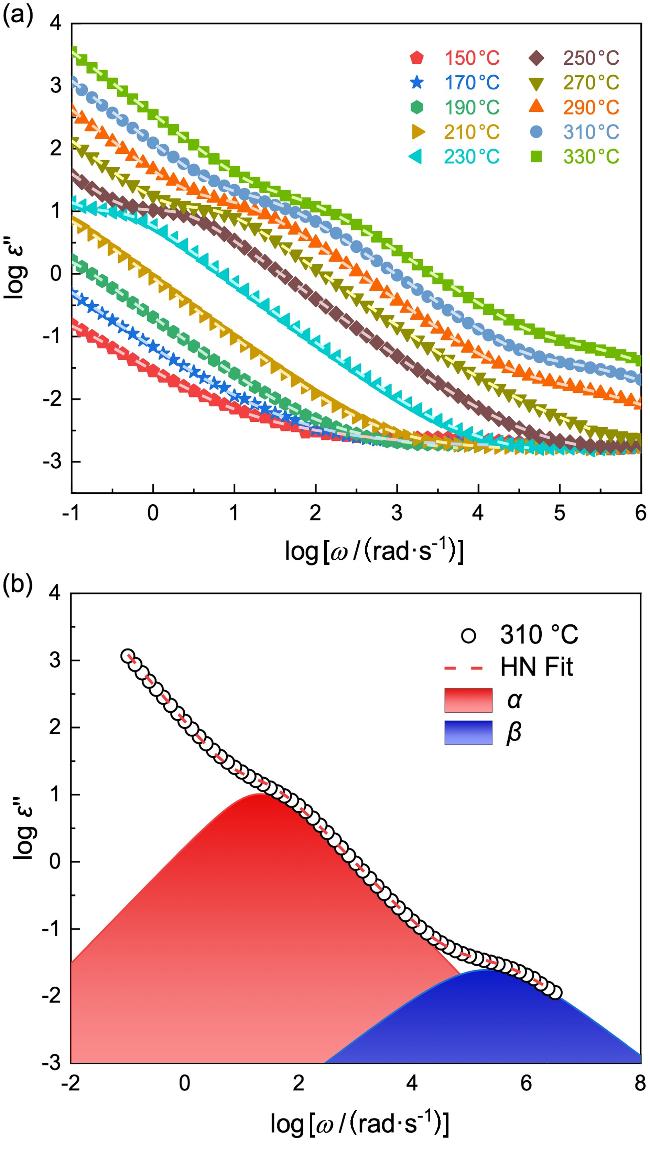

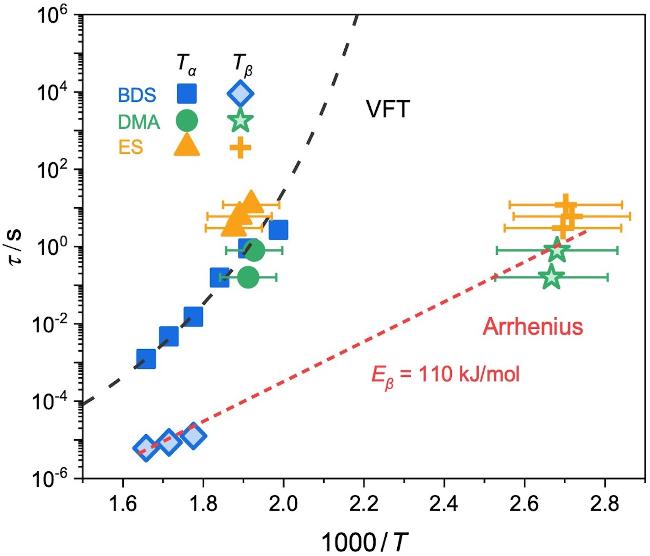

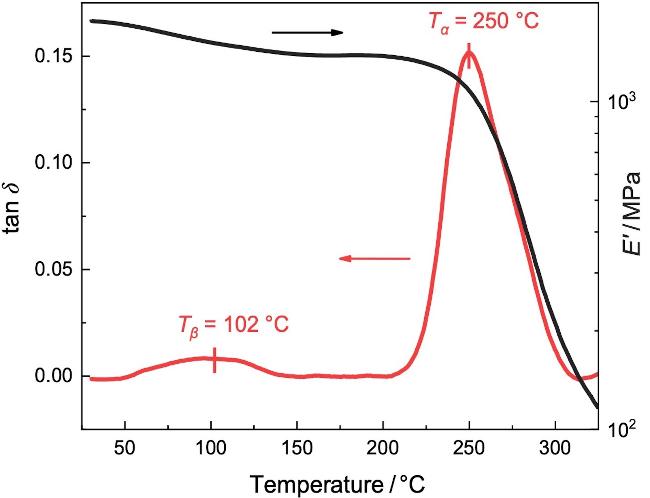

2.2 聚酰亚胺的本体松弛

图3 PI膜的α和β松弛时间与1000/T的关系图. 黑色虚线为VFT方程拟合的结果(公式2), 红色虚线为Arrhenius方程拟合的结果(公式3)Figure 3 α and β relaxation time plotted as a function of the inverse temperature for polyimide film. The dotted lines (red and black) are the fitting of the data to the VFT and Arrhenius equation, respectively |

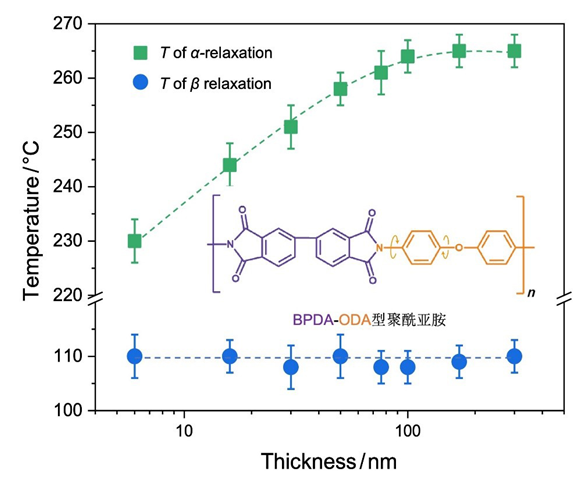

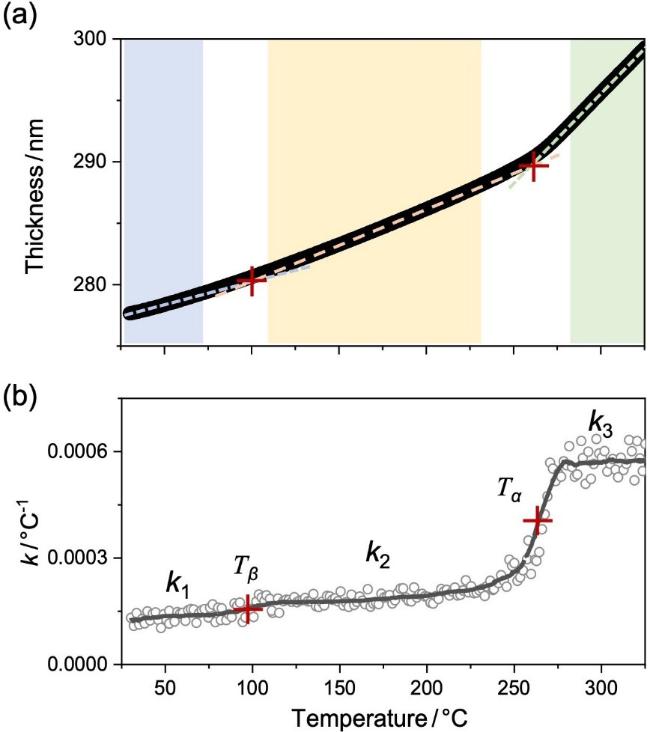

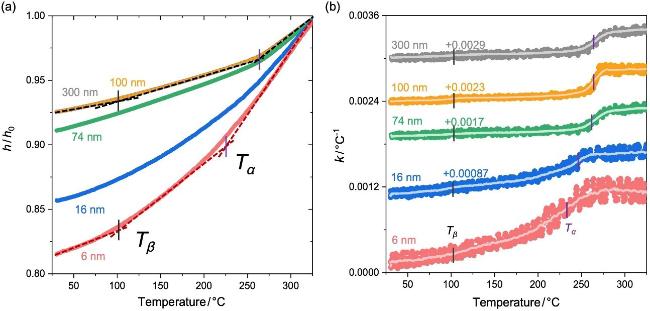

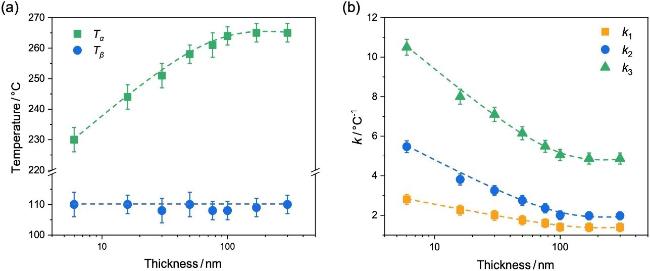

2.3 纳米聚酰亚胺超薄膜的松弛

图6 PI薄膜的(a)归一化厚度(h/h0, h0为薄膜在330 ℃下的膜厚)和(b)膨胀系数随温度的变化. 图(b)中的曲线经过纵向平移, 以更好地展示其差异Figure 6 (a) Normalized thickness (h/h0, h0 is the thickness of films at 330 ℃) and (b) thermal expansion coefficient as a function of temperature for polyimide ultrathin films. The curves in panel (b) have been vertically shifted for better presentation of their difference |

3 结论与展望

4 实验部分

4.1 材料

4.2 聚酰胺酸(Polyamide Acid, PAA)膜的制备

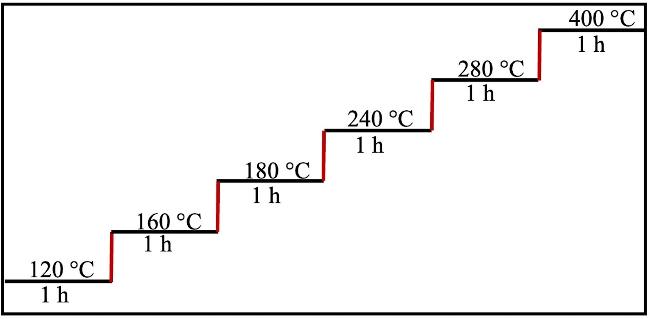

4.3 PAA膜高温亚胺化制备聚酰亚胺薄膜

图8 PAA薄膜高温亚胺化制备PI薄膜的升温程序图Figure 8 Temperature protocol for preparing PI films by imidization of PAA films at high temperature |