Chinese Journal of Organic Chemistry >

Highly Thermal Conductive Organic Polymer System of PMMA/(Core-shell Structured BaTiO3@PMMA Nanoparticles)

Received date: 2014-06-02

Revised date: 2014-06-13

Online published: 2014-07-02

Supported by

Project supported by the National Basic Research Program of China (973 Program, No.2014CB643306) and the National Natural Science Foundation of China (Nos.51403124, 51303034).

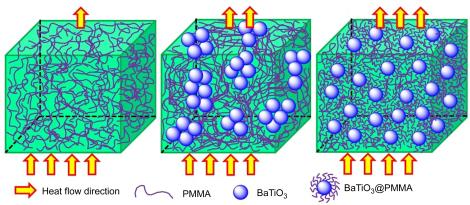

A simple method to fabricate core-shell structured BaTiO3@PMMA hybrid nanoparticles via surface initiated reversible addition-fragmentation chain transfer (RAFT) polymerization is reported. And the effects of functionalization BaTiO3 nanoparticles on thermal properties of polymethyl methacrylate (PMMA) composites are investigated. The functionalized BaTiO3 nanoparticles were characterized by fourier-transform infrared (FT-IR), nuclear magnetic resonance (1H NMR), thermogravimetric analyzer (TGA), and transmission electron microscopy (TEM), which prove that a layer of PMMA polymer completely coated on the BaTiO3 surface, and the hybrid nanoparticles exhibit obvious core-shell structure. PMMA composites were fabricated by incorporating two kinds of fillers: the as-received BaTiO3 nanoparticles and core-shell structured BaTiO3@PMMA hybrid nanoparticles. The study of the thermal conductivity properties and electrical insulation performance of the composite materials indicates that BaTiO3@PMMA results in a strong interface and thus the corresponding PMMA composites exhibit significantly increased thermal conductivity than PMMA composites filled with the as-received BaTiO3 nanoparticles. When the volume content of BaTiO3 nanoparticles is up to 50%, the thermal conductivity of the composite materials which filled with the as-received BaTiO3 nanoparticles is 0.894 W·m-1·K-1, and the thermal conductivity of the composite materials which filled with the core-shell structured BaTiO3@PMMA hybrid nanoparticles is 1.137 W·m-1·K-1. In addition, the two kinds of highly thermal conductive polymer composites still have a good electrical insulating performance and the volume resistivity is maintained at 1015Ω·cm above.

Wu Xinfeng , Wang Ying , Jiang Pingkai , Zhang Fuhua , Zhang Xiqin , Yang Kailiang . Highly Thermal Conductive Organic Polymer System of PMMA/(Core-shell Structured BaTiO3@PMMA Nanoparticles)[J]. Chinese Journal of Organic Chemistry, 2014 , 34(11) : 2309 -2316 . DOI: 10.6023/cjoc201406001

[1] Barrett, J. Microelectron. Reliab. 1998, 38, 1277.

[2] Garimella, S. V.; Lian-Tuu, Y.; Persoons, T. IEEE Trans. Comp. Pack. Man. 2012, 2, 1307.

[3] Otiaba, K. C.; Ekere, N. N.; Bhatti, R. S.; Mallik, S.; Alam, M. O.; Amalu, E. H. Microelectron. Reliab. 2011, 51, 2031.

[4] Yavatkar, R.; Tirumala, M. Microelectron. J. 2008, 39, 930.

[5] T'Joen, C.; Park, Y.; Wang, Q.; Sommers, A.; Han, X.; Jacobi, A. Int. J. Refrig. 2009, 32, 763.

[6] Lee, G. W.; Park, M.; Kim, J.; Lee, J. I.; Yoon, H. G. Composites Part A 2006, 37, 727.

[7] Zhou, W.; Qi, S.; Tu, C.; Zhao, H. J. Appl. Polym. Sci. 2007, 104, 2478.

[8] Pop, E.; Mann, D.; Wang, Q.; Goodson, K. E.; Dai, H. J. Nano Lett. 2006, 6, 96.

[9] Balandin, A. A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C. N. Nano Lett. 2008, 8, 902.

[10] Wang, S.; Tambraparni, M.; Qiu, J.; Tipton, J.; Dean, D. Macromolecules 2009, 42, 5251.

[11] Jezowski, A.; Mucha, J.; Pazik, R.; Strek, W. Appl. Phys. Lett. 2007, 90.

[12] Sato, K.; Horibe, H.; Shirai, T.; Hotta, Y.; Nakano, H.; Nagai, H.; Mitsuishi, K.; Watari, K. J. Mater. Chem. 2010, 20, 2749.

[13] Yung, K. C.; Liem, H. J. Appl. Polym. Sci. 2007, 106, 3587.

[14] Roy, A. K.; Farmer, B. L.; Varshney, V.; Sihn, S.; Lee, J.; Ganguli, S. ACS Appl. Mater. Interface 2012, 4, 545.

[15] Xu, Y.; Chung, D. D. L. Compos. Interface 2000, 7, 243.

[16] Liu, Q.; Zhang, Q.; Chen, S.; Zhou, J.; Lei, X. Chin. J. Org. Chem. 2012, 32, 1846 (in Chinese). (刘清, 张秋禹, 陈少杰, 周健, 雷星锋, 有机化学, 2012, 32, 1846.)

[17] Ren, C. H.; Jiang, X.; Lu, G. L.; Jiang, X. Y.; Huang, X. Y. J. Polym. Sci. Chem. 2014, 52, 1478.

[18] Cai, X.; Hu, W.; Lu, G.; Huang, X. Chin. J. Org. Chem. 2013, 33, 2520 (in Chinese). (蔡晓冰, 胡薇, 陆国林, 黄晓宇, 有机化学, 2013, 33, 2520.)

[19] Jiang, X. Y.; Li, Y. J.; Lu, G. L.; Huang, X. Y. Polym. Chem. 2013, 4, 1402.

[20] Xi, C. B.; Yang, D.; Li, J.; Yan, J. J.; Hu, J. H. Chin. J. Org. Chem. 2012, 32, 2166 (in Chinese). (席陈彬, 杨东, 李静, 晏建军, 有机化学, 2012, 32, 2166.)

[21] Sun, Q. W.; Yu, Y.; Zhang, N.; Zhang, F. Y. Chin. J. Org. Chem. 2012, 32, 889 (in Chinese). (孙庆文, 于颖, 张南, 张法永, 有机化学, 2012, 32, 889.)

[22] Song, X. M.; Yao, W. Q.; Lu, G. L.; Li, Y. J.; Huang, X. Y. Polym. Chem. 2013, 4, 2864.

[23] Li, B. Z.; Li, Y. H. Chin. J. Org. Chem. 2013, 33, 2148 (in Chinese). (李炳臻, 李义和, 有机化学, 2013, 33, 2148.)

[24] Liu, G. Z.; Han, D. E.; Wang, P.; Liu, H. M. Chin. J. Org. Chem. 2013, 33, 1674 (in Chinese). (刘改枝, 韩德恩, 王鹏, 刘宏民, 有机化学, 2013, 33, 1674.)

[25] Cui, L.; Tarte, N. H.; Woo, S. I. Macromolecules 2009, 42, 8649.

[26] Sun, Y. Y.; Zhang, Z. Q.; Wong, C. P. In Proceeding of 54th Electronic Components and Technology Conference, 2004, p. 754, p. 760.

[27] Hung, M. T.; Choi, O.; Ju, Y. S.; Hahn, H. T. Appl. Phys. Lett. 2006, 89.

[28] Convertine, A. J.; Lokitz, B. S.; Lowe, A. B.; Scales, C. W.; Myrick, L. J.; McCormick, C. L. Macromol. Rapid. Commun. 2005, 26, 791.

/

| 〈 |

|

〉 |