1'-Acetonaphthone (

2a)

[10i]: Purified by flash column chromatography [

V(petroleum ether, PE)∶

V(ethyl acetate, EA)=97∶3], 30.5 mg, yellow oil, yield 90%.

1H NMR (400 MHz, Chloroform-

d)

δ: 8.74 (d,

J=8.6 Hz, 1H), 7.99 (d,

J=8.2 Hz, 1H), 7.93 (d,

J=7.2 Hz, 1H), 7.87 (d,

J=8.1 Hz, 1H), 7.63~7.57 (m, 1H), 7.55~7.47 (m, 2H), 2.74 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 201.9, 135.4, 134.0, 133.1, 130.2, 128.8, 128.4, 128.1, 126.5, 126.0, 124.4, 30.0.

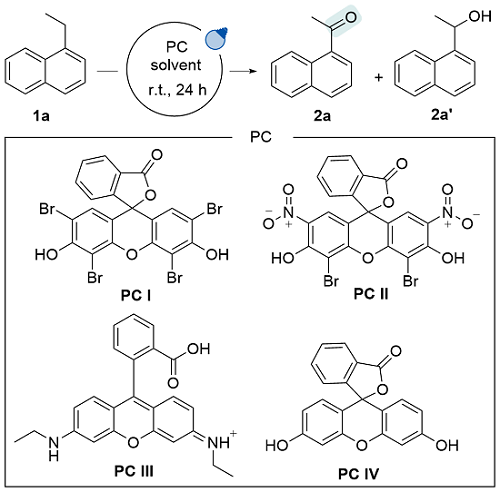

1,4-Diacetylbenzene (

2b): Purified by flash column chromatography [

V(PE)∶

V(EA)=97∶3], 16.5 mg, white solid, yield 51%. m.p. 110~112 ℃ (lit.

[10m] 109.8~110.6 ℃);

1H NMR (400 MHz, Chloroform-

d)

δ: 8.06~8.02 (m, 4H), 2.65 (s, 6H);

13C NMR (100 MHz, Chloroform-

d)

δ: 197.5, 140.2, 128.5, 26.9.

1-(4-Acetylphenyl)-1-propanone (

2c):

[10d] Purified by flash column chromatography [

V(PE)∶

V(EA)=97∶3], 23.1 mg, white solid, yield 66%. m.p. 74~76 ℃;

1H NMR (400 MHz, Chloroform-

d)

δ: 8.05~8.02 (m, 4H), 3.04 (q,

J=7.2 Hz, 2H), 2.65 (s, 3H), 1.25 (t,

J=7.2 Hz, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 200.2, 197.5, 140.1, 140.0, 128.5, 128.2, 32.3, 26.9, 8.1.

4'-Fluoroacetophenone (

2d):

[10m] Purified by flash column chromatography [

V(PE)∶

V(EA)=97∶3], 11 mg, yellow oil, yield 40%.

1H NMR (400 MHz, Chloroform-

d)

δ: 7.91 (dd,

J=8.9, 5.4 Hz, 2H), 7.06 (t,

J=8.6 Hz, 2H), 2.52 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 196.4, 165.8 (d,

1JC-F=254.7 Hz), 133.6 (d,

4JC-F=3.0 Hz), 130.9 (d,

3JC-F=9.3 Hz), 115.6 (d,

2JC-F=21.9 Hz), 26.5;

19F NMR (376 MHz, Chloroform-

d)

δ: -105.38.

4-Iodoacetophenone (

2e): Purified by flash column chromatography [

V(PE)∶

V(EA)=97∶3], 41.6 mg, yellow solid, yield 84%. m.p. 83~85 ℃ (lit.

[10m] 80.3~81.5 ℃);

1H NMR (400 MHz, Chloroform-

d)

δ: 7.83 (d,

J=8.5 Hz, 2H), 7.66 (d,

J=8.5 Hz, 2H), 2.58 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 197.3, 137.9, 129.7, 101.1, 26.5.

1-(4-Nitrophenyl) ethan-1-one (

2f): 10 mg, yellow solid, yield 36%. m.p. 75~77 ℃ (lit.

[10m] 77.9~79.1 ℃);

1H NMR (400 MHz, Chloroform-

d)

δ: 8.32 (d,

J=8.8 Hz, 2H), 8.11 (d,

J=8.8 Hz, 2H), 2.68 (s, 3H);

13C NMR (101 MHz, Chloroform-

d)

δ: 196.2, 150.4, 141.4, 129.3, 123.9, 27.0.

4-Acetylbenzoic acid (

2g):

[10c] Purified by flash column chromatography [

V(PE)∶

V(EA)=9∶1], 14.8 mg, white solid, yield 45%. m.p. 208~210 ℃;

1H NMR (400 MHz, DMSO-

d6)

δ: 8.06 (s, 4H), 2.63 (s, 3H);

13C NMR (100 MHz, DMSO-

d6)

δ: 198.2, 167.1, 140.3, 135.0, 130.0, 128.8, 27.5.

4'-Hydroxyacetophenone (

2h):

[10f] Purified by flash column chromatography [

V(PE)∶

V(EA)=9∶1], 13.6 mg, brown solid, yield 50%. m.p. 132~134 ℃;

1H NMR (400 MHz, Chloroform-

d)

δ: 7.91 (d,

J=8.8 Hz, 2H), 6.90 (d,

J=8.8 Hz, 2H), 2.57 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 197.3, 160.4, 131.0, 130.2, 115.3, 26.4

4'-Methoxyacetophenone (

2i): Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 17.3 mg, white solid, yield 63%. m.p. 50~52 ℃ (lit.

[10m] 36.6~37.1 ℃);

1H NMR (400 MHz, Chloroform-

d)

δ: 7.94 (d,

J=8.8 Hz, 2H), 6.94 (d,

J=8.8 Hz, 2H), 3.87 (s, 3H), 2.56 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 196.8, 163.5, 130.6, 130.3, 113.7, 55.5, 26.4.

4-Acetylbiphenyl (

2j): Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 28.1 mg, brown solid, yield 78%. m.p. 152~154 ℃ (lit.

[10m] 154.7~155.9 ℃);

1H NMR (400 MHz, Chloroform-

d)

δ: 8.03 (d,

J=8.3 Hz, 2H), 7.68 (d,

J=8.3 Hz, 2H), 7.62 (d,

J=7.4 Hz, 2H), 7.46 (t,

J=7.4 Hz, 2H), 7.40 (d,

J=7.2 Hz, 1H), 2.63 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 197.8, 145.8, 139.9, 135.9, 129.0, 128.9, 128.3, 127.3, 127.2, 26.7.

3'-Bromoacetophenone (

2k):

[10m] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 20.1 mg, brown oil, yield 51%.

1H NMR (400 MHz, Chloroform-

d)

δ: 8.09 (s, 1H), 7.88 (d,

J=7.8 Hz, 1H), 7.69 (d,

J=7.9 Hz, 1H), 7.35 (t,

J=7.9 Hz, 1H), 2.60 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 196.66, 138.78, 135.97, 131.38, 130.21, 126.86, 122.95, 26.65.

2'-Bromoacetophenone (

2l):

[10m] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 34.1 mg, yellow oil, yield 40%.

1H NMR (400 MHz, Chloroform-

d)

δ: 7.53 (dd,

J=7.9, 1.0 Hz, 1H), 7.38 (dd,

J=7.6, 1.8 Hz, 1H), 7.29 (td,

J=7.5, 1.2 Hz, 1H), 7.21 (td,

J=7.7, 1.7 Hz, 1H), 2.55 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 201.3, 141.5, 133.8, 131.8, 128.9, 127.4, 118.9, 30.3.

2-Acetylbenzofuran (

2m):

[10b] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 16.6 mg, yellow oil, yield 52%.

1H NMR (400 MHz, Chloroform-

d)

δ: 7.71 (d,

J=7.9 Hz, 1H), 7.58 (d,

J=8.1 Hz, 1H), 7.52~7.45 (m, 2H), 7.34~7.28 (m, 1H), 2.61 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 188.7, 155.7, 152.7, 128.3, 123.9, 123.3, 113.0, 112.5, 26.5.

1-[1'-Biphenyl]-4-yl-1-butanone (

2n):

[10j] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 14.7 mg, white solid, yield 33%. m.p. 76~78 ℃;

1H NMR (400 MHz, Chloroform-

d)

δ: 8.04 (d,

J=8.4 Hz, 1H), 7.68 (d,

J=8.4 Hz, 2H), 7.65~7.60 (m, 2H), 7.47 (t,

J=7.5 Hz, 2H), 7.40 (t,

J=7.3 Hz, 1H), 2.98 (t,

J=7.3 Hz, 2H), 1.80 (h,

J=7.4 Hz, 2H), 1.03 (t,

J=7.4 Hz, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 200.1, 145.6, 139.9, 135.8, 128.9, 128.6, 128.2, 127.3, 127.2, 40.6, 17.9, 13.9.

4-Phenylbenzophenone (

2o): Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 30 mg, yellow solid, yield 53%. m.p. 100~102 ℃ (lit.

[10a] 49.2~50.0 ℃);

1H NMR (400 MHz, Chloroform-

d)

δ: 7.89 (d,

J=8.2 Hz, 2H), 7.83 (d,

J=7.3 Hz, 2H), 7.70 (d,

J=8.1 Hz, 2H), 7.64 (d,

J=7.3 Hz, 2H), 7.59 (t,

J=7.4 Hz, 1H), 7.51~7.45 (m, 4H), 7.40 (t,

J=7.3 Hz, 1H);

13C NMR (100 MHz, Chloroform-

d)

δ: 196.4, 140.0, 137.8, 136.3, 132.4, 130.8, 130.0, 129.0, 128.4, 128.2, 127.3, 127.0.

Benzophenone (

2p): Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 30.6 mg, white solid, yield 83%. m.p. 48~50 ℃ (lit.

[10a] 42.0~42.6 ℃);

1H NMR (400 MHz, Chloroform-

d)

δ: 7.83~7.76 (m, 4H), 7.58 (t,

J=7.4 Hz, 2H), 7.48 (t,

J=7.6 Hz, 4H);

13C NMR (100 MHz, Chloroform-

d)

δ: 196.7, 137.6, 132.4, 130.1, 128.3.

1-Indanone (

2q):

[10i] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 15.3 mg, brown oil, yield 58%.

1H NMR (400 MHz, Chloroform-

d)

δ: 7.69 (d,

J=7.7 Hz, 1H), 7.51 (td,

J=7.5, 1.2 Hz, 1H), 7.41 (d,

J=7.7 Hz, 1H), 7.30 (t,

J=7.4 Hz, 1H), 3.13~3.04 (m, 2H), 2.64~2.59 (m, 2H);

13C NMR (100 MHz, Chloroform-

d)

δ: 207.04, 155.15, 137.09, 134.58, 127.27, 126.69, 123.71, 36.22, 25.81.

1-Tetralone (

2r):

[10h] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 21.9 mg, brown oil, yield 75%.

1H NMR (400 MHz, Chloroform-

d)

δ: 7.96 (dd,

J=7.8, 1.4 Hz, 1H), 7.39 (td,

J=7.5, 1.5 Hz, 1H), 7.23 (t,

J=7.5 Hz, 1H), 7.19~7.15 (m, 1H), 2.89 (t,

J=6.1 Hz, 2H), 2.61~2.56 (m, 2H), 2.07 (p,

J=6.4 Hz, 2H);

13C NMR (100 MHz, Chloroform-

d)

δ: 198.40, 144.49, 133.39, 132.64, 128.76, 127.18, 126.63, 39.18, 29.72, 23.30.

9-Fluorenone (

2s):

[10l] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 16.9 mg, brown solid, yield 47%. m.p. 80~82 ℃;

1H NMR (400 MHz, Chloroform-

d)

δ: 7.65 (d,

J=7.4 Hz, 2H), 7.51 (d,

J=7.3 Hz, 2H), 7.47 (td,

J=7.3, 1.0 Hz, 2H), 7.28 (td,

J=7.3, 1.3 Hz, 2H);

13C NMR (100 MHz, Chloroform-

d)

δ: 193.90, 144.44, 134.67, 134.16, 129.07, 124.31, 120.30.

Phenyl benzoate (

2t):

[10e] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 17.0 mg, white solid, yield 43%. m.p. 70~72 ℃ (lit.

[10e] 71.0~72.0 ℃);

1H NMR (400 MHz, Chloroform-

d)

δ: 8.23~8.18 (m, 2H), 7.64 (t,

J=7.4 Hz, 1H), 7.51 (t,

J=7.7 Hz, 2H), 7.43 (t,

J=7.9 Hz, 2H), 7.28 (d,

J=7.4 Hz, 1H), 7.25~7.20 (m, 2H);

13C NMR (100 MHz, Chloroform-

d)

δ: 165.21, 150.98, 133.60, 130.19, 129.60, 129.51, 128.59, 125.91, 121.74.

p-Anisaldehyde (

2u):

[10k] Purified by flash column chromatography [

V(PE)∶

V(EA)=93∶7], 10 mg, yellow oil, yield 38%.

1H NMR (400 MHz, Chloroform-

d)

δ: 9.89 (s, 1H), 7.85 (d,

J=8.8 Hz, 2H), 7.01 (d,

J=8.7 Hz, 2H), 3.90 (s, 3H);

13C NMR (100 MHz, Chloroform-

d)

δ: 190.8, 164.6, 132.0, 130.0, 114.3, 55.6.

4-Acetamidobenzaldehyde (

2v):

[10g] Purified by flash column chromatography [

V(PE)∶

V(EA)=1∶1], 13.7 mg, white solid, yield 42%. m.p. 148~150 ℃;

1H NMR (400 MHz, DMSO-

d6)

δ: 10.21 (s, 1H), 7.88 (d,

J=8.7 Hz, 2H), 7.69 (d,

J=8.7 Hz, 2H), 2.08 (s, 3H);

13C NMR (100 MHz, DMSO-

d6)

δ: 169.3, 167.4, 143.8, 130.8, 125.4, 118.6, 24.6.

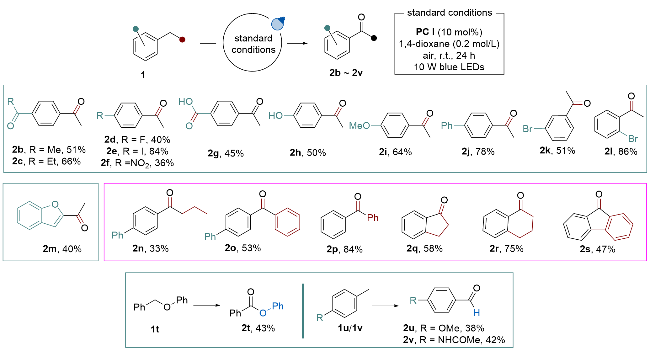

(3S,10R,13R)-10,13-dimethyl-17-((R)-6-methylheptan- 2-yl)-7-oxo-2,3,4,7,8,9,10,11,12,13,14,15,16,17-tetradeca-hydro-1H-cyclopenta[a]phenanthren-3-methyl acetate (2w): Purified by flash column chromatography [V(PE)∶V(EA)=2∶1], 35.4 mg, white solid, yield 40%. m.p. 146~148; 1H NMR (400 MHz, Chloroform-d) δ: 5.70 (d, J=1.5 Hz, 1H), 4.71 (tt, J=11.4, 4.7 Hz, 1H), 2.58~2.51 (m, 1H), 2.46 (ddd, J=13.7, 11.5, 1.7 Hz, 1H), 2.23 (t, J=11.2 Hz, 1H), 2.05 (s, 3H), 2.04~2.00 (m, 1H), 1.99~1.92 (m, 2H), 1.92~1.85 (m, 1H), 1.63 (s, 2H), 1.56 (dd, J=10.5, 4.4 Hz, 4H), 1.52~1.46 (m, 2H), 1.38~1.35 (m, 3H), 1.35~1.32 (m, 3H), 1.31~1.29 (m, 1H), 1.28 (d, J=6.1 Hz, 2H), 1.26 (s, 2H), 1.21 (s, 2H), 1.15~1.11 (m, 4H), 1.10 (s, 2H), 1.03 (d, J=5.5 Hz, 1H), 0.92 (d, J=6.5 Hz, 2H), 0.87 (d, J=1.8 Hz, 3H), 0.86 (d, J=1.8 Hz, 3H), 0.68 (s, 2H); 13C NMR (100 MHz, Chloroform-d) δ: 201.9, 170.3, 163.8, 126.7, 72.2, 54.8, 50.0, 49.8, 45.4, 43.1, 39.5, 38.7, 38.3, 37.8, 36.2, 36.0, 35.7, 29.7, 28.5, 28.0, 27.4, 26.3, 23.8, 22.8, 22.6, 21.2, 18.9, 17.3, 12.0; IR (neat) ν: 2939 2870 1730 1669 1466 1374 1237 1181 1035 cm-1; HRMS (ESI) calcd for C29H46KO5 [M+K]+481.3079, found 481.3077.

Methyl (4R,E)-4-((3S,10R,13R)-3-acetoxy-10,13-dime-thyl-7-oxo-2,3,4,7,8,9,10,11,12,13,14,15,16,17-tetradeca-hydro-1H-cyclopenta[a]phenanthren-17-yl)pent-2-enoate (2x): Purified by flash column chromatography [V(PE)∶V(EA)=2∶1], 45.8 mg, yellow solid, yield 50%. m.p. 217~219 ℃; 1H NMR (400 MHz, Chloroform-d) δ: 6.85 (dd, J=15.6, 9.0 Hz, 1H), 5.78~5.66 (m, 3H), 4.81~4.63 (m, 1H), 3.72 (s, 3H), 2.56 (ddd, J=13.9, 5.1, 1.9 Hz, 2H), 2.47 (ddd, J=13.7, 11.6, 1.8 Hz, 2H), 2.33~2.20 (m, 4H), 2.05 (s, 3H), 2.03~1.98 (m, 4H), 1.96~1.94 (m, 1H), 1.78~1.73 (m, 2H), 1.72~1.66 (m, 5H), 1.62 (dd, J=6.1, 3.5 Hz, 2H), 1.57 (dd, J=11.6, 3.7 Hz, 3H), 1.39~1.30 (m, 3H), 1.30~1.25 (m, 10H), 1.25~1.23 (m, 2H), 1.21 (s, 3H), 1.10 (d, J=6.6 Hz, 3H), 0.71 (s, 3H); 13C NMR (100 MHz, Chloroform-d) δ: 201.5, 170.3, 167.4, 163.9, 154.7, 126.7, 118.8, 72.2, 53.7, 51.4, 49.79, 49.77, 45.3, 43.4, 39.5, 38.5, 38.3, 37.8, 36.0, 29.7, 28.2, 27.4, 26.3, 21.2, 21.1, 19.5, 17.3, 12.3; IR (neat) ν: 2944 2868 1733 1718 1663 1246 1232 1183 1038 cm-1; HRMS (ESI) calcd for C28H42KO5 [M+K]+ 497.2664, found 497.2674.

(2S)-2-((10R,13R)-10,13-dimethyl-7-oxo-1,2,4,7,8,9,10,11,12,13,14,15,16,17-tetradecahydrospiro[cyclopenta [a]phenanthrene-3,2'-[1,3]dioxolan]-17-yl)propyl 4-methylben- zenesulfonate (2y): Purified by flash column chromatography [V(PE)∶V(EA)=2∶1], 42.1 mg, white solid, yield 50%. m.p. 199~200 ℃; 1H NMR (400 MHz, Chloroform-d) δ: 7.78 (d, J=8.3 Hz, 1H), 7.35 (d, J=8.0 Hz, 1H), 5.65 (d, J=1.9 Hz, 1H), 4.04~3.95 (m, 1H), 3.95 (d, J=3.0 Hz, 1H), 2.67 (dd, J=14.7, 1.9 Hz, 1H), 2.45 (s, 2H), 2.34 (td, J=15.0, 4.7 Hz, 1H), 2.19 (t, J=11.0 Hz, 1H), 1.96 (dd, J=9.5, 6.5 Hz, 1H), 1.92~1.81 (m, 2H), 1.77~1.71 (m, 1H), 1.69 (dd, J=6.9, 3.5 Hz, 1H), 1.66~1.62 (m, 2H), 1.61 (s, 1H), 1.58 (d, J=5.3 Hz, 2H), 1.53 (dd, J=9.6, 4.7 Hz, 2H), 1.48 (d, J=4.1 Hz, 1H), 1.19 (s, 2H), 1.01 (d, J=6.6 Hz, 2H), 0.65 (s, 2H); 13C NMR (100 MHz, Chloroform-d) δ: 201.4, 164.6, 144.6, 133.1, 129.8, 127.9, 126.6, 108.9, 75.6, 64.6, 64.5, 50.6, 49.7, 49.5, 45.3, 43.3, 41.7, 38.4, 38.2, 36.2, 35.6, 31.0, 29.7, 27.8, 26.2, 22.7, 21.6, 21.1, 17.0, 16.9, 14.1, 11.9; IR (neat) ν: 2926 1667 1353 1187 1172 1104 1078 1066 925 cm-1; HRMS (ESI) calcd for C27H38NaO5 [M+K]+ 465.2611, found 465.2624.

Methyl (4R,E)-4-((10R,13R)-10,13-dimethyl-7-oxo- 1,2,4,7,8,9,10,11,12,13,14,15,16,17-tetradecahydrospiro[cyclopenta [a]phenanthrene-3,2'-[1,3]dioxolan]-17-yl)pent-2-enoate (2z): Purified by flash column chromatography [V(PE)∶V(EA)=2∶1], 31.8 mg, yellow solid, yield 50%. m.p. 202~204 ℃; 1H NMR (400 MHz, Chloroform-d) δ: 6.87 (dd, J=15.6, 9.0 Hz, 1H), 5.76 (d, J=15.4 Hz, 1H), 5.69 (d, J=1.7 Hz, 1H), 4.02~3.93 (m, 1H), 3.74 (s, 3H), 2.69 (dd, J=14.7, 1.9 Hz, 1H), 2.47~2.39 (m, 1H), 2.35 (dd, J=14.8, 2.9 Hz, 1H), 2.29~2.21 (m, 1H), 2.02 (dt, J=12.6, 3.1 Hz, 1H), 1.95~1.85 (m, 2H), 1.81~1.73 (m, 2H), 1.67~1.59 (m, 6H), 1.56~1.51 (m, 1H), 1.39~1.36 (m, 1H), 1.29 (d, J=6.9 Hz, 2H), 1.23 (s, 3H), 1.12 (d, J=6.6 Hz, 3H), 0.74 (s, 3H); 13C NMR (100 MHz, Chloroform-d) δ: 201.4, 167.4, 164.6, 154.7, 126.6, 118.7, 108.9, 64.6, 64.5, 53.8, 51.4, 49.9, 49.6, 45.3, 43.5, 41.7, 39.5, 38.6, 38.3, 35.6, 31.1, 28.2, 26.3, 21.2, 19.5, 17.0, 12.3; IR (neat) ν: 2951 2925 1725 1672 1166 1100 1077 1049 cm-1; HRMS (ESI) calcd for C24H35KO3 [M+K]+ 410.2218, found 410.2244.

Supporting Information 1H NMR spectra of compounds

2a~

2z. The Supporting Information is available free of charge via the Internet at

http://sioc-journal.cn.