化学学报 ›› 2025, Vol. 83 ›› Issue (4): 415-427.DOI: 10.6023/A24120379 上一篇 下一篇

综述

赵梦飞a,b, 韩赫兴b, 杨幼明a, 李庭刚a,b,c,d,e,*( )

)

投稿日期:2024-12-24

发布日期:2025-02-26

作者简介: |

赵梦飞, 2021年江西理工大学与中国科学院赣江创新研究院联合培养在读博士研究生, 主要研究方向为稀土生物浸出. |

|

韩赫兴, 博士, 中国科学院赣江创新研究院副研究员, 硕士生导师. 2021年博士毕业于中国科学技术大学, 2021~2024年国家纳米科学中心做博士后. 主要从事稀土生物冶金和分离、生物修复、微生物电化学技术和微生物-纳米材料耦合技术研究. |

|

杨幼明, 博士研究生导师. 主要从事稀有金属清洁冶金理论及工程技术研究, 善长复杂难处理低品位稀土精矿冶炼、离子型稀土矿提取、稀土分离、稀土金属冶金、钨与稀土二次资源高值利用技术开发. 主持国家、省市及企业委托项目50多项. 研究成果获国家科技进步二等奖1项、江西省科技进步一等奖1项和二等奖2项, 中国有色金属工业科技进步二等奖2项和三等奖1项, 中国稀土学会科学技术二等奖1项; 获国家授权发明专利26项; 在国内外刊物上发表学术论文90多篇; 参编稀土类教材2部. |

|

李庭刚, 博士, 中国科学院过程工程研究所/中国科学院赣江创新研究院研究员, 博士生导师, 中国科学院过程工程研究所“百人计划”、江西省“千人计划”入选者. 2008年获中国科学院生态环境研究中心博士学位, 2006~2008年在新加坡南洋理工大学进行博士联合培养, 2010~2019年在新加坡国立大学做博士后、特聘研究员, 2019年至今在中国科学院过程工程研究所工作, 环境生物技术课题组组长. 中国科学院赣江创新研究院双聘. 长期从事环境生物过程转化机理与能源资源化技术研究, 主要涉及土壤-地下水修复、高盐有机废水处理与资源化、稀土生物冶金、生物新能源制造、环境污染物定向生物转化与功能材料应用基础研究. 主持国家自然科学基金、国家重点研发计划项目课题、地方科技重大专项以及企业委托等科研项目. 近年来在Science子刊Science Advances, Biotechnology for Biofuels, Environmental Science & Technology, Biotechnology and Bioengineering, Water Research, Bioresource Technology, Journal of Biotechnology, Renewable Energy等主流期刊上发表论文40余篇, 申请和授权发明专利20余项. 担任巴塞尔公约亚太区中心化学品和废物环境管理智库专家, 中国自然资源学会废弃物资源化专业委员会委员, Clean Energy Science and Technology等期刊编委, Membrane期刊客座编辑, 荣获2021年中国产学研促进会科技合作创新奖, 2022年中国发明协会发明创业成果奖二等奖. |

基金资助:

Mengfei Zhaoa,b, Hexing Hanb, Youming Yanga, Tinggang Lia,b,c,d,e( )

)

Received:2024-12-24

Published:2025-02-26

Contact:

E-mail: Supported by:文章分享

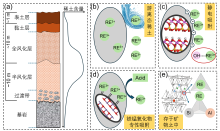

稀土需求的日益增加极大考验了稀土资源的开发, 但作为中重稀土资源主要供应链的离子吸附型稀土矿, 传统化学开采造成了严重的生态破坏. 为解决稀土开采过程中存在的污染问题, 生物浸出技术日益受到关注. 研究人员从浸取理论、工艺等方面展开了一系列探索. 本文综述了离子吸附型稀土矿中稀土元素赋存形态、浸出理论发展和稀土生物浸出过程, 包括其机理、影响因素和最新研究进展. 稀土的生物浸出受到多种因素的影响, 提高稀土的生物浸出效率, 其本质是提高微生物的活性和代谢产物的浓度, 或降低有毒物质影响. 本综述对生物浸出过程的总结和分析, 可为离子吸附型稀土矿生物绿色开采和稀土微生物开采技术的发展提供一定的支持.

赵梦飞, 韩赫兴, 杨幼明, 李庭刚. 离子吸附型稀土矿生物浸出技术研究进展[J]. 化学学报, 2025, 83(4): 415-427.

Mengfei Zhao, Hexing Han, Youming Yang, Tinggang Li. Research Progress on Bioleaching Technology for Ion-Adsorption Type Rare Earth Ores[J]. Acta Chimica Sinica, 2025, 83(4): 415-427.

| 年份 | 进口/t | 出口/t |

|---|---|---|

| 2019 | 124070 | 48576.2 |

| 2020 | 115000 | 36686 |

| 2021 | 140000 | 31600 |

| 2022 | 121000 | 48750 |

| 2023 | 175852.5 | 52306.5 |

| 年份 | 进口/t | 出口/t |

|---|---|---|

| 2019 | 124070 | 48576.2 |

| 2020 | 115000 | 36686 |

| 2021 | 140000 | 31600 |

| 2022 | 121000 | 48750 |

| 2023 | 175852.5 | 52306.5 |

| 矿石 | 微生物 | 浸出剂 | 浸出类型 | 矿浆浓度/% (w/V) | 时间/d | 温度/℃ | 浸出率/% | 文献 |

|---|---|---|---|---|---|---|---|---|

| 氟碳铈矿 | Micromonospora sp. R171 | 丙酮酸、乳酸、草酸 | 一步式生物浸出 | 0.5 | 15 | 25~28 | 0.1 | [ |

| 离子吸附型稀土矿 | Aspergillus sp. | 葡萄糖酸、柠檬酸、草酸 | 两步式生物浸出 | 2 | 3 | 25 | La (72.6)、Ce (15.3)、Dy (62.2)、Lu (64.8) | [ |

| 离子吸附型稀土矿 | Aspergillus niger | 草酸、柠檬酸、琥珀酸 | 两步式生物浸出 | 10 | 3 | 25 | 91 | [ |

| 离子吸附型稀土矿 | Yarrowia lipolytica | 柠檬酸、苹果酸、琥珀酸 | 两步式生物浸出 | 10 | 3 | 25 | 34 | [ |

| 磷矿 | Acidithiobacillus ferrooxidans | 硫酸、Fe3+ | 一步式生物浸出 | 1 | 14 | 30 | 28.46 | [ |

| 独居石 | Penicillium sp. CF1 | 草酸、柠檬酸、磷酸酶 | 一步式生物浸出 | 0.5 | 8 | 30~37 | 0.79 | [ |

| 独居石 | Penicillium sp. CF1 +indigenous consortia | 草酸、柠檬酸、磷酸酶 | 一步式生物浸出 | 0.5 | 8 | 30~37 | 1.52 | [ |

| 独居石 | Enterobacter aerogenes + Acidithiobacillus ferrooxidans | 葡萄糖酸、 乙酸、苹果酸、硫酸 | 一步式生物浸出 | 1 | 12 | 30 | 1.28 | [ |

| 废液催化裂解催化剂 | Gluconobacter oxydans | 葡萄糖酸 | 一步式生物浸出 | 50 | 1 | 30 | 25.7 | [ |

| 煤矸石 | Acidithiobacillus ferrooxidans | 硫酸 | 一步式生物浸出 | 30 | 3 | 35 | 13~14 | [ |

| 矿石 | 微生物 | 浸出剂 | 浸出类型 | 矿浆浓度/% (w/V) | 时间/d | 温度/℃ | 浸出率/% | 文献 |

|---|---|---|---|---|---|---|---|---|

| 氟碳铈矿 | Micromonospora sp. R171 | 丙酮酸、乳酸、草酸 | 一步式生物浸出 | 0.5 | 15 | 25~28 | 0.1 | [ |

| 离子吸附型稀土矿 | Aspergillus sp. | 葡萄糖酸、柠檬酸、草酸 | 两步式生物浸出 | 2 | 3 | 25 | La (72.6)、Ce (15.3)、Dy (62.2)、Lu (64.8) | [ |

| 离子吸附型稀土矿 | Aspergillus niger | 草酸、柠檬酸、琥珀酸 | 两步式生物浸出 | 10 | 3 | 25 | 91 | [ |

| 离子吸附型稀土矿 | Yarrowia lipolytica | 柠檬酸、苹果酸、琥珀酸 | 两步式生物浸出 | 10 | 3 | 25 | 34 | [ |

| 磷矿 | Acidithiobacillus ferrooxidans | 硫酸、Fe3+ | 一步式生物浸出 | 1 | 14 | 30 | 28.46 | [ |

| 独居石 | Penicillium sp. CF1 | 草酸、柠檬酸、磷酸酶 | 一步式生物浸出 | 0.5 | 8 | 30~37 | 0.79 | [ |

| 独居石 | Penicillium sp. CF1 +indigenous consortia | 草酸、柠檬酸、磷酸酶 | 一步式生物浸出 | 0.5 | 8 | 30~37 | 1.52 | [ |

| 独居石 | Enterobacter aerogenes + Acidithiobacillus ferrooxidans | 葡萄糖酸、 乙酸、苹果酸、硫酸 | 一步式生物浸出 | 1 | 12 | 30 | 1.28 | [ |

| 废液催化裂解催化剂 | Gluconobacter oxydans | 葡萄糖酸 | 一步式生物浸出 | 50 | 1 | 30 | 25.7 | [ |

| 煤矸石 | Acidithiobacillus ferrooxidans | 硫酸 | 一步式生物浸出 | 30 | 3 | 35 | 13~14 | [ |

| 浸出剂 | 稀土络合反应 | pKa和logK值 |

|---|---|---|

| 硫酸 | H2SO4↔HSO4-+H+ | pKa=1.99 |

| HSO4-↔SO42-+H+ | pKa=–1.99 | |

| REE3++HSO4-↔REE(HSO4)2+ | logK=3.4~3.3 | |

| REE3++2HSO4-↔REE(HSO4)2+ | logK=5.1~5.3 | |

| 乙酸 | C2H4O2↔(C2H3O2)-+H+ | pKa=4.70 |

| REE3++(C2H3O2)-↔REE(C2H3O2)2+ | logK=1.82~1.85 | |

| REE3++2(C2H3O2)-↔REE(C2H3O2)2+ | logK=2.82~3.16 | |

| REE3++3(C2H3O2)-↔REE(C2H3O2)3 | logK=3.53~4.02 | |

| 苹果酸 | C4H6O5↔(C4H5O5)-+H+ | pKa=5.11 |

| (C4H5O5)-↔(C4H4O5)2-+H+ | pKa=3.40 | |

| REE3++(C4H4O5)2-↔REE(C4H4O5)+ | logK=4.37~5.08 | |

| REE3++2(C4H4O5)2-↔REE(C4H4O5)2- | logK=7.16~8.67 | |

| 柠檬酸 | C6H8O7↔(C6H7O7)-+H+ | pKa=6.40 |

| (C6H7O7)-↔(C6H6O7)2-+H+ | pKa=4.76 | |

| (C6H6O7)2-↔(C6H5O7)3-+H+ | pKa=3.13 | |

| REE3++(C6H5O7)3-↔REE(C6H5O7) | logK=7.1~8.07 | |

| 琥珀酸 | C4H6O4↔(C4H5O4)-+H+ | pKa=5.64 |

| (C4H5O4)-↔(C4H4O4)2-+H+ | pKa=4.21 | |

| REE3++(C4H5O4)-↔REE(C4H5O4)2+ | logK=1.48~1.76 | |

| REE3++2(C4H5O4)-↔REE(C4H5O4)2+ | logK=2.7~3.1 | |

| 葡萄糖酸 | C6H12O7↔(C6H11O7)-+H+ | pKa=3.66 |

| REE3++(C6H11O7)-↔REE(C6H11O7)2+ | logK=2.32~2.85 | |

| REE3++2(C6H11O7)-↔REE(C6H11O7)2+ | logK=4.25~4.78 | |

| 草酸 | C4H6O4↔(C4H5O4)-+H+ | pKa=4.20 |

| (C4H5O4)-↔(C4H4O4)2-+H+ | pKa=1.20 | |

| REE3++(C4H4O4)2-↔REE(C4H4O4)+ | logK=4.71~5.60 | |

| REE3++2(C4H4O4)2-↔REE(C4H4O4)2- | logK=7.83~9.52 |

| 浸出剂 | 稀土络合反应 | pKa和logK值 |

|---|---|---|

| 硫酸 | H2SO4↔HSO4-+H+ | pKa=1.99 |

| HSO4-↔SO42-+H+ | pKa=–1.99 | |

| REE3++HSO4-↔REE(HSO4)2+ | logK=3.4~3.3 | |

| REE3++2HSO4-↔REE(HSO4)2+ | logK=5.1~5.3 | |

| 乙酸 | C2H4O2↔(C2H3O2)-+H+ | pKa=4.70 |

| REE3++(C2H3O2)-↔REE(C2H3O2)2+ | logK=1.82~1.85 | |

| REE3++2(C2H3O2)-↔REE(C2H3O2)2+ | logK=2.82~3.16 | |

| REE3++3(C2H3O2)-↔REE(C2H3O2)3 | logK=3.53~4.02 | |

| 苹果酸 | C4H6O5↔(C4H5O5)-+H+ | pKa=5.11 |

| (C4H5O5)-↔(C4H4O5)2-+H+ | pKa=3.40 | |

| REE3++(C4H4O5)2-↔REE(C4H4O5)+ | logK=4.37~5.08 | |

| REE3++2(C4H4O5)2-↔REE(C4H4O5)2- | logK=7.16~8.67 | |

| 柠檬酸 | C6H8O7↔(C6H7O7)-+H+ | pKa=6.40 |

| (C6H7O7)-↔(C6H6O7)2-+H+ | pKa=4.76 | |

| (C6H6O7)2-↔(C6H5O7)3-+H+ | pKa=3.13 | |

| REE3++(C6H5O7)3-↔REE(C6H5O7) | logK=7.1~8.07 | |

| 琥珀酸 | C4H6O4↔(C4H5O4)-+H+ | pKa=5.64 |

| (C4H5O4)-↔(C4H4O4)2-+H+ | pKa=4.21 | |

| REE3++(C4H5O4)-↔REE(C4H5O4)2+ | logK=1.48~1.76 | |

| REE3++2(C4H5O4)-↔REE(C4H5O4)2+ | logK=2.7~3.1 | |

| 葡萄糖酸 | C6H12O7↔(C6H11O7)-+H+ | pKa=3.66 |

| REE3++(C6H11O7)-↔REE(C6H11O7)2+ | logK=2.32~2.85 | |

| REE3++2(C6H11O7)-↔REE(C6H11O7)2+ | logK=4.25~4.78 | |

| 草酸 | C4H6O4↔(C4H5O4)-+H+ | pKa=4.20 |

| (C4H5O4)-↔(C4H4O4)2-+H+ | pKa=1.20 | |

| REE3++(C4H4O4)2-↔REE(C4H4O4)+ | logK=4.71~5.60 | |

| REE3++2(C4H4O4)2-↔REE(C4H4O4)2- | logK=7.83~9.52 |

| [1] |

Opare, E. O.; Struhs, E.; Mirkouei, A. Renewable Sustainable Energy Rev. 2021, 143, 110917.

|

| [2] |

Rasoulnia, P.; Barthen, R.; Lakaniemi, A. M. Crit. Rev. Environ. Sci. Technol. 2020, 51, 378.

|

| [3] |

Ministry of Land and Resources of the People's Republic of China. 2016. (in Chinese)

|

|

(中国国土资源部, 全国矿产资源规划(2016-2020年), 2016.)

|

|

| [4] |

Ober, J. A. Mineral commodity summaries 2017, U.S. Geological Survey, 2017. https://doi.org/10.3133/70180197.

|

| [5] |

Zhou, B.-L.; Li, Z.-X.; Chen, C.-C. Minerals 2017, 7, 203.

|

| [6] |

Liu, Q.; Zhou, F.; Feng, J.; Liu, X.; Xu, Y.-L.; Wu, X.-Y.; Chi, R.-A. Conserv. Util. Miner. Resour. 2019, 39, 76. (in Chinese)

|

|

(刘琦, 周芳, 冯健, 刘旭, 徐源来, 吴晓燕, 池汝安, 矿产保护与利用, 2019, 39, 76.)

|

|

| [7] |

Chi, R.-A.; Liu, X.-M. J. Chin. Soc. Rare Earths 2019, 37, 129. (in Chinese)

|

|

(池汝安, 刘雪梅, 中国稀土学报, 2019, 37, 129.)

|

|

| [8] |

Kynicky, J.; Smith, M. P.; Xu, C. Elements 2012, 8, 361.

|

| [9] |

Liu, R.-S.; Li, Q.; Gong, M.; Zou, D.-F.; Liao, X.-L.; Liu, X. Adv. Geosci. 2014, 4, 419. (in Chinese)

|

|

(刘仁生, 李强, 龚敏, 邹东风, 缪向亮, 刘茜, 地球科学前沿, 2014, 4, 419.)

|

|

| [10] |

Xu, C.; Kynický, J.; Smith, M. P.; Kopriva, A.; Brtnicky´, M.; Urubek, T.; Yang, Y.-H.; Zhao, Z.; He, C.; Song, W.-L. Nat. Commun. 2017, 8, 1.

|

| [11] |

He, C.; Xu, C.; Zhao, Z.; Kynicky, J.; Song, W.-L.; Wang, L.-Z. Ore Geol. Rev. 2017, 81, 309.

|

| [12] |

Bao, Z.-W.; Zhao, Z.-H. Ore Geol. Rev. 2008, 33, 519.

|

| [13] |

Chen, X.; He, Q.; Chen, J.-F.; Huang, L.; Tan, C.-M.; Yin, Y.-Q.; Jiao, Y.-F.; Xiao, Y.-F. J. Chin. Soc. Rare Earths 2022, 40, 936. (in Chinese)

|

|

(陈昕, 贺强, 陈金发, 黄莉, 谭传满, 尹衍权, 焦芸芬, 肖燕飞, 中国稀土学报, 2022, 40, 936.)

|

|

| [14] |

Xiao, Y.-F.; Lai, F.-G.; Huang, L.; Feng, Z.-Y.; Long, Z.-Q. Hydrometallurgy 2016, 34, 1.

|

| [15] |

Chi, R.-A.; Tian, J.; Luo, X.-P.; Xu, Z.-G.; He, Z.-Y. Nonferrous Met. Sci. Eng. 2012, 3, 1. (in Chinese)

|

|

(池汝安, 田君, 罗仙平, 徐志高, 何正艳, 有色金属科学与工程, 2012, 3, 1.)

|

|

| [16] |

Xiao, Y.-F.; Gao, G.-H.; Huang, L.; Feng, Z.-Y.; Lai, F.-G.; Long, Z.-Q. Miner. Eng. 2018, 120, 35.

|

| [17] |

Zhang, Q.-Y.; Ren, F.-T.; Li, F.-D.; Chen, G.-L.; Yang, G.; Wang, J.-Q.; Du, K.; Liu, S.-B.; Li, Z. Environ. Pollut. 2020, 267, 115449.

|

| [18] |

Xiao, Y.-F.; Feng, Z.-Y.; Huang, X.-W.; Huang, L.; Chen, Y.-Y.; Wang, L.-S.; Long, Z.-Q. Hydrometallurgy 2015, 153, 58.

|

| [19] |

Wang, G.-F.; Xu, J.; Ran, L.-Y.; Zhu, R.-L.; Ling, B.-W.; Wei, J.-M.; Ma, L.-Y.; Zhuan, Y.-F.; Zhu, J.-X.; He, H.-P. Nat. Sustain. 2022, 6, 81.

|

| [20] |

Luo, X.-P.; Feng, B.; Wang, P.-C.; Zhou, H.-P.; Chen, X.-M. Metall. Trans. B 2015, 46, 2405.

|

| [21] |

Tian, J.; Tang, X.-K.; Yin, J.-Q.; Chen, J.; Luo, X.-P.; Rao, G.-H. Metall. Trans. B 2013, 44, 1070.

|

| [22] |

Thompson, V.-S.; Gupta, M.; Jin, H.-Y.; Vahidi, E.; Yim, M.; Jindra, M.-A.; Nguyen, V.; Fujita, Y.; Sutherland, J.-W.; Jiao, Y.-Q.; Reed, D.-W. ACS Sustainable Chem. Eng. 2018, 6, 1602.

|

| [23] |

Keshavarz, S.; Faraji, F.; Rashchi, F.; Mokmeli, M. J. Environ. Manage. 2021, 285, 112153.

|

| [24] |

General Administration of Customs of the People's Republic of China.Table of Import Major Commodity Values (in Chinese).

|

|

(中华人民共和国海关总署, 进口主要商品量值表.)

|

|

| [25] |

General Administration of Customs of the People's Republic of China.Table of Outport Major Commodity Values (in Chinese).

|

|

(中华人民共和国海关总署, 出口主要商品量值表.)

|

|

| [26] |

Orris, G. J.; Seo, Y.; Briggs, D. A.; Cocker, M. D. Global rare earth element occurrence database, U.S. Geological Survey Data Release, 2018. https://doi.org/10.5066/F7DR2TN4.

|

| [27] |

Zhou, M.-F.; Li, X.-X.; Wang, Z.-C.; Li, X.-C.; Liu, J.-C. Chin Sci Bull. 2020, 65, 3809. (in Chinese)

|

|

(周美夫, 李欣禧, 王振朝, 李晓春, 刘嘉成, 科学通报, 2020, 65, 3809.)

|

|

| [28] |

Li, M.-Y.-H.; Zhao, W.-W.; Zhou, M.-F. J. Asian Earth Sci. 2017, 148, 65.

|

| [29] |

Chi, R.-A.; Tian, J.; Li, Z.-J.; Peng, C.; Wu, Y.-X.; Li, S.-R.; Wang, C.-W.; Zhou, Z.-A. J. Rare Earths 2005, (06), 756.

|

| [30] |

Li, M.-Y.-H.; Zhou, M.-F.; Williams-Jones, A. E. Econ. Geol. 2020, 115, 1097.

|

| [31] |

Lai, F.-G.; Gao, G.-H.; Huang, L.; Xiao, Y.-F.; Yang, R.; Li, K.-Z. Hydrometallurgy 2023, 41, 25.

|

| [32] |

Li, M.-Y.-H.; Zhou, M.-F. Am. Mineral. 2020, 105, 92.

|

| [33] |

Liang, X.-L.; Tan, W.; Ma, L.-Y.; Zhu, J.-X.; He, H. P. Earth Sci. Front. 2022, 29, 29. (in Chinese)

|

|

(梁晓亮, 谭伟, 马灵涯, 朱建喜, 何宏平, 地学前缘, 2022, 29, 29.)

doi: 10.13745/j.esf.sf.2021.8.8 |

|

| [34] |

Yang, M.-J.; Liang, X.-L.; Ma, L.-Y.; Huang, J.; He, H.-P.; Zhu, J.-X. Chem. Geol. 2019, 525, 210.

|

| [35] |

Xiao, Y.-F.; Huang, L.; Long, Z.-Q.; Feng, Z.-Y.; Wang, L.-S. J. Rare Earths 2016, 34, 543.

|

| [36] |

Quinn, K. A.; Byrne, R. H.; Schijf, J. Mar. Chem. 2006, 99, 128.

|

| [37] |

Zhang, L.-M.; Dong, H.-L.; Liu, Y.; Bian, L.; Wang, X.; Zhou, Z.-Q.; Huang, Y. Chem. Geol. 2019, 483, 544.

|

| [38] |

Li, Z.-B.; Liu, L.-W.; Chen, J.; Teng, H.-H. Geol. 2016, 44, 319.

|

| [39] |

Li, Z.-Y.; Li, J.-Y.; Xu, R.-K.; Hong, Z.-N.; Liu, Z.-D. Colloids Surf., A 2015, 478, 22.

|

| [40] |

Li, Q.; Qin, L.; Wang, G.-S.; Luo, S.-H.; Long, P.; Peng, C.-L. J. Chin. Soc. Rare Earths 2021, 39, 543. (in Chinese)

|

|

(李琪, 秦磊, 王观石, 罗嗣海, 龙平, 彭陈亮, 中国稀土学报, 2021, 39, 543.)

|

|

| [41] |

Moldoveanu, G. A.; Papangelakis, V. G. Hydrometallurgy 2012, 117-118, 71.

|

| [42] |

Xiao, Y.-F.; Liu, X.-S.; Feng, Z.-Y.; Huang, X.-W.; Huang, L.; Chen, Y.-Y.; Wu, W.-Y. J. Rare Earths 2015, 33, 545.

|

| [43] |

Hou, X.; Xu, Q.-H.; Sun, Y.-Y.; Wang, Y.; Li, J.; Zhou, X.-M.; Li, Y.-X. Rare Earth 2016, 37, 1. (in Chinese)

|

|

(侯潇, 许秋华, 孙圆圆, 王悦, 李静, 周新木, 李永绣, 稀土, 2016, 37, 1.)

|

|

| [44] |

Tian, J.; Yin, J.-Q.; Chi, R.-A.; Rao, G.-H.; Jiang, M.-T.; Kexian, O. Hydrometallurgy 2010, 101, 166.

|

| [45] |

Wang, L.; Liao, C.-F.; Yang, Y.-M.; Xu, H.-B.; Xiao, Y.-F.; Yan, C.-H. J. Rare Earths 2017, 35, 1233.

|

| [46] |

Alkan, M.; Karadaş, M.; Doğan, M.; Demirbaş, Ö. Colloids Surf., A 2005, 259, 155.

|

| [47] |

Fu, H.-P.; Chen, R.-X.; Song, Y.; Wang, T.-W.; Gao, B. Nonferrous Met. (Extr. Metall.) 2021, (03), 180. (in Chinese)

|

|

(伏慧平, 陈仁祥, 宋勇, 王太伟, 高柏, 有色金属(冶炼部分), 2021, (03), 180.)

|

|

| [48] |

Shi, Y.-L.; Zhang, M.; Chen, M.; Feng, B.; Wan, B.-H.; Wang, Q.-P.; Wu, J.-W.; Chen, Z.-Y. Environ. Pollut. Control 2020, 42, 1496. (in Chinese)

|

|

(师艳丽, 张萌, 陈明, 冯兵, 万禀颢, 王启沛, 吴俊伟, 陈振宇, 环境污染与防治, 2020, 42, 1496.)

|

|

| [49] |

Vera, M.; Schippers, A.; Sand, W. Appl. Microbiol. Biotechnol. 2013, 97, 7529.

|

| [50] |

Barnett, M. J.; Palumbo-Roe, B.; Gregory, S. P. Minerals 2018, 8, 236.

|

| [51] |

Brisson, V. L.; Zhuang, W.-Q.; Alvarez-Cohen, L. Biotechnol. Bioeng. 2016, 113, 339.

|

| [52] |

Qu, Y.; Lian, B. Bioresour. Technol. 2013, 136, 16.

|

| [53] |

Rasoulnia, P.; Mousavi, S. M.; Rastegar, S. O.; Azargoshasb, H. Waste Manage. 2016, 52, 309.

doi: 10.1016/j.wasman.2016.04.004 pmid: 27095291 |

| [54] |

Jafari, M.; Abdollahi, H.; Shafaei, S. Z.; Gharabaghi, M.; Jafari, H.; Akcil, A.; Panda, S. Miner. Process. Extr. Metall. Rev. 2018, 40, 87.

|

| [55] |

Fathollahzadeh, H.; Hackett, M. J.; Khaleque, H. N.; Eksteen, J. J.; Kaksonen, A. H.; Watkin, E. L. J. Bioresour. Technol. Rep. 2018, 3, 109.

|

| [56] |

Brisson, V. L.; Zhuang, W.-Q.; Alvarez-cohen, L. Front. Microbiol. 2020, 10, 3008.

|

| [57] |

Barnett, M. J.; Palumbo-Roe, B.; Deady, E. A. Minerals 2020, 10, 649.

|

| [58] |

Tian, Y.; Hu, X.; Song, X.; Yang, A. J. Lett. Appl. Microbiol. 2022, 75, 1111.

|

| [59] |

Meng, X.-Y.; Zhao, H.-B.; Zhang, Y.-S.; Shen, L.; Gu, G.-H.; Qiu, G.-Z.; Zhang, X.-G.; Yu, H.; He, X.; Liu, C. Miner. Eng. 2022, 189, 107900.

|

| [60] |

Zhou, H.; Wang, J.-J.; Yu, X.-Y.; Kang, J.; Qiu, G.-Z.; Zhao, H.-B.; Shen, L. Sep. Purif. Technol. 2024, 330, 125305.

|

| [61] |

Zhao, Y.; Zhao, H.-B.; Shen, L.; Qiu, G.-Z.; Wang, Y.-Y. J. Environ. Manage. 2024, 368, 122184.

|

| [62] |

Shen, L.; Zhou, H.; Shi, Q.-Y.; Meng, X.-Y.; Zhao, Y.; Qiu, G.-Z.; Zhang, X.-G.; Yu, H.; He, X.; He, H.-J.; Zhao, G.-B. Hydrometallurgy 2023, 216, 106019.

|

| [63] |

Corbett, M.-K.; Eksteen, J.-J.; Niu, X.-Z.; Watkin, E. L. J. Res. Microbiol. 2018, 169, 558.

|

| [64] |

Jin, H.-Y.; Reed, D. W.; Thompson, V. S.; Fujita, Y.; Jiao, Y.-Q.; Crain-Zamora, M.; Fisher, J.; Scalzone, K.; Griffel, M.; Hartley, D.; Sutherland, J. W. ACS Sustainable Chem. Eng. 2019, 7, 15311.

|

| [65] |

Zhang, Z.-L.; Allen, L.; Podder, P.; Free, M. L.; Sarswat, P. K. Minerals 2021, 11, 484.

|

| [66] |

Fathollahzadeh, H.; Eksteen, J. J.; Kaksonen, A. H.; Watkin, E. L. J. Appl. Microbiol. Biotechnol. 2018, 103, 1043.

|

| [67] |

Beolchini, F.; Fonti, V.; Dell’Anno, A.; Rocchetti, L.; Vegliò, F. Waste Manage. 2012, 32, 949.

|

| [68] |

Hopfe, St.; Flemming, K.; Lehmann, F.; Möckel, R.; Kutschke, S.; Pollmann, K. Waste Manage. 2017, 62, 211.

|

| [69] |

Reynier, N.; Gagné-Turcotte, R.; Coudert, L.; Costis, S.; Cameron, R.; Blais, J. F. Minerals 2021, 11, 302.

|

| [70] |

Mouna, H. M.; Baral, S. S. J. Environ. Chem. Eng. 2021, 9, 104848.

|

| [71] |

Maes, S.; Zhuang, W.-Q.; Rabaey, K.; Alvarez-Cohen, L.; Hennebel, T. Environ. Sci. Technol. 2017, 51, 1654.

|

| [72] |

Pande, V.; Pandey, S. C.; Sati, D.; Bhatt, P.; Samant, M. Front. Microbiol. 2022, 13, 824084.

|

| [73] |

Naseri, T.; Beiki, V.; Mousavi, S. M.; Farnaud, S. RSC Adv. 2023, 13, 23570.

|

| [74] |

Shen, L.; Zhou, H.; Qiu, G.-Z.; Zhao, G.-B. J. Environ. Chem. Eng. 2024, 12, 112117.

|

| [75] |

Glombitza, F.; Reichel, S. Adv. Biochem. Eng. Biotechnol. 2014, 141, 49.

|

| [76] |

Mahmoud, A.; Cézac, P.; Hoadley, A. F. A.; Contamine, F.; D'Hugues, P. Int. Biodeterior. Biodegrad. 2017, 119, 118.

|

| [77] |

Fathollahzadeh, H.; Becker, T.; Eksteen, J. J.; Kaksonen, A. H.; Watkin, E. L. J. Bioresour. Technol. Rep. 2018, 3, 102.

|

| [78] |

Tributsch, H. Hydrometallurgy 2001, 59, 177.

|

| [79] |

Zhao, M.-F.; Teng, Z.-D.; Ma, X.-Y.; Jiang, X.-L.; Zhang, H.-L.; Yang, Y.-M.; Li, T.-G. J. Rare Earths 2025, 43, 591.

|

| [80] |

Shin, D.; Kim, J.; Kim, B. S.; Jeong, J.; Lee, J. C. Minerals 2015, 5, 189.

|

| [81] |

Peng, T.-J.; Shi, L.-J.; Yu, R.-L.; Gu, G.-H.; Zhou, D.; Chen, M.; Qiu, G.-Z.; Zeng, W.-M. Trans. Nonferrous Met. Soc. China 2016, 26, 2220.

|

| [82] |

Feng, S.-S.; Qiu, Y.-K.; Huang, Z.-Z.; Yin, Y.-J.; Zhang, H.-L.; Zhu, D.-Q.; Tong, Y.-J.; Yang, H.-L. Environ. Res. 2021, 199, 111341.

|

| [83] |

Bao, Y.-P.; Guo, C.-L.; Lu, G.-N.; Yi, X.-Y.; Wang, H.; Dang, Z. Sci. Total Environ. 2018, 616-617, 647.

|

| [84] |

Watling, H. R.; Collinson, D. M.; Fjastad, S.; Kaksonen, A. H.; Li, J.; Morris, C.; Perrot, F. A.; Rea, S. M.; Shiers, D. W. Miner. Eng. 2014, 58, 90.

|

| [85] |

Zhang, L.-J.; Zhou, W.-B.; Liu, Y.-D.; Jia, H.-H.; Zhou, J.; Wei, P.; Zhou, H.-B. Hydrometallurgy 2020, 191, 105227.

|

| [86] |

Jaiswal, M.; Srivastava, S. J. Hazard. Mater. Adv. 2024, 14, 100435.

|

| [87] |

Nguyen, T. H.; Won, S. M.; Ha, M. G.; Nguyen, D. D.; Kang, H. Y. Chemosphere 2021, 282, 131108.

|

| [88] |

Watling, H. Minerals 2016, 6, 49.

|

| [89] |

Brown, R. M.; Mirkouei, A.; Reed, D.; Thompson, V. Renewable Sustainable Energy Rev. 2023, 173, 113099.

|

| [90] |

Ou, M.; Deng, Y.-X.; Wang, F.-F.; Zhu, C.; Zhang, Q.-L.; Zhu, B.-X. Chin. J. Org. Chem. 2013, 33, 1798. (in Chinese)

|

|

(欧敏, 邓雅欣, 王芳芳, 朱纯, 张奇龙, 朱必学, 有机化学, 2013, 33, 1798.)

doi: 10.6023/cjoc201301062 |

|

| [91] |

Shi, S.-L.; Pan, J.-H.; Dong, B.; Zhou, W.-G.; Zhou, C.-C. Minerals 2023, 13, 1186.

|

| [92] |

Kevin, H. J.; Zhou, X.-P. Chin. J. Geochem. 1997, 16, 20.

|

| [93] |

Serrano, M. J. G.; Sanz, L. F. A.; Nordstrom, D. K. Chem. Geol. 2000, 165, 167.

|

| [94] |

Gu, J.; Ding, Y.; Ke, J.; Zhang, Y.-W.; Yan, C.-H. Acta Chim. Sin. 2013, 71, 360. (in Chinese)

|

|

(顾均, 丁祎, 柯俊, 张亚文, 严纯华, 化学学报, 2013, 71, 360.)

doi: 10.6023/A12121014 |

|

| [95] |

Cotton, S. A.; Raithby, P. R. Coord. Chem. Rev. 2017, 340, 220.

|

| [96] |

Li, S.-C.; Jansone-Popova, S.; Jiang, D.-E. Sci. Rep. 2024, 14, 11301.

|

| [97] |

Qian, C.-T.; Wang, C.-H.; Chen, Y.-F. Acta Chim. Sin. 2014, 72, 883. (in Chinese)

|

|

(钱长涛, 王春红, 陈耀峰, 化学学报, 2014, 72, 883.)

doi: 10.6023/A14060434 |

|

| [98] |

Wang, H.-N.; Zhang, A.-G.; Zhang, Z.; Tian, H.-R.; Yue, Q.; Zhao, X.; Lu, Y.; Liu, S.-X. Acta Chim. Sinica 2021, 79, 920. (in Chinese)

|

|

(王赫男, 张安歌, 张仲, 田洪瑞, 岳倩, 赵雪, 鹿颖, 刘术侠, 化学学报, 2021, 79, 920.)

doi: 10.6023/A21040130 |

|

| [99] |

Ilyas, S.; Lee, J. C. ChemBioEng Rev. 2014, 1, 148.

|

| [100] |

Hogan, D. E.; Curry, J. E.; Pemberton, J. E.; Maier, R. M. J. Hazard. Mater. 2017, 340, 171.

|

| [101] |

Mattocks, J. A.; Jung, J. J.; Lin, C.-Y.; Dong, Z.-Y.; Yennawar, N. H.; Featherston, E. R.; Kang-Yun, C. S.; Hamilton, T. A.; Park, D. M.; Boal, A. K.; Joseph, A. Cotruvo Jr J. A. Nature 2023, 618, 87.

|

| [102] |

Jiang, W.-J.; Li, Z.-J.; Zhang, Z.-Y.; Zhang, J.; Liu, T.; Yu, M.; Zhou, Y.-L.; Chai, Z.-F. Acta Chim. Sinica 2008, 66, 1740. (in Chinese)

|

|

(姜文君, 李子杰, 张智勇, 张静, 刘涛, 于明, 周云龙, 柴之芳, 化学学报, 2008, 66, 1740.)

|

|

| [103] |

Zhong, Y.-W.; Qian, X.-N.; Ma, C.; Liu, K.; Zhang, H. J. Acta Chim. Sin. 2023, 81, 1624. (in Chinese)

|

|

(钟越文, 钱希宁, 马超, 刘凯, 张洪杰, 化学学报, 2023, 81, 1624.)

doi: 10.6023/A23070323 |

|

| [104] |

Das, N.; Das, D. J. Rare Earths 2013, 31, 933.

|

| [105] |

Park, D. M.; Reed, D. W.; Yung, M. C.; Eslamimanesh, A.; Lencka, M. M.; Anderko, A.; Fujita, Y.; Riman, R. E.; Navrotsky, A.; Jiao, Y.-Q. Environ. Sci. Technol. 2016, 50, 2735.

|

| [106] |

Cheng, Y.-J.; Zhang, L.; Bian, X.-J.; Zuo, H.-Y.; Dong, H.-L. Environ Sci Pollut Res Int. 2018, 25, 22334.

|

| [107] |

Zhou, Y.; Zhu, N.-M.; Kang, N.-X.; Cao, Y.-L.; Shi, C.-H.; Wu, P.-X.; Dang, Z.; Zhang, X.-P.; Qin, B.-Q. Waste Manage. 2017, 60, 552.

|

| [108] |

Jurkowski, W.; Paper, M.; Brück, T. B. Front. Bioeng. Biotechnol. 2022, 10, 833122.

|

| [109] |

Cao, Y.; Shao, P.-H.; Chen, Y.-D.; Zhou, X.-Y.; Yang, L.-M.; Shi, H.; Yu, K.; Luo, X.-X.; Luo, X.-B. Resour., Conserv. Recycl. 2021, 169, 105519.

|

| [110] |

Minoda, A.; Sawada, H.; Suzuki, S.; Miyashita, S. I.; Inagaki, K.; Yamamoto, T.; Tsuzuki, M. Appl Microbiol Biotechnol. 2015, 99, 1513.

doi: 10.1007/s00253-014-6070-3 pmid: 25283836 |

| [111] |

Lederer, F. L.; Braun, R.; Schöne, L.M.; Pollmann, K. Miner. Eng. 2019, 132, 245.

doi: 10.1016/j.mineng.2018.12.010 |

| [112] |

Ketife, A. M. D. A.; Momani, F. A.; Judd, S. Process Saf. Environ. Prot. 2020, 144, 52.

|

| [113] |

Yan, T.-F.; Liu, S.-D.; Luo, Y.-C.; Zou, Y.-P.; Liu, J.-Q. Acta Chim. Sinica 2021, 79, 999. (in Chinese)

|

|

(闫腾飞, 刘盛达, 罗逸尘, 邹应萍, 刘俊秋, 化学学报, 2021, 79, 999.)

doi: 10.6023/A21050222 |

|

| [114] |

Giese, E. C. World J. Microbiol. Biotechnol. 2020, 36, 52.

|

| [115] |

Diniz, V.; Volesky, B. Water Res. 2005, 39, 239.

|

| [116] |

Béchet, Q.; Shilton, A.; Guieysse, B. Biotechnol. Adv. 2013, 31, 1648.

|

| [117] |

Hu, X.; Cao, J.-C.; Yang, H.-Y.; Li, D.-H.; Qiao, Y.; Zhao, J.-L.; Zhang, Z.-X.; Huang, L. Plos One 2020, 15, e0226557.

|

| [118] |

Lo, Y.-C.; Cheng, C.-L.; Han, Y.-L.; Chen, B.-Y.; Chang, J.-S. Bioresour. Technol. 2014, 160, 182.

|

| [119] |

Oliveira, R. C.; Jouannin, C.; Guibal, E.; Garcia Jr, O. Process Biochem. 2011, 46, 736.

|

| [120] |

Wu, Y.; Wang, Y.-J.; Du, J.-G.; Wang, Z.-H.; Wu, Q.-L. J. Rare Earths 2016, 34, 747.

|

| [121] |

Wang, B.; Yuan, X.-Y.; Han, L.; Wang, X.-Y.; Zhang, L.-J. Environ. Earth Sci. 2015, 74, 5087.

|

| [122] |

Liao, X.-J.; Ye, M.-Y.; Li, S.-P.; Liang, J.-L.; Zhou, J.-L.; Zhou, S.-Y.; Fang, X.-D.; Gan, Q.-W.; Sun, S.-Y. J. Cleaner Prod. 2021, 316, 128319.

|

| [123] |

Zheng, X.-J.; Lin, H.-J.; Du, D.-L.; Li, G.-L.; Alam, O.; Cheng, Z.; Liu, X.-L.; Jiang, S.; Li, J. Ecotoxicol. Environ. Saf. 2024, 284, 116883.

|

| [124] |

Ye, M.-Y.; Liang, J.-L.; Liao, X.-J.; Li, L.-L.; Feng, X.-D.; Qian, W.; Zhou, S.-Y.; Sun, S.-Y. J. Environ. Manage. 2021, 279, 111795.

|

| [125] |

Lei, C.; Yan, B.; Chen, T.; Xiao, X.-M. Environ. Sci. Pollut. Res. 2018, 25, 21233.

|

| [126] |

Zhang, Y.; Li, Q.; Liu, X.-L.; Yin, H.-Q.; Yang, Y.-B.; Xu, B.; Jiang, T.; He, Y.-H. J. Cleaner Prod. 2020, 256, 120391.

|

| [127] |

Feng, S.-S.; Yang, H.-L.; Wang, W. Bioresour. Technol. 2015, 192, 75.

|

| [128] |

Wang, J.; Tian, B.-Y.; Bao, Y.-H.; Qian, C.; Yang, Y.-R.; Niu, T.-Q.; Xin, B.-P. J. Hazard. Mater. 2018, 354, 250.

doi: S0304-3894(18)30348-0 pmid: 29758505 |

| [129] |

Zeng, X.-Y.; Xiao, Z.-H.; Zhang, G.-L.; Wang, A.-D.; Li, Z.-H.; Liu, Y.-H.; Wang, H.; Zeng, Q.-R.; Liang, Y.-S.; Zou, D.-S. J. Anal. Appl. Pyrolysis 2018, 132, 82.

|

| [130] |

Fonti, V.; Dell'Anno, A.; Beolchini, F. Sci. Total Environ. 2016, 563-564, 302.

|

| [131] |

Li, Q.; Zhu, J.-Y.; Li, S.-P.; Zhang, R.-Y.; Xiao, T.-F.; Sand, W. Front. Microbiol. 2020, 11, 44.

|

| [132] |

Hao, X.-D.; Zhu, P.; Zhang, H.-Z.; Liang, Y.-L.; Yin, H.-Q.; Liu, X.-D.; Bai, L.-Y.; Liu, H.-W.; Jiang, H.-D. Sci. Total Environ. 2019, 655, 347.

|

| [133] |

Zhang, R.-Y.; Hedrich, S.; Römer, F.; Goldmann, D.; Schippers, A. Hydrometallurgy 2020, 197, 105443.

|

| [134] |

Pepper, I.; Zerzghi, H.; Bengson, S.; Glenn, E. Arid Land Res. Manage. 2013, 27, 245.

|

| [135] |

Nkuna, R.; Ijoma, G. N.; Matambo, T. S.; Chimwani, N. Minerals 2022, 12, 506.

|

| [136] |

Lin, H.; Liu, C.-J.; Li, B.; Dong, Y.-B. J. Hazard. Mater. 2021, 402, 123829.

|

| [137] |

Pirsaheb, M.; Zadsar, S.; Rastegar, S. O.; Gu, T.-Y.; Hossini, H. Environ. Technol. Innovation 2021, 22, 101480.

|

| [138] |

Pirsaheb, M.; Zadsar, S.; Hossini, H.; Rastegar, S. O.; Kim, H. Environ. Technol. Innovation 2022, 28, 102801.

|

| No related articles found! |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||