化学学报 ›› 2024, Vol. 82 ›› Issue (1): 16-25.DOI: 10.6023/A23080375 上一篇 下一篇

研究论文

投稿日期:2023-08-10

发布日期:2023-10-23

基金资助:

Xiangguo Teng, Liangwei Zhang, Xiaoyu Han, Guowei Li, Jicui Dai( )

)

Received:2023-08-10

Published:2023-10-23

Contact:

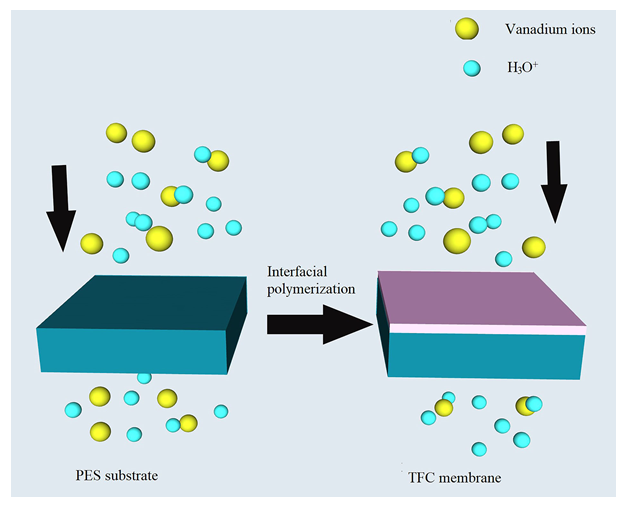

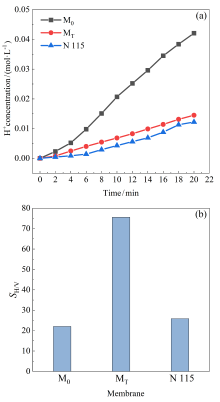

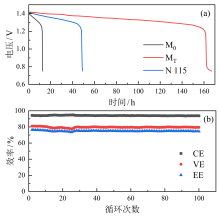

E-mail: Supported by:文章分享

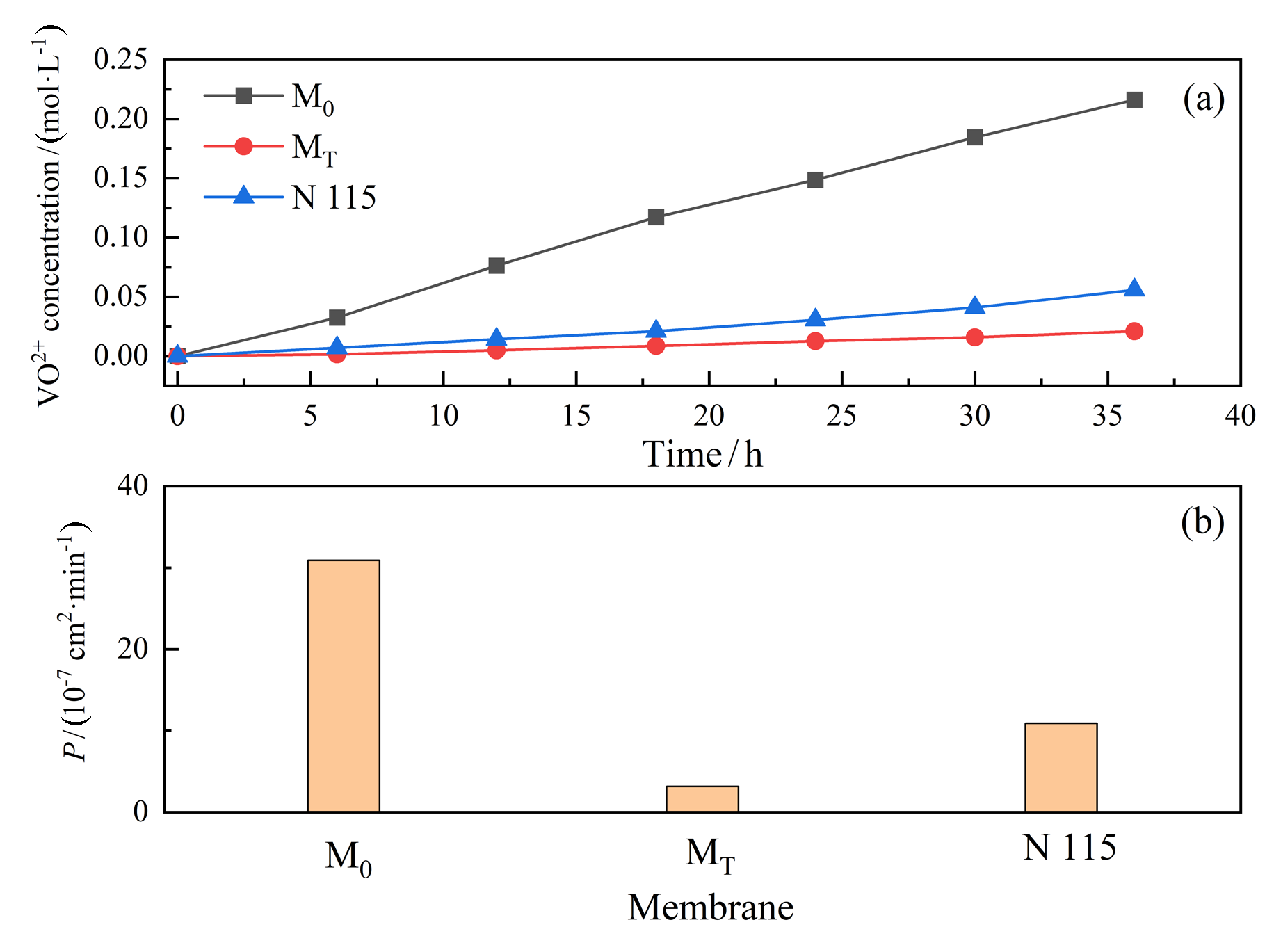

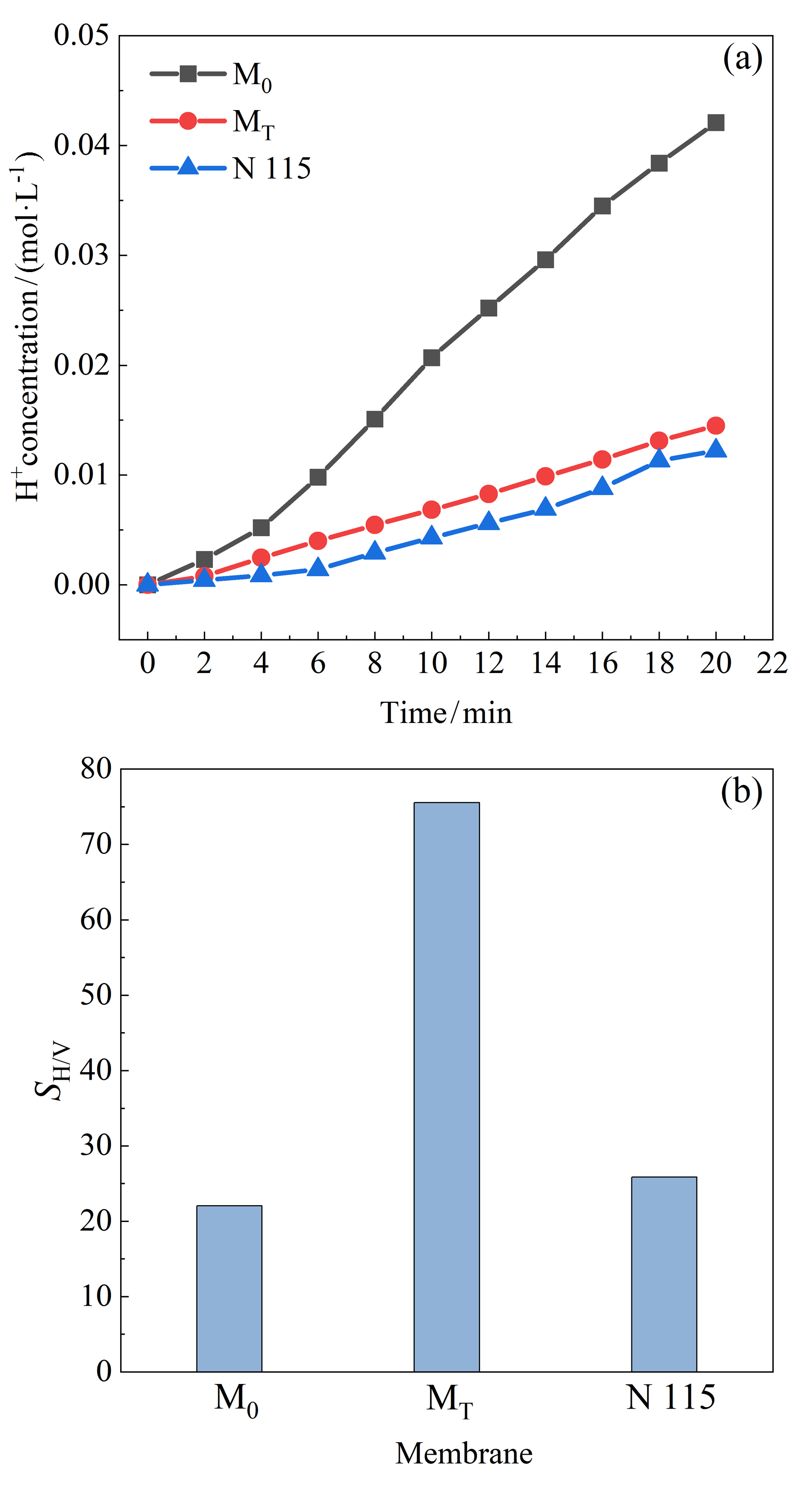

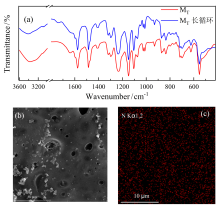

钒电池(VRB)具有容量和功率相互独立、易于模块化、寿命长和安全性高等优点, 因此特别适合作为大规模储能系统使用. 隔膜是VRB的核心部件之一, 对电池的综合性能和成本影响巨大. 全氟磺酸膜如Nafion(杜邦)具有化学稳定性高、电导率高和机械性能好等优点, 因此是当前VRB中所广泛使用的商业化隔膜. 然而, Nafion用于VRB时存在着钒离子渗透率高和成本高两大主要缺点, 严重制约了VRB的商业化进程. 薄层复合(TFC)膜具有皮层和支撑层易调控、制备简单和离子选择性高等特点, 特别适合于在VRB中使用. 但是传统的聚酰胺型TFC膜在VRB强酸电解液中存在潜在的水解和分解问题. 为了制备VRB用高稳定性TFC膜, 本工作以聚乙烯亚胺(PEI)和三聚氰氯(CC)作为两相单体, 通过界面聚合法制备了不含酰胺基的聚胺型TFC膜并应用于VRB. 在此基础上, 对所制备复合膜进行了钒离子渗透率、单电池充放电性能、化学稳定性和长期循环稳定性等物化性能及电化学性能研究. 结果表明: 聚胺TFC膜(MT)的钒离子渗透系数为3.17×10-7 cm2•min-1, 远小于基膜M0 (30.89×10-7 cm2•min-1)和商业N 115膜(Nafion 115, 10.91×10-7 cm2•min-1). MT膜在40 mA•cm-2的电流密度下的能量效率(EE)高达86.2%, 远高于M0 (74.9%)和N 115 (80.0%)膜. 化学稳定性测试表明MT膜的钒离子渗透系数损失率为4.42%, 低于M0 (8.93%)和N 115 (4.86%). 在80 mA•cm-2的电流密度下100次充放电循环内, 所制备TFC膜具有稳定的库仑效率、电压效率和能量效率. 该TFC膜是理想的商业Nafion膜替代产品, 在VRB中有良好的应用前景.

滕祥国, 张良伟, 韩晓玉, 李郭威, 戴纪翠. 钒电池用聚胺薄层复合膜研究[J]. 化学学报, 2024, 82(1): 16-25.

Xiangguo Teng, Liangwei Zhang, Xiaoyu Han, Guowei Li, Jicui Dai. Study on the Polyamine Thin Film Composite Membrane for Vanadium Battery[J]. Acta Chimica Sinica, 2024, 82(1): 16-25.

| 膜 | 质量损失率/% | 浸泡前钒离子 渗透系数/ (×10-7 cm2•min-1) | 浸泡后钒离子 渗透系数/ (×10-7 cm2•min-1) | 钒离子渗透系数 损失率/% |

|---|---|---|---|---|

| M0 | 2.85 | 30.89 | 33.65 | 8.93 |

| MT | 1.66 | 3.17 | 3.31 | 4.42 |

| N 115 | 1.73 | 10.91 | 11.44 | 4.86 |

| 膜 | 质量损失率/% | 浸泡前钒离子 渗透系数/ (×10-7 cm2•min-1) | 浸泡后钒离子 渗透系数/ (×10-7 cm2•min-1) | 钒离子渗透系数 损失率/% |

|---|---|---|---|---|

| M0 | 2.85 | 30.89 | 33.65 | 8.93 |

| MT | 1.66 | 3.17 | 3.31 | 4.42 |

| N 115 | 1.73 | 10.91 | 11.44 | 4.86 |

| 膜 | 电流密度/ (mA•cm-2) | CE/% | VE/% | EE/% | 文献 |

|---|---|---|---|---|---|

| 全氟磺酸填充多孔聚乙烯 | 60 | ≈93 | ≈85 | ≈79 | [ |

| 三维聚偏氟乙烯多孔膜 | 100 | 96 | 85 | 82 | [ |

| 聚苯并咪唑/聚乙烯吡咯烷酮 | 100 | 99.26 | 74.15 | 74.79 | [ |

| 磺化聚酰亚胺/聚乙烯吡咯烷酮 | 20 | 95 | 71 | 67.5 | [ |

| Nafion填充多孔聚偏氟乙烯膜 | 80 | ≈93 | ≈73 | ≈68 | [ |

| 二维MFI 分子筛膜 | 80 | 97.5 | 77.2 | 75.2 | [ |

| 聚酰胺薄层 复合膜 | 80 | 99.2 | 92.8 | 92.1 | [ |

| 多巴胺改性的聚酰胺薄层复合膜 | 80 | 95.7 | 86.8 | 83.1 | [ |

| 层层自组装改性聚醚砜多孔膜 | 80 | 98 | 89.8 | 88 | [ |

| 聚胺薄层复合膜 | 80 | 97.9 | 79.8 | 78.1 | 本文 |

| 膜 | 电流密度/ (mA•cm-2) | CE/% | VE/% | EE/% | 文献 |

|---|---|---|---|---|---|

| 全氟磺酸填充多孔聚乙烯 | 60 | ≈93 | ≈85 | ≈79 | [ |

| 三维聚偏氟乙烯多孔膜 | 100 | 96 | 85 | 82 | [ |

| 聚苯并咪唑/聚乙烯吡咯烷酮 | 100 | 99.26 | 74.15 | 74.79 | [ |

| 磺化聚酰亚胺/聚乙烯吡咯烷酮 | 20 | 95 | 71 | 67.5 | [ |

| Nafion填充多孔聚偏氟乙烯膜 | 80 | ≈93 | ≈73 | ≈68 | [ |

| 二维MFI 分子筛膜 | 80 | 97.5 | 77.2 | 75.2 | [ |

| 聚酰胺薄层 复合膜 | 80 | 99.2 | 92.8 | 92.1 | [ |

| 多巴胺改性的聚酰胺薄层复合膜 | 80 | 95.7 | 86.8 | 83.1 | [ |

| 层层自组装改性聚醚砜多孔膜 | 80 | 98 | 89.8 | 88 | [ |

| 聚胺薄层复合膜 | 80 | 97.9 | 79.8 | 78.1 | 本文 |

| [1] |

Cunha, Á.; Martins, J.; Rodrigues, N.; Brito, F. P. Int. J. Energ. Res. 2015, 39, 889.

doi: 10.1002/er.v39.7 |

| [2] |

Ding, C.; Zhang, H.; Li, X.; Liu, T.; Xing, F. J. Phys. Chem. Lett. 2013, 4, 1281.

doi: 10.1021/jz4001032 |

| [3] |

Yang, Z.; Zhang, J.; Kintner-Meyer, M. C. W.; Lu, X.; Choi, D.; Lemmon, J. P.; Liu, J. Chem. Rev. 2011, 111, 3577.

doi: 10.1021/cr100290v |

| [4] |

Soloveichik, G. L. Chem. Rev. 2015, 115, 11533.

doi: 10.1021/cr500720t pmid: 26389560 |

| [5] |

Kear, G.; Shah, A. A.; Walsh, F. C. Int. J. Energ. Res. 2012, 36, 1105.

doi: 10.1002/er.v36.11 |

| [6] |

Zhang, H.-M.; Wang, X.-L.; 2013, 2, 281. (in Chinese)

|

|

(张华民, 王晓丽, 储能科学与技术, 2013, 2, 281.)

doi: 10.3969/j.issn.2095-4239.2013.03.014 |

|

| [7] |

Skyllas-Kazacos, M.; Rychcik, M.; Robins, R. G.; Fane, A. G.; Green, M. A. J. Electrochem. Soc. 1986, 133, 1057.

doi: 10.1149/1.2108706 |

| [8] |

Rychcik, M.; Skyllas-Kazacos, M. J. Power Sources 1988, 22, 59.

doi: 10.1016/0378-7753(88)80005-3 |

| [9] |

Jia, Z.-J.; Song, S.-Q.; Wang, B.-G. 2012, 1, 50. (in Chinese)

|

|

(贾志军, 宋士强, 王保国, 储能科学与技术, 2012, 1, 50.)

|

|

| [10] |

Liu, M.-Y.; Han, L.-W.; Zheng, J.-T.; Xu, H.-W.; Cao, C.-Z. Chinese Journal of Power Sources 2016, 40, 1330. (in Chinese)

|

|

(刘明义, 韩临武, 郑建涛, 徐海卫, 曹传钊, 电源技术, 2016, 40, 1330.)

|

|

| [11] |

Doan, T. N. L.; Hoang, T. K. A.; Chen, P. RSC Adv 2015, 5, 72805.

doi: 10.1039/C5RA05914C |

| [12] |

Zhang, B.-G.; Zhang, S.-H.; Xing, D.-B.; Yin, C.-X.; Han, R.-L.; Jian, X.-G. 2011, 69, 583. (in Chinese)

|

|

(张本贵, 张守海, 邢东博, 尹春香, 韩润林, 蹇锡高, 化学学报, 2011, 69, 583.)

|

|

| [13] |

Prifti, H.; Parasuraman, A.; Winardi, S.; Lim, T. M.; Skyllas-Kazacos, M. Membranes-Basel 2012, 2, 275.

|

| [14] |

Shi, Y.; Eze, C.; Xiong, B.; He, W.; Zhang, H.; Lim, T. M.; Ukil, A.; Zhao, J. Appl. Energ. 2019, 238, 202.

doi: 10.1016/j.apenergy.2018.12.087 |

| [15] |

Schwenzer, B.; Zhang, J.; Kim, S.; Li, L.; Liu, J.; Yang, Z. ChemSusChem 2011, 4, 1388.

pmid: 22102992 |

| [16] |

Ding, Y.; Wang, L.-H.; Han, X.-T.; 2013, 1476. (in Chinese)

|

|

(丁跃, 王丽华, 韩旭彤, 高分子学报, 2013, 1476.)

|

|

| [17] |

Li, X.; Zhang, H.; Mai, Z.; Zhang, H.; Vankelecom, I. Energ. Environ. Sci. 2011, 4, 1147.

doi: 10.1039/c0ee00770f |

| [18] |

Fetyan, A.; Benetho, B. P.; Bamgbopa, M. O. J. Energy Chem. 2023, 81, 64.

doi: 10.1016/j.jechem.2023.01.058 |

| [19] |

Wang, F.-R.; Jiang, F.-J. Acta Chim. Sinica 2021, 79, 1123. (in Chinese)

doi: 10.6023/A21050231 |

|

(王斐然, 蒋峰景, 化学学报, 2021, 79, 1123.)

doi: 10.6023/A21050231 |

|

| [20] |

Ahn, Y.; Kim, D. Energy Storage Mater. 2020, 31, 105.

|

| [21] |

Wang, F.-R.; Jiang, F.-J. Prog. Chem. 2021, 33, 462. (in Chinese)

|

|

(王斐然, 蒋峰景, 化学进展, 2021, 33, 462.)

doi: 10.7536/PC200567 |

|

| [22] |

Zhang, S.; Liu, Q.-H.; John, L.; Miao, P.; Jiang, Z. Y.; 2020, 40, 50. (in Chinese)

|

|

(张赛, 刘庆华, John, L. 缪平, 姜忠义, 现代化工, 2020, 40, 50.)

|

|

| [23] |

Zhang, H.; Zhang, H.; Li, X.; Mai, Z.; Zhang, J. Energ. Environ. Sci. 2011, 4, 1676.

doi: 10.1039/c1ee01117k |

| [24] |

Zhou, X.; Xue, R.; Zhong, Y.; Zhang, Y.; Jiang, F. J. Membrane Sci. 2020, 595, 117614.

doi: 10.1016/j.memsci.2019.117614 |

| [25] |

Lu, W.; Yuan, Z.; Zhao, Y.; Qiao, L.; Zhang, H.; Li, X. Energy Storage Mater. 2018, 10, 40.

|

| [26] |

Mögelin, H.; Yao, G.; Zhong, H.; Dos Santos, A. R.; Barascu, A.; Meyer, R.; Krenkel, S.; Wassersleben, S.; Hickmann, T.; Enke, D.; Turek, T.; Kunz, U. J. Power Sources 2018, 377, 18.

doi: 10.1016/j.jpowsour.2017.12.001 |

| [27] |

Zhao, Y.; Yuan, Z.; Lu, W.; Li, X.; Zhang, H. J. Power Sources 2017, 342, 327.

doi: 10.1016/j.jpowsour.2016.12.058 |

| [28] |

Chae, I. S.; Luo, T.; Moon, G. H.; Ogieglo, W.; Kang, Y. S.; Wessling, M. Adv. Energy Mater. 2016, 6, 1600517.

doi: 10.1002/aenm.v6.16 |

| [29] |

Lu, W.; Yuan, Z.; Zhao, Y.; Zhang, H.; Zhang, H.; Li, X. Chem. Soc. Rev. 2017, 46, 2199.

doi: 10.1039/C6CS00823B |

| [30] |

Wu, J.; Dai, Q.; Zhang, H.; Li, X. ChemSusChem 2020, 13, 3805.

doi: 10.1002/cssc.v13.15 |

| [31] |

Xu, Z.; Huang, K. Chem. Ind. Eng. Prog. 2022, 41, 1569. (in Chinese)

|

|

(徐至, 黄康, 化工进展, 2022, 41, 1569.)

doi: 10.16085/j.issn.1000-6613.2021-2213 |

|

| [32] |

Zhang, H.-J.; Shen, J.-N.; Gao, C.-J.; 2017, 27, 6. (in Chinese)

|

|

(张慧娟, 沈江南, 高从堦, 过滤与分离, 2017, 27, 6.)

|

|

| [33] |

Xu, G.; Wang, J.; Li, C. Desalination 2013, 328, 83.

doi: 10.1016/j.desal.2013.08.022 |

| [34] |

Dai, Q.; Liu, Z.; Huang, L.; Wang, C.; Zhao, Y.; Fu, Q.; Zheng, A.; Zhang, H.; Li, X. Nat. Commun. 2020, 11, 13.

doi: 10.1038/s41467-019-13704-2 |

| [35] |

Liang, S.; Xu, G.; Jin, Y.; Wu, Z.; Cai, Z.; Zhao, N.; Wu, Z. J. Membrane Sci. 2015, 476, 475.

doi: 10.1016/j.memsci.2014.12.003 |

| [36] |

Yao, C. W.; Burford, R. P.; Fane, A. G.; Fell, C. J. D.; Mcdonogh, R. M. J. Appl. Polym. Sci. 1987, 34, 2399.

doi: 10.1002/app.1987.070340706 |

| [37] |

Dalwani, M.; Benes, N. E.; Bargeman, G.; Stamatialis, D.; Wessling, M. J. Membrane Sci. 2011, 372, 228.

doi: 10.1016/j.memsci.2011.02.012 |

| [38] |

Lee, K. P.; Zheng, J.; Bargeman, G.; Kemperman, A. J. B.; Benes, N. E. J. Membrane Sci. 2015, 478, 75.

doi: 10.1016/j.memsci.2014.12.045 |

| [39] |

Ma, X.; Wen, X.; Gu, S.; Xu, Z.; Zhang, J. J. Membrane Sci. 2013, 430, 62.

doi: 10.1016/j.memsci.2012.11.073 |

| [40] |

Lu, W.; Yuan, Z.; Li, M.; Li, X.; Zhang, H.; Vankelecom, I. Adv. Funct. Mater. 2017, 27, 1604587.

doi: 10.1002/adfm.v27.4 |

| [41] |

Lau, W.; Ismail, A. F. Desalination 2009, 249, 996.

doi: 10.1016/j.desal.2009.09.016 |

| [42] |

Jaafar, J.; Ismail, A. F.; Mustafa, A. Mat. Sci. Eng. A.-Struct. 2007, 460, 475.

|

| [43] |

Daud, S. N. S. S.; Norddin, M. N. A. M.; Jaafar, J.; Sudirman, R.; Othman, M. H. D.; Ismail, A. F. Arab. J. Sci. Eng. 2021, 46, 6189.

doi: 10.1007/s13369-020-04898-5 |

| [44] |

Lau, W. J.; Ismail, A. F. J. Membrane Sci. 2009, 334, 30.

doi: 10.1016/j.memsci.2009.02.012 |

| [45] |

Bai, L.; Wang, M.; Li, Z.; Yang, H.; Peng, Z.; Zhao, Y. J. Membrane Sci. 2022, 643, 120012.

doi: 10.1016/j.memsci.2021.120012 |

| [46] |

Jiang, Z.; Miao, J.; He, Y.; Hong, X.; Tu, K.; Wang, X.; Chen, S.; Yang, H.; Zhang, L.; Zhang, R. RSC Adv. 2019, 9, 37546.

doi: 10.1039/C9RA06528H |

| [47] |

Zhu, X.; Cheng, X.; Luo, X.; Liu, Y.; Xu, D.; Tang, X.; Gan, Z.; Yang, L.; Li, G.; Liang, H. Environ. Sci. Technol. 2020, 54, 6365.

doi: 10.1021/acs.est.9b06779 |

| [48] |

Teng, X.; Guo, Y.; Liu, D.; Li, G.; Yu, C.; Dai, J. J. Membrane Sci. 2020, 601, 117906.

doi: 10.1016/j.memsci.2020.117906 |

| [49] |

Zhang, B.; Liu, S.; Wang, L. H.; Han, X. T.; 2015, 418. (in Chinese)

|

|

(张斌, 刘帅, 王丽华, 韩旭彤, 高分子学报, 2015, 418.)

|

|

| [50] |

Tian, J.; Chang, H.; Gao, S.; Zhang, R. Desalination 2020, 491, 114499.

doi: 10.1016/j.desal.2020.114499 |

| [51] |

Thong, P. T.; Ajeya, K. V.; Dhanabalan, K.; Roh, S.; Son, W.; Park, S.; Jung, H. J. Power Sources 2022, 521, 230912.

doi: 10.1016/j.jpowsour.2021.230912 |

| [52] |

Song, X.-P.; Liu, J.-Y.; Wang, L.-H.; Han, X.-T.; Huang, Q.-L. 2019, 40, 1543. (in Chinese)

|

|

(宋西鹏, 刘金宇, 王丽华, 韩旭彤, 黄庆林, 高等学校化学学报, 2019, 40, 1543.)

doi: 10.7503/cjcu20180720 |

|

| [53] |

Dalal, U.; Kapoor, M.; Verma, A. Energ. Fuel. 2023, 37, 13457.

doi: 10.1021/acs.energyfuels.3c01932 |

| [54] |

Zhang, D.; Huang, K.; Xia, Y.; Cao, H.; Dai, L.; Qu, K.; Xiao, L.; Fan, Y.; Xu, Z. Angew. Chem. Int. Ed. 2023, 62, e2023109.

|

| [55] |

Guo, C.-S. Ph.D. Dissertation, Tiangong University, Tianjin, 2022. (in Chinese)

|

|

(郭昌盛, 博士论文, 天津工业大学,天津, 2022.)

|

|

| [56] |

Shi, Q.; Ni, L.; Zhang, Y.; Feng, X.; Chang, Q.; Meng, J. J. Mater. Chem. A 2017, 5, 13610.

doi: 10.1039/C7TA02552A |

| [57] |

Hu, P.; He, J.; Tian, B.; Xu, Z.; Yuan, T.; Sun, H.; Li, P.; Niu, Q. J. Desalination 2020, 496, 114340.

doi: 10.1016/j.desal.2020.114340 |

| [58] |

Zhu, X.; Tang, X.; Luo, X.; Yang, Z.; Cheng, X.; Gan, Z.; Xu, D.; Li, G.; Liang, H. J. Membrane Sci. 2021, 618, 118738.

doi: 10.1016/j.memsci.2020.118738 |

| [59] |

Zeng, H.; Li, Y.; Wang, C. Sep. Purif. Technol. 2020, 236, 116258.

doi: 10.1016/j.seppur.2019.116258 |

| [60] |

Aravind, K.; Sangeetha, D. Int. J. Polym. Mater. Polym. Biomat. 2014, 64, 220.

doi: 10.1080/00914037.2014.936594 |

| [61] |

Zhang, R.; Yu, S.; Shi, W.; Zhu, J.; Van der Bruggen, B. Sep. Purif. Technol. 2019, 215, 670.

doi: 10.1016/j.seppur.2019.01.045 |

| [62] |

Li, G.-W. M.S. Thesis, Harbin Institute of Technology, Haerbin, 2019. (in Chinese)

|

|

(李郭威, 硕士论文, 哈尔滨工业大学,哈尔滨, 2019.)

|

|

| [63] |

Hasbullah, N.; Sekak, K. A.; Ibrahim, I.; Mahmood, M. R.; Soga, T.; Nagaoka, S.; Mamat, M. H.; Jafar, S. M. Aip Conference Proceedings 2016, 1733, 020049.

|

| [64] |

Dong, Y.-F.; Tan, X.-L.; Guo, Q.; Li, X.; Li, D.; Li, M. Physical Testing and Chemical Analysis Part A: Physical Testing 2011, 47, 535 (in Chinese)

|

|

(董云凤, 谭孝林, 郭强, 李夏, 李丹, 李萌, 理化检验(物理分册), 2011, 47, 535.)

|

|

| [65] |

Yuan, Z.; Zhu, X.; Li, M.; Lu, W.; Li, X.; Zhang, H. Angew. Chem. Int. Ed. 2016, 55, 3058.

doi: 10.1002/anie.v55.9 |

| [66] |

Zheng, L.; Wang, H.; Niu, R.; Zhang, Y.; Shi, H. Electrochim. Acta 2018, 282, 437.

doi: 10.1016/j.electacta.2018.06.083 |

| [67] |

Wang, N.-F. Ph.D. Dissertation, Central South University, Changsha, 2012. (in Chinese)

|

|

(汪南方, 博士论文, 中南大学, 长沙, 2012.)

|

|

| [68] |

Wang, F.; Zhang, Z.; Jiang, F. J. Power Sources 2021, 506, 230234.

doi: 10.1016/j.jpowsour.2021.230234 |

| [1] | 吕会朝, 张成潘, 黄晋, 赵巧玲, 马志, 肖吉昌. 聚苯乙烯-co-聚(2,3,4,5,6-五氟苯乙烯)共聚物: 合成及其多孔薄膜的制备[J]. 化学学报, 2012, 70(9): 1125-1130. |

| [2] | 吕会朝, 徐慎刚, 赵巧玲, 黄晋, 曹少魁, 马志. 基于聚亚甲基的三嵌段聚合物: 合成及其多孔薄膜的制备[J]. 化学学报, 2011, 69(9): 1126-1130. |

| [3] | 耿风华, 陈健壮, 赵巧玲, 李剑, 马志. 呼吸图法制备聚亚甲基-b-聚甲基丙烯酸甲酯多孔薄膜[J]. 化学学报, 2011, 69(22): 2741-2745. |

| [4] | 赵永涛, 席靖宇, 滕祥国, 武增华, 邱新平. 钒电池电解液体积变化规律研究[J]. 化学学报, 2011, 69(02): 132-136. |

| [5] | 滕祥国,赵永涛,席靖宇,武增华,邱新平,陈立泉 . 全钒氧化还原液流电池用Nafion/有机硅复合膜[J]. 化学学报, 2009, 67(6): 471-476. |

| [6] | 郝彦忠, 王伟. 聚3-甲基噻吩修饰硫化物量子点连接纳米结构TiO2膜的光电化学研究[J]. 化学学报, 2007, 65(6): 489-493. |

| [7] | 黄训亭,邵正中,陈新. 天然蚕丝与丝素蛋白多孔膜的生物降解性研究[J]. 化学学报, 2007, 65(22): 2592-2596. |

| [8] | 苏碧桃, 佟永纯, 王克, 白洁, 董娜, 慕红梅, 敏世雄, 佘世雄, 雷自强. 界面法合成聚糠醛纳米球[J]. 化学学报, 2007, 65(12): 1161-1164. |

| [9] | 杨前荣, 陈 新, 邵正中. 然聚电解质壳聚糖/羧甲基壳聚糖配合物膜的研制[J]. 化学学报, 2005, 63(4): 259-262. |

| [10] | 吴惊涛,邓景发. 膜催化研究II. 多孔无要膜的制备与表征及其反应器对甲醇脱氢反应的促进作用[J]. 化学学报, 1994, 52(1): 42-46. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||