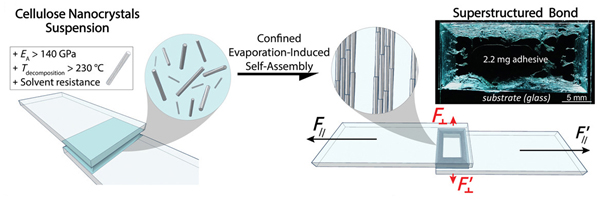

无论是自然界普遍存在的非共价键相互作用,还是共价键结合,都可以产生界面粘附.粘附材料的应用需求广泛,涉及可穿戴设备、电子器件、医疗手术等诸多领域.近些年来,仿生结构粘附材料和仿生粘合剂已经得到了快速的发展,一些人工制备的粘附材料已投入实际应用.然而,结构微加工的局限性和合成路线的复杂性限制了它们的大规模生产.相比而言,纳米颗粒溶液提供了一种更简单和更容易实现强粘附的替代方法.本文就最近报道的"强各向异性粘附的纤维素纳米晶体悬浮液"作一亮点评述.

刘明倩

,

万茜子

,

王树涛

. 超强纳米颗粒溶液粘合剂[J]. 化学学报, 2020

, 78(6)

: 463

-465

.

DOI: 10.6023/A20040110

Interfacial adhesion occurs by covalent bonding or noncovalent interactions that are ubiquitous in nature. Adhesive materials are widely desired in many fields including wearable devices, electronic devices, medical surgeries, etc. In recent years, bio-inspired structural adhesive materials and adhesives have been rapidly developed, and some artificial adhesive materials have been put into practical use. However, the restrictions of structural microfabrication and the complexity of synthetic routes limit their large-scale production. In contrast, the nanoparticle solutions provide a simpler and easier alternative to achieve strong adhesion. Here this article makes a highlight on the recent research of "strong anisotropic adhesion of cellulose nanocrystals suspension".

[1] Jeong, H. E.; Lee, J.-K.; Kim, H. N.; Moon, S. H.; Suh, K. Y. Proc. Natl. Acad. Sci. U. S. A. 2009, 106, 5639.

[2] Iturri, J.; Xue, L. J.; Kappl, M.; Garcia-Fernandez, L.; Barnes, W. J. P.; Butt, H. J.; Campo, A. D. Adv. Funct. Mater. 2015, 25, 1499.

[3] Baik, S.; Kim, D. W.; Park, Y.; Lee, T.-J.; Bhang, S. H.; Pang, C. Nature 2017, 546, 396.

[4] Jenkins, C. L.; Meredith, H. J.; Wilker, J. J. ACS Appl. Mater. Interfaces 2013, 5, 5091.

[5] Zhao, Q.; Lee, D. W.; Ahn, B. K.; Seo, S.; Kaufman, Y.; Israelachvili, J. N.; Waite, J. H. Nat. Mater. 2016, 15, 407.

[6] Harris, T. I.; Gaztambide, D. A.; Day, B. A.; Brock, C. L.; Ruben, A. L.; Jones, J. A.; Lewis, R. V. Biomacromolecules 2016, 17, 3761.

[7] Rose, S.; Prevoteau, A.; Elziere, P.; Hourdet, D.; Marcellan, A.; Leibler, L. Nature 2014, 505, 382.

[8] Meddahi-Pelle, A.; Legrand, A.; Marcellan, A.; Louedec, L.; Letourneur, D.; Leibler, L. Angew. Chem. Int. Ed. 2014, 53, 6369.

[9] Tardy, B. L.; Richardson, J. J.; Greca, L. G.; Guo, J. L.; Ejima, H.; Rojas, O. J. Adv. Mater. 2020, 32, e1906886.