亚表面引发原子转移自由基聚合构筑温度响应型纳米纤维油水分离膜

收稿日期: 2020-09-27

网络出版日期: 2021-01-05

基金资助

项目受国家自然科学基金(52065061); 项目受国家自然科学基金(51805514); 项目受国家自然科学基金(51705507); 中国科学院国际合作局(121B62KYSB2017009); 中国科学院前沿科学重点研究项目(QYZDY-SSW-JSC013)

Temperature-Responsive Nanofibrous Membranes Fabricated by Subsurface-Initiated Atom Transfer Radical Polymerization for Controllable Oil/Water Separation

Received date: 2020-09-27

Online published: 2021-01-05

Supported by

National Natural Science Foundation of China(52065061); National Natural Science Foundation of China(51805514); National Natural Science Foundation of China(51705507); Bureau of International Cooperation, Chinese Academy of Sciences(121B62KYSB2017009); Key Research Projects of Frontier Science of Chinese Academy of Sciences(QYZDY-SSW-JSC013)

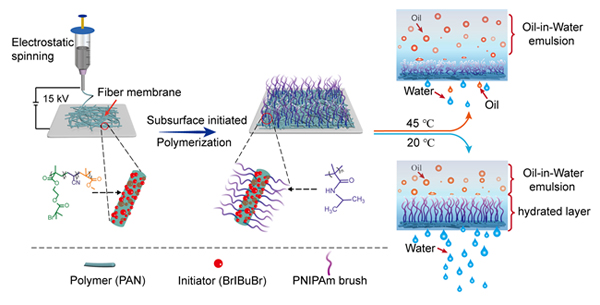

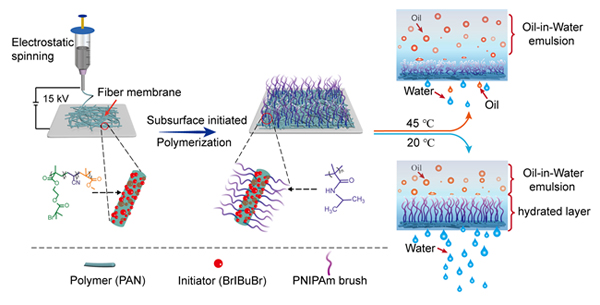

亚表面引发聚合是一种用于制备共价嵌入型聚合物刷的新型改性策略. 该方法在发展高稳定性聚合物刷功能化表界面材料方面具有显著的优势. 本工作利用亚表面引发原子转移自由基聚合(sSI-ATRP)对静电纺丝聚丙烯腈(PAN)基纳米纤维膜进行亚表面改性, 通过接枝聚N-异丙基丙烯酰胺(PNIPAM)制备了温度响应型纳米纤维油水分离膜(PAN-sg-PNIPAM). 当温度低于低临界溶解温度(LCST)时, PNIPAM链与水分子之间的强氢键作用使得聚合物链完全伸展, 分离膜表面亲水且对油滴具有非常低的粘附力, 对油水乳液具有非常高的分离效率(达98.7%); 当温度高于LCST时, PNIPAM链失水收缩, 膜表面变得更加疏水且对油滴的粘附力显著增加, 其油水乳液分离效率显著降低, 仅为9.1%. 此外, 由于共价嵌入聚合物刷的高稳定性, 该分离膜在4 kPa压力下, 20 ℃和45 ℃之间可逆切换10个循环后, 仍能保持非常稳定的渗透通量. 本研究为发展高稳定性的智能型油水分离膜提供了一种新方法.

李乐乐 , 向阳阳 , 刘欢 , 麻拴红 , 李斌 , 马正峰 , 魏强兵 , 于波 , 周峰 . 亚表面引发原子转移自由基聚合构筑温度响应型纳米纤维油水分离膜[J]. 化学学报, 2021 , 79(3) : 353 -360 . DOI: 10.6023/A20090449

Subsurface-initiated polymerization is a novel modification strategy for the preparation of covalently embedded polymer brushes. It shows great advantages in the development of polymer brush-functionalized surface with high stability. In this work, the electrospun polyacrylonitrile (PAN) based nanofibrous membrane was modified by subsurface-initiated atom transfer radical polymerization (sSI-ATRP). Covalently embedded poly(N-isopropylacrylamide) (PNIPAM) brushes were grafted from nanofibrous membranes to prepare temperature-responsive oil/water separation membrane (PAN-sg-PNIPAM). When the temperature is lower than the lower critical solution temperature (LCST), strong hydrogen bond interaction between PNIPAM chains and water molecules makes polymer chains fully extended. The membranes are hydrophilic and show very low underwater oil adhesion, resulting in a very high separation efficiency for oil-water emulsions (up to 98.7%). While the temperature is higher than LCST, PNIPAM chains dehydrate and collapse, the membranes become more hydrophobic and the underwater oil adhesion increases significantly. Thus, the separation efficiency dramatically decreases to as low as 9.1%. In addition, due to the high stability and durability of covalently embedded polymer brushes, the membrane can maintain a very stable permeation flux after reversible switch between 20 ℃ and 45 ℃ for 10 cycles under a pressure of 4 kPa. This study provides a novel method for the development of highly stable, durable and smart oi/water separation membranes.

| [1] | Stokstad, E. Science 2010, 328,1618. |

| [2] | Schnoor, J. L. Environ. Sci. Technol. 2010, 44,4833. |

| [3] | Wang, B.; Liang, W.; Guo, Z.; Liu, W. Chem. Soc. Rev. 2015, 44,336. |

| [4] | Shannon, M. A.; Bohn, P. W.; Elimelech, M.; Georgiadis, J. G.; Marinas, B. J.; Mayes, A. M. Nature 2008, 452,301. |

| [5] | Pezeshki, S. R.; Hester, M. W.; Lin, Q.; Nyman, J. A. Environ. Pollut. 1999, 108,129. |

| [6] | Belkacem, M.; Matamoros, H.; Cabassud, C.; Aurelle, Y.; Cotteret, J. J. Membr. Sci. 1995, 106,195. |

| [7] | Ma, Q.; Cheng, H.; Fane, A. G.; Wang, R.; Zhang, H. Small 2016, 12,2186. |

| [8] | Zhu, Y.; Wang, D.; Jiang, L.; Jin, J. NPG Asia Mater. 2014, 6,e101. |

| [9] | Li, W. T.; Yong, J. L.; Yang, Q.; Chen, F.; Fang, Y.; Hou, X. Acta Phys.-Chim. Sinica 2018, 34,456. (in Chinese) |

| [9] | ( 李文涛, 雍佳乐, 杨青, 陈烽, 方瑶, 侯洵, 物理化学学报, 2018, 34,456.) |

| [10] | Wu, F.; Pickett, K.; Panchal, A.; Liu, M.; Lvov, Y. ACS Appl. Mater. Interfaces 2019, 11,25445. |

| [11] | Liang, B.; Zhang, G. Y.; Zhong, Z. X.; Tomoya, S.; Atsushi, H.; Su, Z. H. Chem. Eng. J. 2019, 362,126. |

| [12] | Cao, Y.; Liu, N.; Fu, C.; Li, K.; Tao, L.; Feng, L.; Wei, Y. ACS Appl. Mater. Interfaces 2014, 6,2026. |

| [13] | Parnell, A. J.; Martin, S. J.; Dang, C. C.; Geoghegan, M.; Jones, R. A. L.; Crook, C. J.; Howse, J. R.; Ryan, A. J. Polymer 2009, 50,1005. 7fcaa455-fafb-4d69-bee2-bb0ee2380bd6 |

| [14] | Zhang, L.; Zhang, Z.; Wang, P. NPG Asia Mater. 2012, 4,e8. |

| [15] | Zhou, Y. N.; Li, J. J.; Luo, Z. H. AIChE J. 2016, 62,1758. |

| [16] | Qu, D. H.; Wang, Q. C.; Zhang, Q. W.; Ma, X.; Tian, H. Chem. Rev. 2015, 115,7543. |

| [17] | Tian, D.; Zhang, X.; Tian, Y.; Wu, Y.; Wang, X.; Zhai, J.; Jiang, L. J. Mater. Chem. 2012, 22,19652. |

| [18] | Zhu, H.; Yang, S.; Chen, D.; Li, N.; Xu, Q.; Li, H.; He, J.; Lu, J. Adv. Mater. Interfaces 2016, 3,1500683. |

| [19] | Xue, B.; Gao, L.; Hou, Y.; Liu, Z.; Jiang, L. Adv. Mater. 2013, 25,273. |

| [20] | Zhou, Y. N.; Li, J. J.; Luo, Z. H. Ind. Eng. Chem. Res. 2015, 54,10714. |

| [21] | Kwon, G.; Kota, A. K.; Li, Y.; Sohani, A.; Mabry, J. M.; Tuteja, A. Adv. Mater. 2012, 24,3666. |

| [22] | Zheng, X.; Guo, Z.; Tian, D.; Zhang, X.; Jiang, L. Adv. Mater. Interfaces 2016, 3,1600461. |

| [23] | Kota, A. K.; Kwon, G.; Choi, W.; Mabry, J. M.; Tuteja, A. Nat. Commun. 2012, 3,1025. |

| [24] | Xu, Z.; Zhao, Y.; Wang, H.; Wang, X.; Lin, T. Angew. Chem., Int. Ed. 2015, 54,4527. |

| [25] | Li, B.; Yu, B.; Zhou, F. Acta Polym. Sinica 2016, 10, 1312. (in Chinese) |

| [25] | ( 李斌, 于波, 周峰, 高分子学报, 2016, 10, 1312.). |

| [26] | Li, B.; Yu, B.; Ye, Q.; Zhou, F. Prog. Chem. 2015, 27,146. (in Chinese) 81cf855d-0604-4ebb-a38c-81f9e75c9fce |

| [26] | ( 李斌, 于波, 叶谦, 周峰, 化学进展, 2015, 27,146.) 81cf855d-0604-4ebb-a38c-81f9e75c9fce |

| [27] | Cao, Y.; Liu, N.; Fu, C.; Li, K.; Tao, L.; Feng, L.; Wei, Y. ACS Appl. Mater. Interfaces 2014, 6,2026. |

| [28] | Yu, Q.; Cho, J.; Phanindhar, S.; Linnea, K. I.; Gabriel, P. L. ACS Appl. Mater. Interfaces 2013, 5,9295. |

| [29] | Wei, T.; Zhan, W. J.; Yu, Q.; Chen, H. ACS Appl. Mater. Interfaces. 2017, 9,25767. |

| [30] | Wei, Q. B.; Cai, M. R.; Zhou, F. Acta Polym. Sinica 2012, 10,1103. (in Chinese) |

| [30] | ( 魏强兵, 蔡美荣, 周峰, 高分子学报, 2012, 10, 1103.). |

| [31] | Wu, Y.; Wei, Q. B.; Cai, M. R.; Zhou, F. Adv. Mater. Interfaces 2015, 2,1400392. |

| [32] | Wei, Q. B.; Cai, M. R.; Zhou, F.; Liu, W. M. Macromolecules 2013, 46,9368. |

| [33] | Zhang, L. B.; Zhang, Z. H.; Wang, P. NPG Asia Mater. 2012, 4,e8. |

| [34] | Tang, Z.; Akiyama, Y.; Okano, T. J. Polym. Sci.: Polym. Phys. 2014, 52,917. |

| [35] | Kim, Y. J.; Matsunaga, Y. T. J. Mater. Chem. B 2017, 5,4307. |

| [36] | Jean, B.; Lee, L. T. J. Phys. Chem. B 2005, 109,5162. |

| [37] | Chen, J.; Gong, X.; Yang, H.; Yao, Y.; Xu, M.; Chen, Q.; Cheng, R. Macromolecules 2011, 44,6227. |

| [38] | Sun, T.; Wang, G.; Feng, L.; Liu, B.; Ma, Y.; Jiang, L.; Zhu, D. Angew. Chem. Int. Ed. 2004, 43,357. |

| [39] | Li, J.; Zhu, L. T.; Luo, Z. H. Chem. Eng. J. 2016, 287,474. |

| [40] | Yu, Q.; Shivapooja, P.; Johnson, L. M.; Tizazu, G.; Leggett, G. J.; Lopez, G. P. Nanoscale 2013, 5,3632. |

| [41] | Xue, B. L.; Gao, L. C.; Hou, Y. P.; Liu, Z. W.; Jiang, L. Adv. Mater. 2013, 25,273. |

| [42] | Liu, Y.; Tas, S.; Zhang, K. H.; De Vos, W. M.; Ma, J. H.; Vancso, G. J. Macromolecules 2018, 51,8435. |

| [43] | Ma, Z. F.; Liu, Q.; Wu, Y.; Li, B.; Yu, B.; Liu, Q. Z.; Zhou, F. Sci. Sinica Chim. 2018, 48,1611. (in Chinese) |

| [43] | ( 马正峰, 刘强, 吴杨, 李斌, 于波, 刘钦泽, 周峰, 中国科学:化学, 2018, 48, 1611.). |

| [44] | Liu, H.; Ma, Z. F.; Yang, W. F.; Pei, X. W.; Zhou, F. Eur. Polym. J. 2019, 112,146. |

| [45] | Li, L. L.; Xiang, Y. Y.; Yang, W. F.; Liu, Z. L.; Cai, M. R.; Ma, Z. F.; Wei, Q. B.; Pei, X. W.; Yu, B.; Zhou, F. J. Colloid Interface Sci. 2020, 575,388. |

| [46] | Feng, H. Y.; Ma, Z. F.; Zhang, Y. J.; Liu, F. Z.; Ma, S. H.; Zhang, R.; Cai, M. R.; Yu, B.; Zhou, F. Macromol. Mater. Eng. 2020, 305,2000135. |

/

| 〈 |

|

〉 |