镍氮掺杂有序大孔/介孔碳负载银纳米颗粒用于高效电催化CO2还原

收稿日期: 2021-03-22

网络出版日期: 2021-06-25

基金资助

国家自然科学基金(21676018)

Nickel-Nitrogen-Doped Ordered Macro-/Mesoporous Carbon Supported Ag Nanoparticles for Efficient Electrocatalytic CO2 Reduction

Received date: 2021-03-22

Online published: 2021-06-25

Supported by

National Natural Science Foundation of China(21676018)

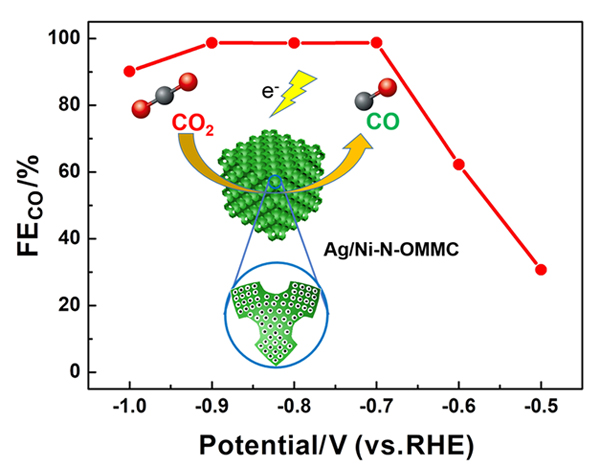

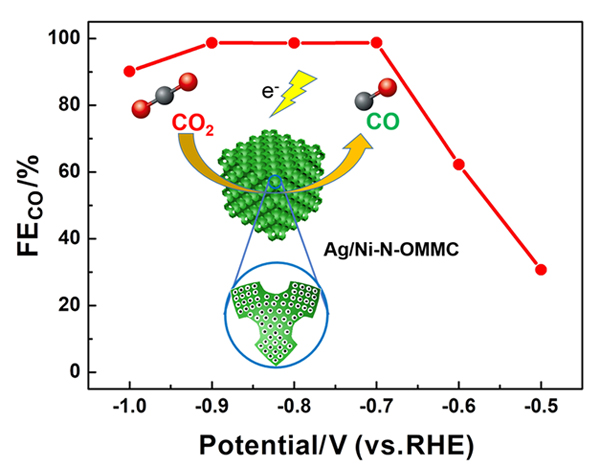

多组分体系中的协同作用为设计高效的二氧化碳还原电催化剂提供了新的思路. 本工作通过双模板法和化学还原法精心设计制备了大孔/介孔镍氮掺杂碳(Ni-N-OMMC)负载银纳米颗粒复合材料(Ag/Ni-N-OMMC), 用于高效电催化还原CO2为CO. 此复合材料表现出良好的电催化活性, 在CO2饱和的0.1 mol•L–1 KHCO3电解液中, 电位为–1.0 V (相对于可逆氢电极, RHE)时CO的电流密度(JCO)高达33.29 mA•cm–2. 并具有较宽的工作电压范围, 在–0.7~–1.0 V (vs. RHE)下, CO的法拉第效率超过90%. 其优异的电催化性能可能归因于Ag纳米颗粒与具有丰富Ni-N x活性位点的Ni-N-OMMC载体之间的协同效应, 以及三维互联有序大孔/介孔结构提供的高比表面积和高效的质量/电荷传输.

穆春辉 , 张艺馨 , 寇伟 , 徐联宾 . 镍氮掺杂有序大孔/介孔碳负载银纳米颗粒用于高效电催化CO2还原[J]. 化学学报, 2021 , 79(7) : 925 -931 . DOI: 10.6023/A21030104

Electrocatalytic CO2 reduction (ECR) into high value-added chemical products has been regarded as an effective strategy to release environmental crisis caused by high concentration of CO2 in the atmosphere, because of its mild operation conditions and the ability to use renewable energy sources as power. Metal-nitrogen-doped carbon-based nanomaterials have been demonstrated as excellent catalysts for electrochemical reduction of CO2 due to their high selectivity and low cost. However, it suffers from the problem of low Faradaic efficiency at high current density, which limits their further applications. In addition, the silver-based catalysts have good catalytic activity for the electrochemical reduction of CO2 to CO, but they can only achieve high selectivity under high overpotentials. The synergistic effect in the multi-component system provides a new idea for the design of efficient electrocatalysts for carbon dioxide reduction. Herein, we first elaborately design and prepare an ordered macro-/mesoporous nickel-nitrogen-doped carbon (Ni-N-OMMC) supported silver nanoparticles composite (Ag/Ni-N-OMMC) by the use of silica colloidal crystal as the hard template and triblock copolymer Pluronic F127 as the mesoporous structure-directing agent, and study the electrocatalytic CO2 reduction performance. Due to the confinement effect, the small silver nanoparticles are successfully loaded on the Ni-N-OMMC support by in-situ chemical reduction. Compared to Ni-N-OMMC, Ag/Ni-N-OMMC exhibits better electrocatalytic activity. The Faradaic efficiency of CO is as high as 98.7% when the potential is –0.7 V vs. reversible hydrogen electrode (RHE) in 0.1 mol•L–1 KHCO3 electrolyte. Moreover, Ag/Ni-N-OMMC has a wide operating voltage range with the Faradaic efficiency of CO over 90% at –0.7~ –1.0 V, and shows a high current density of CO (33.29 mA•cm–2) at –1.0 V. The excellent ECR performance of Ag/Ni-N-OMMC may be attributed to the synergistic effect between Ag nanoparticles and the Ni-N-OMMC support with abundant Ni-N x active sites, as well as the high specific surface area and efficient mass/charge transfer provided by the three-dimensional interconnected ordered macro-/mesoporous structure. This study provides an idea for future design and preparation of metal-carbon composite electrocatalysts with high activity and selectivity.

| [1] | Xiao, J.; Gao, M.-R.; Liu, S.-B.; Luo, J.-L. ACS Appl. Mater. Interfaces 2020, 12, 31431. |

| [2] | Jin, H.-D.; Xiong, L.-K.; Zhang, X.; Lian, Y.-B.; Chen, S.; Lu, Y.-T.; Deng, Z.; Peng, Y. Acta Phys.-Chim. Sin. 2021, 37, 2006017. (in Chinese) |

| [2] | (金惠东, 熊力堃, 张想, 连跃彬, 陈思, 陆永涛, 邓昭, 彭扬, 物理化学学报, 2021, 37, 2006017.) |

| [3] | Liu, S.-B.; Lu, X.-F.; Xiao, J.; Wang, X.; Lou, X.-W. Angew. Chem., Int. Ed. 2019, 58, 13828. |

| [4] | Wang, Y.-L.; Tian, Y.; Lang, Z.-L.; Guan, W.; Yan, L.-K. J. Mater. Chem. A 2018, 6, 21056. |

| [5] | Zhou, P.; Chao, Y.-G.; Lv, F.; Lai, J.-P.; Wang, K.; Guo, S.-J. Sci. Bull. 2020, 65, 720. |

| [6] | Shi, J.-F.; Jiang, Y.-J.; Jiang, Z.-Y.; Wang, X.-Y.; Wang, X.-L.; Zhang, S.-H.; Han, P.-P.; Yang, C. Chem. Soc. Rev. 2015, 44, 5981. |

| [7] | Du, C.-Y.; Chen, Y.-F. Acta Chim. Sinica 2020, 78, 938. (in Chinese) |

| [7] | (杜重阳, 陈耀峰, 化学学报, 2020, 78, 938.) |

| [8] | Song, B.; Qin, A.-J.; Tang, B.-Z. Acta Chim. Sinica 2020, 78, 9. (in Chinese) |

| [8] | (宋波, 秦安军, 唐本忠, 化学学报, 2020, 78, 9.) |

| [9] | Ma, Y.-N.; Shi, R.; Zhang, T.-R. Acta Chim. Sinica 2021, 79, 369. (in Chinese) |

| [9] | (马一宁, 施润, 张铁锐, 化学学报, 2021, 79, 369.) |

| [10] | Bushuyev, O. S.; De Luna, P.; Dinh, C. T.; Tao, L.; Saur, G.; van de Lagemaat, J.; Kelley, S. O.; Sargent, E. H. Joule 2018, 2, 825. |

| [11] | Peng, Z.-K.; Ding, H.-M.; Chen, R.-F.; Gao, C.; Wang, C. Acta Chim. Sinica 2019, 77, 681. (in Chinese) |

| [11] | (彭正康, 丁慧敏, 陈如凡, 高超, 汪成, 化学学报, 2019, 77, 681.) |

| [12] | Wang, Y.-X.; Cao, L.; Libretto, N. J.; Li, X.; Li, C.-Y.; Wan, Y.-D.; He, C.; Lee, J.; Gregg, J.; Zong, H.; Su, D.; Miller, J. T.; Mueller, T.; Wang, C. J. Am. Chem. Soc. 2019, 141, 16635. |

| [13] | Zhang, W.-J.; Hu, Y.; Ma, L.-B.; Zhu, G.-Y.; Wang, Y.-R.; Xue, X.-L.; Chen, R.-P.; Yang, S.-Y.; Jin, Z. Adv. Sci. 2018, 5, 1700275. |

| [14] | Chen, Q.; Kuang, Q.; Xie, Z.-X. Acta Chim. Sinica 2021, 79, 10. (in Chinese) |

| [14] | (陈钱, 匡勤, 谢兆雄, 化学学报, 2021, 79, 10.) |

| [15] | Wang, W.; Shang, L.; Chang, G.-J.; Tan, C.-Y.; Shi, R.; Zhao, Y.-X.; Waterhouse, G.; Yang, D.-J.; Zhang, T.-R. Adv. Mater. 2019, 31, 1808276. |

| [16] | Gu, J.; Hsu, C. S.; Bai, L.-C.; Chen, H.-M.; Hu, X.-L. Science 2019, 364, 1091. |

| [17] | Yan, C.-C.; Li, H.-B.; Ye, Y.-F.; Wu, H.-H.; Cai, F.; Si, R.; Xiao, J.-P.; Miao, S.; Xie, S.-H.; Yang, F.; Li, Y.-S.; Wang, G.-X.; Bao, X.-H. Energy Environ. Sci. 2018, 11, 1204. |

| [18] | Xu, C.-C.; Zhi, X.; Vasileff, A.; Wang, D.; Jin, B.; Jiao, Y.; Zheng, Y.; Qiao, S.-Z. Small Struct. 2021, 2, 2000058. |

| [19] | Ju, W.; Bagger, A.; Hao, G.-P.; Varela, A. S.; Sinev, I.; Bon, V.; Cuenya, B. R.; Kaskel, S.; Rossmeisl, J.; Strasser, P. Nat. Commun. 2017, 8, 944. |

| [20] | Jiang, K.; Siahrostami, S.; Zheng, T.-T.; Hu, Y.-F.; Hwang, S.; Stavitski, E.; Peng, Y.-D.; Dynes, J.; Gangisetty, M.; Su, D.; Attenkofer, K.; Wang, H.-T. Energy Environ. Sci. 2018, 11, 893. |

| [21] | Zhang, B.; Zhao, T.-J.; Feng, W.-J.; Liu, Y.-X.; Wang, H.-H.; Su, H.; Lv, L.-B.; Li, X.-H.; Chen, J.-S. Nano Res. 2018, 11, 2450. |

| [22] | Huang, X.-X.; Ma, Y.-J.; Zhi, L.-J. Acta Phys.-Chim. Sin. 2021, 37, 2011050. (in Chinese) |

| [22] | (黄小雄, 马英杰, 智林杰, 物理化学学报, 2021, 37, 2011050.) |

| [23] | Zhao, C.-M.; Dai, X.-Y.; Yao, T.; Chen, W.-X.; Wang, X.-Q.; Wang, J.; Yang, J.; Wei, S.-Q.; Wu, Y.-E.; Li, Y.-D. J. Am. Chem. Soc. 2017, 139, 8078. |

| [24] | Sun, M.-H.; Huang, S.-Z.; Chen, L.-H.; Li, Y.; Yang, X.-Y.; Yuan, Z.-Y.; Su, B.-L. Chem. Soc. Rev. 2016, 45, 3479. |

| [25] | Kou, W.; Zhang, Y.-X.; Dong, J.; Mu, C.-H.; Xu, L.-B. ACS Appl. Energy Mater. 2020, 3, 1875. |

| [26] | Shi, R.; Guo, J.-H.; Zhang, X.-R.; Waterhouse, G.; Han, Z.-J.; Zhao, Y.-X.; Shang, L.; Zhou, C.; Jiang, L.; Zhang, T.-R. Nat. Commun. 2020, 11, 3028. |

| [27] | Deng, W.-Y.; Zhang, L.; Dong, H.; Chang, X.-X.; Wang, T.; Gong, J.-L. Chem. Sci. 2018, 9, 6599. |

| [28] | Gao, D.-F.; Zhou, H.; Wang, J.; Miao, S.; Yang, F.; Wang, G.-X.; Wang, J.-G.; Bao, X.-H. J. Am. Chem. Soc. 2015, 137, 4288. |

| [29] | Back, S.; Yeom, M. S.; Jung, Y. ACS Catal. 2015, 5, 5089. |

| [30] | Salehi-Khojin, A.; Jhong, H. R. M.; Rosen, B. A.; Zhu, W.; Ma, S.; Kenis, P. J. A.; Masel, R. I. J. Phys. Chem. C 2013, 117, 1627. |

| [31] | Liu, H.-J.; Cui, W.-J.; Jin, L.-H.; Wang, C.-X.; Xia, Y.-Y. J. Mater. Chem. 2009, 19, 3661. |

| [32] | Fang, Y.-Y.; Dai, W.; Chen, L.; Ma, N. Mater. Lett. 2016, 174, 246. |

| [33] | Sun, T.-T.; Dong, J.; Huang, Y.; Ran, W.; Chen, J.-F.; Xu, L.-B. J. Mater. Chem. A 2018, 6, 12751. |

| [34] | Wu, J.-J.; Liu, M.-J.; Sharma, P.-P.; Yadav, R. M.; Ma, L.-L.; Yang, Y.-C.; Zou, X.-L.; Zhou, X.-D.; Vajtai, R.; Yakobson, B. I.; Lou, J.; Ajayan, P. M. Nano Lett. 2016, 16, 466. |

| [35] | Varela, A. S.; Ju, W.; Bagger, A.; Franco, P.; Rossmeisl, J.; Strasser, P. ACS Catal. 2019, 9, 7270. |

| [36] | Bokare, A. D.; Chikate, R. C.; Rode, C. V.; Paknikar, K. M. Appl. Catal., B 2008, 79, 270. |

| [37] | Zhang, H.; Wang, G.; Chen, D.; Lv, X.-J.; Li, J.-H. Chem. Mater. 2008, 20, 6543. |

| [38] | Pan, F.-P.; Li, B.-Y.; Deng, W.; Du, Z.-C.; Gang, Y.; Wang, G.-F.; Li, Y. Appl. Catal., B 2019, 252, 240. |

| [39] | Gao, S.; Lin, Y.; Jiao, X.-C.; Sun, Y.-F.; Luo, Q.-Q.; Zhang, W.-H.; Li, D.-Q.; Yang, J.-L.; Xie, Y. Nature 2016, 529, 68. |

| [40] | Liu, S.; Yang, H.-B.; Huang, X.; Liu, L.-H.; Cai, W.-Z.; Gao, J.-J.; Li, X.-N.; Zhang, T.; Huang, Y.-Q.; Liu, B. Adv. Funct. Mater. 2018, 28, 1800499. |

| [41] | Lu, P.-L.; Yang, Y.-J.; Yao, J.-N.; Wang, M.; Dipazir, S.; Yuan, M.-L.; Zhang, J.-X.; Wang, X.; Xie, Z.-J.; Zhang, G.-J. Appl. Catal., B 2019, 241, 113. |

/

| 〈 |

|

〉 |