Al-MOF基多级孔Al2O3固定化酶反应器的构筑及构效关系研究

收稿日期: 2021-08-16

网络出版日期: 2021-10-11

基金资助

国家自然科学基金(22003037); 国家自然科学基金(22173056); 陕西省教育厅重点实验室项目(20JS043); 商洛学院自然科学基金项目(19SKY003); 商洛学院自然科学基金项目(20SKY005); 商洛学院科研团队项目(20SCX01)

Construction and Structure-Activity Relationship of Immobilized Enzyme Reactor Based on Al-MOF-Derived Al2O3 with Hierarchical Structure

Received date: 2021-08-16

Online published: 2021-10-11

Supported by

National Natural Science Foundation of China(22003037); National Natural Science Foundation of China(22173056); Key Laboratory Project of Education Department of Shaanxi Province(20JS043); Natural Science Foundation Project(19SKY003); Natural Science Foundation Project(20SKY005); Scientific Research Team Project(20SCX01)

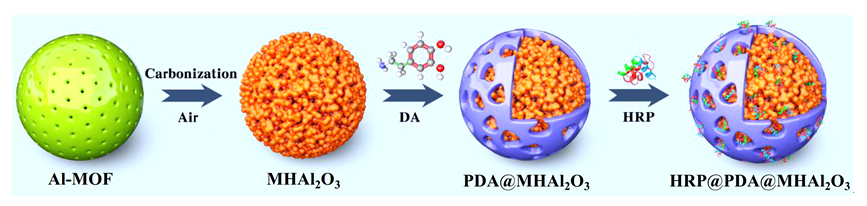

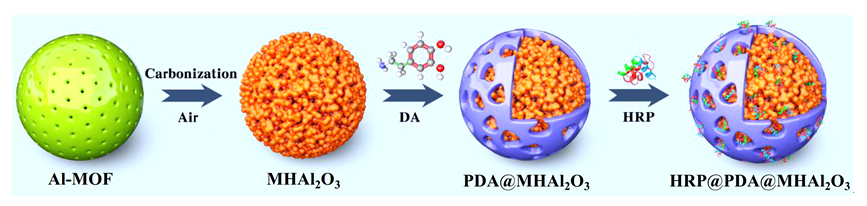

针对生物酶在固相载体负载后存在的催化活性与稳定性之间“此消彼长”的问题, 本工作采用“自牺牲模板”策略以铝基金属有机骨架材料(Al-MOF)为前驱体设计制备多级孔Al2O3 (MHAl2O3)材料, 再以“聚多巴胺(PDA)”仿生膜对材料表面进行功能化修饰后用以固载辣根过氧化物酶(HRP). 通过调节前驱体的煅烧温度来实现载体孔径大小的调控, 探讨了载体的孔道限域效应对固定化酶反应器催化活性的影响, 所得固定化酶反应器的热稳定性和重复使用性显著提高. 为了解析固定化酶反应器的构效关系, 采用酶动力学和热动力学参数研究了固定化酶反应器催化过程中酶与底物的相互作用, 结果表明固载后酶分子对底物的亲和性和专一性得到提升. 将固定化酶反应器用于模拟废水中苯胺黑药的催化降解时, 表现出非常高效的催化效率.

高霞 , 潘会宾 , 贺曾贤 , 杨柯 , 乔成芳 , 刘永亮 , 周春生 . Al-MOF基多级孔Al2O3固定化酶反应器的构筑及构效关系研究[J]. 化学学报, 2021 , 79(12) : 1502 -1510 . DOI: 10.6023/A21080385

Although enzyme catalysis has many advantages such as green, high efficiency and so on, the industrial application of enzyme is often hampered by a lack of long-term operational stability and difficult to re-use. These drawbacks can generally be overcome by immobilization of the enzyme on a solid carrier. However, the immobilized enzyme reactor often can not remain all the initial catalytic activity due to the enzyme shedding during reuse, change of conformation and the difficulty for substrates to access the active site of enzyme in the carrier, etc. The contradiction between catalytic activity and stability of biological enzyme molecules supported on solid phase carriers has become a bottleneck in the design and preparation of immobilized enzyme reactors. Therefore, it is a challenging task to construct an immobilized enzyme reactor with both high catalytic activity and high stability. In this work, aluminum-based metal-organic framework (Al-MOF)-derived hierarchical porous Al2O3 (MHAl2O3) was prepared by the self-sacrificial template strategy and functionally modified with “polydopamine (PDA)” bionic membrane for entrapping horseradate peroxidase (HRP). The pore size was regulated by changing the calcination temperature of precursor. The influence of channel confinement effect of the carrier on the catalytic activity of the enzyme reactor was discussed, and the thermal stability and reusability of the HRP@PDA@MHAl2O3 was significantly improved. After 1 h at 70 ℃, 98.5% of the catalytic activity of HRP@PDA@MHAl2O3 could be maintained. After 10 times of reuse, 90.9% of the catalytic activity was still maintained. In order to analyze the structure-activity relationship of the enzyme reactor, the interaction between enzyme and substrate in the reaction catalyzed by HRP@PDA@MHAl2O3 was studied by means of enzyme kinetics and thermodynamic parameters, which showed that the affinity and specificity of the enzyme to the substrate were improved. When the enzyme reactor was applied to the catalytic degradation of aniline aerofloat in simulated wastewater, the degradation rate of 40 mg•L-1 substrate in 30 min reached 82.7% under the best reaction conditions.

| [1] | Zhou, Y. G.; Mohamadi, R. M.; Poudineh, M.; Kermanshah, L.; Ahmed, S.; Safaei, T. S.; Stojcic, J.; Nam, R. K.; Sargent, E. H.; Kelley, S. O. Small 2016, 12, 727. |

| [2] | Chen, W.; Jin, B.; Hu, Y. L.; Lu, Y.; Xia, X. H. Small 2012, 8, 1001. |

| [3] | Cui, J. W.; He, S.; Dai, S.; Liu, L. Y.; Zhao, A.; Lu, L.; Yang, P.; Chen, J.; Huang, N. Chem. Eng. J. 2021, 424, 130392. |

| [4] | Cheng, H. P.; Hu, M. C.; Zhai, Q. G.; Li, S. N.; Jiang, Y. C. Chem. Eng. J. 2018, 347, 703. |

| [5] | Zhuang, W.; Quan, X. B.; Wang, Z. F.; Zhou, W. F.; Yang, P. P.; Ge, L.; Hernandez, B. V.; Wu, J. L.; Li, M.; Zhou, J.; Zhu, C. J.; Ying, H. J. Chem. Eng. J. 2020, 394, 125038. |

| [6] | Sankaran, R.; Show, P. L.; Chang, J. S. Biofuel. Bioprod. Bior. 2016, 10, 896. |

| [7] | Zhao, X. B.; Qi, F.; Yuan, C. L.; Du, W.; Liu, D. H. Renew. Sust. Energy Rev. 2015, 44, 182. |

| [8] | An, K. J.; Kwon, S. G.; Park, M.; Na, H. B.; Baik, S.; Yu, J. H.; Kim, D.; Son, J. S.; Kim, Y.W.; Song, I. C.; Moon, W. K.; Park, H. M.; Hyeon, T. Nano Lett. 2008, 8, 4252. |

| [9] | Xiong, S. L.; Zeng, H. C. Angew. Chem. Int. Ed. 2012, 51, 949. |

| [10] | Chen, J.; He, S. M.; Huang, B.; Zhang, L. Y.; Qiao, Z. Q.; Wang, J.; Yang, G. C.; Huang, H.; Hao, Q. L. Appl. Surf. Sci. 2018, 457, 508. |

| [11] | Journet, C.; Maser, W. K.; Bernier, P.; Loiseau, A.; Lamy de la Chapelle, M.; Lefrant, S.; Deniard, P.; Lee, R.; Fischer, J. E. Nature 1997, 388, 756. |

| [12] | Ishaq, S.; Tamime, R.; Bilad, M. R.; Khan, A. L. Sep. Purif. Technol. 2019, 210, 442. |

| [13] | Deng, Q.; Wang, R. Catal. Commun. 2019, 120, 11. |

| [14] | Zhang, W. Q.; Li, Q. Y.; Yang, X. Y.; Ma, Z.; Wang, H. H.; Wang, X. J. Acta Chim. Sinica 2017, 75, 80 (in Chinese). |

| [14] | ( 张文强, 李秋艳, 杨馨雨, 马征, 王欢欢, 王晓军, 化学学报, 2017, 75, 80.) |

| [15] | Small, L. J.; Hill, R. C.; Krumhansl, J. L.; Schindelholz, M. E.; Chen, Z.; Chapman, K. W.; Zhang, X.; Yang, S.; Schröder, M.; Nenoff, T. M. ACS Appl. Mater. Inter. 2019, 11, 27982. |

| [16] | Chang, Z.; Qiao, Y.; Yang, H. J.; Deng, H.; Zhu, X. Y.; He, P.; Zhou, H. S. Acta Chim. Sinica 2021, 79, 139 (in Chinese). |

| [16] | ( 常智, 乔羽, 杨慧军, 邓瀚, 朱星宇, 何平, 周豪慎, 化学学报, 2021, 79, 139.) |

| [17] | Wu, M. X.; Yang, Y. W. Adv. Mater. 2017, 29, 1606134. |

| [18] | Chen, X. R.; Tong, R. L.; Shi, Z. Q.; Yang, B.; Liu, H.; Ding, S. P.; Wang, X.; Lei, Q. F.; Wu, J.; Fang, W. J. ACS. Appl. Mater. Inter. 2018, 10, 2328. |

| [19] | Liu, Y.; Shao, X. X.; Kong, D. Q.; Li, G. Q.; Li, Q. S. Colloids Surf. B Biointerfaces 2021, 197, 111450. |

| [20] | Zhao, R. N.; Hu, M. C.; Li, S. N.; Zhai, Q. G.; Jiang, Y. C. Acta Chim. Sinica 2017, 75, 293 (in Chinese). |

| [20] | ( 赵睿南, 胡满成, 李淑妮, 翟全国, 蒋育澄, 化学学报, 2017, 75, 293.) |

| [21] | Nadar, S.; Rathod, V. K. Int. J. Biol. Macromol. 2018, 120, 2293. |

| [22] | Liu, X. P.; Yan, Z. Q.; Zhang, Y.; Liu, Z. W.; Sun, Y. H.; Ren, J. S.; Qu, X. G. ACS Nano 2019, 13, 5222. |

| [23] | Yao, X. F.; Li, Y. W. Chin. Sci. Bull. 2015, 60, 1906 (in Chinese). |

| [23] | ( 姚显芳, 李映伟, 科学通报, 2015, 60, 1906.) |

| [24] | Bhadra, B. N.; Vinu, A.; Serre, C.; Jhung, S. H. Mater. Today 2019, 25, 88. |

| [25] | Zhong, M.; Kong, L.; Li, N.; Liu, Y. Y.; Zhu, J.; Bu, X. H. Coord. Chem. Rev. 2019, 388, 172. |

| [26] | Salunkhe, R. R.; Kaneti, Y. V.; Yamauchi, Y. ACS Nano 2017, 11, 5293. |

| [27] | Wei, W. B.; Dong, S. Y.; Huang, G. Q.; Xie, Q.; Huang, T. L. Sens. Actuators B: Chem. 2018, 260, 189. |

| [28] | Xie, W.; Zhou, L. J.; Xu, J.; Guo, Q. L.; Jiang, F. L.; Liu, Y. Acta Phys.-Chim. Sin. 2020, 36, 1905051 (in Chinese). |

| [28] | ( 谢文, 周莲娇, 徐娟, 郭清莲, 蒋风雷, 刘义, 物理化学学报, 2020, 36, 1905051.) |

| [29] | Li, L.; Xiang, S. L.; Cao, S. Q.; Zhang, J. Y.; Ouyang, G. F.; Chen, L. P.; Su, C. Y. Nat. Commun. 2013, 4, 1774. |

| [30] | Chen, Y.; Xiao, Z.; Liu, Y.; Fan, L. Z. J. Mater. Chem. 2017, 5, 24178. |

| [31] | Gao, X.; Zhai, Q. G.; Hu, M. C.; Li, S. N.; Song, J.; Jiang, Y. C. J. Chem. Technol. Biot. 2019, 94, 1249. |

| [32] | Song, Y. C.; Hu, M. C.; Li, S. N.; Zhai, Q. G.; Jiang, Y. C. Chem. J. Chin. Univ. 2019, 40, 1805 (in Chinese). |

| [32] | ( 宋艺超, 胡满成, 李淑妮, 翟全国, 蒋育澄, 高等学校化学学报, 2019, 40, 1805.) |

| [33] | Yang, Y.; Wang, S.; Zhou, Z.; Zhang, R.; Shen, H.; Song, J.; Su, P.; Yang, Y. BioChem. Eng. J. 2018, 137, 108. |

| [34] | Cao, D. L.; Cheng, W. J.; Tao, K.; Liang, Y. X. Macromol. Res. 2018, 26, 616. |

| [35] | Xiang, L.; Xiao, T.; Mo, C. H.; Zhao, H. M.; Li, Y. W.; Li, H.; Cai, Q. Y.; Zhou, D. M.; Wong, M. H. Ecotoxicol. Environ. Saf. 2018, 154, 84. |

| [36] | Fu, P. F.; Ma, Y. H.; Lei, B. L.; Li, G.; Lin, X. F. Environ. Technol. 2021, 42, 659. |

| [37] | Gao, X.; Zhai, Q. G.; Hu, M. C.; Li, S. N.; Jiang, Y. C. Catal. Sci. Technol. 2021, 11, 2446. |

/

| 〈 |

|

〉 |