高性能无钴化钙钛矿型高熵氧化物负极材料的制备及储锂性能研究

收稿日期: 2023-02-23

网络出版日期: 2023-04-18

基金资助

安徽省自然科学基金(2008085ME125); 先进金属材料绿色制备与表面技术教育部重点实验室主任基金(GFST2022ZR08); 安徽省高校自然科学研究重点项目(KJ2020A0268)

Preparation and High-performance Lithium-ion Storage of Cobalt-free Perovskite High-entropy Oxide Anode Materials

Received date: 2023-02-23

Online published: 2023-04-18

Supported by

Natural Science Foundation of Anhui Province(2008085ME125); Director's Fund of Key Laboratory of Green Fabrication and Surface Technology of Advance Matal Materials, Ministry of Education(GFST2022ZR08); University Natural Science Research Project of Anhui Province in China(KJ2020A0268)

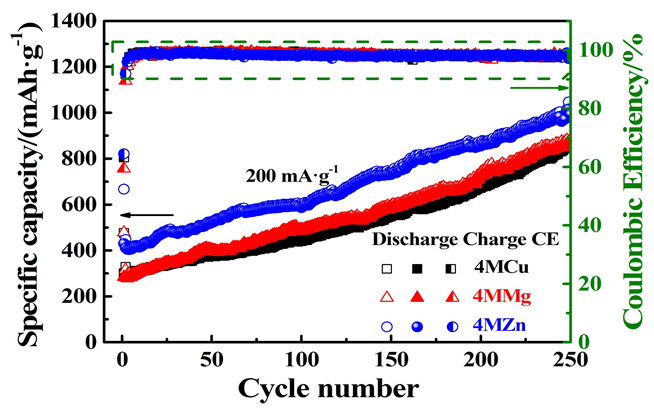

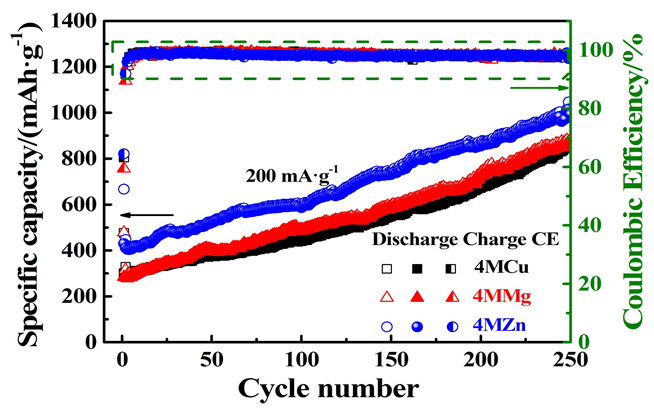

高熵氧化物由于独特的高熵效应、多主元协同效应和可定制的结构, 作为能量存储材料受到广泛地关注. 本研究采用金属硝酸盐为金属源, 甘氨酸为燃料, 通过溶液燃烧法成功合成了一系列无钴的钙钛矿型高熵氧化物La(Cr0.2Fe0.2Mn0.2Ni0.2M0.2)O3 (M=Cu, Mg, Zn)锂离子电池负极材料, 研究了粉体的微观结构和电化学性能. 结果表明: 所制备的钙钛矿型高熵氧化物La(Cr0.2Fe0.2Mn0.2Ni0.2M0.2)O3均为单相钙钛矿结构, 形貌为多孔网状且各组成元素分布均匀, 其中引入非活性元素Mg或活性元素Cu的高熵氧化物电化学性能相近; 无钴化La(Cr0.2Fe0.2Mn0.2Ni0.2Zn0.2)O3电极具有最高的比容量(200 mA•g−1电流密度下循环250圈后可逆比容量为1014 mAh•g−1)、优异的循环稳定性(1000 mA•g−1电流密度下循环1000圈后可逆比容量为450 mAh•g−1且几乎没有容量衰减)以及卓越的倍率性能(100 mA•g−1电流密度下可逆比容量为396 mAh•g−1, 3000 mA•g−1电流密度下可逆比容量为198 mAh•g−1, 容量保持率为47.9%). 电化学性能提升主要归因于活性元素Zn的加入可以在还原过程中形成Li-Zn合金使得电极比容量明显增加; 同时较高的比表面积、介孔结构以及丰富的表面氧空位使其具有较高的电导率(0.14 S•cm−1)、锂离子扩散系数(2.1×10−12 cm2•s−1)和较大的赝电容贡献率, 从而显著提升了材料的比容量和倍率性能. 因此, 引入能够与锂发生合金化反应的元素(如Zn)可以极大地提高电化学性能, 有利于为设计成本低廉、性能优异的无钴化高熵材料提供新的设计理念和思路.

贾洋刚 , 陈诗洁 , 邵霞 , 程婕 , 林娜 , 方道来 , 冒爱琴 , 李灿华 . 高性能无钴化钙钛矿型高熵氧化物负极材料的制备及储锂性能研究[J]. 化学学报, 2023 , 81(5) : 486 -495 . DOI: 10.6023/A23020046

High-entropy oxides (HEOs) have become increasingly popular as energy storage materials owing to their unique high-entropy effect, multi-principal synergy effect and customizable structure. In this study, a series of cobalt-free perovskite high-entropy oxide La(Cr0.2Fe0.2Mn0.2Ni0.2M0.2)O3 (M=Cu, Mg, Zn) lithium-ion battery anode materials were successfully synthesized by solution combustion method using metal nitrate as the metal source and glycine as the fuel. The microstructure and electrochemical properties of the as-prepared powders were investigated. The results show that the as-prepared high- entropy oxides crystalize into single-phase perovskite structure with porous foam-like shape and chemical/microstructural homogeneity. Furthermore, the as-prepared HEOs introducing inactive element Mg or active element Cu possess similar electrochemical performance; while the La(Cr0.2Fe0.2Mn0.2Ni0.2Zn0.2)O3 electrode exhibits a highest reversible capacity (1014 mAh•g−1 at 200 mA•g−1 after 250 cycles), excellent cycling stability (450 mAh•g−1 at 1000 mA•g−1 and almost no capacity decay after 1000 cycles) and outstanding rate performance. Such excellent performance can be attributed to the addition of active element Zn, which can form Li-Zn alloy during the reduction process that makes the specific capacity increase significantly. Meanwhile, its higher specific surface area, mesoporous structure and abundant surface oxygen vacancies result in higher conductivity (0.14 S•cm−1), increased larger lithium ion diffusion coefficient (2.1×10−12 cm2•s−1), and pseudo-capacitance contribution, thus significantly enhances the specific capacity and rate performance of the as-prepared material. Therefore, the introduction of electrochemically active metals, which can react with Li alloying, such as Zn, can improve the electrochemical performance, thereby providing ideas for designing cobalt-free HEOs with low-cost and excellent performance for energy storage.

| [1] | Liu, Y. Y.; Zhu, Y. Y.; Cui, Y. Nat. Energy 2019, 4, 540. |

| [2] | Zhang, H.; Wang, F.; Wang, Y.; Wei, H. W.; Zhang, W.; Cao, R.; Zheng, H. Q. J. Colloid Interface Sci. 2023, 631, 191. |

| [3] | Wei, S.; Wan, C. C.; Zhang, L. Y.; Liu, X. Y.; Tian, W. Y.; Su, J. H.; Cheng, W. J.; Wu, Y. Q. Chem. Eng. J. 2022, 429, 132242. |

| [4] | Casimir, A.; Zhang, H.; Ogoke, O.; Amine, J. C.; Lu, J.; Wu, G. Nano Energy 2016, 27, 359. |

| [5] | Wang, Y. T.; Jiang, N.; Pan, D. H.; Jiang, H.; Hu, Y. J.; Li, C. Z. Chem. Eng. J. 2022, 437, 135422. |

| [6] | Wang, X. L.; Liu, J.; Hu, Y. F.; Ma, R. G.; Wang, J. C. Sci. China Mater. 2022, 65, 1421. |

| [7] | Patra, J.; Nguyen, T. X.; Tsai, C. C.; Clemens, O.; Li, J.; Pal, P.; Chan, W. K.; Lee, C. H.; Chen, H. Y. T.; Ting, J. M.; Chang, J. K. Adv. Funct. Mater. 2022, 32, 2110992. |

| [8] | Nguyen, T. X.; Tsai, C.-C.; Patra, J.; Clemens, O.; Chang, J.-K.; Ting, J.-M. Chem. Eng. J. 2022, 430, 132658. |

| [9] | Fang, L.; Ding, X. L.; Song, Y.; Liu, D. M.; Li, Y. T.; Zhang, Q. A. Chem. J. Chinese Universities 2019, 40, 1456. (in Chinese) |

| [9] | (方亮, 丁晓丽, 宋云, 柳东明, 李永涛, 张庆安, 高等学校化学学报, 2019, 40, 1456.) |

| [10] | Nishikubo, T.; Sakai, Y.; Oka, K.; Mizumaki, M.; Watanuki, T.; Machida, A.; Maejima, N.; Ueda, S.; Mizokawa, T.; Azuma, M. Appl. Phys. Express 2018, 11, 61102. |

| [11] | Xu, Y.; Xu, X.; Bi, L. J. Adv. Ceram. 2022, 11, 794. |

| [12] | Zheng, Y.; Zou, M.; Zhang, W.; Yi, D.; Lan, J.; Nan, C. W.; Lin, Y. H. J. Adv. Ceram. 2021, 10, 377. |

| [13] | Xiang, H.; Xing, Y.; Dai, F.-Z.; Wang, H.; Su, L.; Miao, L.; Zhang, G.; Wang, Y.; Qi, X.; Yao, L.; Wang, H.; Zhao, B.; Li, J.; Zhou, Y. J. Adv. Ceram. 2021, 10, 385. |

| [14] | Zhang, W.; Zhao, B.; Xiang, H.; Dai, F.-Z.; Wu, S.; Zhou, Y. J. Adv. Ceram. 2021, 10, 62. |

| [15] | Yan, S.; Luo, S.; Yang, L.; Feng, J.; Li, P.; Wang, Q.; Zhang, Y.; Liu, X. J. Adv. Ceram. 2022, 11, 158. |

| [16] | Sarkar, A.; Velasco, L.; Wang, D.; Wang, Q. S.; Talasila, G.; Biasi, L. d.; Kübel, C.; Brezesinski, T.; Bhattacharya, S. S.; Hahn, H.; Breitung, B. Nat. Commun. 2018, 9, 3400. |

| [17] | Xiao, B.; Wu, G.; Wang, T. D.; Wei, Z. G.; Sui, Y. W.; Shen, B. L.; Qi, J. Q.; Wei, F. X.; Meng, Q. K.; Ren, Y. J.; Xue, X. L.; Zheng, J. C.; Mao, J.; Dai, K. H. Ceram. Int. 2021, 47, 33972. |

| [18] | Shao, X.; Jia, Y. G.; Cheng, J.; Fang, D. L.; Mao, A. Q.; Tan, J. Chin. J. Process Eng. 2022, DOI:10.12034/j.issn.1009-606X.222242. (in Chinese) |

| [18] | (邵霞, 贾洋刚, 程婕, 方道来, 冒爱琴, 檀杰, 过程工程学报, 2022, DOI:10.12034/j.issn.1009-606X.222242.) |

| [19] | Jia, Y. G.; Shao, X.; Cheng, J.; Wang, P. P.; Mao, A. Q. Chem. J. Chinese Universities 2022, 43, 157. (in Chinese) |

| [19] | (贾洋刚, 邵霞, 程婕, 王朋朋, 冒爱琴, 高等学校化学学报, 2022, 43, 157.) |

| [20] | Li, S.; Peng, Z. J.; Fu, X. L. J. Adv. Ceram. 2023, 12, 59. |

| [21] | Luo, X. F.; Patra, J.; Chuang, W. T.; Nguyen, T. X.; Ting, J. M.; Li, J.; Pao, C. W.; Chang, J. K. Adv. Sci. 2022, 9, 2201219. |

| [22] | Ghigna, P.; Airoldi, L.; Fracchia, M.; Callegari, D.; Anselmi- Tamburini, U.; D'Angelo, P.; Pianta, N.; Ruffo, R.; Cibin, G.; de Souza, D. O.; Quartarone, E. ACS Appl. Mater. Interfaces 2020, 12, 50344. |

| [23] | Guo, M.; Liu, Y. F.; Zhang, F. N.; Cheng, F. H.; Cheng, C. F.; Miao, Y.; Gao, F.; Yu, J. J. Adv. Ceram. 2022, 11, 742. |

| [24] | Liu, X. F.; Xing, Y. Y.; Xu, K.; Zhang, H. J.; Gong, M. X.; Jia, Q. L.; Zhang, S. W.; Lei, W. Small 2022, 18, 524. |

| [25] | Fang, D. L.; Zhao, Y. C.; Wang, S. S.; Hu, T. S.; Zheng, C. H. Electrochim. Acta 2020, 330, 135346. |

| [26] | Feng, D. Y.; Dong, Y. B.; Zhang, L. L.; Ge, X.; Zhang, W.; Dai, S.; Qiao, Z. A. Angew. Chem., Int. Ed. 2020, 59, 19503. |

| [27] | Zheng, Y.; Yi, Y. K.; Fan, M. H.; Liu, H. Y.; Li, X.; Zhang, R.; Li, M. T.; Qiao, Z. A. Energy Storage Mater. 2019, 23, 678. |

| [28] | Wang, Q.; Wu, Y. Z.; Pan, N.; Yang, C. Y.; Wu, S.; Li, D. J.; Gu, S. N.; Zhou, G. W.; Chai, J. L. Front. Chem. 2022, 10, 1052560. |

| [29] | Hu, Q. L.; Yue, B.; Shao, H. Y.; Yang, F.; Wang, J. H.; Wang, Y.; Liu, J. H. J. Alloys Compd. 2021, 852, 157002. |

| [30] | Wang, P. P.; Jia, Y. G.; Shao, X.; Cheng, J.; Mao, A. Q.; Tan, J.; Fang, D. L. CIESC J. 2022, 73, 5625. (in Chinese) |

| [30] | (王朋朋, 贾洋刚, 邵霞, 程婕, 冒爱琴, 檀杰, 方道来, 化工学报, 2022, 73, 5625.) |

| [31] | Tian, K. H.; Duan, C. Q.; Ma, Q.; Li, X. L.; Wang, Z. Y.; Sun, H. Y.; Luo, S. H.; Wang, D.; Liu, Y. G. Rare Met. 2021, 41, 1265. |

| [32] | Li, L.; Meng, T.; Wang, J.; Mao, B. G.; Huang, J. B.; Cao, M. H. ACS Appl. Mater. Interfaces 2021, 13, 24804. |

| [33] | Tang, Z. K.; Xue, Y. F.; Teobaldi, G.; Liu, L. M. Nanoscale Horiz. 2020, 5, 1453. |

| [34] | Duan, C. Q.; Tian, K. H.; Li, X. L.; Wang, D.; Sun, H. Y.; Zheng, R. G.; Wang, Z. Y.; Liu, Y. G. Ceram. Int. 2021, 47, 32025. |

| [35] | Xiang, H. Z.; Xie, H. X.; Chen, Y. X.; Zhang, H.; Mao, A. Q.; Zheng, C. H. J. Mater. Sci. 2021, 56, 8127. |

| [36] | Chchiyai, Z.; Hdidou, L.; Tayoury, M.; Chari, A.; Tamraoui, Y.; Alami, J.; Dahbi, M.; Manoun, B. J. Alloys Compd. 2023, 935, 167997. |

| [37] | Wang, K.; Hua, W. B.; Huang, X. H.; Stenzel, D.; Wang, J. B.; Ding, Z. M.; Cui, Y. Y.; Wang, Q. S.; Ehrenberg, H.; Breitung, B.; Kubel, C.; Mu, X. K. Nat. Commun. 2023, 14, 1487. |

| [38] | Xiao, B.; Wu, G.; Wang, T.; Wei, Z. G.; Xie, Z. L.; Sui, Y. W.; Qi, J. Q.; Wei, F. X.; Zhang, X. H.; Tang, L. B.; Zheng, J. C. ACS Appl. Mater. Interfaces 2023, 15, 2792. |

| [39] | Bi, W. C.; Zhang, L. F.; Chen, J.; Tian, R. X.; Huang, H.; Yao, M. Acta Chim. Sinica 2022, 80, 756. (in Chinese) |

| [39] | (毕文超, 张琳锋, 陈健, 田瑞雪, 黄昊, 姚曼, 化学学报, 2022, 80, 756.) |

| [40] | Kim, H.; Choi, W.; Yoon, J.; Um, J. H.; Lee, W.; Kim, J.; Cabana, J.; Yoon, W. S. Chem. Rev. 2020, 120, 6934. |

| [41] | Zhang, M.; Lei, X.; Lv, Y.; Liu, X.; Ding, Y. Chinese J. Chem. 2021, 39, 2801. |

| [42] | Sun, M.; Sheng, X. L.; Li, S. J.; Cui, Z. P.; Li, T.; Zhang, Q. Y.; Xie, F.; Wang, Y. Q. J. Alloys Compd. 2022, 926, 166809. |

| [43] | Nguyen, A. T.; Nguyen, T.-A.; Mittova, V. O.; Ngo, H. D.; Le, M. L. P.; Nguyen, D. Q.; Mittova, I. Y.; Nguyen, V. H.; Hiroshi, S.; Bui, H. T.; Nguyen, T. L. J. Mater. Sci.: Mater. Electron. 2022, 33, 19082. |

| [44] | Nguyen, A. T.; Phung, V. D.; Mittova, V. O.; Ngo, H. D.; Vo, T. N.; Thi, M. L. L.; Nguyen, V. H.; Mittova, I. Y.; Le, M. L. P.; Ahn, Y. N.; Kim, I. T.; Nguyen, T. L. Scr. Mater. 2022, 207, 114259. |

| [45] | Li, S. H.; Wang, X. H.; Shi, Z. M.; Wang, J.; Ji, G. J.; Yaer, X. Materials 2022, 15, 6929. |

| [46] | Li, H. Q.; Bin, Y.; Yang, S. H.; Fan, Y.; Hui, W. J.; Yin, W.; Hai, L. J. J. Alloys Compd. 2021, 852, 157002. |

| [47] | Yan, J. H.; Wang, D.; Zhang, X. Y.; Li, J. S.; Du, Q.; Liu, X. Y.; Zhang, J. R.; Qi, X. W. J. Mater. Sci. 2020, 55, 6942. |

| [48] | Xiang, H. Z.; Xie, H. X.; Li, W. C.; Liu, X. L.; Mao, A. Q.; Yu, H. Y. Chem. J. Chinese Universities 2020, 41, 1801. (in Chinese) |

| [48] | (项厚政, 谢鸿翔, 李文超, 刘晓磊, 冒爱琴, 俞海云, 高等学校化学学报, 2020, 41, 1801.) |

| [49] | Chen, H.; Qiu, N.; Wu, B. Z.; Yang, Z. M.; Sun, S.; Wang, Y. RSC Adv. 2020, 10, 9736. |

| [50] | Chen, H.; Qiu, N.; Wu, B. Z.; Yang, Z. M.; Sun, S.; Wang, Y. RSC Adv. 2019, 9, 28908. |

| [51] | Shen, L. F.; Lv, H. F.; Chen, S. Q.; Kopold, P.; Aken, P. A. v.; Wu, X. J.; Maier, J.; Yu, Y. Adv. Mater. 2017, 29, 142. |

| [52] | Augustyn, V.; Come, J.; Lowe, M. A.; Kim, J. W.; Taberna, P.-L.; Tolbert, S. H.; Abru?a, H. D.; Simon, P.; Dunn, B. Nat. Mater. 2013, 12, 518. |

| [53] | Shi, A. D.; Chen, S.; Zheng, S. S.; Wang, Z. L. Acta Chim. Sinica 2021, 79, 1511. (in Chinese) |

| [53] | (史傲迪, 陈思, 郑淞生, 王兆林, 化学学报, 2021, 79, 1511.) |

| [54] | Lv, H. L.; Wang, X. J.; Yu, Y.; Tao, L.; Zhang, L. Y. Acta Phys.- Chim. Sin. 2023, 39, 10014. |

| [55] | Chou, S. L.; Wang, J. Z.; Liu, H. K.; Dou, S. X. J. Phys. Chem. C 2011, 115, 16220. |

| [56] | Du, X. Y.; Wen, H.; Zhang, X. D.; Yue, Y. Z.; Hong, L.; Zhang, X. G.; Min, D. D.; Gea, X. X.; Yi, D. J. Mater. Chem. 2012, 22, 5960. |

| [57] | Wang, J. B.; Cui, Y. Y.; Wang, Q. S.; Wang, K.; Huang, X. H.; Stenzel, D.; Sarkar, A.; Azmi, R.; Bergfeldt, T.; Bhattacharya, S. S.; Kruk, R.; Hahn, H.; Schweidler, S.; Brezesinski, T.; Breitung, B. Sci. Rep. 2020, 10, 18430. |

| [58] | Castelli, G. F.; D?rfler, W. Comput. Math. Appl. 2019, 77, 1527. |

| [59] | Li, T. X.; Li, D. L.; Zhang, Q. B.; Gao, J. H.; Kong, X. Z.; Fan, X. Y.; Gou, L. Acta Chim. Sinica 2021, 79, 678. (in Chinese) |

| [59] | (李童心, 李东林, 张清波, 高建行, 孔祥泽, 樊小勇, 苟蕾, 化学学报, 2021, 79, 678.) |

| [60] | Fan, X. Y.; Zhang, S.; Zhu, Y. Q.; Jing, M. S.; Wang, K. X.; Zhang, L. L.; Li, J. L.; Xu, L.; Gou, L.; Li, D. L. Acta Chim. Sinica 2022, 80, 517. (in Chinese) |

| [60] | (樊小勇, 张帅, 朱永强, 敬茂森, 王凯鑫, 张露露, 李巨龙, 许磊, 苟蕾, 李东林, 化学学报, 2022, 80, 517.) |

| [61] | Liang, S. S.; Kang, S. S.; Yang, D.; Hu, J. H. Acta Chim. Sinica 2022, 80, 1264. (in Chinese) |

| [61] | (梁世硕, 康树森, 杨东, 胡建华, 化学学报, 2022, 80, 1264.) |

| [62] | Xiao, B.; Wu, G.; Wang, T.; Wei, Z.; Sui, Y.; Shen, B.; Qi, J.; Wei, F.; Zheng, J. Nano Energy 2022, 95, 106962. |

/

| 〈 |

|

〉 |