离子聚合原位固态化构建高安全锂电池固态聚合物电解质的研究进展★

收稿日期: 2023-03-20

网络出版日期: 2023-05-26

基金资助

项目受国家自然科学基金(52073298); 项目受国家自然科学基金(52273221); 中国科学院青年创新促进会(2020217); 江苏省高效电化学储能技术重点实验室开放课题基金(EEST2022-1)

Research Progress of Ion-initiated in situ Generated Solid Polymer Electrolytes for High-safety Lithium Batteries★

Received date: 2023-03-20

Online published: 2023-05-26

Supported by

National Natural Science Foundation of China(52073298); National Natural Science Foundation of China(52273221); Youth Innovation Promotion Association of Chinese Academy of Sciences(2020217); Open Fund of Jiangsu Key Laboratory of Electrochemical Energy Storage Technologies(EEST2022-1)

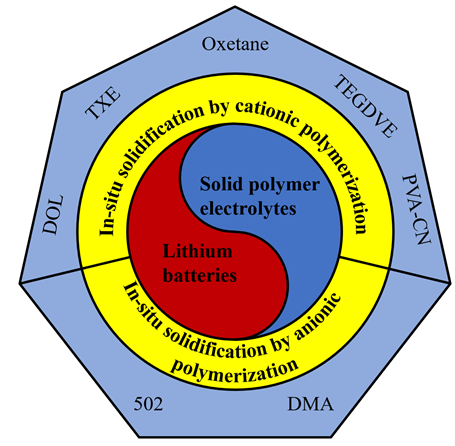

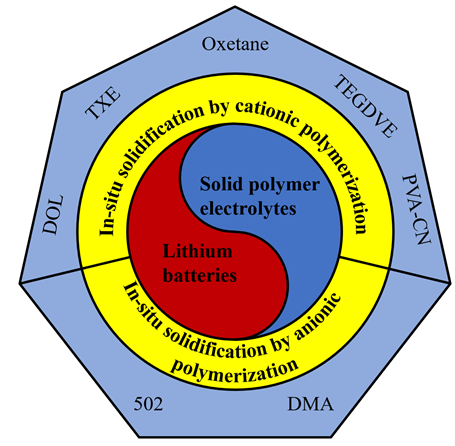

锂离子电池已经广泛应用于电动汽车、移动智能设备、大规模储能等国民经济的诸多方面, 并逐步向深海、深空、深地、单兵作战装备等特种应用领域进军. 然而采用传统碳酸酯液态电解液的锂电池普遍存在易泄露、易燃烧、易爆炸等潜在安全隐患, 因此亟待开发高安全的固态电解质. 固态聚合物电解质因其优越的机械韧性, 以及可以有效兼容现有锂电池生产工艺等优点而受到极大关注. 具体到制备工艺方面, 溶液铸膜法等非原位技术制备的固态聚合物电解质因其与正负极之间存在不良固/固接触, 导致产生较高的界面阻抗进而恶化电池性能; 相比较而言, 采用原位固态化制备技术, 则有利于液态前驱体充分润湿正负极进而保证良好的界面稳定性和高效离子传输. 然而, 目前大多数原位固态化技术是自由基热聚合需要加入额外引发剂且需要高温等苛刻条件; 而离子聚合则具有巨大优势, 其可以在室温条件下以锂盐或锂金属等作为引发剂进而有效避免杂质引入. 截至目前离子聚合原位固态化构建高安全锂电池固态聚合物电解质已取得相当大的研究进展, 因此本文从阳离子聚合和阴离子聚合两方面对原位固态化构建的固态聚合物电解质进行系统阐述, 并在文末对离子聚合原位固态化策略构建高安全锂电池固态聚合物电解质所存在的挑战和未来发展趋势进行了详细论述.

苑志祥 , 张浩 , 胡思伽 , 张波涛 , 张建军 , 崔光磊 . 离子聚合原位固态化构建高安全锂电池固态聚合物电解质的研究进展★[J]. 化学学报, 2023 , 81(8) : 1064 -1080 . DOI: 10.6023/A23030085

Lithium-ion batteries, widely used in many aspects of the national economy such as electric vehicles, mobile intelligent devices and large-scale energy storage, have gradually entered special applications area including deep sea, deep space, deep ground and individual combat equipment. However, lithium batteries using traditional carbonate liquid electrolytes often suffer from potential safety risk such as electrolyte leakage, flammability and explosion, so it is urgent to develop a new generation of high-safety solid electrolytes. Among them, solid polymer electrolytes have attracted great attention because of their superior mechanical flexibility and compatibility with the main production processes of lithium battery. In terms of preparation process, solid polymer electrolytes prepared via solution-casting often easily lead to high interfacial resistance and then deteriorate the battery performance. In contrast, liquid organic precursors used in in-situ polymerization strategy can sufficiently penetrate the positive and negative electrodes to guarantee superior interfacial compatibility and efficient ionic conduction. At present, most of in-situ polymerization strategies are based on free radical thermal polymerization with additional initiators and the need for harsh conditions such as high temperature. Ion polymerization can use lithium salt or lithium metal as an initiator at room temperature, thereby effectively avoiding the introduction of impurities. Up to now, researchers have made considerable research progress in the construction of solid polymer electrolytes by ion-initiated in situ polymerization. Hence, this review mainly summarizes the research progress of solid polymer electrolytes from the aspects of cationic polymerization and anionic polymerization. In addition, we also elaborates the challenges and development trends of solid polymer electrolytes through ion-initiated in situ polymerization for high-safety lithium batteries in the future.

| [1] | Zheng Q.; Jiang L.-X.; Xu Y.-J.; Gao S.; Liu T.; Qu C.; Chen H.-S.; Li X.-F. Bull. Chin. Acad. Sci. 2022, 37, 529. (in Chinese) |

| [1] | ( 郑琼, 江丽霞, 徐玉杰, 高嵩, 刘涛, 曲超, 陈海生, 李先锋, 中国科学院院刊, 2022, 37, 529.) |

| [2] | Tu Z. Y.; Zachman M. J.; Choudhury S.; Wei S. Y.; Ma L.; Yang Y.; Kourkoutis L. F.; Archer L. A. Adv. Energy Mater. 2017, 7, 9. |

| [3] | Zhang W.; Yu H. C.; Wu L. J.; Liu H.; Abdellahi A.; Qiu B.; Bai J. M.; Orvananos B.; Strobridge F. C.; Zhou X. F.; Liu Z. P.; Ceder G.; Zhu Y. M.; Thornton K.; Grey C. P.; Wang F. Sci. Adv. 2018, 4, 11. |

| [4] | Holoubek J.; Yu M. Y.; Yu S. C.; Li M. Q.; Wu Z. H.; Xia D. W.; Bhaladhare P.; Gonzalez M. S.; Pascal T. A.; Liu P.; Chen Z. ACS Energy Lett. 2020, 5, 1438. |

| [5] | Cheng X. B.; Zhao C. Z.; Yao Y. X.; Liu H.; Zhang Q. Chem 2019, 5, 74. |

| [6] | Liu J.; Xu J.-Y.; Lin Y.; Li J.; Lai Y.-Q.; Yuan C.-F.; Zhang J.; Zhu K. Acta Chim. Sinica 2013, 71, 869. (in Chinese) |

| [6] | ( 刘晋, 徐俊毅, 林月, 李劼, 赖延清, 袁长福, 张锦, 朱凯, 化学学报, 2013, 71, 869.) |

| [7] | Jaumaux P.; Liu Q.; Zhou D.; Xu X. F.; Wang T. Y.; Wang Y. Z.; Kang F. Y.; Li B. H.; Wang G. X. Angew. Chem., Int. Ed. 2020, 59, 9134. |

| [8] | Yabuuchi N. Chem. Lett. 2017, 46, 412. |

| [9] | Lee H.; Oh P.; Kim J.; Cha H.; Chae S.; Lee S.; Cho J. Adv. Mater. 2019, 31, 1900376. |

| [10] | Zheng B.-Z.; Wang H.-C.; Ma J.-L.; Gong Z.-L.; Yang Y. Sci. Sinica Chim. 2017, 47, 579. (in Chinese) |

| [10] | ( 郑碧珠, 王红春, 马嘉林, 龚正良, 杨勇, 中国科学:化学, 2017, 47, 579.) |

| [11] | Zhang J.-J.; Yang J.-F.; Wu H.; Zhang M.; Liu T.-T.; Zhang J.-N.; Dong S.-M.; Cui G.-L. Acta Polym. Sinica 2019, 50, 890. (in Chinese) |

| [11] | ( 张建军, 杨金凤, 吴瀚, 张敏, 刘亭亭, 张津宁, 董杉木, 崔光磊, 高分子学报, 2019, 50, 890.) |

| [12] | Yao P. H.; Yu H. B.; Ding Z. Y.; Liu P. C.; Lu J.; Lavorgna M.; Wu J. W.; Liu X. J. Front. Chem. 2019, 7, 17. |

| [13] | Shi X. J.; Ma N. Y.; Wu Y. X.; Lu Y. H.; Xiao Q. Z.; Li Z. H.; Lei G. T. Solid State Ionics 2018, 325, 112. |

| [14] | Liu T. T.; Zhang J. J.; Han W.; Zhang J. N.; Ding G. L.; Dong S. M.; Cui G. L. J. Electrochem. Soc. 2020, 167, 9. |

| [15] | Li W.-T.; Zhong H.; Mai Y.-H. Prog. Chem. 2021, 33, 988. (in Chinese) |

| [15] | ( 李文涛, 钟海, 麦耀华, 化学进展, 2021, 33, 988.) |

| [16] | Vijayakumar V.; Anothumakkool B.; Kurungot S.; Winter M.; Nair J. R. Energy Environ. Sci. 2021, 14, 2708. |

| [17] | Hamrahjoo M.; Hadad S.; Dehghani E.; Salami-Kalajahi M.; Roghani-Mamaqani H. Eur. Polym. J. 2022, 173, 14. |

| [18] | Ouyang H.; Min S.; Yi J.; Liu X. Y.; Ning F. H.; Xu Y.; Jiang Y.; Zhao B.; Zhang J. J. ACS Appl. Mater. Interfaces 2022, 14, 53648. |

| [19] | Lin Z. Y.; Guo X. W.; Wang Z. C.; Wang B. Y.; He S. M.; O'Dell L. A.; Huang J.; Li H.; Yu H. J.; Chen L. Q. Nano Energy 2020, 73, 9. |

| [20] | Li H. P.; Xu Z. X.; Yang J.; Wang J. L.; Hirano S. I. Sustainable Energy Fuels 2020, 4, 5469. |

| [21] | Okada M.; Yamashita Y.; Ishii Y. Makromol. Chem. 1964, 80, 196. |

| [22] | Zhao Q.; Liu X.; Stalin S.; Khan K.; Archer L. A. Nat. Energy. 2019, 4, 365. |

| [23] | Chen D. L.; Zhu M.; Kang P. B.; Zhu T.; Yuan H. C.; Lan J. L.; Yang X. P.; Sui G. Adv. Sci. 2022, 9, e2103663. |

| [24] | Geng Z.; Huang Y. L.; Sun G. C.; Chen R. S.; Cao W. Z.; Zheng J. Y.; Li H. Nano Energy 2022, 91, 106679. |

| [25] | Zhao C. Z.; Zhao Q.; Liu X.; Zheng J.; Stalin S.; Zhang Q.; Archer L. A. Adv. Mater. 2020, 32, e1905629. |

| [26] | Ma Q.; Yue J.; Fan M.; Tan S. J.; Zhang J.; Wang W. P.; Liu Y.; Tian Y. F.; Xu Q.; Yin Y. X.; You Y.; Luo A.; Xin S.; Wu X. W.; Guo Y. G. Angew. Chem., Int. Ed. 2021, 60, 16554. |

| [27] | Xiang J. W.; Zhang Y.; Zhang B.; Yuan L. X.; Liu X. T.; Cheng Z. X.; Yang Y.; Zhang X. X.; Li Z.; Shen Y.; Jiang J. J.; Huang, Y H. Energy Environ. Sci. 2021, 14, 3510. |

| [28] | Yu J.; Lin X. D.; Liu J. P.; Yu J. T. T.; Robson M. J.; Zhou G. D.; Law H. M.; Wang H. R.; Tang B. Z.; Ciucci F. Adv. Energy Mater. 2022, 12, 2102932. |

| [29] | Chen Y.; Huo F.; Chen S. M.; Cai W. B.; Zhang S. J. Adv. Funct. Mater. 2021, 31, 2102347. |

| [30] | Xu G. Y.; Kushima A.; Yuan J. R.; Dou H.; Xue W. J.; Zhang X. G.; Yan X. H.; Li J. Energy Environ. Sci. 2017, 10, 2544. |

| [31] | Liu F. Q.; Wang W. P.; Yin Y. X.; Zhang S. F.; Shi J. L.; Wang L.; Zhang X. D.; Zheng Y.; Zhou J. J.; Li L.; Guo Y. G. Sci. Adv. 2018, 4, 9. |

| [32] | Li M. J.; Yang J. X.; Shi Y. Q.; Chen Z. F.; Bai P. X.; Su H.; Xiong P. X.; Cheng M. R.; Zhao J. W.; Xu Y. H. Adv. Mater. 2022, 34, e2107226. |

| [33] | Wu H.; Tang B.; Du X. F.; Zhang J. J.; Yu X. R.; Wang Y. T.; Ma J.; Zhou Q.; Zhao J. W.; Dong S. M.; Xu G. J.; Zhang J. N.; Xu H.; Cui G. L.; Chen L. Q. Adv. Sci. 2020, 7, 2003370. |

| [34] | Zhang J. N.; Wu H.; Du X. F.; Zhang H.; Huang L.; Sun F.; Liu T. T.; Tian S. W.; Zhou L. X.; Hu S. J.; Yuan Z. X.; Zhang B. T.; Zhang J. J.; Cui G. L. Adv. Energy Mater. 2023, 13, 2202529. |

| [35] | Zhang K.; Wu F.; Wang X. R.; Zheng L. M.; Yang X. Y.; Zhao H. C.; Sun Y. H.; Zhao W. B.; Bai Y.; Wu C. Adv. Funct. Mater. 2021, 32, 2107764. |

| [36] | Hwang S. S.; Cho C. G.; Kim H. Electrochem. Commun. 2010, 12, 916. |

| [37] | Zhou D.; He Y. B.; Liu R. L.; Liu M.; Du H. D.; Li B. H.; Cai Q.; Yang Q. H.; Kang F. Y. Adv. Energy Mater. 2015, 5, 1500353. |

| [38] | Cui Y. Y.; Chai J. C.; Du H. P.; Duan Y. L.; Xie G. W.; Liu Z. H.; Cui G. L. ACS Appl. Mater. Interfaces 2017, 9, 8737. |

| [39] | Guo D.; Shinde D. B.; Shin W.; Abou-Hamad E.; Emwas A. H.; Lai Z. P.; Manthiram A. Adv. Mater. 2022, 34, 2201410. |

/

| 〈 |

|

〉 |