铜掺杂氮化碳电催化硝酸盐产氨性能研究

收稿日期: 2023-11-21

网络出版日期: 2024-02-21

基金资助

景德镇市级科技计划项目(20234NY006); 景德镇市级科技计划项目(20234SF009); 景德镇陶瓷大学研究生创新创业项目(JYC202312); 与大学本科生创新项目(X202310408145); 与大学本科生创新项目(X202310408140)

Study on Performance of Copper Doped Carbon Nitride Electrocatalyzing Nitrate to Produce Ammonia

Received date: 2023-11-21

Online published: 2024-02-21

Supported by

Jingdezhen municipal Science and Technology program projects(20234NY006); Jingdezhen municipal Science and Technology program projects(20234SF009); Jingdezhen Ceramic University graduate innovation and entrepreneurship project(JYC202312); Undergraduate innovation program(X202310408145); Undergraduate innovation program(X202310408140)

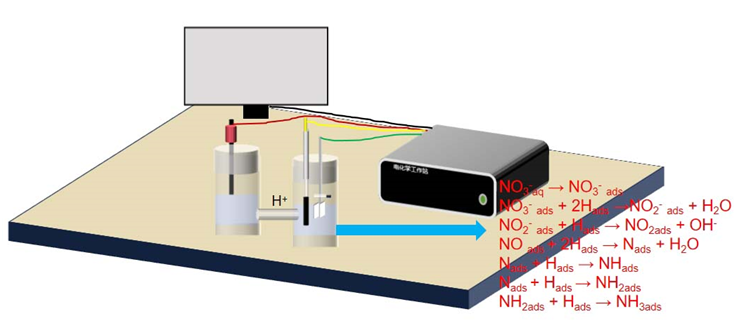

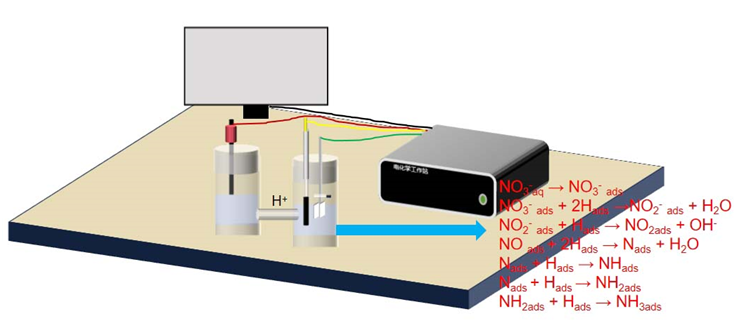

NH3是硝酸盐还原产物之一, 不仅在工业中需要大量应用, 在清洁生产过程中也是一种非常有前途的能源载体, 现有的哈伯-博施(Haber-Bosch)工艺生产NH3会对大气环境造成危害, 而电催化法由于便捷、安全且能够在常温和常压下催化合成NH3成为最近研究的热点. 本实验以3-氨基-1,2,4三唑为前驱体, 利用热解法先合成C3N5, 再通过调控铜元素的比例在煅烧条件下合成Cu-C3N5, 合成一系列材料形貌、晶体构相、化学价态存在差异的C3N5基催化剂, 并评价这些催化剂的电化学性能以及电催化硝酸盐还原产氨性能, 通过在0.1 mol/L KOH+0.1 mol/L KNO3混合电解液中进行1 h电解实验后发现, 氨气产量和法拉第效率可以达到0.541 mmol•h−1•mgcat−1和87.79%, 远远高于C3N5, 且该催化剂在循环试验和长时间实验中具有良好的活性和稳定性, 表明在电催化硝酸盐领域中具有一定的研究价值.

韩晶 , 廖润华 , 邓文强 , 梁博宇 , 周雨晴 , 任帅 , 洪燕 . 铜掺杂氮化碳电催化硝酸盐产氨性能研究[J]. 化学学报, 2024 , 82(3) : 295 -302 . DOI: 10.6023/A23110508

As the increasing demand for ammonia in other industries such as energy, the ammonia production now available can no longer meet the needs of industrial production, and the existing Haber-Bosch process for the production of NH3 will cause harm to the atmospheric environment. Therefore, there is an urgent need to find a new method that is compatible with or can replace the existing ammonia production process. Nitrate wastewater contains a large amount of nitrogen, and NH3 is one of the nitrate reduction products, the reduction of nitrate into ammonia can not only reduce the environmental pollution of nitrate nitrogen, but also alleviate the industrial demand for ammonia, nitrate wastewater treatment methods are generally physical, chemical and biological, but there are shortcomings of long cycle time and high cost. The electrocatalytic method is convenient, safe and can catalyze the synthesis of NH3 at room temperature and pressure, which makes the electrocatalytic synthesis of NH3 become a hot research topic in recent years. In this experiment, 3-amino-1,2,4-triazole was loaded into alumina crucible and used as the precursor to synthesize C3N5 by pyrolysis method in Muffle furnace, and then Cu-C3N5 was synthesized under calcination conditions by modulating the ratio of copper elements, which resulted in a series of C3N5-based catalysts with differences in material morphology, crystal conformation, and chemical valence state, including five catalysts of different proportions were synthesized. These catalysts were tested, then their electrochemical performance and electrocatalytic reduction of nitrate to produce ammonia performance were evaluated, and it was found that the ammonia yield and Faraday efficiency could reach 0.541 mmol•h−1•mgcat−1 and 87.79% by 1 h electrolysis experiments in a mixed electrolyte solution of 0.1 mol/L KOH+0.1 mol/L KNO3, which are much higher than that of C3N5, and the catalyst has good activity and stability in cyclic and long time experiments, indicating that it has some research value in the field of electrocatalytic nitrate.

| [1] | Lee, W. S.; Zhou, K. J.; Hepting, M. Nat. Phys. 2020, 17, 53. |

| [2] | Liu, H.; Lang, X.; Zhu, C. Angew. Chem. Int. Ed. 2022, 61, e202202556. |

| [3] | Hu, Q.; Qin, Y.; Wang, X. CCS Chem. 2022, 4, 2053. |

| [4] | Wang, J. H.; Wang, S.; Tong, X. H. J. Shaanxi University Sci. Tec. 2017, 35, 34 (in Chinese). |

| [4] | (王家宏, 王思, 童新豪, 陕西科技大学学报, 2017, 35, 34.) |

| [5] | MacFarlane, D. R.; Cherepanov, P. V.; Choi, J. Joule 2020, 4, 1186. |

| [6] | Clark, C. A.; Reddy, C. P.; Xu, H. ACS Catal. 2019, 10, 494. |

| [7] | Li, M. M.S. Thesis, China University of Petroleum (East China), Qingdao, 2014 (in Chinese). |

| [7] | (李猛, 硕士论文, 中国石油大学(华东), 青岛, 2014.) |

| [8] | Gu, L.; Kuang, M.; Chen, J. Chinese J. Struc. Chem. 2023, 42, 100067. |

| [9] | Wu, Z. Y.; Song, Y. H.; Liu, Y. B. Chem. Catalysis 2023, 3, 100786. |

| [10] | Hong, Q. L.; Zhou, J.; Zhai, Q. G. Chem. Commun. 2021, 57, 11621. |

| [11] | Cheng, J.; Sun, W.; Dai, G. Fuel 2023, 332. |

| [12] | Xu, D.; Li, Y.; Yin, L. Front. Environ. Sci. Eng. 2018, 12, 9. |

| [13] | Theerthagiri, J.; Park, J.; Das, H. T. Environ. Chem. Lett. 2022, 20, 2929. |

| [14] | Dai, C. C.; Sun, Y. M.; Chen, G. Angew. Chem. Int. Ed. 2020, 59, 9418. |

| [15] | Long, J.; Chen, S. M.; Zhang, Y. L. Angew. Chem. Int. Ed. 2020, 59, 9711. |

| [16] | Chen, D.; Zhang, S. C.; Bu, X. M. Nano Energy 2022, 98. |

| [17] | Niu, Z. D.; Fan, S. Y.; Li, X. Y. ACS Appl. Energy Mater. 2022, 5, 3339. |

| [18] | Chen, G. F.; Yuan, Y. F.; Jiang, H. F. Nat. Energy. 2020, 5, 605. |

| [19] | Dima, G. E.; Beltramo, G. L.; Koper, M. T. M. Electrochim. Acta 2005, 50, 4318. |

| [20] | Zhao, H.; Wang, F. D.; Qian, G. L. Ind. Water Treat. 2024, 44, 60 (in Chinese). |

| [20] | (赵慧, 王富东, 钱光磊, 工业水处理, 2024, 44, 60.) |

| [21] | Reyter, D.; Chamoulaud, G.; Bélanger, D. J. Electroanal. Chem. 2006, 596, 13. |

| [22] | Fu, X. B.; Zhao, X. G.; Hu, X. B. Appl. Mater. Today. 2020, 19. |

| [23] | Wang, X. D.; Zhu, M. Q.; Zeng, G. S. Nanoscale 2020, 12, 9385. |

| [24] | Sun, J.; Alam, D.; Daiyan, R. Energy Environ. Sci. 2021, 14, 865. |

| [25] | Wang, Y. T.; Zhou, W.; Jia, R. R. Angew. Chem. Int. Ed. 2020, 59, 5350. |

| [26] | Zou, Y. J.; Xiao, K.; Qin, Q. ACS Nano 2021, 15, 6551. |

| [27] | Liu, T. Y.; Yang, G. J.; Wang, W. Environ. Res. 2020, 188, 109741. |

| [28] | Li, K.; Cai, W.; Zhang, Z. C. Chem. Eng. J. 2022, 435, 135017. |

| [29] | Bai, J. L.; Yang, B. S.; Liu, B. Shanxi Daxue Xuebao, Ziran Kexueban 2022, 45, 1319 (in Chinese). |

| [29] | (白惊雷, 杨斌盛, 刘斌, 山西大学学报(自然科学版), 2022, 45, 1319.) |

| [30] | Ma, C.; Yu, Z. G.;, J. Wei, J. J.. Appl. Catal. B 2022, 319. |

| [31] | Nam, K. B.; Lee, S. H.; Hong, S. C. Appl. Surf. Sci. 2021, 544. |

| [32] | Feng, W. H, ; Fang, J. Z.; Zhou, G. Y. Mol. Catal. 2017, 434, 69. |

| [33] | Li, X. W.; Wang, B.; Yin, W. X. Acta Phys.-Chim. Sin. 2020, 36, 1902001. |

| [34] | Wang, B. M.S. Thesis, Shanxi University, Taiyuan, 2021 (in Chinese). |

| [34] | (王波, 杨斌盛, 刘斌, 硕士论文, 山西大学, 太原, 2021.) |

| [35] | Song, T. L.; Zou, M. S.; Lu, D. F. Textbook of X-ray Photoelectron Spectroscopy Data Analysis, Beijing Institute of Technology Press, Beijing, 2022, p. 468 (in Chinese). |

| [35] | (宋廷鲁, 邹美帅, 鲁德凤, X射线光电子能谱数据分析, 北京理工大学出版社, 北京(自然科学版), 2022, p. 468.) |

| [36] | Yu, K. Q. M.S. Thesis, Jilin University, Changchun, 2023 (in Chinese). |

| [36] | (于凯强, 硕士论文, 吉林大学, 长春(自然科学版), 2023.) |

| [37] | Lin, Y. X.; Zhang, S. N.; Xue, Z. H. Nat. Commun. 2019, 10, 4380. |

| [38] | Liu, S. Y. M.S. Thesis, Inner Mongolia University, Hohhot, 2022 (in Chinese). |

| [38] | (刘思媛, 硕士论文, 内蒙古大学, 呼和浩特, 2022.) |

/

| 〈 |

|

〉 |