用于生物大分子药物胞内递送的多重刺激响应型微凝胶载体

收稿日期: 2024-04-10

网络出版日期: 2024-06-25

基金资助

国家自然科学基金(22078087); 中央高校基本科研业务费(2022ZFJH004)

Multi-Responsive Microgel Carrier for Intracellular Delivery of Biomacromolecular Drugs

Received date: 2024-04-10

Online published: 2024-06-25

Supported by

National Natural Science Foundation of China(22078087); Fundamental Research Funds for the Central Universities(2022ZFJH004)

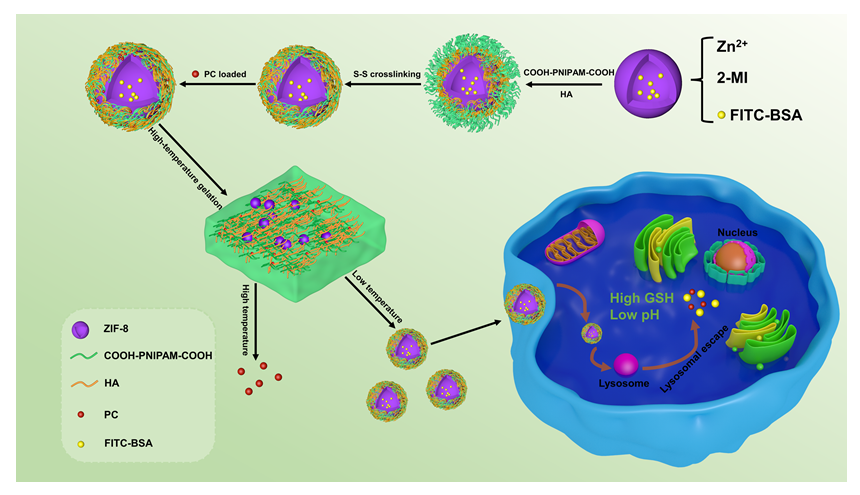

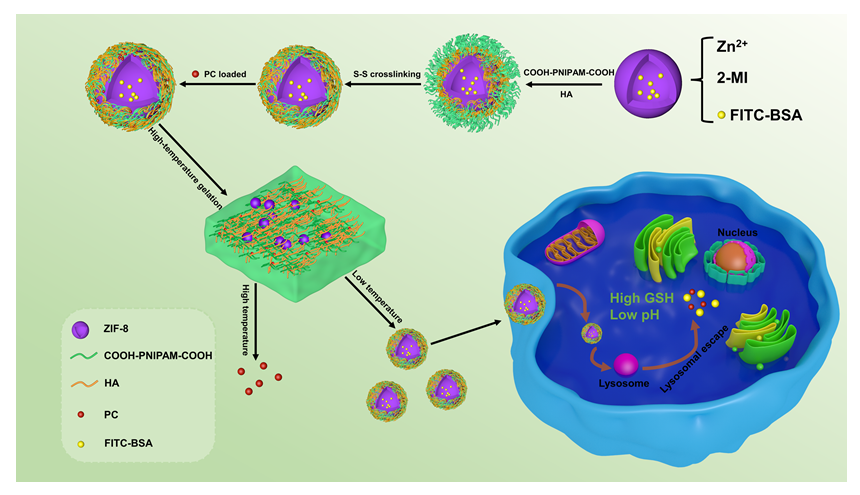

生物大分子药物疗效优、特异性强, 但细胞转染困难且容易失活, 本工作开发了一种多功能微凝胶载体ZIF@HA/PNIPAM1:kgel, 用于多药分区共载及细胞内、外的独立释放. 该微凝胶表现出多重刺激响应能力, 其核ZIF-8遇酸溶解, 凝胶层高温收缩且可被谷胱甘肽(GSH)还原解离. 小分子药物原花青素(PC)和大分子牛血清蛋白(FITC-BSA)作为药物模型可以分别包载于凝胶层和ZIF-8中. 体外释药实验证明微凝胶在正常生理环境下能有效防止药物泄漏; 在模拟肿瘤细胞外、内部微环境时, PC和FITC-BSA最高可分别达到74%和88%的释放量. 本工作构建的载药系统将有助于生物大分子的胞内安全、有效递送及解决多药耐药问题, 研究思路将对于大病化疗、受损组织修复等所需大分子胞内递送的研究提供有意义的科学指导.

李梦丽 , 张婕 , 刘丽珍 , 徐首红 , 刘洪来 . 用于生物大分子药物胞内递送的多重刺激响应型微凝胶载体[J]. 化学学报, 2024 , 82(8) : 856 -864 . DOI: 10.6023/A24040125

As known, biological macromolecules have good curative effect and strong specificity, but cell transfection is difficult and easy to inactivate. In this paper, we developed a multifunctional microgel carrier for multi-drug co-loading and independent release in and out of cells. Firstly, poly(N-isopropylacrylamide) (COOH-PNIPAM-COOH) was prepared by reversible addition fragmentation chain transfer (RAFT) polymerization method and assembled with hyaluronic acid (HA) on the surface of ZIF-8 by electrostatic interaction. Then, microgel carrier ZIF@HA/PNIPAM1:kgel was obtained by cross-linking disulfide bonds. The microgel showed good anti-dilution stability and multi-stimulus response ability. They also have triple response of temperature, pH and glutathione (GSH) sensitivity with a low critical solubilization temperature (LCST) of 42 ℃ and the pH-sensitive point of 5.89. The nuclear ZIF-8 could be dissolved in acid, the gel layer would shrink at high temperature and could be dissociated by glutathione (GSH) reduction. As drug models, small molecule proanthocyanidins (PC) and macromolecule bovine serum protein (FITC-BSA) were loaded in the gel layer and ZIF-8 respectively to study the release behavior of co-loaded two-drug. In vitro drug release experiments proved that the microgel could effectively prevent drug leakage under normal physiological environment, and the release amounts of PC and BSA were both below 15%. Meanwhile, the drug release behaviors in the simulated tumor microenvironment outside and inside cells were also studied. It was found that under specific conditions, the maximum release amounts could reach 74% for PC and 88% for BSA respectively, showing that the release of the two drugs had good controllability and independent. When high temperature is applied alone (simulating tumor extracellular environment), the gel layer shrinks, resulting in PC release. Under acidic and high GSH (mimicking the internal environment of tumor cells) conditions, both the gel and ZIF-8 dissociate, and FITC-BSA is released. The drug delivery system constructed in this work will contribute to the safe and effective delivery of biological macromolecules and solve the problem of multi-drug resistance. The research ideas will provide meaningful scientific guidance for the research of intracellular delivery of macromolecules required for chemotherapy of serious diseases and repair of damaged tissues.

Key words: microgel; ZIF-8; multiple responses; drug controlled release; multidrug co-loading

| [1] | Shanmuganathan, R.; Edison, T. N. J. I.; LewisOscar, F.; Kumar, P.; Shanmugam, S.; Pugazhendhi, A. Int. J. Biol. Macromol. 2019, 130, 727. |

| [2] | Liao, Y.; Wang, D. M.; Gu, Z. J. Acta Chim. Sinica 2021, 79, 1438 (in Chinese). |

| [2] | (廖友, 王冬梅, 谷战军, 化学学报, 2021, 79, 1438.) |

| [3] | Wang, T.; Zhao, L.; Wang, K. W.; Bai, Y. F.; Feng, F. Acta Chim. Sinica 2021, 79, 600 (in Chinese). |

| [3] | (王涛, 赵璐, 王科伟, 白云峰, 冯锋, 化学学报, 2021, 79, 600.) |

| [4] | Zhang, C.; Yang, K.; Yang, G. Int. J. Biol. Macromol. 2024, 258, 129070. |

| [5] | Mishra, V.; Tripathi, V.; Yadav, P.; Singh, M. P. Int. J. Biol. Macromol. 2023, 234, 123617. |

| [6] | Wang, Y. Z.; Liu, Y. H.; Xu, S. H.; Liu, H. L. Acta Phys.-Chim. Sin. 2019, 35, 876 (in Chinese). |

| [6] | (王义洲, 刘晔宏, 徐首红, 刘洪来, 物理化学学报, 2019, 35, 876.) |

| [7] | Hashemzadeh, A.; Amerizadeh, F.; Asgharzadeh, F.; Drummen, G. P. C.; Hassanian, S. M.; Landarani, M.; Avan, A.; Sabouri, Z.; Darroudi, M.; Khazaei, M. J. Cluster Sci. 2022, 33, 2345. |

| [8] | Song, Y.; Han, S.; Liu, S.; Sun, R.; Zhao, L.; Yan, C. ACS Appl. Mater. Interfaces 2023, 15, 25339. |

| [9] | Lawson, H. D.; Walton, S. P.; Chan, C. ACS Appl. Mater. Interfaces 2021, 13, 7004. |

| [10] | Tian, Y.; Gao, Z.; Li, M.; Hu, M.; Hao, J.; Cui, J. Chem. Mater. 2023, 35, 5593. |

| [11] | Duan, W.; Hang, L.; Ma, Y.; Wang, Q.; Tang, X.; Jiang, W.; Wu, Y.; Lv, W.; Wang, Y. ACS Appl. Mater. Interfaces 2023, 15, 39039. |

| [12] | Long, Y.; Feng, Y.; He, Y.; Luo, B.; Liu, M. ACS Appl. Nano Mater. 2022, 5, 5813. |

| [13] | Parsaei, M.; Akhbari, K. Inorg. Chem. 2022, 61, 14528. |

| [14] | Jung, S.; Chang, S.; Kim, N.-E.; Choi, S.-O.; Song, Y.-J.; Yuan, Y.; Kim, J. ACS Appl. Nano Mater. 2022, 5, 13671. |

| [15] | Ho, P. H.; Salles, F.; Di Renzo, F.; Trens, P. Inorg. Chim. Acta 2020, 500, 119229. |

| [16] | Dave, R.; Randhawa, G.; Kim, D.; Simpson, M.; Hoare, T. Mol. Pharmaceutics 2022, 19, 1704. |

| [17] | Ayar, Z.; Shafieian, M.; Mahmoodi, N.; Sabzevari, O.; Hassannejad, Z. J. Appl. Polym. Sci. 2021, 138, e51167. |

| [18] | Caputo, T. M.; Aliberti, A.; Cusano, A. M.; Ruvo, M.; Cutolo, A.; Cusano, A. J. Appl. Polym. Sci. 2021, 138, e50147. |

| [19] | Jawahar, N.; Meyyanathan, S. Int. J. Hlth. Allied Sc. 2012, 1, 217. |

| [20] | Schroeder, R.; Richtering, W.; Potemkin, I. I.; Pich, A. Macromolecules 2018, 51, 6707. |

| [21] | Li, C.; Si, X.; Li, J. B.; Zhang, Y. Acta Chim. Sinica 2023, 81, 1240 (in Chinese). |

| [21] | (李琛, 司笑, 李金波, 张艳, 化学学报, 2023, 81, 1240.) |

| [22] | Pu, X.; Li, Z. J.; Shi, J. Q.; Zhu, Y. Q.; Du, J. Z. Acta Chim. Sinica 2023, 81, 1438 (in Chinese). |

| [22] | (溥旭, 李泽娟, 石隽秋, 朱云卿, 杜建忠, 化学学报, 2023, 81, 1438.) |

| [23] | Gaur, M.; Maurya, S.; Akhtar, M. S.; Yadav, A. B. ACS Omega 2023, 8, 18751. |

| [24] | Lv, M.; Sun, M.; Wu, M.; Zhang, F.; Yin, H.; Sun, Y.; Liu, R.; Fan, Z.; Du, J. Nano Lett. 2022, 22, 9621. |

| [25] | He, W.; Xing, X.; Wang, X.; Wu, D.; Wu, W.; Guo, J.; Mitragotri, S. Adv. Funct. Mater. 2020, 30, 1910566. |

| [26] | Zhang, Y.; Sun, T.; Jiang, C. Acta Pharm. Sin. B 2018, 8, 34. |

| [27] | Engelbrecht, A. M.; Mattheyse, M.; Ellis, B.; Loos, B.; Thomas, M.; Smith, R.; Peters, S.; Smith, C.; Myburgh, K. Cancer Lett. 2007, 258, 144. |

| [28] | Zhang, B.; Kang, M.; Xie, Q.; Xu, B.; Sun, C.; Chen, K.; Wu, Y. J. Agric. Food Chem. 2011, 59, 537. |

| [29] | Lacombe, A.; Wu, V. C. H.; White, J.; Tadepalli, S.; Andre, E. E. Food Microbiol. 2012, 30, 124. |

| [30] | Vera de Rosso, V.; Hillebrand, S.; Cuevas Montilla, E.; Bobbio, F. O.; Winterhalter, P.; Mercadante, A. Z. J. Food Compos. Anal. 2008, 21, 291. |

| [31] | Martí, M. P.; Pantaleón, A.; Rózek, A.; Soler, A.; Valls, J.; Macià, A.; Romero, M.-P.; Motilva, M. J. Sep. Sci. 2010, 33, 2841. |

| [32] | Lei, B.; Zhang, Y.; Chen, M.; Xu, S.; Liu, H. Colloid Surface A 2022, 648, 129269. |

/

| 〈 |

|

〉 |