基于蒽基电子传输材料设计及蓝光钙钛矿QLED性能研究

收稿日期: 2024-09-10

网络出版日期: 2024-11-20

基金资助

国家级大学生创新创业训练计划项目(202310288035); 国家自然科学基金(22279059); 国家自然科学基金(62404104); 江苏省自然科学基金(BK20240083); 江苏省自然科学基金(BK20241465); 江苏省卓越博士后计划(2023ZB844); 中国博士后面上项目(2023M731687); 南京理工大学大型仪器开放基金资助

Molecular Design of Anthracene-Based Electron-Transporting Materials for Efficient Blue Perovskite QLEDs

Received date: 2024-09-10

Online published: 2024-11-20

Supported by

National Undergraduate Training Program for Innovation and Entrepreneurship(202310288035); National Natural Science Foundation of China(22279059); National Natural Science Foundation of China(62404104); Natural Science Foundation of Jiangsu Province(BK20240083); Natural Science Foundation of Jiangsu Province(BK20241465); Jiangsu Funding Program for Excellent Postdoctoral Talent(2023ZB844); China Postdoctoral Science Foundation(2023M731687); NJUST Large Instrument Equipment Open Fund

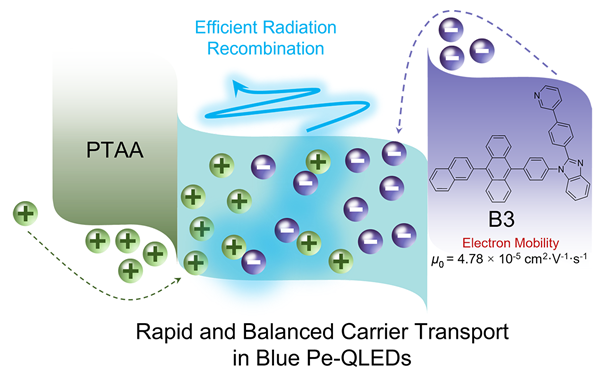

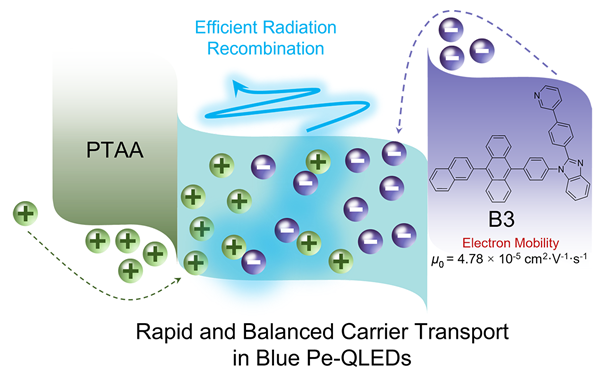

钙钛矿量子点发光二极管(Pe-QLEDs)具有色纯度高、色域宽、多功能发光特性和低成本溶液加工能力等特点, 因此在高清柔性显示中具有巨大的应用潜力. 然而, 在常用的多层“三明治”电致发光器件结构中, 载流子传输层之间的传输能力的差异限制了其发展. 在本研究中, 设计并定制合成了两种以蒽骨架为核心的新型电子传输材料, 分别命名为B1和B3. 得益于电子迁移率的显著提高, 基于B3制备的天蓝光Pe-QLED器件实现了高效的载流子复合, 最终表现出8.82%的外量子效率(EQE)和2.40 V低启亮电压. 相比之下, 基于1,3,5-三(1-苯基-1H-苯并咪唑-2-基)苯(TPBi)制备器件的EQE仅为6.11%, 启亮电压高达3.20 V. 本研究验证了载流子平衡传输在提高器件效率方面的重要作用, 并为蓝光Pe-QLEDs中设计高电子迁移率的电子传输材料提供了参考思路.

关键词: 钙钛矿量子点发光二极管; 电子传输材料; 结构调控; 载流子传输平衡; 蒽骨架

谭可莹 , 方平 , 丁杜鹏 , 袁诗晨 , 刘辰 , 杨诗羽 , 魏昌庭 , 徐勃 . 基于蒽基电子传输材料设计及蓝光钙钛矿QLED性能研究[J]. 化学学报, 2025 , 83(1) : 1 -9 . DOI: 10.6023/A24090272

Perovskite quantum dot light-emitting diodes (Pe-QLEDs) hold significant promise for high-definition flexible displays due to their exceptional color purity, wide color gamut, versatile light-emitting properties, and cost-effective solution processing capabilities. However, the varying transport capacities of the carrier-transporting layers in commonly used multilayer ‘sandwich’ electroluminescent device structures pose limitations on their development. In this study, we synthesized two asymmetric anthracene-based compounds, designated as B1 and B3, featuring a large π-conjugated anthracene-based skeleton as their core, which exhibit sufficiently high thermal stability suitable for vacuum thermal deposition method. Additionally, we optimized the group size and push-pull electronic characteristics of the peripheral groups to enhance carrier transport capability. From the measured space-charge-limited current data of electron-only devices, we calculated high electron transport mobilities of 4.78×10−5 cm2•V−1•s−1 for B1 and 4.13×10−5 cm2•V−1•s−1 for B3. Based on these impressive physicochemical properties, the external quantum efficiency (EQE) of the sky-blue Pe-QLEDs prepared with B1 and B3 as the electron-transporting layer (ETL) reached 6.32% and 8.82%, respectively, while the maximum brightness was 4631.77 cd•m−2 and 3585.29 cd•m−2, respectively. B1- and B3-based Pe-QLEDs devices outperformed the control device using 1,3,5-tris(1-phenyl-1H-benzimidazol-2-yl)benzene (TPBi) as the ETL, which exhibited an EQE of 6.11% and brightness of 3041.77 cd•m−2. Notably, both B1 and B3 also enhance the electron injection capability of the devices and significantly reduce the device turn-on voltage (2.20 V and 2.40 V, respectively), primarily attributed to their more balanced carrier transport within the devices. Ultimately, transient electroluminescence and electrochemical impedance spectroscopy confirmed that B1 and B3 facilitate the rapid establishment of steady-state emission within the device and effectively reduce carrier accumulation at the interfaces. Among these electron-transporting materials (ETMs), B3 enhances the effective recombination ratio, resulting in improved device efficiency. This study highlights the critical role of balanced carrier transport in enhancing device efficiency and provides valuable insights for the design of high electron mobility ETMs aimed at constructing efficient Pe-QLEDs.

| [1] | Chan, W. C. W.; Nie, S. Science 1998, 281, 2016. |

| [2] | Hines, M. A.; Guyot-Sionnest, P. J. Phys. Chem. 1996, 100, 468. |

| [3] | Murray, C. B.; Norris, D. J.; Bawendi, M. G. J. Am. Chem. Soc. 1993, 115, 8706. |

| [4] | Cho, H.; Jeong, S.-H.; Park, M.-H.; Kim, Y.-H.; Wolf, C.; Lee, C.-L.; Heo, J. H.; Sadhanala, A.; Myoung, N.; Yoo, S.; Im, S. H.; Friend, R. H.; Lee, T.-W. Science 2015, 350, 1222. |

| [5] | Protesescu, L.; Yakunin, S.; Bodnarchuk, M. I.; Krieg, F.; Caputo, R.; Hendon, C. H.; Yang, R. X.; Walsh, A.; Kovalenko, M. V. Nano Lett. 2015, 15, 3692. |

| [6] | Song, J.; Li, J.; Li, X.; Xu, L.; Dong, Y.; Zeng, H. Adv. Mater. 2015, 27, 7162. |

| [7] | Peng, Y.; Zhao, Y.; Yang, J.; Zhang, X.; Cheng, J. Acta Chim. Sinica 2024, 82, 879 (in Chinese). |

| [7] | ( 彭亚晶, 赵雨新, 杨金辉, 仉昕昕, 程佳玲, 化学学报, 2024, 82, 879.) |

| [8] | Akkerman, Q. A.; Rainò, G.; Kovalenko, M. V.; Manna, L. Nature Mater. 2018, 17, 394. |

| [9] | Li, H.; Feng, Y.; Zhu, M.; Yun, G.; Fan, C.; Cui, Q.; Cai, Q.; Yang, K.; He, P.; Dai, X.; Huang, J.; Ye, Z. Nature Nanotech. 2024, 19, 638. |

| [10] | Wang, J.; Li, M.; Cai, B.; Ren, H.; Fan, W.; Xu, L.; Yao, J.; Wang, S.; Song, J. Angew. Chem. Int. Ed. 2024, 63, e202410689. |

| [11] | Nong, Y.; Yao, J.; Li, J.; Xu, L.; Yang, Z.; Li, C.; Song, J. Adv. Mater. 2024, 36, 2402325. |

| [12] | Lim, J.; Bae, W. K.; Kwak, J.; Lee, S.; Lee, C.; Char, K. Opt. Mater. Express 2012, 2, 594. |

| [13] | Zaiats, G.; Ikeda, S.; Kamat, P. V. NPG Asia Mater. 2020, 12, 57. |

| [14] | Zhao, L.; Lee, K. M.; Roh, K.; Khan, S. U. Z.; Rand, B. P. Adv. Mater. 2019, 31, 1805836. |

| [15] | Xu, L.; Li, J.; Cai, B.; Song, J.; Zhang, F.; Fang, T.; Zeng, H. Nat. Commun. 2020, 11, 3902. |

| [16] | Zou, C.; Liu, Y.; Ginger, D. S.; Lin, L. Y. ACS Nano 2020, 14, 6076. |

| [17] | Yuan, S.; Zheng, X.; Shen, W.-S.; Liu, J.; Cui, L.-S.; Zhang, C.; Tian, Q.-S.; Wu, J.-J.; Zhou, Y.-H.; Wang, X.-D.; Wang, Z.-K.; Han, P.; Luther, J. M.; Bakr, O. M.; Liao, L.-S. ACS Energy Lett. 2022, 7, 1348. |

| [18] | Zhang, X.; Lin, H.; Huang, H.; Reckmeier, C.; Zhang, Y.; Choy, W. C. H.; Rogach, A. L. Nano Lett. 2016, 16, 1415. |

| [19] | Zhang, W.; Smith, J.; Hamilton, R.; Heeney, M.; Kirkpatrick, J.; Song, K.; Watkins, S. E.; Anthopoulos, T.; McCulloch, I. J. Am. Chem. Soc. 2009, 131, 10814. |

| [20] | Li, J.; Xu, L.; Wang, T.; Song, J.; Chen, J.; Xue, J.; Dong, Y.; Cai, B.; Shan, Q.; Han, B.; Zeng, H. Adv. Mater. 2017, 29, 1603885. |

| [21] | Yang, F.; Chen, H.; Zhang, R.; Liu, X.; Zhang, W.; Zhang, J.; Gao, F.; Wang, L. Adv. Funct. Mater. 2020, 30, 1908760. |

| [22] | Jia, J.; Zhu, L.; Wei, Y.; Wu, Z.; Xu, H.; Ding, D.; Chen, R.; Ma, D.; Huang, W. J. Mater. Chem. C 2015, 3, 4890. |

| [23] | Fang, T.; Wang, T.; Li, X.; Dong, Y.; Bai, S.; Song, J. Sci. Bull. 2021, 66, 2302253. |

| [24] | Yuan, S.; Fang, T.; Huang, J.; Li, X.; Wei, C.; Zhou, Y.; Li, Y.; Zheng, X.; Huang, J.; Su, J.; Baryshnikov, G.; Choy, W. C. H.; Zeng, H.; Xu, B. ACS Energy Lett. 2023, 8, 818. |

| [25] | Lin, L.; Zhang, Q.; Ni, Y.; Shang, L.; Zhang, X.; Yan, Z.; Zhao, Q.; Chen, J. Chem 2022, 8, 1822. |

| [26] | Li, X.-S.; Peng, Y.-Q.; Yang, Q.-S.; Xing, H.-W.; Lu, F.-P. Acta Phys. Sin. 2007, 56, 5441 (in Chinese). |

| [26] | ( 李训栓, 彭应全, 杨青森, 刑宏伟, 路飞平, 物理学报, 2007, 56, 5441.) |

| [27] | Wang, C.; Dong, H.; Jiang, L.; Hu, W. Chem. Soc. Rev. 2018, 47, 422. |

| [28] | Ye, S.; Wang, Y.; Guo, R.; Zhang, Q.; Lv, X.; Duan, Y.; Leng, P.; Sun, S.; Wang, L. Chem. Eng. J. 2020, 393, 124694. |

| [29] | Liu, H.; Kang, L.; Li, J.; Liu, F.; He, X.; Ren, S.; Tang, X.; Lv, C.; Lu, P. J. Mater. Chem. C 2019, 7, 10273. |

| [30] | Zhang, D.; Song, X.; Li, H.; Cai, M.; Bin, Z.; Huang, T.; Duan, L. Adv. Mater. 2018, 30, 1707590. |

| [31] | Zhang, D.; Duan, L. J. Phys. Chem. Lett. 2019, 10, 2528. |

| [32] | Wang, Q.; Chen, Y.; Yan, C.; Zeng, X.; Fu, X.; Pan, L.; Cao, J.; Yang, S.; Li, W.; Chen, X.; Yang, W. ACS Energy Lett. 2023, 8, 3710. |

| [33] | Gao, D.; Li, R.; Chen, X.; Chen, C.; Wang, C.; Zhang, B.; Li, M.; Shang, X.; Yu, X.; Gong, S.; Pauporté, T.; Yang, H.; Ding, L.; Tang, J.; Chen, J. Adv. Mater. 2023, 35, 2301028. |

| [34] | Ye, S.; Guo, R.; Xiang, S.; Zhang, Q.; Lv, X.; Liu, W.; Fan, L.; Leng, P.; Sun, S.; Wang, L. Mater. Chem. Front. 2019, 3, 812. |

| [35] | Jia, M.; Xu, X.; Peng, J.; Zhang, J.; Yao, C.; Li, L. Adv. Opt. Mater. 2016, 4, 1635. |

| [36] | Pan, J.; Wei, C.; Wang, L.; Zhuang, J.; Huang, Q.; Su, W.; Cui, Z.; Nathan, A.; Lei, W.; Chen, J. Nanoscale 2018, 10, 592. |

| [37] | Blakesley, J. C.; Castro, F. A.; Kylberg, W.; Dibb, G. F. A.; Arantes, C.; Valaski, R.; Cremona, M.; Kim, J. S.; Kim, J.-S. Org. Electron. 2014, 15, 1263. |

| [38] | Malliaras, G. G.; Salem, J. R.; Brock, P. J.; Scott, C. Phys. Rev. B 1998, 58, 13411. |

| [39] | Javaux, C.; Mahler, B.; Dubertret, B.; Shabaev, A.; Rodina, A. V.; Efros, A. L.; Yakovlev, D. R.; Liu, F.; Bayer, M.; Camps, G.; Biadala, L.; Buil, S.; Quelin, X.; Hermier, J. P. Nature Nanotech. 2013, 8, 206. |

| [40] | Shen, Y.; Hu, X.-M.; Guo, M.-L.; Li, Y.-Q.; Tang, J.-X. J. Phys. Chem. Lett. 2024, 15, 7916. |

| [41] | Xu, M.; Peng, Q.; Zou, W.; Gu, L.; Xu, L.; Cheng, L.; He, Y.; Yang, M.; Wang, N.; Huang, W.; Wang, J. Appl. Phys. Lett. 2019, 115, 041102. |

| [42] | Wei, C.; Xu, B.; Zhang, M.; Su, Z.; Gu, J.; Guo, W.; Gao, X.; Su, W.; Cui, Z.; Jeon, S.; Fan, Z.; Zeng, H. eScience 2024, 4, 100227. |

| [43] | Tang, P.; Xie, L.; Xiong, X.; Wei, C.; Zhao, W.; Chen, M.; Zhuang, J.; Su, W.; Cui, Z. ACS Appl. Mater. Interfaces 2020, 12, 13087. |

| [44] | Li, X.; Haghshenas, M.; Wang, L.; Huang, J.; Sheibani, E.; Yuan, S.; Luo, X.; Chen, X.; Wei, C.; Xiang, H.; Baryshnikov, G.; Sun, L.; Zeng, H; Xu, B. ACS Energy Lett. 2023, 8, 1445. |

/

| 〈 |

|

〉 |