锆基金属有机框架材料在氧传感器上的应用

收稿日期: 2024-11-01

网络出版日期: 2024-12-19

基金资助

国家自然科学基金(22175179)

Zirconium-Based Metal-Organic Frameworks for Oxygen Sensing

Received date: 2024-11-01

Online published: 2024-12-19

Supported by

National Natural Science Foundation of China(22175179)

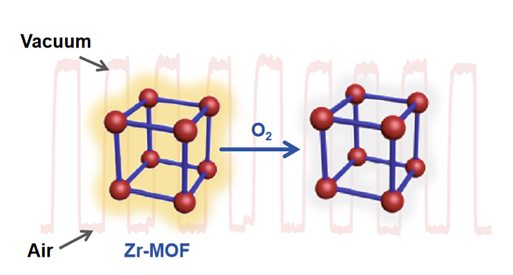

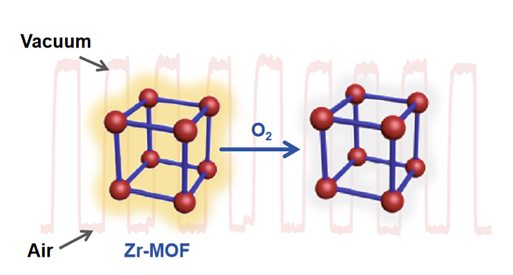

氧气传感在环境监测、医疗保健、工业生产和应用安全等各领域都发挥着至关重要的作用, 而金属有机框架(MOFs)由于具有较强的氧吸附能力, 有望应用于氧气传感并提高其响应性能. 本工作选取4个常见的锆基MOF材料并比较了其与配体的荧光发射和荧光寿命, 阐述了其发光机理. 4种锆基MOF均表现出对氧气的荧光淬灭性能, 证明了氧气是有效淬灭锆基MOF的荧光的主要空气组分. 其中, MOF-808和UiO-66具有良好的稳定性, 有望成为氧气传感器的候选材料. 在探究Zr基MOF中导致荧光淬灭的组成时, 通过对比具有相同配体的铬MOF, 证明了Zr4+是引发荧光淬灭的主要因素, 理论计算以及氧气吸附测试辅助验证了锆基MOF在氧气传感中的优势. 另外, UiO-66较短的恢复响应时间证明了MOF中孔道的作用, MOF荧光寿命的降低揭示了氧气对MOF荧光路径的抑制. 这些发现预计将为开发敏感的氧气传感器提供理论指导.

王跃 , 邹莹 , 张元 , 郑舒婕 , 王恒宇 , 刘天赋 , 李仁富 . 锆基金属有机框架材料在氧传感器上的应用[J]. 化学学报, 2025 , 83(1) : 45 -51 . DOI: 10.6023/A24110333

Oxygen sensing plays a vital role in a variety of fields, including environmental monitoring, healthcare, industrial processes, and safety management. Metal-organic frameworks (MOFs), owing to their robust oxygen adsorption capacity and tunable structure, are anticipated to be applied in oxygen sensing to enhance response performance. In this work, we synthesized four common Zr-MOFs (MOF-808, UiO-66, NU-1000, NH2-UiO-66) using the solvothermal method and validated the interaction between the ligands and zirconium clusters by comparing their fluorescence emission and lifetime. Then, the fluorescence of these four MOFs were tested under vacuum, air, and oxygen atmospheres. The experiments demonstrate that oxygen is the main air component that effectively quenches the fluorescence of zirconium-based MOFs. Recirculation experiments and powder X-ray diffraction of MOFs before and after fluorescence quenching indicate that zirconium-based MOFs exhibit high photo-stability. Under vacuum and pure oxygen conditions, UiO-66 can quench 88% of its fluorescence, with response and recovery times as low as 13 s and 15 s, respectively. This rapid detection of O2 over multiple cycles suggests that UiO-66 possesses a high level of sensitivity. In contrast, the fluorescence of chromium-based MOFs with the same ligands is hardly affected. This may be related to the electronic structure of tetravalent zirconium being able to match the electronic structure of paramagnetic oxygen, allowing the fluorescence process of the MOF to be quenched under the action of oxygen. To explore the advantages of zirconium-based MOFs in oxygen sensing, density functional theory calculations are adopted to determine the adsorption energy of oxygen with MIL-100(Cr) and MOF-808(Zr), which have the same ligands, confirming that one of the reasons for the special sensitivity of zirconium-based MOFs to oxygen is the shorter collision radius between Zr metal clusters and O2 molecules. The reduction in fluorescence lifetime confirmed the interaction between oxygen and the MOF. These findings are expected to provide theoretical guidance for the development of sensitive oxygen sensors.

| [1] | Kitagawa, Y.; Nakai, T.; Hosoya, S.; Shoji, S.; Hasegawa, Y. ChemPlusChem 2023, 88, e202300149. |

| [2] | Ellis, J. E.; Sorescu, D. C.; Burkert, S. C.; White, D. L.; Star, A. ACS Appl. Mater. 2013, 9, 27142. |

| [3] | Zhao, H. M.; Wang, Q. Q.; Wang, S. M.; Yin, J. Y.; Wang, H. B.; Shao, W. H.; Yao, Z. X.; Yao, J. T.; Zang, L. X. Inorg. Chem. Front. 2023, 10, 5161. |

| [4] | Salaris, N.; Chen, W. Q.; Haigh, P.; Caciolli, L.; Giobbe, G. G.; De Coppi, P.; Papakonstantinou, I.; Tiwari, M. K. Biosens. Bioelectron. 2024, 255, 116198. |

| [5] | Duong, H. D.; Sohn, O. J.; Rhee, J. I. Biosensors-Basel 2020, 10, 86. |

| [6] | Liang, Y. N.; Wu, Z. X.; Wei, Y. N.; Ding, Q. L.; Zilberman, M.; Tao, K.; Xie, X.; Wu, J. Nano-Micro Lett. 2022, 14, 52. |

| [7] | Ji, H. Y.; Liu, Y.; Chen, G. L.; Kong, L.; Yuan, Z. Y.; Meng, F. L. Sensor Actuat. B-Chem. 2024, 414, 315884. |

| [8] | Biring, S.; Sadhu, A. S.; Deb, M. Sensors 2019, 19, 5124. |

| [9] | Ren, T.; Jin, X.; Deng, S. H.; Guo, K.; Gao, Y. H.; Shi, X.; Xu, L.; Bai, X.; Shang, Y. B.; Jin, P. K.; Wang, X. C. J. Clean. Prod. 2024, 434, 140332. |

| [10] | Willett, M. Sensors 2014, 14, 6084. |

| [11] | Papkovsky, D. B.; Dmitriev, R. I. Chem. Soc. Rev. 2013, 42, 8700. |

| [12] | Mirzaei, A.; Kim, J. Y.; Kim, H. W.; Kim, S. S. Acc. Chem. Res. 2024, 57, 2395. |

| [13] | Dou, Z. S.; Yu, J. C.; Cui, Y. J.; Yang, Y.; Wang, Z. Y.; Yang, D. R.; Qian, G. D. J. Am. Chem. Soc. 2014, 136, 5527. |

| [14] | Xu, R. Y.; Wang, Y. F.; Duan, X. P.; Lu, K. D.; Micheroni, D.; Hu, A. G.; Lin, W. B. J. Am. Chem. Soc. 2016, 138, 2158. |

| [15] | Zhu, C. Y.; Wang, Z.; Mo, J. T.; Fan, Y. N.; Pan, M. J. Mater. Chem. C 2020, 8, 9916. |

| [16] | Zhao, D.; Cui, Y. J.; Yang, Y.; Qian, G. D. CrystEngComm 2016, 18, 3746. |

| [17] | Zhang, Y. M.; Yuan, S.; Day, G.; Wang, X.; Yang, X. Y.; Zhou, H. C. Coord. Chem. Rev. 2018, 354, 28. |

| [18] | Zhang, Y. F.; Zhang, Z. H.; Fang, H.; Guo, X. A.; Ma, Y. N.; Zhang, Y. Z.; Xue, D. X. Inorg. Chem. 2023, 62, 20513. |

| [19] | Chen, Z. J.; Feng, L.; Liu, L. M.; Bhatt, P. M.; Adil, K.; Emwas, A. H.; Assen, A. H.; Belmabkhout, Y.; Han, Y.; Eddaoudi, M. Langmuir 2018, 34, 14546. |

| [20] | Dai, Q. Q.; Yang, Z. F.; Li, J.; Cao, Y.; Tang, H. B.; Wei, X. C. Renew. Energy 2021, 163, 1588. |

| [21] | Wang, N.; Ma, L.; Li, Z. X.; Zhou, C. Y.; Su, X. G. Inorg. Chem. Front. 2024, 11, 3820. |

| [22] | Huang, N.; Yuan, S.; Drake, H.; Yang, X. Y.; Pang, J. D.; Qin, J. S.; Li, J. L.; Zhang, Y. M.; Wang, Q.; Jiang, D. L.; Zhou, H. C. J. Am. Chem. Soc. 2017, 139, 18590. |

| [23] | Zhu, Y. T.; Zhu, L. W.; Song, W. M.; Deng, C. H. Inorg. Chem. Commun. 2023, 154, 110917. |

| [24] | Guo, T. T.; Wei, Q. H.; Gao, H. Y.; Chen, J.; Wang, C. A.; Liu, Z. Y.; Li, J.; Wang, G. Mater. Today Chem. 2023, 34, 101693. |

| [25] | Sonal, S.; Mishra, B. K. Chem. Eng. J. 2021, 424, 130509. |

| [26] | Jia, C.; He, T.; Wang, G. M. Coord. Chem. Rev. 2023, 476, 214930. |

| [27] | Tan, J. X.; Chen, Z. Y.; Chen, C. H.; Hsieh, M. F.; Lin, A. Y. C.; Chen, S. S.; Wu, K. C. W. J. Hazard. Mater. 2023, 451, 131113. |

| [28] | Li, Z. P.; Geng, J. X.; Liu, Y. Y.; Sun, Z. C.; Wang, Y.; Wang, A. J. Chem. J. Chin. Univ. 2023, 44, 20230059 (in Chinese). |

| [28] | ( 李子鹏, 耿佳鑫, 刘颖雅, 孙志超, 王耀, 王安杰, 高等学校化学学报, 2023, 44, 20230059.) |

| [29] | Zhang, J.; Xia, T.; Zhao, D.; Cui, Y.; Yang, Y.; Qian, G. Sensor Actuat. B-Chem. 2018, 260, 63. |

| [30] | Xia, T. F.; Jiang, L. C.; Zhang, J.; Wan, Y. T.; Yang, Y.; Gan, J. L.; Cui, Y. J.; Yang, Z. M.; Qian, G. D. Microporous Mesoporous Mater. 2020, 305, 110396. |

| [31] | Lemon, C. M. Pure Appl. Chem. 2018, 90, 1359. |

| [32] | Furukawa, H.; Gándara, F.; Zhang, Y. B.; Jiang, J. C.; Queen, W. L.; Hudson, M. R.; Yaghi, O. M. J. Am. Chem. Soc. 2014, 136, 4369. |

| [33] | Mondloch, J. E.; Bury, W.; Fairen-Jimenez, D.; Kwon, S.; DeMarco, E. J.; Weston, M. H.; Sarjeant, A. A.; Nguyen, S. T.; Stair, P. C.; Snurr, R. Q.; Farha, O. K.; Hupp, J. T. J. Am. Chem. Soc. 2013, 135, 10294. |

| [34] | Han, Y. T.; Liu, M.; Li, K. Y.; Zuo, Y.; Zhang, G. L.; Zhang, Z. C.; Guo, X. W. Chin. J. Appl. Chem. 2016, 33, 368 (in Chinese). |

| [34] | ( 韩易潼, 刘民, 李克艳, 左轶, 张国亮, 张宗超, 郭新闻, 应用化学, 2016, 33, 368.) |

| [35] | Duan, Z. G.; Pei, Y.; Zheng, S. S.; Wang, Z. Y.; Wang, Y. G.; Wang, J. J.; Hu, Y.; Lv, C. X.; Zhong, W. Chin. J. Inorg. Chem. 2024, 40, 496 (in Chinese). |

| [35] | ( 段章圭, 裴毅, 郑珊珊, 王召阳, 王勇光, 王骏杰, 胡杨, 吕春欣, 钟伟, 无机化学学报, 2024, 40, 496.) |

/

| 〈 |

|

〉 |