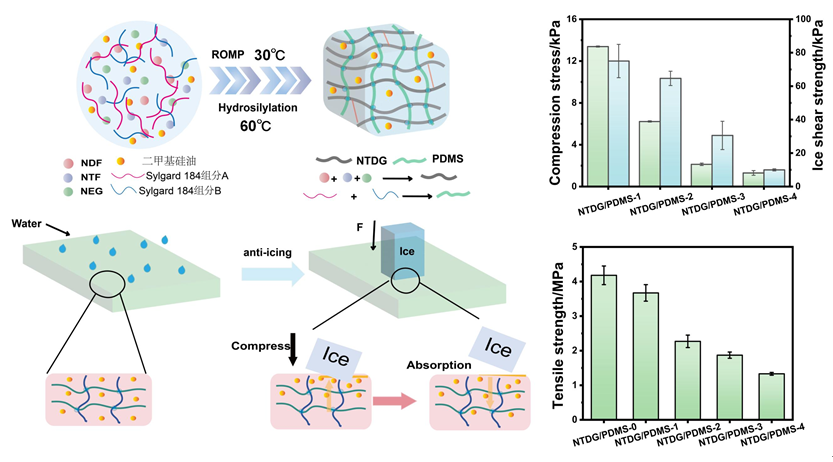

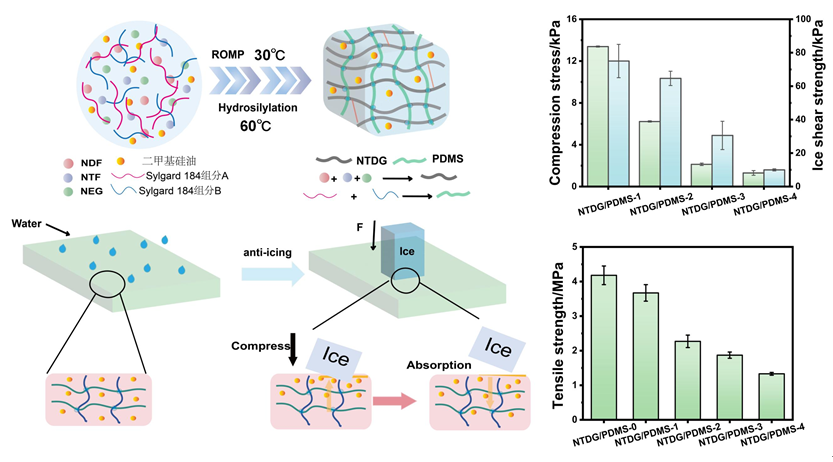

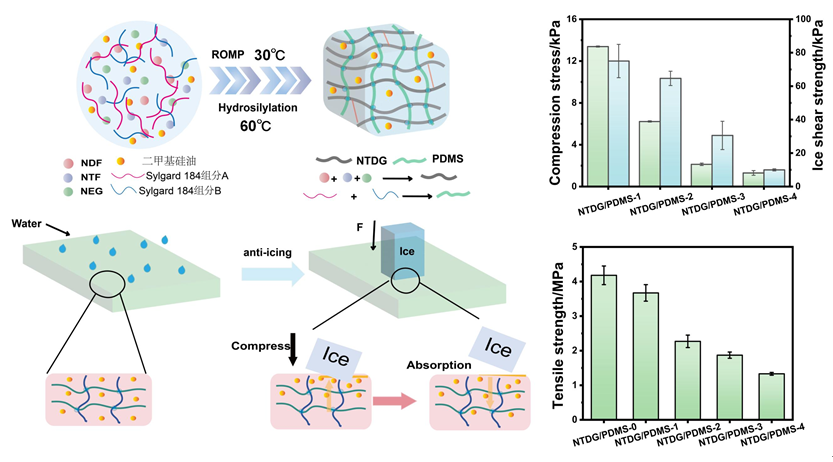

防冰材料在实际应用中长期面临耐久性不足、在复杂恶劣环境(如高湿度、超低温)下稳定性较差等挑战。因此,开发兼具高机械强度、良好耐久性和低冰粘附强度的新型材料具有重要意义。本文以降冰片烯基三氟乙酯(NTF)、降冰片烯基十二氟庚酯(NDF),二降冰片烯基乙二醇酯(NEG)分别为第一网络的单体和交联剂,Sylgard184 A和B组分为第二网络的单体,二甲基硅油为功能添加剂,通过开环易位聚合(ROMP)和硅氢加成反应成功制备了一系列二甲基硅油含量可调的含氟降冰片烯/PDMS双网络有机凝胶(NTDG/PDMS)。实验结果表明,硅油含量对材料的拉伸强度和冰剪切强度呈现较好的调控作用。随着硅油含量由0增加至80%,NTDG/PDMS凝胶的拉伸强度仍高于1.33 MPa,而冰剪切强度由211.59 kPa显著降低至9.96 kPa,结冰延迟时间也逐步延长至428 s。NTDG/PDMS-4在经历60次摩擦循环后,冰剪切强度由9.96 kPa增加至19.13 kPa,仅增加9.17 kPa,变化幅度较小,表现出优异的抗结冰性和机械耐久性。该类双网络有机凝胶兼具较高的机械强度、卓越的抗结冰性能及耐摩擦性能,在防冰领域显示出广阔的应用前景。

Ace-resistant materials have long been plagued by critical challenges in practical applications, including insufficient durability and compromised stability under complex harsh conditions (e.g., high humidity, ultra-low temperature) . Therefore, developing advanced materials that synergistically integrate high mechanical strength, superior durability, and low ice adhesion strength remains of paramount significance. Herein, we rationally designed target materials by leveraging the complementary merits of fluorinated norbornene polymers (low surface energy, high mechanical strength) and PDMS (low elastic modulus, low surface energy). Specifically, the first network (fluorinated norbornene polymer) was constructed via ring-opening metathesis polymerization (ROMP) using Grubbs 2nd generation catalyst, with norbornenyl trifluoroethyl ester (NTF) and norbornenyl dodecafluoroheptyl ester (NDF) as comonomers, and di-norbornenyl ethylene glycol ester (NEG) as the cross-linker. The second network was fabricated through hydrosilylation reaction, employing Sylgard 184 Components A and B as monomer precursors and dimethyl silicone oil as a functional additive. Through the sequential polymerization strategy, a series of fluorinated norbornene/PDMS double-network organogels (NTDG/PDMS) with tunable dimethyl silicone oil contents were successfully synthesized. The physicochemical and functional properties of the as-prepared double-network organogels were systematically characterized. Experimental results revealed that the dimethyl silicone oil content exerted a prominent regulatory effect on the tensile strength and ice shear strength (τ₁ce) of the materials . As the silicone oil content increased from 0 to 80%, the tensile strength of NTDG/PDMS gels retained above 1.33 MPa, while the ice shear strength underwent a significant reduction from 211.59 kPa to 9.96 kPa (well below the 100 kPa threshold for icephobic materials ), accompanied by a gradual extension of icing delay time to 428 s. Mechanical durability assessment demonstrated that after 60 friction cycles, the ice shear strength of NTDG/PDMS-4 only increased from 9.96 kPa to 19.13 kPa (a marginal increment of 9.17 kPa) with minimal variation, manifesting exceptional ice resistance and structural robustness. Collectively, this double-network organogel integrates high mechanical strength, outstanding ice-resistant performance, and favorable friction resistance, thereby holding broad application prospects in the field of ice protection.

[1] Cheng S.; Guo P.; Wang X.; Che P.; Han X.; Jin R.; Heng L.; Jiang L. Chem. Eng. J. 2022, 431, 133411.

[2] Hou Y.; Choy K. L. Prog. Org. Coat. 2022, 163, 106637.

[3] Zhu G.; Tian Y.; Wu J.; Yang G.; Hua Z. ACS Appl. Polym.Mater. 2022,4, 7626-7633.

[4] Tian S.; Li R.; Liu X.; Wang J.; Yu J.; Xu S.; Tian Y.; Yang J.; Zhang L. Research 2023, 6, 0140.

[5] Qin L.; Wu,Y.; Ma Z. H.; Li H. X.; Lu S. L.; Wang Z.; Liu,J.; Dong W. D.; Zhang T. ACS Appl. Polym.Mater. 2023, 5, 6278-6287.

[6] Xie W.; Zhang Y.; Wang L.; Li J.; Ding T.; Liu K.; Jiang L. ACS Nano 2023, 17, 14889-14901.

[7] Liu K.; Wang Y.; Li Z.; Zhang S.; Wang H.; Chen B. Chem. Eng. J. 2024, 479, 147653.

[8] Ma G. J.; Zheng H. K.;Chang S. N.;Wang S. S.Acta Chim. Sinica 2019, 77, 269-277(in Chinese). (马国佳, 郑海坤, 常士楠, 王硕硕, 化学学报, 2019, 77, 269-277.)

[9] Xing Q. S.; Chen X. L.; Tao J. Y.; Chen A. F.; Zhang Y. M.; Lei C. H. Acta. Polym. Sin. 2023, 54, 1123-1132(in Chinese). (邢清松, 陈旭龙, 陶嘉宇, 陈安伏, 张艳梅, 雷彩红, 高分子学报, 2023, 54(8): 1123-1132.)

[10] Li Y.; Lu Y. M.; Wang P. F.; Cao Y. Z.; Dai C. A. Prog. Chem. 2021, 33, 2362-2377(in Chinese). (李玥, 卢亚妹, 王鹏飞, 曹莹泽, 戴春爱, 化学进展, 2021, 33, 2362-2377.)

[11] Tran H. H.; Lee D.; Riassetto D. Rep. Prog. Phys. 2023, 86, 066601.

[12] Zhang P. F.; Li Y. F.; Li X. B.; Xu W. H.; Dong Z. C.; Zhang L.; Hou Y. P. Nat. Commun. 2023, 14, 723.

[13] Golovin K.; Dhyani A.; Thouless M. D.; Tuteja A. Science 2019, 364, 371.

[14] Shi B.; Wen J. M.; Liu R. D.; Wu H. J.; Yi X. J.Air Force Eng. Univ. (Nat. Sci. Ed.). 2025,26, 10-17(in Chinese). (师宾, 温佳明, 刘蕊迪, 吴宏景, 易贤, 空军工程大学学报, 2025, 26, 10-17.)

[15] Hao Y.; Li J.; Wang C.; Jiang W.; Zeng X.; Yoo C. G.; Yang G.; Ji X.; L, G. ACS Appl. Polym. Mater. 2024, 6, 141-153.

[16] Rao Q.; Zhang J.; Zhan X.; Chen F.; Zhang Q. J. Mater. Chem. A. 2020, 8, 2481-2489.

[17] Ru Y.; Fang R.; Gu Z.; Jiang L.; Liu M. Angew. Chem. Int. Edit. 2020, 59, 11876-11880.

[18] Zhuo Y.; Chen J.; Xiao S.; Li T.; Wang F.; He J.; Zhang Z. Mater.Horiz. 2021, 8, 3266-3280.

[19] Zhang Y.; Li S.; Wang J.; Chen H. Macromolecules 2023, 56, 4500-4512.

[20] Smith J. A.; Johnson B. C.; Lee K. Adv. Funct. Mater. 2023, 33, 2301234.

[21] Luo G. Z.; Gao Z. L.; Liu S.; Chen X.; Yang H.; Wu J. Langmuir 2024, 40, 11785-11794.

[22] Gong K.; Liu X. X.; Zhang H.; Cheng X.; Zhou C. J.; Wang Y.; Li M. Prog. Org. Coat. 2025, 204, 109274.

[23] Jiang Y. G.Master's Thesis, Dalian Maritime University, Dalian, 2021(in Chinese). (姜钰国. 硕士论文. 大连海事大学. 大连. 2021.)

[24] Song C. Chem. Ind. Eng.Prog. 2022, 41, 5890-5898(in Chinese). (宋超. 化工进展, 2022, 41, 5890-5898.)

[25] Du Y. J.; Wang Y. S.; Zou Z. N. Bull. Geol. Sci.Technol. 2024, 43, 226-234(in Chinese). (杜勇江, 王运生, 邹子南. 地质科技通报, 2024, 43, 226-234.)

[26] Zhang Z.; Chaudhuri K.; Kaefer F.; Malanoski AP.; Page KA. ACS Appl. Mater. Interfaces 2024, 16, 19594-19604.

[27] Cai Z.; Badr R. G.M.; Hauer, L. Soft Matter 2024, 20: 7300.

[28] Zhuo Y. Z.; Chen J. H.; Xiao S. B.; He J. Y.; Zhang Z.W.Materials Horizons. 2021, 8, 3266-3280.

[29] Zhang M.; Li H.; Wang L.; Liu R.; Chen A. F.; Lei C. H. Acta. Polym. Sin. 2024, 55, 456-465(in Chinese).(张明, 李华, 王磊, 刘蕊, 陈安伏, 雷彩红. 高分子学报,2024, 55, 456-465.)

[30] Chen Y.; Li S. H.; Li Y. F.[J]. Mech. Eng. 2022, 58(12): 64-74(in Chinese). (陈源, 李淑慧, 李永丰. 机械工程学报, 2022, 58, 64-74.)

[31] Li P.; Liu Z.; H. Yin, Y. High. Volt. Eng. 2018, 44, 2215-2222(in Chinese). (李鹏, 刘泽洪, 殷禹. 高电压技术, 2018, 44, 2215-2222.)

[32] Fang X. L.; Zheng H. J.Powder Metall. Technol. 2020, 38, 313-318(in Chinese). (方晓凌, 郑海军. 粉末冶金技术, 2020, 38, 313-318.)

[33] Tuteja A.; Dhyani A.; Golovin K.; Lee D. W.; Mabry J. M. Chem. Eng. J. 2025, 488, 135678.

[34] He Z. W.; Xiao S. B.; Gao H. J. Soft Matter 2017, 13, 6562-6568.

[35] Shen Y. Z.; Wu X. H.; Tao J.; Zhu C. L.; Lai Y. K.; Chen Z. Prog. Mater. Sci. 2019, 103, 509-557.