Acta Chimica Sinica ›› 2021, Vol. 79 ›› Issue (12): 1518-1525.DOI: 10.6023/A21070343 Previous Articles Next Articles

Article

投稿日期:2021-07-24

发布日期:2021-10-09

通讯作者:

贺宇飞, 李殿卿

基金资助:

Min Zhao, Xue Wang, Yanan Liu, Yufei He( ), Dianqing Li

), Dianqing Li

Received:2021-07-24

Published:2021-10-09

Contact:

Yufei He, Dianqing Li

Supported by:Share

Min Zhao, Xue Wang, Yanan Liu, Yufei He, Dianqing Li. Preparation of Efficient Pd/MgAl-LDO@Al2O3 Catalyst for Phenol Hydrogenation to Cyclohexanone[J]. Acta Chimica Sinica, 2021, 79(12): 1518-1525.

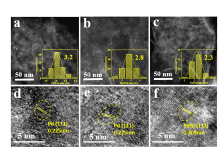

| 样品 | 比表面积/(m2•g–1) | 孔容/(cm3•g–1) | 平均孔径/nm | 负载量/% | 分散度/% |

|---|---|---|---|---|---|

| Pd/Al2O3 | 107 | 0.19 | 5.8 | 0.90 | 26.1 |

| Pd/MgAl-LDO@Al2O3 | 139 | 0.34 | 9.8 | 0.83 | 33.2 |

| Pd/NiAl-LDO@Al2O3 | 148 | 0.27 | 7.1 | 0.87 | 35.9 |

| 样品 | 比表面积/(m2•g–1) | 孔容/(cm3•g–1) | 平均孔径/nm | 负载量/% | 分散度/% |

|---|---|---|---|---|---|

| Pd/Al2O3 | 107 | 0.19 | 5.8 | 0.90 | 26.1 |

| Pd/MgAl-LDO@Al2O3 | 139 | 0.34 | 9.8 | 0.83 | 33.2 |

| Pd/NiAl-LDO@Al2O3 | 148 | 0.27 | 7.1 | 0.87 | 35.9 |

| [1] |

Li, B. L.; Liu, R. Y.; Liang, R. X.; Jia, Y. X. Acta Chim. Sinica 2017, 75, 448 (in Chinese).

doi: 10.6023/A17020080 |

|

( 李保乐, 刘人荣, 梁仁校, 贾义霞, 化学学报, 2017, 75, 448.)

doi: 10.6023/A17020080 |

|

| [2] |

Weng, X.; Dong, J.; She, T. T.; Bai, G. Y. Journal of Hebei University 2018, 3, 239 (in Chinese).

|

|

( 温昕, 董洁, 舍添添, 白国义, 河北大学学报, 2018, 3, 239.)

|

|

| [3] |

Shore, S. G.; Ding, E.; Park, C.; Keane, M. A. Catal. Commun. 2002, 3, 77.

doi: 10.1016/S1566-7367(02)00052-3 |

| [4] |

Sikhwivhilu, L. M.; Coville, N. J.; Naresh, D.; Chary, K. Appl. Catal. A, 2007, 324, 52.

doi: 10.1016/j.apcata.2007.03.004 |

| [5] |

Neri, G.; Visco, A. M.; Donato, A.; Milone, C.; Malentacchi, M.; Gubitosa, G. Appl. Catal. A, 1994, 110, 49.

doi: 10.1016/0926-860X(94)80104-5 |

| [6] |

Chary, K. V. R.; Naresh, D.; Vishwanathan, V.; Sadakane, M.; Ueda, W. Catal. Commun. 2007, 8, 471.

doi: 10.1016/j.catcom.2006.07.017 |

| [7] |

Scirè, S.; Minicò, S.; Crisafulli, C. Appl. Catal. A, 2002, 235, 21.

doi: 10.1016/S0926-860X(02)00237-5 |

| [8] |

Gonzalez-Velasco, J. R.; Gonzalez-Marcos, M. P.; Arnaiz, S.; Gutierrez-Ortiz, J. I.; Gutierrez-Ortiz, M. A. Ind. Eng. Chem. Res. 1995, 34, 1031.

doi: 10.1021/ie00043a004 |

| [9] |

Wang, Y.; Yao, J.; Li, H. R.; Su, D. S.; Antonietti, M. J. Am. Chem. Soc. 2011, 42, 939.

|

| [10] |

Souza, P. M. D.; Rabelo-Neto, R. C.; Borges, L. E. P.; Jacobs, G.; Davis, B. H.; Sooknoi, T.; Resasco, D.; Nornoha, F. B. ACS Catal. 2015, 4, 1318.

doi: 10.1021/cs500312z |

| [11] |

Makowski, P.; Cakan, R. D.; Antonietti, M.; Goettmann, F.; Titirici, M. M. Chem. Commun. 2008, 39, 999.

|

| [12] |

Li, H.; Liu, J. L.; Li, H. X. Mater. Lett. 2008, 62, 2321.

doi: 10.1016/j.matlet.2007.11.080 |

| [13] |

Xiang, Y. Z.; Ma, L.; Lu, C. S.; Zhang, Q. F.; Li, X. N. Green Chem. 2008, 10, 939.

doi: 10.1039/b803217c |

| [14] |

Liu, H. Z.; Jiang, T.; Han, B. X.; Liang, S. G.; Zhou, Y. X. Science 2009, 326, 1250.

doi: 10.1126/science.1179713 |

| [15] |

Li, X. Z.; Cheng, L.; Wang, X. Y. Res. Chem. Intermed. 2018, 45, 1249.

doi: 10.1007/s11164-018-3687-3 |

| [16] |

Cavani, F.; Trifirò, F.; Vaccari, A. Catal. Today 1991, 11, 173.

doi: 10.1016/0920-5861(91)80068-K |

| [17] |

Yu, J.; Yang, Y. S.; Wei, M. Acta Chim. Sinica 2019, 77, 1129 (in Chinese).

doi: 10.6023/A19070260 |

|

( 余俊, 杨宇森, 卫敏, 化学学报, 2019, 77, 1129.)

doi: 10.6023/A19070260 |

|

| [18] |

Debecker, D. P.; Gaigneaux, E. M.; Busca, G. Chem. Eur. J. 2009, 15, 3920.

doi: 10.1002/chem.v15:16 |

| [19] |

Sivasamy, A.; Cheah, K. Y.; Fornasiero, P.; Kemausuor, F.; Zinoviev, S.; Miertus, S. ChemSusChem 2010, 2, 278.

doi: 10.1002/cssc.v2:4 |

| [20] |

Sikhwivhilu, L.; Coville, N.; Naresh, D.; Chary, K. V. R.; Vishwanathan, V. Appl. Catal. A, 2007, 324, 52.

doi: 10.1016/j.apcata.2007.03.004 |

| [21] |

Veloso, C. O.; Pérez, C. N.; Souza, B. M. D.; Lima, E. C.; Dias, A. G.; Monteiro, J. L. F.; Henriques, C. A. Micropor. Mesopor. Mater. 2008, 107, 23.

doi: 10.1016/j.micromeso.2007.05.036 |

| [22] |

Brindley, G. W.; Kikkawa, S. Clay. Clay Miner. 1980, 28, 87.

doi: 10.1346/CCMN |

| [23] |

Mahata, N.; Vishwanathan, V. Catal. Today 1999, 49, 65.

doi: 10.1016/S0920-5861(98)00409-X |

| [24] |

Zhong, J. W.; Chen, J. Z.; Chen, L. M. Catal. Sci. Technol. 2014, 4, 3555.

doi: 10.1039/C4CY00583J |

| [25] |

Yuan, X. Q.; Li, B. T.; Li, B.; Wang, X. J. Fuel Process. Technol. 2021, 211, 106581.

doi: 10.1016/j.fuproc.2020.106581 |

| [26] |

Chowdhury, S. R.; Maiyalagan, T.; Bhattachraya, S. K.; Gayen, A. Electrochim. Acta 2020, 342, 136028.

doi: 10.1016/j.electacta.2020.136028 |

| [27] |

Rai, R. K.; Gupta, K.; Behrens, S.; Li, J.; Xu, Q.; Singh, S. K. ChemCatChem 2015, 7, 1806.

doi: 10.1002/cctc.v7.12 |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||