Preparation of N Modified Ni2P-Nx/SiO2 Catalysts and Hydrodeoxygenation Performance of m-Cresol

Received date: 2024-07-15

Online published: 2024-09-06

Supported by

National Natural Science Foundation of China(22278068)

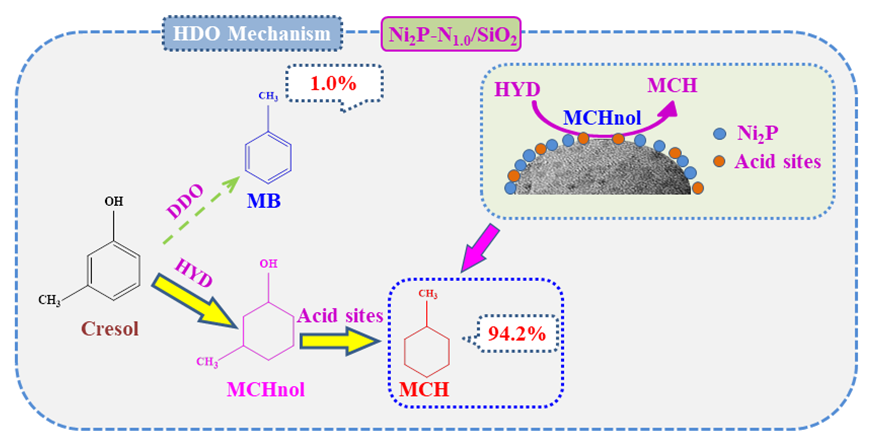

The gradual depletion of fossil fuels and increasing environmental pollution problems inspire researchers to seek renewable and clean energy. Lignocellulosic biomass is deemed to be a sustainable and promising resource to produce chemicals and fuels due to its abundant existence in nature. Hydrodeoxygenation (HDO) of phenolic compounds in bio-fuel is a promising technology to convert biomass materials to value-added chemicals and fuels. However, the development of highly efficient catalysts remains a great challenge. In this work, a series of N modified Ni2P-Nx/SiO2 catalysts were prepared by impregnation method. The structure of the catalysts was characterized by X-ray diffraction (XRD), N2 physical adsorption desorption (BET), H2 temperature programmed reduction (H2-TPR), NH3 temperature programmed desorption (NH3-TPD), pyridine infrared (Py-FTIR), transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS), and the influence of Ni/N molar ratio on the physicochemical properties of the catalysts was systematically investigated. Using m-cresol as a model compound, the effects of Ni/N molar ratio, reaction temperature, reaction time, and reaction pressure on the HDO performance were studied. It was found that the appropriate introduction of N element can promote the formation of smaller active particles, improve the dispersion of active components, thus enhancing the catalytic activity. The Ni2P-N1.0/SiO2 catalyst with a Ni/N ratio of 1.0 exhibited the best HDO activity. Under the conditions of 250 ℃, 3 MPa, and 1 h, m-cresol conversion reached 93.2%, and the selectivity of the target product methylcyclohexane (MCH) reached 94.2%. Based on the product distribution, it can be inferred HDO of m-cresol over Ni2P-Nx/SiO2 catalyst proceeded mainly via hydrogenation-deoxygenation (HYD) pathway. Furthermore, this series of catalysts also displayed excellent recyclability, m-cresol conversion, as well as the selectivity towards MCH did not decrease obviously even after 5 successive cycles. We believe that this strategy can provide a simple and repeatable route to synthesize high-performance HDO catalysts.

Key words: N modified; Ni2P-Nx/SiO2 catalyst; m-cresol; hydrodeoxygenation; methylcyclohexane

Shuai Wang , Hua Song . Preparation of N Modified Ni2P-Nx/SiO2 Catalysts and Hydrodeoxygenation Performance of m-Cresol[J]. Acta Chimica Sinica, 2024 , 82(9) : 979 -986 . DOI: 10.6023/A24070217

| [1] | Chen S.; Miao C.; Xie H.; Jiao Z.; Zhang X.; Zhou G. Biomass Bioenergy 2024, 180, 107002. |

| [2] | Wang S.; Jiang N.; Zhu T.; Zhang Q.; Zhang C.; Wang H.; Chen Y.; Li F.; Song H. Catal. Sci. Technol. 2022, 12, 1586. |

| [3] | Zhang Q.; Wang S.; Jiang, N ; Jiang, B.; Liu Y.; Chen Y.; Li F.; Song H. J. Catal. 2024, 432, 115338. |

| [4] | Liu L.; Zhang J.; Wang L.; Xiao F. Acta Chim. Sinica 2023, 81, 533 (in Chinese). |

| [4] | (刘露杰, 张建, 王亮, 肖丰收, 化学学报, 2023, 81, 533.) |

| [5] | Li Z.; Ren X.; Wang Y.; Li Z.; Ma S.; Qiu Z. Journal of Molecular Catalysis 2022, 36, 42 (in Chinese). |

| [5] | (李志勤, 任枭雄, 王元哲, 李宗轩, 马少博, 邱泽刚, 分子催化, 2022, 36, 42.) |

| [6] | Ochoa E.; Torres D.; Pinilla J. L.; Suelves I. J. Environ. Chem. Eng. 2021, 9, 105146. |

| [7] | LiBretto N.; Tacey S.; Zubair M.; Bui T.; Unocic K.; Baddour F.; Griffin M.; Schaidle J.; Farberow C.; Ruddy D.; Bedford N.; Habas S. J. Mater. Chem. A 2023, 11, 16788. |

| [8] | Pitakjakpipop P.; Song C. Energy Fuels 2023, 37, 8311. |

| [9] | Jiang B.; Zhang Y. ; Wang H.; Liu K.; Jiang N.; Li J.; Song H. Chem. Eng. J. 2024, 495, 153118. |

| [10] | Gou X.; Jiang B.; Zhu T.; Zhang Q.; Wang S.; Li F.; Wang H.; Song H. Fuel 2024, 375, 32580. |

| [11] | Zhu T.; Liu K.; Wang H.; Wang J.; Li F.; Wang C.; Song H. Fuel 2023, 331, 125663. |

| [12] | Xu B.; Wei X.; Sun J.; Liu J.; Ma L. Acta Chim. Sinica 2023, 81, 239 (in Chinese). |

| [12] | (徐斌, 韦秀芝, 孙江敏, 刘建国, 马隆龙, 化学学报, 2023, 81, 239.) |

| [13] | Wang S.; Li F.; Liu Y.; Zhang Q.; Song H. New J. Chem. 2022, 46, 16941. |

| [14] | Ning X.; Sun Y.; Fu H.; Qu X.; Xu Z.; Zheng S. Chemosphere 2020, 241, 124978. |

| [15] | Zhang Z.; Tang M.; Chen J. Appl. Surf. Sci. 2016, 360, 353. |

| [16] | Zhao H.; Liu C.; Zheng Y.; Li S.; Gao Y.; Ma Q.; Wang F.; Dong Z. ACS Catal. 2024, 14, 8619. |

| [17] | Feitosa L. F.; Berhault G.; Laurenti D.; Teixeira da Silva V. Ind. Eng. Chem. Res. 2019, 58, 16164. |

| [18] | Zhou M.; Ye J.; Liu P.; Xu J.; Jiang J. ACS Sustainable Chem. Eng. 2017, 5, 8824. |

| [19] | Zhang Q.; Wang H.; Wang S.; Wang Y.; Zhang M.; Song H. Acta Chim. Sinica 2024, 82, 287 (in Chinese). |

| [19] | (张强, 王欢, 王帅, 王园园, 张梅, 宋华, 化学学报, 2024, 82, 287.) |

| [20] | Wang W.; Wang X.; Wang Y.; Jiang B.; Song H. React. Chem. Eng. 2022, 7, 978. |

| [21] | Wu C.; Kopold P.; Aken P. A.; Maier J.; Yu Y. Adv. Mater. 2017, 29, 1604015. |

| [22] | Wang M.; Lin M.; Li J.; Huang L.; Zhuang Z.; Lin C.; Zhou L.; Mai L. Chem. Commun. 2017, 53, 8372. |

| [23] | Jampa S.; Puente-Urbina A.; Ma Z. Q.; Wongkasemjit S.; Luterbacher J. S.; van Bokhoven J. A. ACS Sustainable Chem. Eng. 2019, 7, 4058. |

| [24] | Antar M.; Lyu D. M.; Nazari M.; Shah A.; Zhou X. M.; Smith D. L. Renew. Sust. Energy Rev. 2021, 139, 110691. |

| [25] | Kabir G.; Hameed B. H. Renew. Sust. Energy Rev. 2017, 70, 945. |

/

| 〈 |

|

〉 |