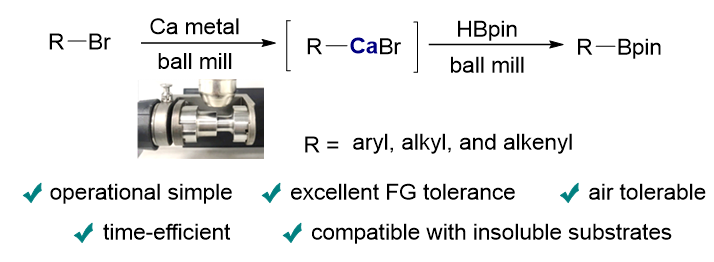

Direct Borylation of Organohalides Using Mechanochemically Generated Calcium-Based Heavy Grignard Reagents (R-CaX)

Received date: 2024-09-11

Online published: 2024-10-17

Supported by

China Postdoctoral Science Foundation(2021M692713); Natural Science Foundation of Jiangsu Province(BK20210789)

The study of calcium-based Grignard reagents (R-CaX) has historically been limited due to the challenges in their synthesis. However, calcium’s biocompatibility and distinct chemical properties make it a highly promising candidate for organic synthesis applications. Unlike their magnesium-based counterparts (R-MgX), calcium-based reagents exhibit stronger polarity and a higher degree of ionic character in the carbon-metal bond. This increased ionic nature can result in unique reactivity, offering advantages in specific transformations where magnesium-based reagents may be less effective. Traditional methods for synthesizing calcium-based Grignard reagents are cumbersome, requiring the pre-activation of metallic calcium through processes involving toxic materials such as liquid ammonia or highly reactive lithium. These harsh conditions not only present safety concerns but also limit the reagents' practicality, particularly in industrial applications where scalability and safety are crucial. In recent years, mechanochemistry has emerged as a sustainable alternative to conventional methods, providing opportunities to improve reaction efficiency and reduce the use of solvents. The mechanical energy generated by ball milling has been shown to disrupt the inert surface layer of metallic calcium, allowing for in situ activation. This enables the calcium to react with organohalides, forming calcium-based Grignard reagents without the need for toxic reagents or complex pre-activation steps. Once formed, these reagents can act as carbon nucleophiles, reacting with pinacolborane (HBpin) to form organoboron compounds, which are valuable intermediates in organic synthesis. This study demonstrates that by utilizing the continuous mechanical energy of ball milling, a variety of boronated products can be synthesized efficiently and with high yields. The method also shows broad substrate compatibility, particularly excelling in reactions involving poorly soluble aryl bromides, where traditional solution-based systems often fail. In conclusion, this work marks the first successful application of calcium-based Grignard reagents in borylation reactions via mechanochemical methods, offering a novel and efficient approach that addresses the limitations of conventional techniques.

Yuhan Liu , Pan Gao . Direct Borylation of Organohalides Using Mechanochemically Generated Calcium-Based Heavy Grignard Reagents (R-CaX)[J]. Acta Chimica Sinica, 2024 , 82(11) : 1114 -1119 . DOI: 10.6023/A24090273

| [1] | Hanusa, T. P. Chem. Rev. 1993, 93, 1023. |

| [2] | The Chemistry of Organo-magnesium Compounds, Eds.: Rappoport, Z.; Marek, I., Wiley-VCH, Weinheim, Germany, 2008. |

| [3] | (a) Banno, T.; Hayakawa, Y.; Umeno, M. J. Organomet. Chem. 2002, 653, 288. |

| [3] | (b) Peltzer, R. M.; Gauss, J.; Eisenstein, O.; Cascella, M. J. Am. Chem. Soc. 2020, 142, 2984. |

| [4] | Harder, S. Chem. Rev. 2010, 110, 3852. |

| [5] | Holleman, A. F.; Wiberg, E.; Wiberg, N. Inorganic Chemistry, De Gruyter, Berlin, 2001. |

| [6] | (a) Wu, T.-C.; Xiong, H.; Rieke, R. D. J. Org. Chem 1990, 55, 5045. |

| [6] | (b) Mochida, K.; Ogawa, H. J. Organomet. Chem. 1983, 243, 131. |

| [6] | (c) Li, H.; Wang, X.-Y.; Wei, B.; Xu, L.; Zhang, W.-X.; Pei, J.; Xi, Z. Nat. Commun. 2014, 5, 4508. |

| [6] | (d) Westerhausen, M.; Koch, A.; G?rls, H.; Krieck, S. Chem.-Eur. J. 2017, 23, 1456. |

| [7] | Beckmann, E. Ber. Dtsch. Chem. Ges 1905, 38, 904. |

| [8] | (a) Gilman, H.; Schulze, F. J. Am. Chem. Soc 1926, 48, 2463. |

| [8] | (b) Bryce-Smith, D.; Skinner, A. C. J. Chem. Soc 1963, 577. |

| [8] | (c) Kawabata, N.; Matsumura, A.; Yamashita, S. Tetrahedron 1973, 29, 1069. |

| [8] | (d) Kawabata, N.; Matsumura, A.; Yamashita, S. J. Org. Chem 1973, 38, 4268. |

| [9] | (a) Langer, J.; Krieck, S.; Fischer, R.; G?rls, H.; Walther, D.; Westerhausen, M. Organometallics 2009, 28, 5814. |

| [9] | (b) Maercker, A. Angew. Chem. Int. Ed. 1987, 26, 972. |

| [10] | Westerhausen, M.; Langer, J.; Krieck, S.; Fischer, R.; G?rls, H.; K?hler, M. Top. Organomet. Chem 2013, 45, 29. |

| [11] | D'Alterio, M. C.; Casals-Crua?as, è.; Tzouras, N. V.; Talarico, G.; Nolan, S. P.; Poater, A. Chem. Eur. J 2021, 27, 13481. |

| [12] | Baker, R. H.; Schlesinger, A. H. J. Am. Chem. Soc 1945, 67, 1499. |

| [13] | Chen, J.-Q.; Li, J.-H.; Dong, Z.-B. Adv. Synth. Catal 2020, 362, 3311. |

| [14] | (a) Zhang, Z.; Huang, S.; Liu, W.; Zhao, L.-L.; Hu, C.; Yan, X. Green Synth. Catal 2023, 4, 300. |

| [14] | (b) McCallum, T. Green Synth. Catal 2023, 4, 10. |

| [14] | (c) Wang, H.; Xu, T. Chinese J. Org. Chem 2023, 43, 3328 (in Chinese). |

| [14] | (王贺盼, 徐涛, 有机化学, 2023, 43, 3328.) |

| [15] | (a) James, S. L.; Adams, C. J.; Bolm, C.; Braga, D.; Collier, P.; Fri??i?, T.; Grepioni, F.; Harris, K. D. M.; Hyett, G.; Jones, V.; Krebs, A.; Mack, J.; Maini, L.; Orpen, A. G.; Parkin, I. P.; Shearouse, W. C.; Steed, J. W.; Waddell, D. C. Chem. Soc. Rev 2012, 41, 413. |

| [15] | (b) Zhou, K.; Mao, Y.; Wu, F.; Lou, S.; Xu, D. Chinese J. Org. Chem. 2021, 41, 4623 (in Chinese). |

| [15] | (周琨, 毛羊杰, 吴峰伟, 娄绍杰, 许丹倩, 有机化学, 2021, 41, 4623.) |

| [15] | (c) Wang, H.; Ying, P.; Yu, J.; Su, W. Chinese J. Org. Chem. 2021, 41, 1897 (in Chinese). |

| [15] | (王浩, 应娉, 俞静波, 苏为科, 有机化学, 2021, 41, 1897.) |

| [16] | (a) Wang, G.-W.; Komatsu, K.; Murata, Y.; Shiro, M. Nature 1997, 387, 583. |

| [16] | (b) Wang, G.-W. Chin. J. Chem 2021, 39, 1797. |

| [16] | (c) Li, L.; Niu, C.; Wang, G.-W. Chin. J. Chem 2022, 40, 2539. |

| [17] | Koch, A.; Dufrois, Q.; Wirgenings, M.; G?rls, H.; Krieck, S.; Etienne, M.; Pohnert, G.; Westerhausen, M. Chem.-Eur. J. 2018, 24, 16840. |

| [18] | Pharmacopeia of the United States of America, 32nd revision, and the National Formulary, 27th ed., US Pharmacopeia, 2009. |

/

| 〈 |

|

〉 |