1 引言

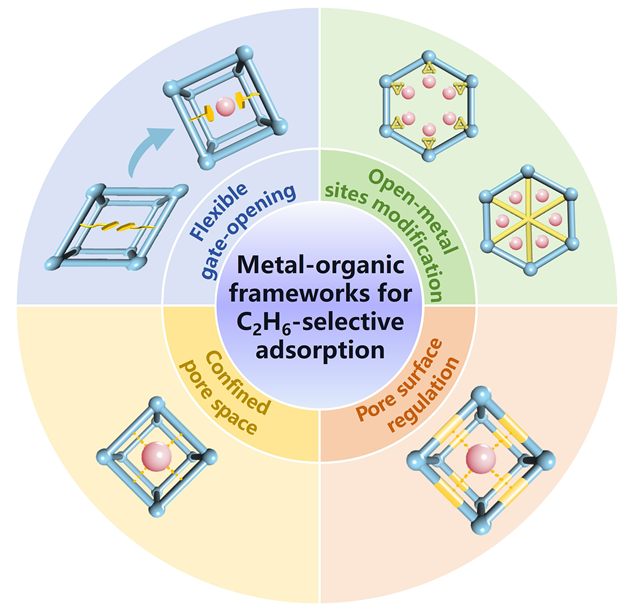

2 C2H6选择性MOF的结构识别机制

2.1 柔性识别机制

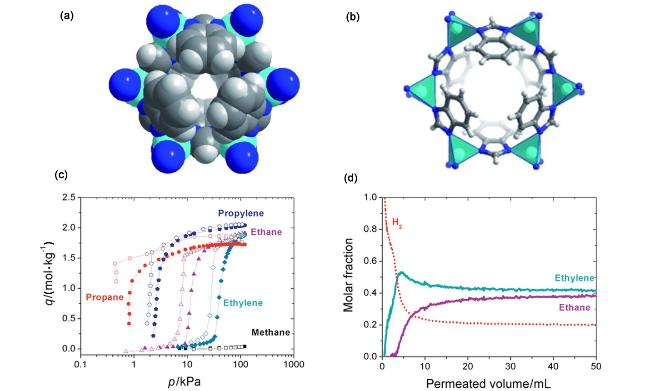

图 1 (a) ZIF-7的孔腔结构; (b)六元环孔口的侧面视图(锌簇以多面体形式表示); (c)在298 K下ZIF-7对多种烃类的吸附-脱附等温线; (d)在298 K和1 bar下C2H4和C2H6的等摩尔混合气的穿透曲线[25]Figure 1 (a) The main cavity structure of ZIF-7; (b) side view of the hexagonal ring aperture, with zinc clusters represented as polyhedrons; (c) adsorption-desorption isotherms of various hydrocarbons on ZIF-7 at 298 K; (d) the breakthrough curves of an equimolar mixture of C2H4 and C2H6 at 298 K and 1 bar.[25] Copyright 2010 American chemical society |

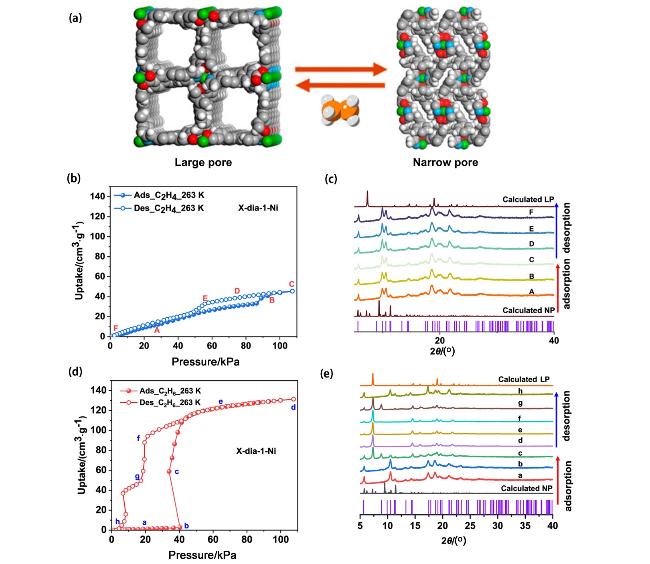

图2 (a) X-dia-1-Ni的LP相和NP相的孔结构示意图; (b, c, d, e) X-dia-1-Ni在气体吸附过程中的可逆结构演变[35]Figure 2 (a) Illustrations of the pore structure of the LP and NP phases of X-dia-1-Ni, respectively; (b, c, d, e) Reversible structural evolution of X-dia-1-Ni during gas adsorption.[35] Copyright 2024 American chemical Society |

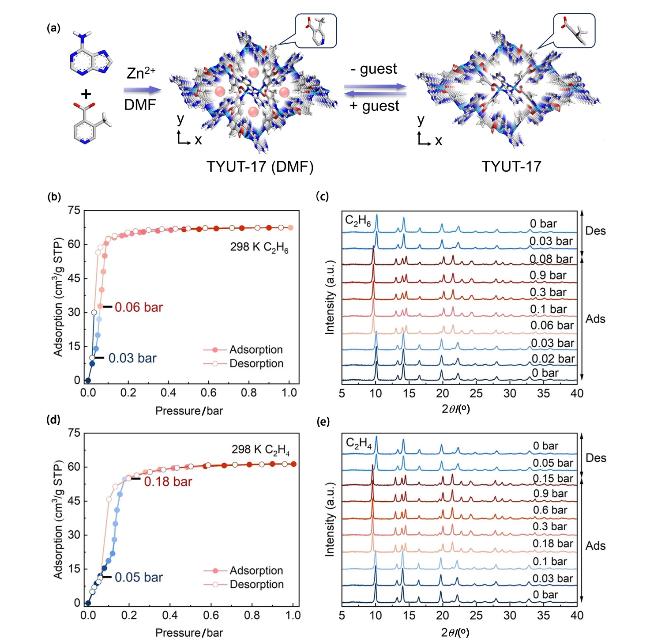

图3 (a)通过单晶X射线衍射揭示的TYUT-17在负载客体相和无客体相之间的结构转变(其中3-甲基异烟酸配体发生了旋转); (b, c, d, e) TYUT-17在气体吸附过程中的可逆结构演变[38]Figure 3 (a) The structural transformation of TYUT-17 between the guest-loaded and guest-free phases revealed by single-crystal X-ray diffraction, in which the 3-methylisonicotinic acid ligand undergoes rotation; (b, c, d, e) reversible structural evolution of TYUT-17 during gas adsorption. [38] Copyright 2025 WILEY-VCH GmbH |

2.2 金属开放位点修饰识别机制

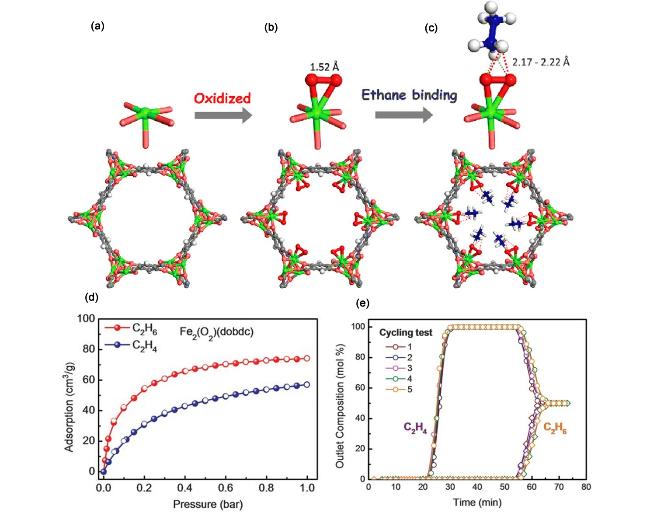

图4 (a) Fe2(dobdc)、(b) Fe2(O2)(dobdc)和(c) Fe2(O2)(dobdc)⊃C2D6在7 K下的结构; (d) C2H6和C2H4单组分吸附等温线; (e) C2H6/C2H4 (50/50, V/V)混合气穿透曲线[6]Figure 4 The structures of Fe2(dobdc) (a), Fe2(O2)(dobdc) (b), and Fe2(O2)dobdc⊃C2D6 (c) at 7 K; (d) C2H6 and C2H4 adsorption isotherms of Fe2(O2)(dobdc); (e) experimental column breakthrough curves for a C2H6/C2H4 (50/50, V/V) mixture.[6] Copyright 2018 American Association for the Advancement of Science |

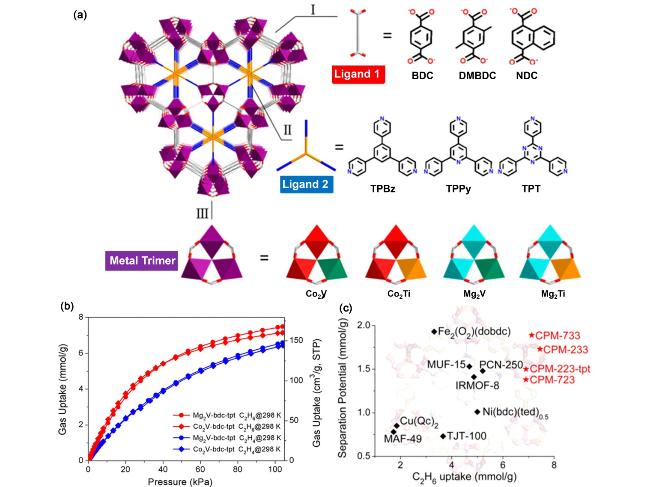

图5 (a)孔分割金属有机框架的三种模块: 配体1、配体2以及金属三聚体; (b) 298 K下, Mg2V-bdc-tpt和Co2V-bdc-tpt对C2H6和C2H4的吸附等温线; (c)部分高性能C2H6选择性材料的分离潜力与单一组分C2H6吸附量的关系[39]Figure 5 (a) Three modules of PSP metal-organic frameworks: Ligand 1, Ligand 2, and metal trimers; (b) adsorption isotherms of C2H6 and C2H4 in Mg2V-bdc-tpt and Co2V-bdc-tpt at 298 K; (c) separation potential versus single-component C2H6 uptake for the select high-performance C2H6-selective materials.[39] Copyright 2020 American chemical society |

2.3 孔表面调控识别机制

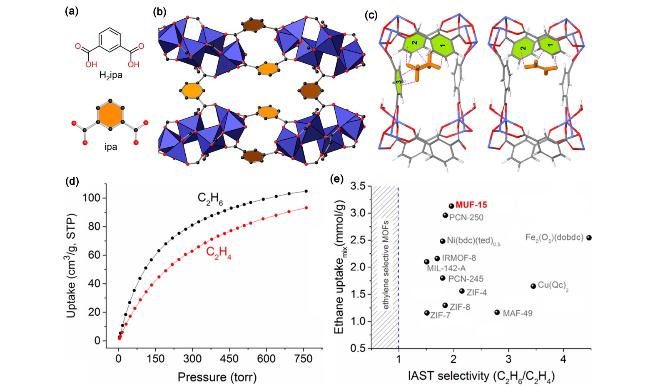

图6 (a) H2ipa连接体与(b) MUF-15的结构; (c) C2H6和C2H4优先吸附位点对比; (d) 293 K下MUF-15对C2H6和C2H4的吸附等温线; (e) MUF-15与部分C2H6选择性材料的C2H6吸附量及选择性对比[49]Figure 6 (a) Structure of the H2ipa linker; (b) Framework structure of MUF-15; (c) Comparison of the preferential C2H6 and C2H4 adsorption sites; (d) Adsorption isotherms of C2H6 and C2H4 on MUF-15 at 293 K; (e) Comparison of C2H6 adsorption capacity and selectivity between MUF-15 and selected ethane-selective materials[49] Copyright 2019 American chemical society |

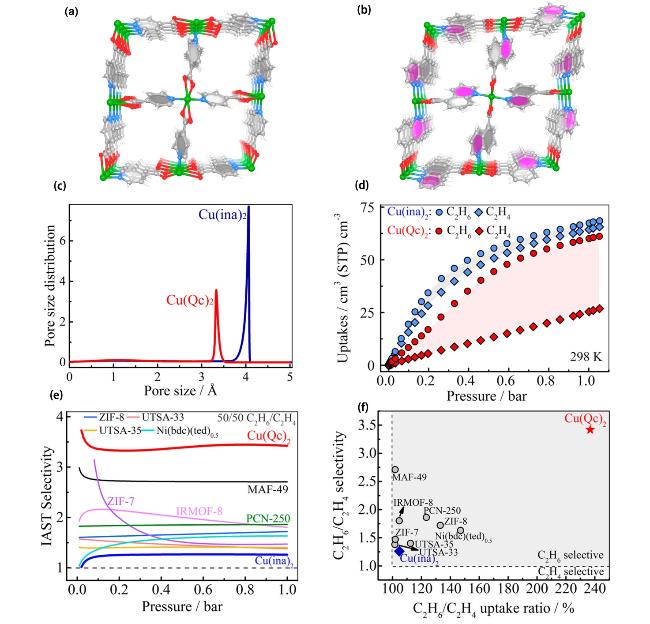

图7 (a) Cu(ina)2和(b) Cu(Qc)2的晶体结构和孔道对比; (c) Cu(ina)2和Cu(Qc)2的孔径分布; (d) Cu(ina)2和Cu(Qc)2在298 K时C2H6和C2H4的吸附等温线; (e) Cu(ina)2和Cu(Qc)2与其他材料的C2H6/C2H4选择性对比; (f) 298 K和1 bar下, Cu(ina)2和Cu(Qc)2的C2H6/C2H4选择性与吸附量对比[24]Figure 7 Comparison of crystal structures and channels between Cu(ina)2 (a) and Cu(Qc)2 (b); (c) Pore size distribution for Cu(ina)2 and Cu(Qc)2, based on sphere probes; (d) C2H6 and C2H4 sorption isotherms for Cu(ina)2 and Cu(Qc)2 at 298 K; (e) Comparative C2H6/C2H4 selectivity of Cu(ina)2 and Cu(Qc)2 versus benchmark materials; (f) Comparative C2H6/C2H4 selectivity and uptake capacity of Cu(ina)2 and Cu(Qc)2 at 298 K and 1 bar.[24] Copyright 2018 American chemical society |

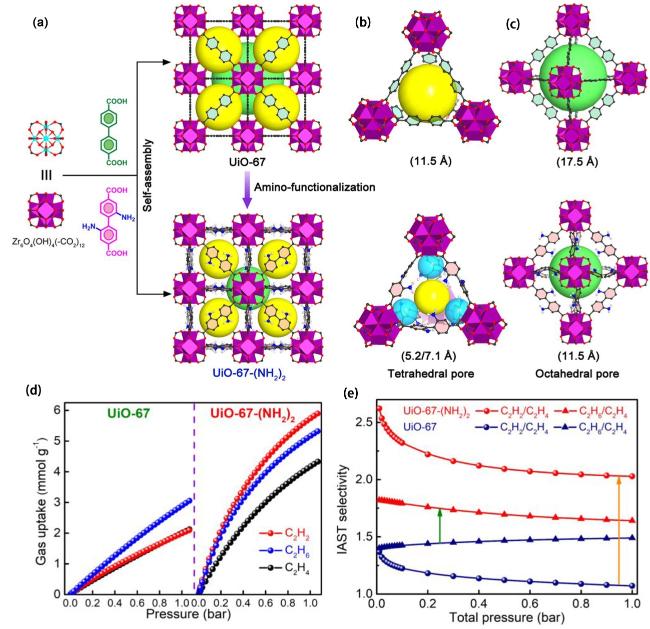

图8 (a) UiO-67与UiO-67-(NH2)2的晶体结构对比; (b, c) 四面体笼与八面体笼对比; (d) UiO-67与UiO-67-(NH2)2在296 K下的气体吸附等温线; (e) 296 K下C2H6/C2H4 (50/50)和C2H2/C2H4 (1/99)混合物的IAST选择性曲线[54]Figure 8 Comparison of (a) crystal structures between UiO-67 and UiO-67-(NH2)2; (b, c) tetrahedral cages and octahedral cages; (d) gas adsorption isotherms of UiO-67 and UiO-67-(NH2)2 at 296 K; (e) IAST selectivity curves for 50/50 C2H6/C2H4 and 1/99 C2H2/C2H4 mixtures at 296 K.[54] Copyright 2022 American chemical society |

2.4 限域空间识别机制

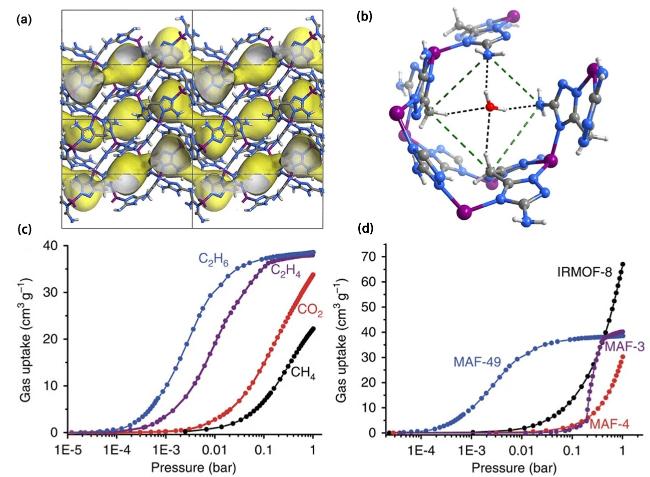

图9 (a) MAF-49的结构及孔形貌; (b) MAF-49的C2H6吸附位点; (c) MAF-49在316 K时对C2H6, C2H4, CO2和CH4的气体吸附等温线; (d) MAF-49, MAF-3, MAF-4和IRMOF-8在316 K时测得的C2H6吸附等温线对比[23]Figure 9 (a) Framework and pore surface structures of MAF-49; (b) preferential adsorption sites for C2H6 in MAF-49; (c) gas adsorption isotherms for C2H6, C2H4, CO2 and CH4 in MAF-49 at 316 K; (d) C2H6 adsorption isotherms of MAF-49, MAF-3, MAF-4 and IRMOF-8 measured at 316 K.[23] Copyright 2015 Springer Nature |

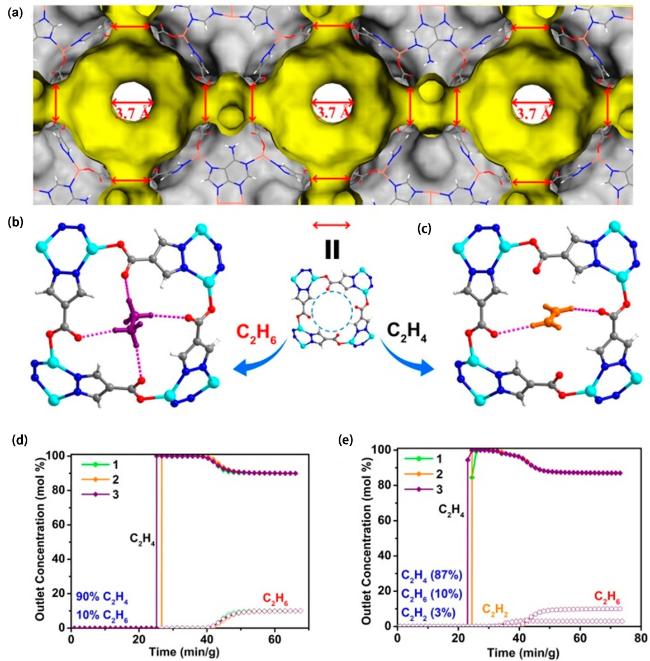

图10 (a) JNU-2的笼状结构; (b, c)通过DFT计算的C2H6和C2H4与JNU-2的主客体相互作用; (d), (e)分别为在干燥条件下C2H6/C2H4 (10/90)和C2H6/C2H4/C2H2 (10/87/3)混合气通过JNU-2填充床的三次循环动态穿透曲线[62]Figure 10 (a) Cage structure in JNU-2; (b, c) Comparison of the host-guest interactions of C2H6 and C2H4 with JNU-2 at the aperture by DFT calculations; (d, e) Three cycles of dynamic breakthrough curves for C2H6/C2H4(10/90) and C2H6/C2H4/C2H2 (10/87/3) mixtures through a packed bed of JNU-2 under dry condition.[62] Copyright 2019 American chemical society |

表1 C2H6/C2H4分离代表性MOF材料Table 1 Representative MOF materials for C2H6/C2H4 separation. |

| MOF材料 | 吸附机理 | BET/ (m2•g-1) | 孔容/ (cm3•g-1) | 孔径/ (Å or Å×Å) | 吸附量(mmol/g) (298 K, 1 bar) | IAST选择性 (50:50, 298 K, 1 bar) | 参考 文献 | |

|---|---|---|---|---|---|---|---|---|

| C2H4 | C2H6 | |||||||

| ZIF-7 | 柔性“开门”效应 | — | — | — | 1.90 | 2.00 | 2.5 | [25] |

| IRMOF-8 | 孔表面调控 | 1360 | 0.69 | 12.6 | 3.20 | 4.00 | 1.75 | [26] |

| MAF-49 | 限域空间 | — | — | — | 1.69 | 1.72 | 2.71 | [23] |

| Ni(bdc)(ted)0.5 | 孔表面调控 | 1701 | 0.79 | 7.94 | 3.40 | 5.00 | 1.85 | [27] |

| PCN-250 | 孔表面调控 | 1470 | 0.56 | 5.9/6.8/9.3 | 4.22 | 5.21 | 1.9 | [29] |

| Cu(Qc)2 | 孔表面调控 | 240 | 0.11 | 3.3 | 0.78 | 1.85 | 3.4 | [24] |

| Fe2(O2)(dobdc) | 金属空位点修饰 | 1073 | — | — | 2.55 | 3.32 | 4.4 | [6] |

| NbU-5 | 金属空位点修饰 | 671 | — | 4-5 | 3.04 | 3.39 | — | [44] |

| NOTT-101 | 金属空位点修饰 | 2930 | — | 7.3/13.6 | 6.92 | 7.59 | — | [44] |

| Ni(TMBDC)(DABCO)0.5 | 孔表面调控 | 894 | 0.39 | 5.9 | 5.02 | 5.45 | 1.99a | [69] |

| MUF-15 | 孔表面调控 | 1130 | 0.51 | 8.5×3.5 | 4.15b | 4.69b | 1.96b | [49] |

| MOF-801 | 孔表面调控 | 861 | — | 4.7 | 2.10 | 2.59 | 2.1 | [70] |

| JNU-2 | 限域空间 | 1219 | 0.56 | 3.4/4.6/6.7 | 3.62 | 4.11 | 1.6 | [62] |

| CPM-223 | 金属空位点修饰 | 1461 | — | 6.8 | 6.34 | 6.91 | 1.57 | [39] |

| CPM-223-tpbz | 金属空位点修饰 | 1662 | — | 6.8 | 6.25 | 6.88 | 1.51 | [39] |

| CPM-223-tppy | 金属空位点修饰 | 1599 | — | 6.8 | 7.17 | 7.34 | 1.28 | [39] |

| CPM-233 | 金属空位点修饰 | 1598 | — | 6.8 | 6.52 | 7.45 | 1.64 | [39] |

| CPM-238 | 金属空位点修饰 | 1444 | — | 5.9 | 5.25 | 5.56 | 1.43 | [39] |

| CPM-723 | 金属空位点修饰 | 1370 | — | 6.8 | 6.67 | 6.91 | 1.5 | [39] |

| CPM-733 | 金属空位点修饰 | 1329 | — | 7.3 | 6.37 | 7.13 | 1.75 | [39] |

| CPM-736 | 金属空位点修饰 | 473 | — | 5.9 | 3.88 | 4.03 | 1.48 | [39] |

| CPM-738 | 金属空位点修饰 | 1162 | — | 5.9 | 4.56 | 4.67 | 1.42 | [39] |

| Cd-PNMI | 孔表面调控 | 264 | — | 8.5×12.6 | 1.41 | 1.87 | 1.27c | [71] |

| Mn-PNMI | 孔表面调控 | 818 | — | 9.1×13.3 | 2.02 | 2.76 | 1.38c | [71] |

| Zn-PNMI | 孔表面调控 | 305 | — | 8.3×11.8 | 1.46 | 1.63 | 1.42c | [71] |

| NIIC-20-Bu | 限域空间 | 1033 | 0.555 | 2 | 1.4 | 2.5 | 15.4 | [72] |

| NIIC-20-Et | 限域空间 | 1161 | 0.836 | 5.5 | 1.8 | 2.4 | 3.5 | [72] |

| NIIC-20-GI | 限域空间 | 963 | 0.567 | 5.4 | 1.7 | 2.1 | 8.7 | [72] |

| NIIC-20-Pe | 限域空间 | 1023 | 0.567 | 1.8 | 1.6 | 2.2 | 8.4 | [72] |

| NIIC-20-Pr | 限域空间 | 1117 | 0.773 | 5 | 1.9 | 2.4 | 4 | [72] |

| NPU-1 | 孔表面调控 | 1396 | 0.47 | 4.8 | 4.20 | 4.50 | 1.32 | [73] |

| NPU-2 | 孔表面调控 | 1580 | 0.66 | 6 | 3.45 | 4.44 | 1.52 | [73] |

| NPU-3 | 孔表面调控 | 1834 | 0.77 | 7.8 | 2.22 | 3.36 | 3.21 | [73] |

| LIFM-31 | 金属空位点修饰 | 1711 | 0.71 | 6.8/11.8 | 1.80 | 2.40 | 1.4 | [40] |

| LIFM-61 | 金属空位点修饰 | 1194 | 0.49 | 7.3/11.8 | 1.40 | 1.70 | 1.3 | [40] |

| LIFM-62 | 金属空位点修饰 | 1977 | 0.82 | 5.9/11.7 | 2.00 | 2.60 | 1.4 | [40] |

| LIFM-63 | 金属空位点修饰 | 1486 | 0.62 | 5.6/8.6 | 2.10 | 3.00 | 1.6 | [40] |

| MOF-525 | 金属空位点修饰 | 3116 | — | — | 2.11 | 2.71 | 1.46 | [74] |

| MOF-525(Co) | 金属空位点修饰 | 2934 | — | — | 1.92 | 2.22 | 1.87 | [74] |

| UPC-612 | 金属空位点修饰 | 2016 | — | 14/20 | 2.79 | 3.58 | 1.4 | [74] |

| UPC-613 | 金属空位点修饰 | 853 | — | 7/12 | 2.31 | 2.55 | 1.48 | [74] |

| Ni(IN)2 | 孔表面调控 | 520 | 0.305 | 6 | 3.03 | 3.05 | 2.44 | [50] |

| SNNU-40 | 孔表面调控 | 2234 | 1.22 | 6.5 | 4.91 | 7.54 | 1.58 | [75] |

| NKMOF-8-Br | 孔表面调控 | 352 | 0.21 | 6.6 | 3.67 | 4.22 | 2.65 | [47] |

| NKMOF-8-Me | 孔表面调控 | 655 | 0.3 | 5.9 | 4.67 | 4.82 | 1.88 | [47] |

| Co(AIN)2 | 孔表面调控 | 450 | 0.19 | 6 | 3.14 | 3.17 | 2.96 | [46] |

| Zn-atz-oba | 限域空间 | 711 | 0.287 | 3.2/4.4 | 2.03 | 2.05 | 1.27 | [63] |

| Zn2(BDC)(H2BPZ)0.5(HBPZ)(BPZ)0.5 | 孔表面调控 | 977 | 0.47 | 8.8~10.2 | 3.26 | 3.47 | 1.5 | [76] |

| BIF-108-Zn | 金属空位点修饰 | 708 | 0.39 | 6.4 | 2.75 | 2.80 | 1.37 | [43] |

| UiO-67-(NH2)2 | 孔表面调控 | 2022 | 0.8 | 11.5/7.5/6.8 | 4.32d | 5.32d | 1.7d | [54] |

| MOF-841 | 孔表面调控 | 1426 | 0.53 | 8.5 | 3.40 | 4.70 | 1.6 | [77] |

| Zn-FBA | 孔表面调控 | 297 | — | 6 | 1.14 | 1.25 | 2.9 | [48] |

| Zn-(BDC)(H2BPZ) | 孔表面调控 | 907 | — | 8.0~10.2 | 3.29 | 3.63 | 2.2 | [45] |

| CuTiF6-TPPY | 孔表面调控 | 685 | 0.32 | 6 | 2.42 | 2.82 | 2.12 | [78] |

| Zn(ad)(int) | 限域空间 | 617 | — | 8 | 2.14 | 2.32 | 2.4 | [61] |

| Zn-ATA | 限域空间 | — | — | 3.5 | 1.20 | 1.10 | 1.75 | [79] |

| FJI-H11-Me | 孔表面调控 | — | — | — | 2.08 | 2.59 | 2.09e | [80] |

| PCP-IPA | 限域空间 | — | 0.19 | 4.7×5.6 | 2.13 | 2.50 | 2.8 | [64] |

| UPC-66-a | 柔性“开门”效应 | 483 | — | 7 | 2.41b | 2.72b | 1.65b | [81] |

| Tb-MOF-76(NH2) | 孔表面调控 | — | — | 8.2 | 2.97 | 3.27 | 2.1 | [53] |

| NKMOF-14-PZ | 限域空间 | 1561 | — | 8 | 3.44 | 5.64 | 1.89 | [82] |

| NKMOF-14-PD | 限域空间 | 1449 | — | 8 | 3.39 | 5.34 | 1.96 | [82] |

| UiO-66-CF3 | 孔表面调控 | 487 | — | 6.1 | 1.13 | 1.47 | 1.9 | [56] |

| PCP-IPA-NH2 | 孔表面调控 | 387 | 0.13 | 3.8×5.6 | 1.80 | 1.94 | 2.19 | [83] |

| PCP-FDCA | 孔表面调控 | 542 | 0.17 | 3.3×5.2 | 3.08 | 3.17 | 1.65 | [83] |

| Zn2(oba)2(dmimpym) | 孔表面调控 | 354 | — | 10~13 | 2.16 | 2.52 | 1.8 | [84] |

| Ni-MOF 2 | 孔表面调控 | 1501 | — | 8.1 | 4.69 | 5.94 | 1.9 | [60] |

| HIAM-210 | 孔表面调控 | 566 | 0.24 | 4.02 | 2.12 | 2.34 | 2 | [85] |

| TKL-105 | 孔表面调控 | 1509 | — | 6.2 | 4.44 | 5.62 | 1.37 | [86] |

| TKL-106 | 孔表面调控 | 1636 | — | 6.1 | 4.51 | 5.61 | 1.5 | [86] |

| TKL-107 | 孔表面调控 | 1454 | — | 6 | 5.24 | 6.00 | 1.36 | [86] |

| HIAM-326 | 孔表面调控 | 388 | 0.243 | 5.05 | 1.87 | 2.28 | 1.9 | [87] |

| JNU-6 | 孔表面调控 | 1411 | 0.59 | 5.4 | 3.77 | 5.07 | 1.47 | [88] |

| JNU-6-CH3 | 孔表面调控 | 1270 | 0.51 | 4.1 | 3.93 | 4.63 | 1.67 | [88] |

| Y-TATB | 限域空间 | 1562 | 0.62 | 7.5/12 | 2.98 | 4.32 | 1.87 | [66] |

| MOF-808 | 孔表面调控 | 1542 | — | 7.3/18 | 1.05 | 1.14 | 1.05 | [55] |

| MOF-808-Ind | 孔表面调控 | 948 | — | 12/14.8 | 1.39 | 1.68 | 1.23 | [55] |

| MOF-808-bzz | 孔表面调控 | 1003 | — | — | 2.20 | 1.90 | 1.9 | [55] |

| MOF-808-lzo | 孔表面调控 | 1130 | — | — | 1.56 | 1.74 | 1.22 | [55] |

| Zn-trz-ox | 孔表面调控 | 561 | — | 5.42 | 4.10 | 4.21 | 2.15 | [89] |

| UiO-66-2Me0.5 | 孔表面调控 | 944 | 0.39 | 9.7 | — | 1.85 | 1.82 | [90] |

| UiO-66-2Me | 孔表面调控 | 755 | 0.3 | 9.1 | — | 2.15 | 2.93 | [90] |

| FJI-W-66 | 柔性“开门”效应 | 329 | — | 5.2/4.4 | 1.29 | 1.32 | 1.39 | [91] |

| Zn-fa-datz(1) | 孔表面调控 | — | — | 6.1 | 1.69 | 1.97 | 1.6 | [92] |

| Zn-fa-atz(2) | 孔表面调控 | — | 0.283 | 6.3 | 1.50 | 1.40 | 1.4 | [92] |

| X-dia-1-Ni | 柔性“开门”效应 | — | — | — | 1.58f | 5.54f | 3.72f | [35] |

| X-dia-1-Ni0.89Co0.11 | 柔性“开门”效应 | — | — | — | 0.54f | 4.96f | 5.47f | [35] |

| MAC-4 | 孔表面调控 | 1180 | — | 6.4/10.8 | 3.71 | 4.78 | 2 | [93] |

| MAF-X10 | 孔表面调控 | 1644 | 0.67 | 4.9×6.8 | 3.57 | 5.07 | 1.5 | [94] |

| MAF-X10(Me) | 孔表面调控 | 1782 | 0.62 | 4.9×5.8 | 4.01 | 5.01 | 1.3 | [94] |

| MAF-X10(Cl) | 孔表面调控 | 1751 | 0.63 | 4.9×6.2 | 4.05 | 5.87 | 1.6 | [94] |

| MAF-X10(F) | 孔表面调控 | 1931 | 0.67 | 4.9×6.5 | 4.09 | 6.27 | 1.8 | [94] |

| ZNU-10 | 限域空间 | 1171 | 0.45 | 8.59 | 1.57 | 2.13 | 1.64 | [95] |

| Ni-bodc-tpt | 金属空位点修饰 | 1094 | — | 5~7 | 4.72 | 5.87 | 1.8 | [96] |

| V-bdc-tpt | 金属空位点修饰 | 1720 | 0.68 | 5.0/6.4 | 7.13 | 7.45 | 1.43 | [42] |

| V-bdc-tppy | 金属空位点修饰 | 1670 | 0.66 | 5.0/6.2 | 6.31 | 6.45 | 1.34 | [42] |

| V-bdc-tpbz | 金属空位点修饰 | 1460 | 0.6 | 5.0/6.0 | 5.83 | 5.97 | 1.30 | [42] |

| V-bpdc-tph | 金属空位点修饰 | 2964 | 1.18 | 10.9 | 3.12 | 5.37 | — | [42] |

| NTU-73-COOH | 孔表面调控 | 228 | 0.039 | 5.3 | 0.58 | 0.53 | 0.66 | [97] |

| NTU-73-CF3 | 孔表面调控 | 889 | 0.153 | 7.7 | 2.77 | 2.80 | 1.18 | [97] |

| NTU-73-CH3 | 孔表面调控 | 1078 | 0.185 | 9.2 | 3.47 | 4.01 | 1.33 | [97] |

| Zn-PCTF | 限域空间 | 934 | 0.357 | 7.3/8 | 2.83 | 3.53 | 1.75 | [98] |

| CuIn(3-ain)4 | 限域空间 | 429 | 0.231 | 5.4 | 2.68 | 2.71 | 3.32 | [65] |

| TJE-O | 孔表面调控 | 492 | — | 7.6 | 3.04 | 2.99 | 1.69 | [99] |

| TJE-S | 孔表面调控 | 331 | — | 7.8 | 2.10 | 2.59 | 2.79 | [99] |

| HIAM-316 | 孔表面调控 | 1110 | — | 5 | 2.01 | 2.76 | 1.67 | [100] |

| NKPOC-DS | 柔性“开门”效应 | 1016 | — | 5.7×3.6 | 2.38 | 2.75 | 1.43 | [36] |

| TYUT-17 | 柔性“开门”效应 | 505 | — | 6.7 | 2.74 | 3.01 | 6.41g | [38] |

| RT-Cu(Qc)2 | 孔表面调控 | 251 | 0.132 | — | 0.56 | 2.04 | 4.00 | [101] |

| CAU-23 | 孔表面调控 | 1240 | 0.42 | 5.7 | 3.80 | 4.00 | 1.54 | [102] |

| Zn-BPZ-TATB | 孔表面调控 | 1142 | 0.48 | 6.5/9.3 | 4.10 | 4.69 | 1.70 | [103] |

| MOF-303 | 孔表面调控 | 1244 | 0.52 | 5.8 | 5.00 | 5.01 | 1.70 | [104] |

| ZrT-1-ethenyl | 限域空间 | 915 | — | 5.4/10.3 | 2.46 | 2.79 | 1.40 | [105] |

| ZrT-1-alkyne | 限域空间 | 951 | — | 5.6/10.3 | 2.24 | 2.53 | 1.93 | [105] |

| Zn-CO3-datz | 限域空间 | 312 | 0.1795 | 5.9 | 1.69 | 1.80 | 1.71 | [106] |

| CoV-zMA-tpt | 金属空位点修饰 | 1679 | 0.651 | 6.3/7.8 | 5.98 | 6.61 | 1.54 | [107] |

| CSMOF-C5 | 孔表面调控 | — | — | 6.1 | 1.94 | 2.41 | 1.56 | [108] |

| MLMOF-C5 | 孔表面调控 | — | — | 5.4/8.4 | 1.61 | 2.69 | 2.25 | [108] |

| CFA-Zn-OAc | 孔表面调控 | 1875 | 0.64 | 6.8/10 | 3.16 | 3.97 | 1.49 | [109] |

| CFA-Zn-OH | 孔表面调控 | 2576 | 1.04 | 6.8/10.9 | 2.56 | 3.36 | 2.13 | [109] |

| UPC-250 | 孔表面调控 | 1674 | 0.94 | 7.8 | 2.32 | 3.56 | 1.47 | [110] |

| UPC-251 | 孔表面调控 | 1516 | 0.88 | 7.6 | 2.15 | 3.54 | 1.51 | [110] |

| NTU-70P | 孔表面调控 | 855 | 0.3411 | 6 | 3.74 | 4.03 | 2.6 | [111] |

| NTU-101 | 柔性“开门”效应 | 760 | 0.132 | — | 3.20 | 3.26 | — | [37] |

| NTU-101-NH2 | 柔性“开门”效应 | 650 | 0.111 | — | 2.31 | 2.48 | — | [37] |

| PAC-1 | 孔表面调控 | 346 | — | 13.1 | 1.90 | 2.09 | 1.4 | [52] |

| JNU-74a | 孔表面调控 | 1006 | 0.38 | 6.4-10.9 | 3.19 | 3.67 | 2.3 | [112] |

| SMS-POC-1 | 孔表面调控 | 1921 | — | — | 3.33 | 4.33 | 2.4 | [113] |

| ZnFPCP | 孔表面调控 | 330 | 0.17 | 4.9/5.3 | — | 1.11 | 2.93 | [114] |

| DMOF-TF-Cu | 孔表面调控 | 994 | 0.43 | 7.2 | 2.59 | 3.40 | 1.6 | [115] |

| DMOF-TF-Zn | 孔表面调控 | 1360 | 0.52 | 7.5 | 2.91 | 4.04 | 1.7 | [115] |

a C2H6/C2H4=1/15 (V/V); b 293 K; c C2H6/C2H4=1/9 (V/V); d 296 K; e C2H6/C2H4=1/99 (V/V); f 273 K; g 0.1 bar. |

3 C2H6吸附剂类型和多组分分离应用拓展

3.1 C2H6吸附剂类型的拓展

3.2 多组分分离应用的拓展

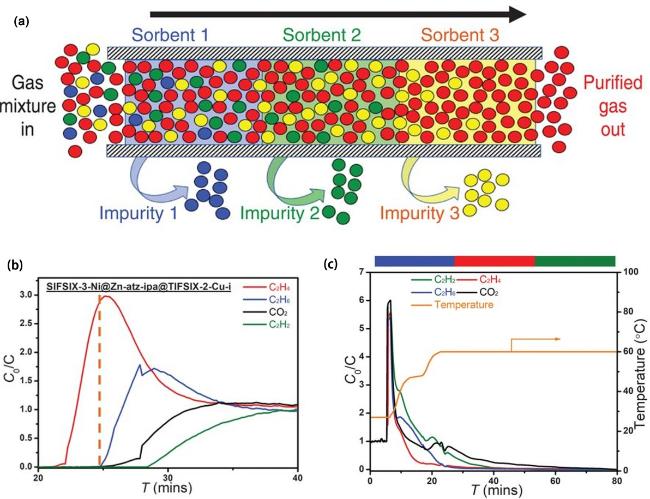

图12 (a) 协同吸附分离技术(SSST)示意图; (b, c)在298 K, 1 bar下, 采用SIFSIX-3-Ni@Zn-atz-ipa@TIFSIX-2-Cu-i串联填充色谱柱, 对CO2/C2H2/C2H4/C2H6 (1:1:1:1)分离的实验穿透和脱附曲线[128]Figure 12 (a) Schematic diagram of synergistic sorbent separation technology (SSST); (b, c) experimental column breakthrough and desorption curves for CO2/C2H2/C2H4/C2H6 (1:1:1:1) were obtained using a tandem-packed column of SIFSIX-3-Ni@Zn-atz-ipa@TIFSIX-2-Cu-i at 298 K and 1 bar.[128] Copyright © 2019 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science |