[1] Liu, H. Z. Chem. Ind. Eng. Prog. 2013, 32, 1995(in Chinese). (刘化章, 化工进展, 2013, 32, 1995.)

[2] Klerke, A.; Christensen, C. H.; Norskov, J. K.; Vegge, T. J. Mater. Chem. 2008, 18, 2304.

[3] Guo, J. P.; Chen, P. Chem 2017, 3, 709.

[4] Valera-Medina, A.; Xiao, H.; Owen-Jones, M.; David, W. I. F.; Bowen, P. J. Prog. Energy Combust. Sci. 2018, 69, 63.

[5] Smith, C.; Hill, A. K.; Torrente-Murciano, L. Energy Environ. Sci. 2020, 13, 331.

[6] Erisman, J. W.; Sutton, M. A.; Galloway, J.; Klimont, Z.; Winiwarter, W. Nat. Geosci. 2008, 1, 636.

[7] Wang, Q. R.; Guo, J. P.; Chen, P. J. Energy Chem. 2019, 36, 25(in Chinese). (王倩茹, 郭建平, 陈萍, 能源化学, 2019, 36, 25.)

[8] Norskov, J. K.; Chen, J. G. Sustainable Ammonia Synthesis, US Department of Energy, 2016.

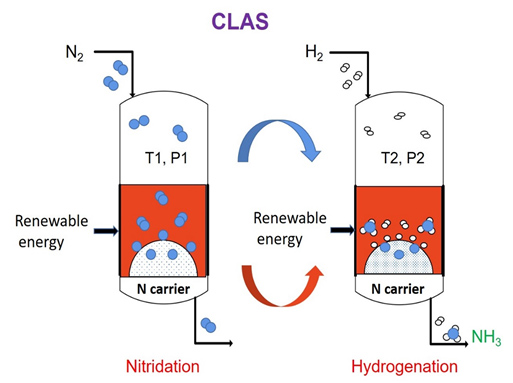

[9] Zeng, L.; Cheng, Z.; Fan, J. A.; Fan, L. S.; Gong, J. L. Nat. Rev. Chem. 2018, 2, 349.

[10] Gao, W. B.; Guo, J. P.; Wang, P. K.; Wang, Q. R.; Chang, F.; Pei, Q. J.; Zhang, W. J.; Liu, L.; Chen, P. Nat. Energy 2018, 3, 1067.

[11] Koerts, T.; Vansanten, R. A. J. C. S. Chem. Commun. 1991, 1281.

[12] Wang, Q. R.; Guo, J. P.; Chen, P. Joule 2020, 4, 705.

[13] Zeng, L.; Luo, S. W.; Li, F. X.; Fan, L. S. Sci. China Chem. 2012, 42, 260(in Chinese). (曾亮, 罗四维, 李繁星, 范良士, 中国科学:化学, 2012, 42, 260.)

[14] Chen, S.; Zeng, L.; Mu, R. T.; Xiong, C. Y.; Zhao, Z. J.; Zhao, C. J.; Pei, C. L.; Peng, L. M.; Luo, J.; Fan, L. S.; Gong, J. L. J. Am. Chem. Soc. 2019, 141, 18653.

[15] Gao, Y. F.; Wang, X. J.; Liu, J. C.; Huang, C. D.; Zhao, K.; Zhao, Z. L.; Wang, X. D.; Li, F. X. Sci. Adv. 2020, 6, eaaz9339.

[16] Tomkins, P.; Ranocchiari, M.; van Bokhoven, J. A. Acc. Chem. Res. 2017, 50, 418.

[17] Groothaert, M. H.; Smeets, P. J.; Sels, B. F.; Jacobs, P. A.; Schoonheydt, R. A. J. Am. Chem. Soc. 2005, 127, 1394.

[18] Cheng, Z.; Baser, D. S.; Nadgouda, S. G.; Qin, L.; Fan, J. A.; Fan, L. S. ACS Energy Lett. 2018, 3, 1730.

[19] Huang, C. D.; Wu, J.; Chen, Y. T.; Tian, M.; Rykov, A. I.; Hou, B. L.; Lin, J.; Chang, C. R.; Pan, X. L.; Wang, J. H.; Wang, A. Q.; Wang, X. D. Commun. Chem. 2018, 1, 55.

[20] Liu, Y.; Qin, L.; Cheng, Z.; Goetze, J. W.; Kong, F. H.; Fan, J. A.; Fan, L. S. Nat. Commun. 2019, 10, 6.

[21] Xu, B. J.; Bhawe, Y.; Davis, M. E. Proc. Natl. Acad. Sci. U. S. A. 2012, 109, 9260.

[22] Abanades, S.; Flamant, G. Solar Energy 2006, 80, 1611.

[23] Zhu, X.; Imtiaz, Q.; Donat, F.; Muller, C. R.; Li, F. X. Energy Environ. Sci. 2020, 13, 772.

[24] Duan, Y. F.; Chen, C. Z.; Zhang, J. S.; Wang, X. H.; Wei, J. J. Sci. China Chem. 2020, 50, 337(in Chinese). (段一菲, 陈存壮, 张军社, 王新赫, 魏进家, 中国科学:化学, 2020, 50, 337.)

[25] Jennings, J. R. Catalytic ammonia synthesis:Fundamentals and practice, Plenum Press, New York, 1991.

[26] Frank, A. R. Trans. Faraday Soc. 1908, 4, 099.

[27] Michalsky, R.; Pfromm, P. H. AlChE J. 2012, 58, 3203.

[28] Haber, F.; van Oordt, G. Z. Anorg. Chem. 1905, 44, 341.

[29] Chen, J. G.; Crooks, R. M.; Seefeldt, L. C.; Bren, K. L.; Bullock, R. M.; Darensbourg, M. Y.; Holland, P. L.; Hoffman, B.; Janik, M. J.; Jones, A. K.; Kanatzidis, M. G.; King, P.; Lancaster, K. M.; Lymar, S. V.; Pfromm, P.; Schneider, W. F.; Schrock, R. R. Science 2018, 360, eaar6611.

[30] Galvez, M. E.; Halmann, M.; Steinfeld, A. Ind. Eng. Chem. Res. 2007, 46, 2042.

[31] Galvez, M. E.; Frei, A.; Halmann, M.; Steinfeld, A. Ind. Eng. Chem. Res. 2007, 46, 2047.

[32] Molisani, A. L.; Yoshimura, H. N. Mater. Res. Bull. 2010, 45, 733.

[33] Wu, Y.; Jiang, G. D.; Zhang, H. B.; Sun, Z.; Gao, Y.; Chen, X. P.; Liu, H. Z.; Tian, H. J.; Lai, Q. H.; Fan, M. H.; Liu, D. Chem. Commun. 2017, 53, 10664.

[34] Gao, Y.; Wu, Y.; Zhang, Q.; Chen, X. P.; Jiang, G. D.; Liu, D. Int. J. Hydrogen Energy 2018, 43, 16589.

[35] Wu, Y.; Gao, Y.; Zhang, Q.; Cai, T.; Chen, X.; Liu, D.; Fan, M. Fuel 2020, 264, 116821.

[36] Zhang, Q.; Wu, Y.; Gao, Y.; Chen, X.; Liu, D.; Fan, M. Int. J. Hydrogen Energy 2020, 45, 9903.

[37] Michalsky, R.; Pfromm, P. H. Solar Energy 2011, 85, 2642.

[38] Michalsky, R.; Pfromm, P. H. J. Phys. Chem. C 2012, 116, 23243.

[39] Michalsky, R.; Parman, B. J.; Amanor-Boadu, V.; Pfromm, P. H. Energy 2012, 42, 251.

[40] Heidlage, M. G.; Kezar, E. A.; Snow, K. C.; Pfromm, P. H. Ind. Eng. Chem. Res. 2017, 56, 14014.

[41] Medford, A. J.; Vojvodic, A.; Hummelshoj, J. S.; Voss, J.; Abild-Pedersen, F.; Studt, F.; Bligaard, T.; Nilsson, A.; Norskov, J. K. J. Catal. 2015, 328, 36.

[42] Appl, M. Ammonia:Principles and industrial practice, Wiley-VCH, Weinheim, 1999.

[43] Michalsky, R.; Avram, A. M.; Peterson, B. A.; Pfromm, P. H.; Peterson, A. A. Chem. Sci. 2015, 6, 3965.

[44] Laassiri, S.; Zeinalipour-Yazdi, C. D.; Catlow, C. R. A.; Hargreaves, J. S. J. Appl. Catal. B 2018, 223, 60.

[45] Michalsky, R.; Pfromm, P. H.; Steinfeld, A. Interface Focus 2015, 5, 20140084.

[46] Shan, N.; Chikan, V.; Pfromm, P.; Liu, B. J. Phys. Chem. C 2018, 122, 6109.

[47] Shan, N. N.; Huang, C. R.; Lee, R. T.; Manavi, N.; Xu, L. B.; Chikan, V.; Pfromm, P. H.; Liu, B. ChemCatChem 2020, 12, 2233.

[48] Jacobsen, C. J. H. Chem. Commun. 2000, 1057.

[49] Jacobsen, C. J. H.; Dahl, S.; Clausen, B. S.; Bahn, S.; Logadottir, A.; Norskov, J. K. J. Am. Chem. Soc. 2001, 123, 8404.

[50] Kojima, R.; Aika, K. Chem. Lett. 2000, 514.

[51] McKay, D.; Gregory, D. H.; Hargreaves, J. S. J.; Hunter, S. M.; Sun, X. Chem. Commun. 2007, 3051.

[52] Hunter, S. M.; McKay, D.; Smith, R. J.; Hargreaves, J. S. J.; Gregory, D. H. Chem. Mater. 2010, 22, 2898.

[53] Hunter, S. M.; Gregory, D. H.; Hargreaves, J. S. J.; Richard, M.; Duprez, D.; Bion, N. ACS Catal. 2013, 3, 1719.

[54] Zeinalipour-Yazdi, C. D.; Hargreaves, J. S. J.; Catlow, C. R. A. J. Phys. Chem. C 2015, 119, 28368.

[55] Alexander, A. M.; Hargreaves, J. S. J.; Mitchell, C. Top. Catal. 2012, 55, 1046.

[56] Alexander, A. M.; Hargreaves, J. S. J.; Mitchell, C. Top. Catal. 2013, 56, 1963.

[57] Roy, D.; Navarro-Vazquez, A.; Schleyer, P. V. R. J. Am. Chem. Soc. 2009, 131, 13045.

[58] Swearer, D. F.; Knowles, N. R.; Everitt, H. O.; Halas, N. J. ACS Energy Lett. 2019, 4, 1505.

[59] McEnaney, J. M.; Singh, A. R.; Schwalbe, J. A.; Kibsgaard, J.; Lin, J. C.; Cargnello, M.; Jaramillo, T. F.; Nørskov, J. K. Energy Environ. Sci. 2017, 10, 1621.

[60] Goshome, K.; Miyaoka, H.; Yamamoto, H.; Ichikawa, T.; Ichikawa, T.; Kojima, Y. Mater. Trans. 2015, 56, 410.

[61] Yamaguchi, S.; Ichikawa, T.; Wang, Y. M.; Nakagawa, Y.; Isobe, S.; Kojima, Y.; Miyaoka, H. ACS Omega 2017, 2, 1081.

[62] Yamaguchi, T.; Shinzato, K.; Yamamoto, K.; Wang, Y.; Nakagawa, Y.; Isobe, S.; Ichikawa, T.; Miyaoka, H.; Ichikawa, T. Int. J. Hydrogen Energy 2020, 45, 6806.

[63] Gao, W. B.; Guo, J. P.; Chen, P. Chin. J. Chem. 2019, 37, 442.

[64] Veser, G. Nat. Energy 2018, 3, 1025.

[65] Hagen, S.; Barfod, R.; Fehrmann, R.; Jacobsen, C. J. H.; Teunissen, H. T.; Chorkendorff, I. J. Catal. 2003, 214, 327.

[66] Liu, T.; Temprano, I.; Jenkins, S. J.; King, D. A. J. Chem. Phys. 2013, 139, 184708

[67] Vojvodic, A.; Medford, A. J.; Studt, F.; Abild-Pedersen, F.; Khan, T. S.; Bligaard, T.; Norskov, J. K. Chem. Phys. Lett. 2014, 598, 108.

[68] Michalsky, R.; Steinfeld, A. Catal. Today 2017, 286, 124.

[69] Bartel, C. J.; Rumptz, J. R.; Weimer, A. W.; Holder, A. M.; Musgrave, C. B. ACS Appl. Mater. Interfaces 2019, 11, 24850. |