化学学报 ›› 2024, Vol. 82 ›› Issue (7): 755-762.DOI: 10.6023/A24030095 上一篇 下一篇

研究论文

段晓宣a, 王恒燕a, 潘大海b,*( ), 陈树伟b, 于峰a,*(

), 陈树伟b, 于峰a,*( ), 闫晓亮a, 李瑞丰a

), 闫晓亮a, 李瑞丰a

投稿日期:2024-03-21

发布日期:2024-05-15

基金资助:

Xiaoxuan Duana, Hengyan Wanga, Dahai Panb,*( ), Shuwei Chenb, Feng Yua,*(

), Shuwei Chenb, Feng Yua,*( ), Xiaoliang Yana, Ruifeng Lia

), Xiaoliang Yana, Ruifeng Lia

Received:2024-03-21

Published:2024-05-15

Contact:

*E-mail: Supported by:文章分享

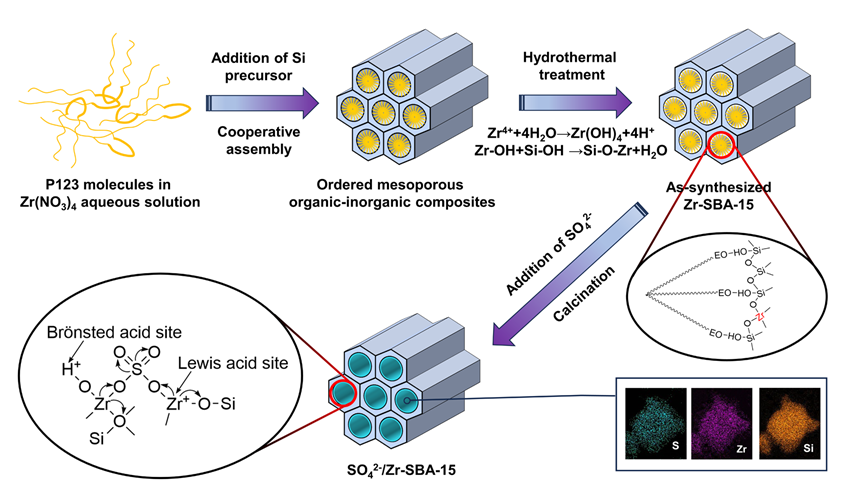

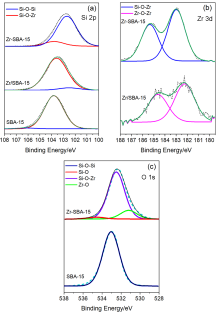

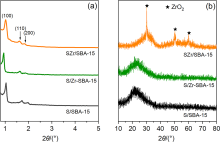

借助硝酸锆水解所产生的弱酸性环境, 结合高温水热处理, 一步合成了具有规整有序孔道结构且孔壁表面富含锆氧物种的Zr-SBA-15介孔材料, 并将其用于硫酸基团的高效稳定负载. 介孔骨架中大量锆原子的高度均匀掺杂及孔壁表面Zr—O—Si键的形成不仅有利于负载更多量的硫酸基团, 且能在诱使超强酸性中心产生的同时, 有效抑制硫酸化锆氧活性组分在反应过程中流失, 致使固体酸材料SO42−/Zr-SBA-15显示出较传统负载型硫酸化氧化锆固体酸更高的酸量和酸强度, 继而在大豆油合成生物柴油酯交换反应中显示出明显提升的催化活性和稳定性, 其在经三次重复使用过程中, 均可实现将91%以上的大豆油近完全转化为生物柴油.

段晓宣, 王恒燕, 潘大海, 陈树伟, 于峰, 闫晓亮, 李瑞丰. SBA-15负载硫酸化氧化锆固体酸材料的设计合成及其酯交换反应催化性能研究[J]. 化学学报, 2024, 82(7): 755-762.

Xiaoxuan Duan, Hengyan Wang, Dahai Pan, Shuwei Chen, Feng Yu, Xiaoliang Yan, Ruifeng Li. Designed Synthesis of SBA-15 Supported Sulfated Zirconia Solid Acid Materials and Their Catalytic Performance for Transesterification Reaction[J]. Acta Chimica Sinica, 2024, 82(7): 755-762.

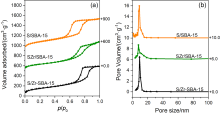

| Sample | a0a/ nm | SBETb/ (m2•g−1) | VPc/ (cm3•g−1) | DPd/ nm | w(S)e/ % |

|---|---|---|---|---|---|

| S/Zr-SBA-15 | 10.7 | 539 | 0.96 | 9.1 | 1.91 |

| S/SBA-15 | 9.8 | 627 | 0.98 | 8.8 | 0.31 |

| SZr/SBA-15 | 9.8 | 467 | 0.91 | 7.7 | 0.98 |

| Sample | a0a/ nm | SBETb/ (m2•g−1) | VPc/ (cm3•g−1) | DPd/ nm | w(S)e/ % |

|---|---|---|---|---|---|

| S/Zr-SBA-15 | 10.7 | 539 | 0.96 | 9.1 | 1.91 |

| S/SBA-15 | 9.8 | 627 | 0.98 | 8.8 | 0.31 |

| SZr/SBA-15 | 9.8 | 467 | 0.91 | 7.7 | 0.98 |

| Sample | Weak acid/ (μmol•g−1) | Medium acid/ (μmol•g−1) | Strong acid/ (μmol•g−1) | Super acid/ (μmol•g−1) | Total acid/ (μmol•g−1) |

|---|---|---|---|---|---|

| S/Zr-SBA-15 | 40.10 | 67.44 | 188.42 | 22.26 | 318.23 |

| SZr/SBA-15 | 39.98 | 106.76 | 69.34 | — | 216.08 |

| S/SBA-15 | 17.63 | 43.69 | 27.88 | — | 89.20 |

| Sample | Weak acid/ (μmol•g−1) | Medium acid/ (μmol•g−1) | Strong acid/ (μmol•g−1) | Super acid/ (μmol•g−1) | Total acid/ (μmol•g−1) |

|---|---|---|---|---|---|

| S/Zr-SBA-15 | 40.10 | 67.44 | 188.42 | 22.26 | 318.23 |

| SZr/SBA-15 | 39.98 | 106.76 | 69.34 | — | 216.08 |

| S/SBA-15 | 17.63 | 43.69 | 27.88 | — | 89.20 |

| [1] |

Tang W.-Q.; Gao M.; Zhang B.-X.; Wang X.-N.; Wu C.-F.; Wang Q.-H.; Liu S. J. Environ. Chem. Eng. 2023, 11, 109797.

|

| [2] |

Jiang L.; Fan Y.-Q.; Zhang X.-X.; Pei Y.; Yan S.-R.; Qiao M.-H.; Fan K.-N.; Zong B.-N. Acta Chim. Sinica 2023, 81, 231 (in Chinese).

doi: 10.6023/A22120509 |

|

(姜兰, 范义秋, 张晓昕, 裴燕, 闫世润, 乔明华, 范康年, 宗保宁, 化学学报, 2023, 81, 231.)

doi: 10.6023/A22120509 |

|

| [3] |

Fatimah I.; Yanti I.; Suharto T. E.; Sagadevan S. Inorg. Chem. Commun. 2022, 143, 109808.

|

| [4] |

Parekh A.; Mishra M. K.; Shukla A. D. Appl Catal, A. 2023, 663, 119268.

|

| [5] |

Rattanaphra D.; Temrak A.; Nuchdang S.; Kingkam W.; Puripunyavanich V.; Thanapimmetha A.; Saisriyoot M.; Srinophakun P. Energy Rep. 2021, 7, 5374.

|

| [6] |

Wang G.; Li Z.-X. Chem. Eng. J. 2022, 432, 134395.

|

| [7] |

Wang S.; Meng X.; Liu N.-W.; Shi L. Sep. Purif. Technol. 2023, 308, 122731.

|

| [8] |

Sekewael S. J.; Pratika R. A.; Hauli L.; Amin A. K.; Utami M.; Wijaya K. Catalysts 2022, 12, 191.

|

| [9] |

Delarmelina M.; Deshmukh G.; Goguet A.; Catlow C. R. A.; Manyar H. J. Phys. Chem. C 2021, 125, 27578.

doi: 10.1021/acs.jpcc.1c06920 pmid: 34970379 |

| [10] |

Wang S.; Pu J.-L.; Wu J.-Q.; Liu H.-J.; Xu H.-Y.; Li X.; Wang H. ACS Omega 2020, 5, 30139.

|

| [11] |

Wang P.-Z.; Yue Y.-Y.; Wang T.-H.; Bao X.-J. Int. J. Energy Res. 2020, 44, 3270.

|

| [12] |

Colmenares-Zerpa J.; Gajardo J.; Peixoto A. F.; Silva D. S. A.; Silva J. A.; Gispert-Guirado F.; Llorca J.; Urquieta-Gonzalez E. A.; Santos J. B. O.; Chimentão R. J. J. Solid. State. Chem. 2022, 312, 123296.

|

| [13] |

Liu Z.-H.; Zhang Z.-Z.; Zhou Y.-L.; Wang Z.-L.; Du M.-Y.; Wen Z.; Yan B.; Ma Q.-X.; Liu N.; Xue B. Fuel 2024, 356, 129631.

|

| [14] |

Colmenares-Zerpa J.; Chimentão R. J.; Gispert-Guirado F.; Peixoto A. F.; Llorca J. Mater. Lett. 2021, 301, 130326.

|

| [15] |

Jin D.-F.; Hu G.-B.; Jin H.-X.; Wang X.-Q.; Hong B.; Peng X.-L.; Ge H.-L. Rare Metal Mat. Eng. 2012, 41, 379.

|

| [16] |

Huo L.-M.; Wang T.; Xuan K.; Li L.; Pu Y.-F.; Li C.-X.; Qiao C.-Z.; Yang H.; Bai Y. Catalysts 2021, 11, 710.

|

| [17] |

Tang Y.-Q.; Zong E.-M.; Wan H.-Q.; Xu Z.-Y.; Zheng S.-R.; Zhu D.-Q. Microporous Mesoporous Mater. 2012, 155, 192.

|

| [18] |

Sabbaghi A.; Lam F. L. Y.; Hu X.-J. J. Mol. Catal. A: Chem. 2015, 409, 69.

|

| [19] |

Ahn H.; Chen H. W.; Landheer D.; Wu X.; Chou L. J.; Chao T. S. Thin Solid Films 2004, 455-456, 318.

|

| [20] |

Sabbaghi A.; Lam F. L. Y.; Hu X.-J. Appl. Catal., A 2015, 508, 25.

|

| [21] |

Chen S.-Y.; Lee J.-F.; Cheng S. J. Catal. 2010, 270, 196.

|

| [22] |

Thunyaratchatanon C.; Luengnaruemitchai A.; Chaisuwan T.; Chollacoop N.; Chen S.-Y.; Yoshimura Y. Microporous Mesoporous Mater. 2017, 253, 18.

|

| [23] |

Wei Y.-F.; Li Y.-F.; Tan Y.; Zhou J.; Wu Z.-M.; Liu Y.-J. Mater. Lett. 2015, 141, 145.

|

| [24] |

Sareen S.; Mutreja V.; Singh S.; Pal B. J. Colloid Interface Sci. 2016, 461, 203.

|

| [25] |

Gajardo J.; Colmenares-Zerpa J.; Peixoto A. F.; Silva D. S. A.; Silva J. A.; Gispert-Guirado F.; Llorca J.; Urquieta-Gonzalez E. A.; Santos J. B. O.; Szanyi J.; Sepúlveda C.; Álvarez M. G.; Chimentão R. J. J. Porous Mater. 2023, 30, 1687.

|

| [26] |

Krishnan C. K.; Hayashi T.; Ogura M. Adv. Mater. 2008, 20, 2131.

|

| [27] |

Liu X.-X.; Wang K.; Liu B.-Q.; Guo Z.-M.; Zhang C.; Lv Z.-G. J. Solid State Chem. 2021, 300, 122239.

|

| [28] |

Naghavi M.; Mazloom G.; Akbari A.; Banisharif F. Chem. Eng. Res. Des. 2021, 174, 454.

|

| [29] |

Ren K.-Q.; Kong D.-C.; Meng X.; Wang X.; Shi L.; Liu N.-W. J. Saudi Chem. Soc. 2019, 23, 198.

|

| [30] |

Ganiyu S. A.; Alhooshani K. Energy Fuels 2019, 33, 3047.

|

| [31] |

Noda L. K.; De Almeida R. M.; Probst L. F. D.; Gonçalves N. S. J. Mol. Catal. A: Chem. 2005, 225, 39.

|

| [32] |

Yan G. X.; Wang A.-Q.; Wachs I. E.; Baltrusaitis J. Appl. Catal., A 2019, 572, 210.

|

| [33] |

Rizwanul Fattah I. M.; Ong H. C.; Mahlia T. M. I.; Mofijur M.; Silitonga A. S.; Rahman S. M. A.; Ahmad A. Front. Energy Res. 2020, 8, 101.

|

| [34] |

Garcia C.; Teixeira S.; Marciniuk L.; Schuchardt U. Bioresour. Technol. 2008, 99, 6608.

|

| [1] | 邓权政, 毛文婷, 韩璐. 介观尺度多孔材料的电子显微学结构解析[J]. 化学学报, 2022, 80(8): 1203-1216. |

| [2] | 廉优芬, 闫碌碌, 王羽, 漆新华. 果糖一步水热合成碳微球固体酸催化纤维素水解[J]. 化学学报, 2014, 72(4): 502-507. |

| [3] | 邵悦, 马勇. 氨基表面功能化的有序介孔杂合材料的一步法合成及其对重金属离子和CO2 的吸附特性[J]. 化学学报, 2012, 70(18): 1957-1962. |

| [4] | 陈崇城, 陈航榕, 叶争青, 施剑林, 俞建长. 多级孔结构WO3/ZrO2 固体酸催化剂的烷基化催化性能研究[J]. 化学学报, 2012, 0(04): 423-428. |

| [5] | 马亚军, 薛成虎. 吡啶氮桥联双环三唑鎓盐的合成及其在催化苯偶姻缩合、酯交换反应中的应用[J]. 化学学报, 2010, 68(9): 897-903. |

| [6] | 王业红, 谭涓, 刘靖, 陈颖, 李旭影. 萃取法脱除介孔磷酸镍模板剂的研究[J]. 化学学报, 2010, 68(23): 2471-2476. |

| [7] | 朱瑾瑜, 沈逸, 吴龙, 甘思文, 陈安琪, 沈祝萍, 潘小庆, 陈勇. 有机/无机复合介孔膜的合成及其生物酶吸附行为研究[J]. 化学学报, 2010, 68(21): 2231-2237. |

| [8] | 阮礼波, 刘烽, 欧文华, 毛海舫, 潘仙华. H3PO4/Zr(OH)4高效促进NBS对取代烷基苯的亲电溴代[J]. 化学学报, 2010, 68(07): 713-716. |

| [9] | 宋琳, 朱大章, 孙晓宇, 汪世龙, 孙冬梅. 介孔球状纳米羟基磷灰石的多级组装合成[J]. 化学学报, 2009, 67(23): 2697-2702. |

| [10] | 袁金芳,李健生,顾娟,夏敏亚,孙秀云,韩卫清,王连军. 一种合成六方板状Zr-Ce-SBA-15介孔材料的新方法[J]. 化学学报, 2009, 67(11): 1271-1275. |

| [11] | 田博士,杨春. 温敏性介孔复合材料PNIPAAm/SBA-15的制备与表征[J]. 化学学报, 2008, 66(5): 505-510. |

| [12] | 曹洁明, 吴伟, 陈煜, 刘劲松, 曹喻霖, 何建平, 唐亚文, 杨春, 陆天虹. 新型阳极材料Pt-Ru/CMK-3的制备与性能研究[J]. 化学学报, 2007, 65(12): 1117-1122. |

| [13] | 张蝶青,万颖,李和兴. 喷雾干燥辅助表面活性剂自组装制备新型SiO2介孔材料[J]. 化学学报, 2006, 64(9): 894-898. |

| [14] | 张存满,刘茜,徐政. 具有碱催化活性的有序氮氧化硅MCM-41介孔分子筛的制备与性能研究[J]. 化学学报, 2006, 64(4): 313-319. |

| [15] | 牛红英,郭海明,姚洁,王越,王公应. 茂钛类络合物催化碳酸二甲酯和苯酚酯交换反应合成碳酸二苯酯的研究[J]. 化学学报, 2006, 64(12): 1269-1272. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||