Beta分子筛催化剂上甲苯和三甲苯烷基转移反应条件优化及其反应机理研究

收稿日期: 2016-02-03

网络出版日期: 2016-05-13

基金资助

项目受国家自然科学基金面上项目(21273263, 21273264), 山西省回国留学人员科研资助项目(2014-102)和山西省人社厅留学回国人员择优资助项目资助.

Optimization of Reaction Conditions in the Transalkylation of Toluene with 1,2,4-Trimethylbenzene Catalyzed by Beta Zeolite and the Investigation of Its Reaction Mechanism

Received date: 2016-02-03

Online published: 2016-05-13

Supported by

Project supported by the National Natural Science Foundation of China (21273263, 21273264), the Research Project Supported by Shanxi Scholarship Council of China (2014-102) and Department of Human Resource and Social Security of Shanxi Province.

李艳春 , 王浩 , 董梅 , 李俊汾 , 王国富 , 秦张峰 , 樊卫斌 , 王建国 . Beta分子筛催化剂上甲苯和三甲苯烷基转移反应条件优化及其反应机理研究[J]. 化学学报, 2016 , 74(6) : 529 -537 . DOI: 10.6023/A16020077

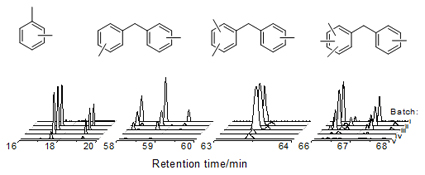

The effect of reaction conditions and acidic property of Beta zeolite on the transalkylation reaction between toluene and trimethylbenzene (TMB) was studied systematically. The results indicate that the activity and stability of catalysts are strongly dependent on the reaction conditions including reactant composition, reaction temperature and pressure, and crystal size as well as the acidic property of the zeolite. For TMB disproportionation reaction, the addition of toluene should be helpful to the increase of selectivity of xylene. In the meantime, for the disproportionation reaction of toluene, the mixing of TMB into feedstocks can also increase the xylene yield. Therefore, the higher yield of xylene is obtained at the equal molar ratio of toluene and TMB as feedstocks. The temperature of reaction plays an important role on the transalkylation of toluene with TMB. The catalytic activity of transalkylation increases gradually with the increasing of reaction temperature until 450 ℃, and then the dealkylation reaction and the formation of coke will be intensified with the further increasing of temperature, which leads to the decrease of catalytic stability. Therefore, the optimum temperature for transalkylation reaction is 450 ℃. The increasing of reaction pressure also has a positive effect on the catalytic activity of transalkylation. Thus, the transalkylation reaction is conducted at the pressure of 3 MPa taking into account the bearing capacity of reactor. The transalkylation catalytic activity is decreased with the increase of Si/Al ratio of Beta zeolite because of the reduction of the amount of acid sites that act as the active sites for transformation of alkylaromatics. The catalytic stability of zeolite could be significantly improved with the decrease of crystal size. In order to investigate the reaction mechanism of transalkylation, gas chromatography-mass spectrometry (GC-MS) technique is used to study the generation and decomposition of intermediate species over Beta zeolite during the transalkylation reaction at the lower experiment temperature of 150 ℃ because the intermediate species is instable at higher reaction temperature. The results indicate that the transalkylation of toluene with 1,2,4-TMB occurs via the bimolecular intermediate mechanism. As the bulky species, the formation and decomposition of these intermediate species require a large zeolite channel. Therefore, the Beta zeolite with 12 member-ring large pore shows higher catalytic activity for transalkylation reaction.

[1] Tsai, T.-C.; Liu, S.-B.; Wang, I. Appl. Catal. A 1999, 181, 355.

[2] Xu, O.; Su, H.; Ji, J.; Jin, X.; Chu, J. Chin. J. Chem. Eng. 2007, 15, 326.

[3] Tukur, N. M.; Al-Khattaf, S. Energy Fuels 2007, 21, 2499.

[4] Chen, Q. L.; Kong, D. J.; Yang, W. S. Petrochem. Technol. 2004, 33, 909.(陈庆龄, 孔德金, 杨卫胜, 石油化工, 2004, 33, 909.)

[5] Hamedi, N.; Iranshahi, D.; Rahimpour, M. R.; Raeissi, S.; Rajaei, H. J. Taiwan Inst. Chem. Eng. 2015, 48, 56.

[6] Ali, S. A.; Ogunronbi, K. E.; Al-Khattaf, S. S. Chem. Eng. Res. Des. 2013, 91, 2601.

[7] Ali, S. A.; Aitani, A. M.; Ercan, C.; Wang, Y.; Al-Khattaf, S. Chem. Eng. Res. Des. 2011, 89, 2125.

[8] Tsai, T.-C.; Liu, S.-B.; Wang, I. Catal. Surv. Asia 2009, 13, 94.

[9] ?ejka, J.; Wichterlová, B. Catal. Rev.: Sci. Eng. 2002, 44, 375.

[10] Chen, N. Y.; Degnan, T. F. Chem. Eng. Prog. 1988, 84, 32.

[11] Lee, Y.-K.; Park, S.-H.; Rhee, H.-K. Catal. Today 1998, 44, 223.

[12] Chao, K.-J.; Leu, L.-J. Zeolites 1989, 9, 193.

[13] Krej?í, A.; Al-Khattaf, S.; Ali, M. A.; Bejblová, M.; ?ejka, J. Appl. Catal., A 2010, 377, 99.

[14] Yue, Y. H.; Tang, Y.; Kan, Y. Z.; Gao, Z. Acta Chim. Sinica 1996, 54, 591.(乐英红, 唐颐, 阚勇志, 高滋, 化学学报, 1996, 54, 591.)

[15] Meshram, N. R.; Kulkarni, S. B.; Ratnasamy, P. J. Chem. Technol. Biotechnol., Chem. Technol. 1984, 34, 119.

[16] Ji, Y. J.; Zhang, B.; Zhang, K.; Xu, L.; Peng, H. G.; Wu, P. 1980, 38, 191.(纪永军, 张斌, 张坤, 徐乐, 彭洪根, 吴鹏, 化学学报, 1980, 38, 191.)

[17] Higgins, J. B.; LaPierre, R. B.; Schlenker, J. L.; Rohrman, A. C.; Wood, J. D.; Kerr, G. T.; Rohrbaugh, W. J. Zeolites 1988, 8, 446.

[18] Hegde, S. G.; Kumar, R.; Bhat, R. N.; Ratnasamy, P. Zeolites 1989, 9, 231.

[19] Wang, I.; Tsai, T. C.; Huang, S. T. Ind. Eng. Chem. Res. 1990, 29, 2005.

[20] Dumitriu, E.; Hulea, V.; Kaliaguine, S.; Huang, M. M. Appl. Catal., A 1996, 135, 57.

[21] Corma, A.; Llopis, F.; Monton, J. B. J. Catal. 1993, 140, 384.

[22] Al-Khattaf, S.; Ali, S. A.; Aitani, A. M.; Zilkova, N.; Kubicka, D.; Cejka, J. Catal. Rev.: Sci. Eng. 2014, 56, 333.

[23] Corma, A.; Sastre, E. J. Catal. 1991, 129, 177.

[24] Xiong, Y.; Rodewald, P. G.; Chang, C. D. J. Am. Chem. Soc. 1995, 117, 9427.

[25] Svelle, S.; Olsbye, U.; Lillerud, K.-P.; Kolboe, S.; Bjørgen, M. J. Am. Chem. Soc. 2006, 128, 5618.

[26] Li, Y. C.; Wang, H.; Dong, M.; Li, J. F.; Qin, Z. F.; Wang, J. G.; Fan, W. B. RSC Adv. 2015, 5, 66301.

[27] Newsam, J.; Treacy, M. M.; Koetsier, W.; De Gruyter, C. Proc. R. Soc. Lond. A 1988, 420, 375.

[28] Min, H.-K.; Chidambaram, V.; Hong, S. B. J. Phys. Chem. C 2010, 114, 1190.

[29] Byun, Y.; Jo, D.; Shin, D. N.; Hong, S. B. ACS Catal. 2014, 4, 1764.

[30] Camblor, M. A.; Mifsud, A.; Pérez-Pariente, J. Zeolites 1991, 11, 792.

/

| 〈 |

|

〉 |