收稿日期: 2020-12-07

网络出版日期: 2021-02-05

基金资助

国家重大研究计划(2016YFA0200803); 国家重大研究计划(2017YFA0204504); 国家重大研究计划(2016YFB0402004); 国家自然科学基金(51673207); 国家自然科学基金(51873221); 国家自然科学基金(52073292); 中科院-荷兰合作项目(1A111KYSB20190072); 北京市科技计划(Z181100004418012)

Research Progress of Bioinspired Photonic Crystal Fibers

Received date: 2020-12-07

Online published: 2021-02-05

Supported by

Ministry of Science and Technology of China(2016YFA0200803); Ministry of Science and Technology of China(2017YFA0204504); Ministry of Science and Technology of China(2016YFB0402004); National Natural Science Foundation of China(51673207); National Natural Science Foundation of China(51873221); National Natural Science Foundation of China(52073292); Chinese Academy of Sciences and Dutch research project(1A111KYSB20190072); Beijing Municipal Science & Technology Commission(Z181100004418012)

裴广晨 , 王京霞 , 江雷 . 仿生光子晶体纤维的研究进展[J]. 化学学报, 2021 , 79(4) : 414 -429 . DOI: 10.6023/A20120556

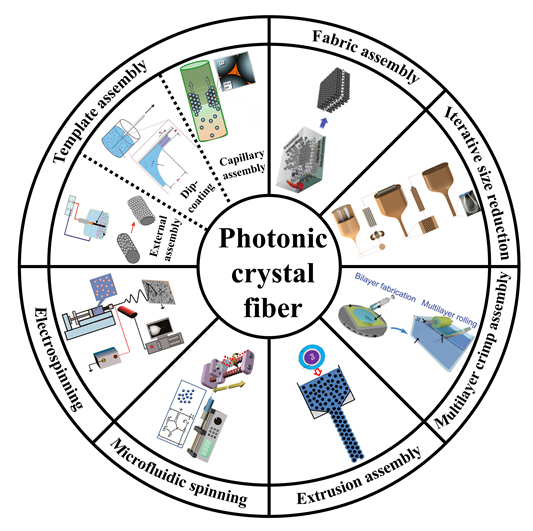

Photonic crystal (PC) fibers exist in many creatures in nature, which give them bright structural colors. PC fibers refer to fibers with the PC structure, which have a highly saturated structural color. Traditional chemical dyes in the textile industry are difficult to degrade to produce chemical pollution and waste of water resources. PC fibers with structural colors are of great significance for replacing traditional chemical dyes in the textile industry and have great potential in making wearable smart sensing devices. They can be used to prepare various sensor-responsive PC fibers when combined with responsive materials or flexible substrates. This paper reviews the fabrication methods, performance, applications and other related research works of PC fibers. PC fibers are mainly composed of colloidal microspheres. To show the structure and properties of PCs, the colloidal microsphere units are mixed with fiber materials and arranged in an orderly manner, or are directly assembled to fibrous materials. The fabrication methods of PC fibers mainly include template assembly, electrospinning, microfluidic spinning, extrusion assembly, multilayer crimp assembly, iterative size reduction and fabric assembly method. PC fibers have many excellent properties. For example, PC fibers are superhydrophobic after being stacked and arranged, which are similar to feathers of drakes with self-cleaning effect. The inverse opal PC fibers have high porosity, high specific area and periodic structure, which can greatly improve the application performance. PC fibers or fiber stacked fibrous membranes have a bright structural color, which can be used for the fabrication of various responsive PC fibers, such as strain-, humidity-, photothermal-, solvent-, and magnetic-response fiber, which are of great significance to the research and application of wearable smart sensors. Finally, the application prospects of PC fibers in the textile industry and intelligent sensing field are discussed.

Key words: photonic crystal fibers; bioinspired; textile; sensing

| [1] | Kertész, K.; Bálint, Z.; Vértesy, Z.; Márk, G.I.; Lousse, V.; Vigneron, J.P.; Biró, L.P. Curr. Appl. Phys. 2006, 6,252. |

| [2] | Shi, N.N.; Tsai, C.C.; Camino, F.; Bernard, G.D.; Yu, N.F.; Wehner, R. Science 2015, 349,298. |

| [3] | Kolle, M.; Lethbridge, A.; Kreysing, M.; Baumberg, J.J.; Aizenberg, J.; Vukusic, P. Adv. Mater. 2013, 25,2239. |

| [4] | Gao, B.B.; He, Z.Z.; He, B.F.; Gu, Z.Z. Sens. Actuator B Chem. 2019, 288,734. |

| [5] | Yoshioka, S.; Kinoshita, S. Forma 2002, 17,169. |

| [6] | Zi, J.; Yu, X.D.; Li, Y.Z.; Hu, X.H.; Xu, C.; Wang, X.J.; Liu, X.H.; Fu, R.T. Proc. Natl. Acad. Sci. U. S. A. 2003, 100,12576. |

| [7] | Burg, S.L.; Parnell, A.J. J. Phys. Condes. Matter 2018, 30,413001. |

| [8] | Khudiyev, T.; Dogan, T.; Bayindir, M. Sci. Rep. 2014, 4,4718. |

| [9] | Han, C.; Kim, H.; Jung, H.; Lee, S.I.; Jablonski, P.G.; Jeon, H. Optica 2017, 4,464. |

| [10] | Moon, J.H.; Kim, S.; Yi, G.R.; Lee, Y.H.; Yang, S.M. Langmuir 2004, 20,2033. |

| [11] | Ni, H.B.; Wang, M.; Chen, W. Opt. Express 2011, 19,25900. |

| [12] | Zhao, Z.; Wang, H.; Shang, L.R.; Yu, Y.R.; Fu, F.F.; Zhao, Y.J.; Gu, Z.Z. Adv. Mater. 2017, 29,1704569. |

| [13] | Kim, S.H.; Hwang, H.; Yang, S.M. Angew. Chem. Int. Ed. 2012, 51,3601. |

| [14] | Liu, Z.; Zhang, Q.; Wang, H.; Li, Y. Chem. Commun. 2011, 47,12801. |

| [15] | Moon, J.H.; Yi, G.R.; Yang, S.M. J. Colloid Interf. Sci. 2005, 287,173. |

| [16] | Yuan, W.; Li, Q.; Zhou, N.; Zhang, S.; Ding, C.; Shi, L.; Zhang, K.Q. ACS Appl. Mater. Interfaces 2019, 11,19388. |

| [17] | Zhang, J.; He, S.S.; Liu, L.M.; Guan, G.Z.; Lu, X.; Sun, X.M.; Peng, H.S. J. Mater. Chem. C 2016, 4,2127. |

| [18] | Zhou, N.; Zhang, A.; Shi, L.; Zhang, K.Q. ACS Macro Lett. 2013, 2,116. |

| [19] | Meng, J.Y.; Li, X.; Gong, Y.; Wang, R.; Zheng, Y.P.; Zhang, D.Q. Acta Polym. Sin. 2018, (3),389. (in Chinese) |

| [19] | ( 孟佳意, 李昕, 龚龑, 王锐, 郑一平, 张德权, 高分子学报, 2018, (3),389.) |

| [20] | Lai, C.H.; Yang, Y.L.; Chen, L.Y.; Huang, Y.J.; Chen, J.Y.; Wu, P.W.; Cheng, Y.T.; Huang, Y.T. J. Electrochem. Soc. 2011, 158,37. |

| [21] | Yuan, X.F.; Liu, Z.F.; Shang, S.L.; Wang, H.Z.; Zhang, Q.H.; Li, Y.G.; Jin, W.S. RSC Adv. 2016, 6,16319. |

| [22] | Liu, Z.F.; Zhang, Q.H.; Wang, H.Z.; Li, Y.G. Nanoscale 2013, 5,6917. |

| [23] | Sun, X.; Zhang, J.; Lu, X.; Fang, X.; Peng, H.S. Angew. Chem. Int. Ed. 2015, 54,3630. |

| [24] | Li, K.; Zhang, Q.; Wang, H.; Li, Y. ACS Appl. Mater. Interfaces 2014, 6,13043. |

| [25] | Liu, Z.F.; Zhang, Q.H.; Wang, H.Z.; Li, Y.G. J. Colloid Interf. Sci. 2013, 406,18. |

| [26] | Shang, S.L.; Liu, Z.F.; Zhang, Q.H.; Wang, H.Z.; Li, Y.G. J. Mater. Chem. A 2015, 3,11093. |

| [27] | Shang, S.L.; Zhang, Q.H.; Wang, H.Z.; Li, Y.G. J. Colloid Interf. Sci. 2016, 483,11. |

| [28] | Zhang, K.Q.; Yuan, W.; Zhou, N.; Wu, C.J., Electrospun Nanofibers for Energy and Environmental Applications, Eds.: Ding, B.; Yu, J., Springer-Verlag Berlin Heidelberg, 2014, p. 403. |

| [29] | Wu, C.; Yuan, W.; Al-Deyab, S.S.; Zhang, K.Q. Appl. Surf. Sci. 2014, 313,389. |

| [30] | Lim, J.M.; Moon, J.H.; Yi, G.R.; Heo, C.J.; Yang, S.M. Langmuir 2006, 22,3445. |

| [31] | Lim, J.M.; Yi, G.R.; Moon, J.H.; Heo, C.J.; Yang, S.M. Langmuir 2007, 23,7981. |

| [32] | Yuan, W.; Zhang, K.Q. Langmuir 2012, 28,15418. |

| [33] | Yuan, W.; Zhou, N.; Shi, L.; Zhang, K.Q. ACS Appl. Mater. Interfaces 2015, 7,14064. |

| [34] | Yuan, S.J.; Meng, W.H.; Du, A.H.; Cao, X.Y.; Zhao, Y.; Wang, J.X.; Jiang, L. Chinese J. Polym. Sci. 2019, 37,729. |

| [35] | Kim, G.H.; An, T.; Lim, G. Nanoscale Res. Lett. 2018, 13,204. |

| [36] | Li, G.X.; Shen, H.X.; Li, Q.; Tian, Y.; Wang, C.F.; Chen, S. Mater. Lett. 2019, 242,179. |

| [37] | Zhang, Y.; Tian, Y.; Xu, L.L.; Wang, C.F.; Chen, S. Chem. Commun. 2015, 51,17525. |

| [38] | Finlayson, C.E.; Goddard, C.; Papachristodoulou, E.; Snoswell, D.R. E.; Kontogeorgos, A.; Spahn, P.; Hellmann, G.P.; Hess, O.; Baumberg, J.J. Opt. Express 2011, 19,3144. |

| [39] | Tan, A.T. L.; Beroz, J.; Kolle, M.; Hart, A.J. Adv. Mater. 2018, 30,e1803620. |

| [40] | Kohri, M.; Yanagimoto, K.; Kawamura, A.; Hamada, K.; Imai, Y.; Watanabe, T.; Ono, T.; Taniguchi, T.; Kishikawa, K. ACS Appl. Mater. Interfaces 2018, 10,7640. |

| [41] | Meng, X.; Pan, H.; Lu, T.; Chen, Z.X.; Chen, Y.R.; Zhang, D.; Zhu, S.M. Nanotechnology 2018, 29,325604. |

| [42] | Zeng, Q.; Ding, C.; Li, Q.S.; Yuan, W.; Peng, Y.; Hu, J.C.; Zhang, K.Q. RSC Adv. 2017, 7,8443. |

| [43] | Li, Q.S.; Zhang, Y.F; Shi, L.; Qiu, H.H.; Zhang, S.M.; Qi, N.; Hu, J.C.; Yuan, W.; Zhang, X.H.; Zhang, K.Q. ACS Nano 2018, 12,3095. |

| [44] | Liu, G.J.; Zhou, L.; Zhang, G.Q.; Li, Y.C.; Chai, L.Q.; Fan, Q.G.; Shao, J.Z. Mater. Design 2017, 114,10. |

| [45] | Wang, X.H.; Li, Y.C.; Zhou, L.; Chai, L.Q.; Fan, Q.G.; Shao, J.Z. Dyes. Pigments 2019, 169,36. |

| [46] | Shi, X.; He, J.; Wu, L.; Chen, S.; Lu, X. J. Coat. Technol. Res. 2020, 17,1033. |

| [47] | Liu, G.; Han, P.; Chai, L.; Li, Z.; Zhou, L. Colloid Surf. A-Physicochem. Eng. Asp. 2020, 600,124991. |

| [48] | Liu, G.; Han, P.; Wu, Y.; Li, H.; Zhou, L. Opt. Mater. 2019, 98,109503. |

| [49] | Liu, G.; Guo, Y.; Zhou, L.; Wu, Y.; Chen, M.; He, Z. J. Mater. Sci. 2019, 54,10929. |

| [50] | Shi, X.; He, J.; Xie, X.; Dou, R.; Lu, X. Dyes. Pigments 2019, 165,137. |

| [51] | Zhao, Y.; Xie, Z.; Gu, H.; Zhu, C.; Gu, Z. Chem. Soc. Rev. 2012, 41,3297. |

| [52] | Shang, L.; Zhang, W.; Xu, K.; Zhao, Y. Mater. Horizons 2019, 6,945. |

| [53] | Gao, W.; Rigout, M.; Owens, H. J. Nanopart. Res. 2017, 19,303. |

| [54] | Wang, H.; Zhang, K.Q. Sensors 2013, 13,4192. |

| [55] | Wang, Z.; Guo, Z. J. Bionic Eng. 2018, 15,1. |

| [56] | Zhao, C.; Ma, Y.; Wang, Y.; Zhou, X.; Li, H.; Li, M.; Song, Y. Acta Chim. Sinica 2018, 76,9. (in Chinese) |

| [56] | ( 赵聪, 马颖, 汪洋, 周雪, 李会增, 李明珠, 宋延林, 化学学报, 2018, 76,9.) |

| [57] | Liu, X.; Qin, L.; Zhan, Y.; Chen, M.; Yu, Y. Acta Chim. Sinica 2020, 78,478. (in Chinese) |

| [57] | ( 刘晓珺, 秦朗, 詹媛媛, 陈萌, 俞燕蕾, 化学学报, 2020, 78,478.) |

| [58] | Wu, P.; Wang, J.; Jiang, L. Mater. Horizons 2020, 7,338. |

| [59] | Wan, L.; Zhang, M.; Wang, J.; Jiang, L. Acta Chim. Sinica 2016, 74,639. (in Chinese) |

| [59] | ( 万伦, 张漫波, 王京霞, 江雷, 化学学报, 2016, 74,639.) |

| [60] | Cui, L.; Fan, S.; Yu, C.; Kuang, M.; Wang, J. Acta Chim. Sinica 2017, 75,967. (in Chinese) |

| [60] | ( 崔丽影, 范莎莎, 于存龙, 邝旻旻, 王京霞, 化学学报, 2017, 75,967.) |

| [61] | Wu, P.; Liu, J.; Xie, Z.; Guo, J.; Wang, J. Chinese J. Polym. Sci. 2018, 36,555. |

| [62] | Liu, J.; Shang, Y.; Zhang, D.; Xie, Z.; Hu, R.; Wang, J. Chinese J. Polym. Sci. 2017, 35,1043. |

/

| 〈 |

|

〉 |