石墨烯量子点/铁基金属-有机骨架复合材料高效光催化二氧化碳还原※

收稿日期: 2021-10-13

网络出版日期: 2021-11-30

基金资助

项目受国家重点基础研发计划项目(2018YFA0208600); 项目受国家重点基础研发计划项目(2018YFA0704502); 国家自然科学基金(21671188); 国家自然科学基金(21871263); 国家自然科学基金(22071245); 国家自然科学基金(22033008); 国家自然科学基金(22171265); 国家自然科学基金(22001094); 中国科学院青年创新促进会优秀会员项目(Y201850); 中国福建光电信息科学与技术创新实验室(闽都创新实验室)项目(2021ZZ103); 广东省基础与应用基础研究基金(2020A1515110003)

Graphene Quantum Dots Supported on Fe-based Metal-Organic Frameworks for Efficient Photocatalytic CO2 Reduction※

Received date: 2021-10-13

Online published: 2021-11-30

Supported by

National Key Research and Development Program of China(2018YFA0208600); National Key Research and Development Program of China(2018YFA0704502); National Natural Science Foundation of China(21671188); National Natural Science Foundation of China(21871263); National Natural Science Foundation of China(22071245); National Natural Science Foundation of China(22033008); National Natural Science Foundation of China(22171265); National Natural Science Foundation of China(22001094); Youth Innovation Promotion Association, CAS(Y201850); Fujian Science & Technology Innovation Laboratory for Optoelectronic Information of China(2021ZZ103); Guangdong Basic and Applied Basic Research Foundation(2020A1515110003)

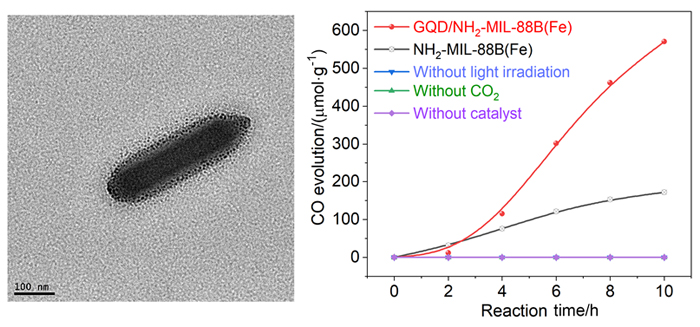

利用可见光将二氧化碳光还原为有用的化学品是一项有前景但充满挑战的工作. 金属有机骨架(MOFs)作为一种新兴的具高孔隙率、高比表面积、强吸附富集CO2能力、结构和功能可调的多孔材料, 在光催化二氧化碳还原反应中具有极强的应用潜力. 但大多数金属有机骨架材料存在可见光吸收范围窄、光生载流子快速复合等问题, 导致催化二氧化碳还原活性仍然较低. 通过静电自组装策略将纳米级胺基化金属有机骨架材料(NH2-MIL-88B(Fe))和羧酸化石墨烯量子点(GQD)通过静电作用结合, 得到GQD/NH2-MIL-88B(Fe)复合材料. 该复合催化剂有效结合了金属有机骨架强二氧化碳吸附富集能力和GQD的可见光吸收范围宽、电子传导能力强等优点, 因此与纯金属有机骨架材料NH2- MIL-88B(Fe)相比较, 该复合材料能高效光催化还原CO2为CO, 并在10 h可见光下活性高达590 μmol/g, 约为NH2-MIL-88B(Fe)活性的四倍. 这项工作为制备高活性催化CO2的金属有机骨架复合材料提供了借鉴.

王旭生 , 杨胥 , 陈春辉 , 李红芳 , 黄远标 , 曹荣 . 石墨烯量子点/铁基金属-有机骨架复合材料高效光催化二氧化碳还原※[J]. 化学学报, 2022 , 80(1) : 22 -28 . DOI: 10.6023/A21100455

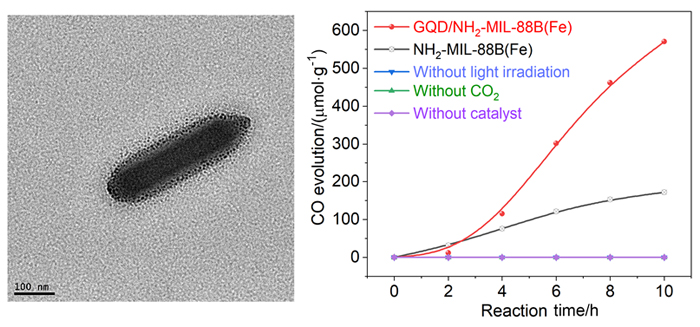

Photocatalytic reduction of CO2 to valuable chemicals is an essential but still remains challenging. Metal-organic frameworks (MOFs) featuring high special surface area, large CO2 adsorption uptakes, adjustable structures and function, have become a kind of promising porous materials for photocatalytic CO2 reduction. However, MOFs often suffer from problems like short light harvesting range, rapid recombination of photogenerated carriers, resulting in lower activity. Here, graphene quantum dots (GQD) were supported on the Fe-based nano-sized MOFs, NH2-MIL-88B(Fe), via electrostatic self-assembly strategy. GQDs were prepared by electrolysis of graphite rod in pure water firstly, and then centrifuged to remove the large species. Transmission electron microscope (TEM) reveals that ultrafine GQDs with 3 nm were obtained. Atomic force microscope (AFM) further demonstrates that the thickness of GQDs is around 0.34—1.5 nm (1—4 stacked layers). The MOFs, NH2-MIL-88B(Fe), were synthesized with traditional solvothermal method, with a nano spindle shape of 250 nm×40 nm. The amino groups on MOFs provide strong electrostatic force with the carboxylic groups on GQDs, making the composite very stable and efficient electron transfer. High resolution transmission electron microscope (TEM) reveals that the nano MOFs were surrounded by tiny GQDs firmly. The bandgap of composite was determined by solid ultraviolet visible diffuse reflectance spectroscopy (UV-Vis DRS) and Mott-Schottky measurement, which indicate that it is thermodynamically appropriate for photocatalytic CO2 reduction. Photocurrent experiments further demonstrate the composite is beneficial for the photogenerated electron-hole separation. Thus, the resulting GQD/NH2-MIL-88B(Fe) composite showed much enhanced CO production rate (4 times) compared with the parent NH2-MIL-88B(Fe), reaching 590 μmol/g under 10 h visible light irradiation with triethanolamine (TEOA) as sacrificial agent. The hugely improved photoreduction activity benefits from both the high CO2 adsorption of MOFs and the enhanced separation of photogenerated electrons and holes. This work provides an avenue for preparation of MOFs based materials with high CO2 photoreduction activity.

| [1] | Meng, D. L.; Zhang, M. D.; Si, D. H.; Mao, M. J.; Hou, Y.; Huang, Y. B.; Cao, R. Angew. Chem., Int. Ed. 2021, 60, 25485. |

| [2] | Yi, J. D.; Si, D. H.; Xie, R.; Yin, Q.; Zhang, M. D.; Wu, Q.; Chai, G. L.; Huang, Y. B.; Cao, R. Angew. Chem., Int. Ed. 2021, 60, 17108. |

| [3] | Yi, J. D.; Xie, R.; Xie, Z. L.; Chai, G. L.; Liu, T. F.; Chen, R. P.; Huang, Y. B.; Cao, R. Angew. Chem., Int. Ed. 2020, 59, 23641. |

| [4] | Zou, Y. H.; Huang, Y. B.; Si, D. H.; Yin, Q.; Wu, Q. J.; Weng, Z.; Cao, R. Angew. Chem., Int. Ed. 2021, 60, 20915. |

| [5] | Diercks, C. S.; Liu, Y.; Cordova, K. E.; Yaghi, O. M. Nat. Mater. 2018, 17, 301. |

| [6] | Zhang, W.; Mohamed, A. R.; Ong, W. J. Angew. Chem., Int. Ed. 2020, 59, 22894. |

| [7] | Wang, X. S.; Li, L.; Li, D.; Ye, J. Solar RRL 2020, 4, 1900547. |

| [8] | Hu, J.; Chen, D.; Mo, Z.; Li, N.; Xu, Q.; Li, H.; He, J.; Xu, H.; Lu, J. Angew. Chem., Int. Ed. 2019, 58, 2073. |

| [9] | Yu, H.; Li, J.; Zhang, Y.; Yang, S.; Han, K.; Dong, F.; Ma, T.; Huang, H. Angew. Chem., Int. Ed. 2019, 58, 3880. |

| [10] | Hong, D.; Kawanishi, T.; Tsukakoshi, Y.; Kotani, H.; Ishizuka, T.; Kojima, T. J. Am. Chem. Soc. 2019, 141, 20309. |

| [11] | Yu, H.; Haviv, E.; Neumann, R. Angew. Chem., Int. Ed. 2020, 59, 6219. |

| [12] | Liang, J.; Wu, Q.; Huang, Y. B.; Cao, R. EnergyChem 2021, 3, 100064. |

| [13] | Wang, X.-S.; Liang, J.; Li, L.; Lin, Z.-J.; Bag, P. P.; Gao, S.-Y.; Huang, Y.-B.; Cao, R. Inorg. Chem. 2016, 55, 2641. |

| [14] | Wang, X.-S.; Chen, C.-H.; Ichihara, F.; Oshikiri, M.; Liang, J.; Li, L.; Li, Y.; Song, H.; Wang, S.; Zhang, T.; Huang, Y.-B.; Cao, R.; Ye, J. Appl. Catal. B: Environ. 2019, 253, 323. |

| [15] | He, C.; Liang, J.; Zou, Y.-H.; Yi, J.-D.; Huang, Y.-B.; Cao, R. Natl. Sci. Rev. 2021, DOI:10.1093/nsr/nwab157. |

| [16] | Xiong, W.; Li, H.; You, H.; Cao, M.; Cao, R. Natl. Sci. Rev. 2020, 7, 609. |

| [17] | Li, X.; Yan, B.; Huang, W.; Fu, L.; Sun, X.; Lv, A. Acta Chim. Sinica 2021, 79, 459. (in Chinese) |

| [17] | ( 李旭飞, 闫保有, 黄维秋, 浮历沛, 孙宪航, 吕爱华, 化学学报 2021, 79, 459.) |

| [18] | Wu, Q.; Zhang, C.; Sun, K.; Jiang, H.-L. Acta Chim. Sinica 2020, 78, 688. (in Chinese) |

| [18] | ( 吴浅耶, 张晨曦, 孙康, 江海龙, 化学学报 2020, 78, 688.) |

| [19] | Lin, Z.-J.; Cao, R. Acta Chim. Sinica 2020, 78, 1309. |

| [19] | ( 林祖金, 曹荣, 化学学报 2020, 78, 1309) |

| [20] | Zhang, X.; Li, X.; Xiong, W.; Li, H.; Cao, R. Acta Chim. Sinica 2021, 79, 180. (in Chinese) |

| [20] | ( 张晓萌, 李希雅, 熊晚枫, 李红芳, 曹荣, 化学学报 2021, 79, 180.) |

| [21] | Pan, Y.; Qian, Y.; Zheng, X.; Chu, S. Q.; Yang, Y.; Ding, C.; Wang, X.; Yu, S. H.; Jiang, H. L. Natl. Sci. Rev. 2021, 8, nwaa224. |

| [22] | Wang, H.-N.; Zou, Y.-H.; Sun, H.-X.; Chen, Y.; Li, S.-L.; Lan, Y.-Q. Coord. Chem. Rev. 2021, 438, 213906. |

| [23] | Huang, Q.; Liu, J.; Feng, L.; Wang, Q.; Guan, W.; Dong, L. Z.; Zhang, L.; Yan, L. K.; Lan, Y. Q.; Zhou, H. C. Natl. Sci. Rev. 2020, 7, 53. |

| [24] | Fu, Y.; Sun, D.; Chen, Y.; Huang, R.; Ding, Z.; Fu, X.; Li, Z. Angew. Chem., Int. Ed. 2012, 51, 3364. |

| [25] | Wang, D.; Huang, R.; Liu, W.; Sun, D.; Li, Z. ACS Catal. 2014, 4, 4254. |

| [26] | Xu, H. Q.; Hu, J.; Wang, D.; Li, Z.; Zhang, Q.; Luo, Y.; Yu, S. H.; Jiang, H. L. J. Am. Chem. Soc. 2015, 137, 13440. |

| [27] | Zhang, H.; Wei, J.; Dong, J.; Liu, G.; Shi, L.; An, P.; Zhao, G.; Kong, J.; Wang, X.; Meng, X.; Zhang, J.; Ye, J. Angew. Chem., Int. Ed. 2016, 55, 14310. |

| [28] | Chen, E. X.; Qiu, M.; Zhang, Y. F.; Zhu, Y. S.; Liu, L. Y.; Sun, Y. Y.; Bu, X.; Zhang, J.; Lin, Q. Adv. Mater. 2018, 30, 1704388. |

| [29] | Dong, L. Z.; Zhang, L.; Liu, J.; Huang, Q.; Lu, M.; Ji, W. X.; Lan, Y. Q. Angew. Chem., Int. Ed. 2020, 59, 2659. |

| [30] | Chen, Q.; Kuang, Q.; Xie, Z. Acta Chim. Sinica 2021, 79, 10. (in Chinese) |

| [30] | ( 陈钱, 匡勤, 谢兆雄, 化学学报 2021, 79, 10.) |

| [31] | Zhao, H.; Wang, X.; Feng, J.; Chen, Y.; Yang, X.; Gao, S.; Cao, R. Catal. Sci. Technol. 2018, 8, 1288. |

| [32] | Shi, L.; Wang, T.; Zhang, H.; Chang, K.; Ye, J. Adv. Funct. Mater. 2015, 25, 5360. |

| [33] | Wang, X.; Zhao, X.; Zhang, D.; Li, G.; Li, H. Appl. Catal. B: Environ. 2018, 228, 47. |

| [34] | Han, Z.; Fu, Y.; Zhang, Y.; Zhang, X.; Meng, X.; Zhou, Z.; Su, Z. Dalton Trans. 2021, 50, 3186. |

| [35] | Jiang, Z.; Xu, X.; Ma, Y.; Cho, H. S.; Ding, D.; Wang, C.; Wu, J.; Oleynikov, P.; Jia, M.; Cheng, J.; Zhou, Y.; Terasaki, O.; Peng, T.; Zan, L.; Deng, H. Nature 2020, 586, 549. |

| [36] | Li, H.; Kang, Z.; Liu, Y.; Lee, S.-T. J. Mater. Chem. 2012, 22, 24230. |

| [37] | Lim, S. Y.; Shen, W.; Gao, Z. Chem. Soc. Rev. 2015, 44, 362. |

| [38] | Wang, J.; Cheng, C.; Huang, Y.; Zheng, B.; Yuan, H.; Bo, L.; Zheng, M.-W.; Yang, S.-Y.; Guo, Y.; Xiao, D. J. Mater. Chem. C 2014, 2, 5028. |

| [39] | Aguilera-Sigalat, J.; Bradshaw, D. Coord. Chem. Rev. 2016, 307, 267. |

| [40] | Martindale, B. C.; Hutton, G. A.; Caputo, C. A.; Reisner, E. J. Am. Chem. Soc. 2015, 137, 6018. |

| [41] | Dong, Y.; Han, Q.; Hu, Q.; Xu, C.; Dong, C.; Peng, Y.; Ding, Y.; Lan, Y. Appl. Catal. B: Environ. 2021, 293, 120214. |

| [42] | Ming, H.; Ma, Z.; Liu, Y.; Pan, K.; Yu, H.; Wang, F.; Kang, Z. Dalton Trans. 2012, 41, 9526. |

| [43] | Liu, J.; Liu, Y.; Liu, N.; Han, Y.; Zhang, X.; Huang, H.; Lifshitz, Y.; Lee, S. T.; Zhong, J.; Kang, Z. Science 2015, 347, 970. |

| [44] | Bian, J.; Huang, C.; Wang, L.; Hung, T.; Daoud, W. A.; Zhang, R. ACS Appl. Mater. Inter. 2014, 6, 4883. |

| [45] | Li, H.; He, X.; Kang, Z.; Huang, H.; Liu, Y.; Liu, J.; Lian, S.; Tsang, C. H.; Yang, X.; Lee, S. T. Angew. Chem., Int. Ed. 2010, 49, 4430. |

/

| 〈 |

|

〉 |