基于BiOCl-Fe2O3@TiO2介孔复合材料的光电化学合成氨性能研究

收稿日期: 2021-12-15

网络出版日期: 2022-01-25

基金资助

国家自然科学基金(21972027)

BiOCl-Fe2O3@TiO2 Mesoporous Composite for Photoelectrochemical Synthesis of Ammonia

Received date: 2021-12-15

Online published: 2022-01-25

Supported by

National Natural Science Foundation of China(21972027)

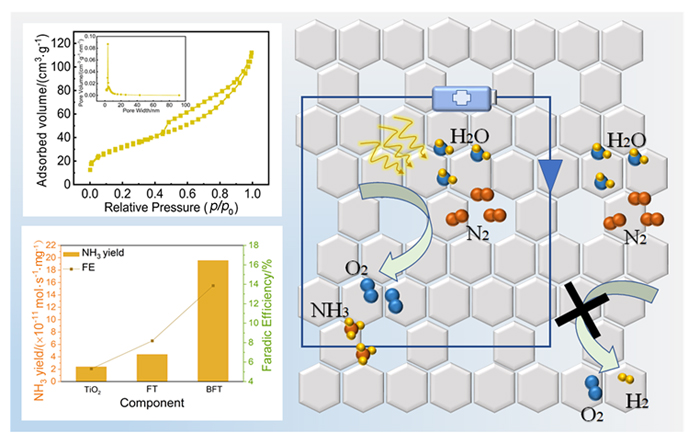

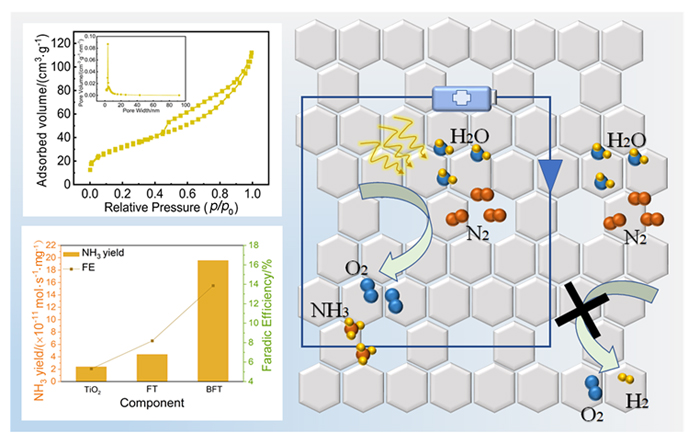

传统合成氨工艺存在能耗高、污染严重的问题. 因此, 高效、低能耗绿色合成氨工艺的开发迫在眉睫. 光电化学以H2O和N2为原料, 可以在太阳光驱动下, 在常温常压条件下实现氨的合成, 因而受到广泛重视. 但总的来说, 效率和产率都达不到实际要求. 新型高效催化剂及工艺的开发是提高合成氨产率及效率的关键. 非贵金属催化剂具备成本低、来源广泛、可操作性强的优势, 有利于光电化学合成氨的产业化. 本实验采用溶胶凝胶结合原位热裂解的方法制备了分散性好、结构均匀的BiOCl-Fe2O3@TiO2复合材料, 对其物相、微观结构、表面状态、光学性能、电学性能等方面进行了系统表征, 并探究了该材料在常温常压下光电化学合成氨的催化活性. 结果表明, 同纯介孔TiO2相比, BiOCl-Fe2O3@TiO2的吸收带隙变窄, 可见光吸收能力增强, 光生载流子的利用率增加, 光电合成氨的产率提升了7倍, 且BiOCl-Fe2O3@TiO2显示了优异的化学稳定性. 本研究工作为绿色合成氨催化材料及工艺设计提供了新思路.

应霞薇 , 浮建军 , 曾敏 , 刘文 , 张天宇 , 沈培康 , 张信义 . 基于BiOCl-Fe2O3@TiO2介孔复合材料的光电化学合成氨性能研究[J]. 化学学报, 2022 , 80(4) : 503 -509 . DOI: 10.6023/A21120562

Nitrogen reduction reaction is an indispensable part of chemical production, and traditional Haber-Bosch process has the problems of high energy consumption and serious CO2 emission. Solar-driven photoelectrochemical synthesis of ammonia has received much attention because it can be carried out under mild conditions. However, the yield of ammonia and conversion efficiency are too low to be practical due to the high dissociation energy of the triply bonded nitrogen molecule. The development of non-precious metal oxide catalysts for ammonia synthesis has the advantages of low commercial cost, high selectivity, and strong operability, which may provide the possibility for commercialization in green ammonia synthesis. In this work, we reported the synthesis of BiOCl-Fe2O3@TiO2 mesoporous composite through a sol-gel method followed by in-situ decomposition approach. The obtained composites were systematically characterized and utilized for photoelectrochemical synthesis of ammonia. The results show that Fe2O3 is strongly coupled with TiO2 to produce a metal oxide-semiconductor heterojunction, while BiOCl nanoparticles are uniformly distributed on the surfaces. Compared to pure TiO2, the band gap of composite becomes remarkably narrowed. As a result, the visible light absorption is enhanced and the utilization of photogenerated carriers is increased. In addition, BiOCl-Fe2O3@TiO2 composite has plenty of Ti3+ for improving the photoelectric migration efficiency. With the presence of BiOCl, the yield of ammonia is significantly increased. Compared with pure TiO2, the ammonia yield of BiOCl-Fe2O3@TiO2 is increased by 7 times, and its ammonia production rate remains stable over 10 h test. Our work offers a new route for photoelectrocatalytic synthesis of green ammonia.

| [1] | Snyder, C. S.; Davidson, E. A.; Smith, P.; Venterea, R. T. Curr. Opin. Environ. Sustain. 2014, 9-10, 46. |

| [2] | Kroeze, C.; de Vries, W.; Seitzinger, S. P. Curr. Opin. Environ. Sustain. 2014, 9-10, 105. |

| [3] | Jonassen, K. R.; Hagen, L. H.; Vick, S. H. W.; Arntzen, M. Ø.; Eijsink, V. G. H.; Frostegård, Å.; Lycus, P.; Molstad, L.; Pope, P. B.; Bakken, L. R. ISME J. 2021, 16, 580. |

| [4] | Qing, G.; Ghazfar, R.; Jackowski, S.; Habibzadeh, F.; Maleka Ashtiani, M.; Chen, C.; Smith, M.; Hamann, T. Chem. Rev. 2020, 120, 5437. |

| [5] | Zhao, S.; Lu, X.; Wang, L.; Gale, J.; Amal, R. Adv. Mater. 2019, 31, 1805367. |

| [6] | Erisman, J. W.; Sutton, M. A.; Galloway, J.; Klimont, Z.; Winiwarter, W. Nat. Geosci. 2008, 1, 636. |

| [7] | Suryanto, B. H. R.; Du, H.; Wang, D.; Chen, J.; Simonov, A. N.; Macfarlane, D. R. Nat. Catal. 2019, 2, 290. |

| [8] | Liu, J.; Wei, Z.; Dou, Y.; Feng, Y.; Ma, J. Rare Met. 2020, 39, 874. |

| [9] | Zhou, P.; Chao, Y.; Lv, F.; Lai, J.; Wang, K.; Guo, S. Sci. Bull. 2020, 65, 720. |

| [10] | Zhao, Y.; Zhao, Y.; Shi, R.; Wang, B.; Waterhouse, G. I. N.; Wu, L. Z.; Tung, C. H.; Zhang, T. Adv. Mater. 2019, 31, 1806482. |

| [11] | Zhang, L.; Ji, X.; Ren, X.; Ma, Y.; Shi, X.; Tian, Z.; Asiri, A. M.; Chen, L.; Tang, B.; Sun, X. Adv. Mater. 2018, 30, 1800191. |

| [12] | Yu, J.; Yang, Y.; Wei, M. Acta Chim Sinica. 2019, 77, 1129. (in Chinese) |

| [12] | (余俊, 杨宇森, 卫敏, 化学学报, 2019, 77, 1129.) |

| [13] | Han, Q.; Wu, C.; Jiao, H.; Xu, R.; Wang, Y.; Xie, J.; Guo, Q.; Tang, J. Adv. Mater. 2021, 33, 2008180. |

| [14] | Huang, H.; Shi, R.; Zhang, X.; Zhao, J.; Su, C.; Zhang, T. Angew. Chem. Int. Ed. 2021, 60, 22963. |

| [15] | Liu, D.; Wang, J.; Bian, S.; Liu, Q.; Gao, Y.; Wang, X.; Chu, P. K.; Yu, X. Adv. Funct. Mater. 2020, 30, 2002731. |

| [16] | Xiong, K.; Chen, J.; Yang, N.; Jiang, S.; Li, L.; Wei, Z. Acta Chim. Sinica 2021, 79, 1138. (in Chinese) |

| [16] | (熊昆, 陈伽瑶, 杨娜, 蒋尚坤, 李莉, 魏子栋, 化学学报, 2021, 79, 1138.) |

| [17] | Li, R.; Weng, Y.; Zhou, X.; Wang, X.; Mi, Y.; Chong, R.; Chong, R.; Han, H.; Li, C. Energy Environ. Sci. 2015, 8, 2377. |

| [18] | Yu, W.; Zhao, L.; Chen, F.; Zhang, H.; Guo, L. J. Phys. Chem. Lett. 2019, 10, 3024. |

| [19] | Xu, F.; Meng, K.; Cheng, B.; Wang, S.; Xu, J.; Yu, J. Nat. Commun. 2020, 11, 4613. |

| [20] | Chen, X.; Shen, S.; Guo, L.; Mao, S. S. Chem. Rev. 2010, 110, 6503. |

| [21] | Yu, L.; Liu, J.; Xu, X.; Zhang, L.; Hu, R.; Liu, J.; Ouyang, L.; Yang, L.; Zhu, M. ACS Nano 2017, 11, 5120. |

| [22] | Pool, J. A.; Lobkovsky, E.; Chirik, P. J. Nature 2004, 427, 527. |

| [23] | Xiong, H.; Wu, L.; Liu, Y.; Gao, T.; Li, K.; Long, Y.; Zhang, R.; Zhang, L.; Qiao, Z.; Huo, Q.; Ge, X.; Song, S.; Zhang, H. Adv. Energy Mater. 2021, 9, 1901634. |

| [24] | Zeng, M.; Zeng, X.; Peng, X.; Zhu, Z.; Liao, J.; Liu, K.; Wang, G.; Lin, S. Appl. Surf. Sci. 2016, 388, 352. |

| [25] | Mi, P. P.; Guo, M. G.; Dai, Y.; Zhang, X. Mod. Chem. Ind. 2021, 41, 138. (in Chinese) |

| [25] | (米盼盼, 郭明钢, 代岩, 张旭, 现代化工, 2021, 41, 138.) |

| [26] | Cui, Z.; Song, H.; Ge, S.; He, W.; Liu, Y. Appl. Surf. Sci. 2019, 467-468, 505. |

| [27] | Zhang, W.; Dong, X.; Liang, Y.; Liu, R.; Sun, Y.; Dong, F. Rare Met. 2019, 38, 437. |

| [28] | Xu, L.; Xie, Y.; Li, L.; Hu, Z.; Wang, Y.; Yu, J. C. Mater. Today Phys. 2021, 21, 100551. |

| [29] | Zhou, G.; Wang, F.; Shi, R. J. Catal. 2021, 398, 148. |

| [30] | Yamashita, T.; Hayes, P. Appl. Surf. Sci. 2008, 254, 2441. |

| [31] | Zhao, Y.; Shi, R.; Bian, X.; Zhou, C.; Zhao, Y.; Zhang, S.; Wu, F.; Waterhouse, G. I. N.; Wu, L.; Tung, C.; Zhang, T. Adv. Sci. 2019, 6, 1802109. |

| [32] | Liu, Q. X.; Ai, L. H.; Jiang, J. J. Mater. Chem. A 2018, 6, 4102. |

| [33] | Zhan, S.; Zhang, F. Acta Chim. Sinica 2021, 79, 146. (in Chinese) |

| [33] | (詹溯, 章福祥, 化学学报, 2021, 79, 146.) |

| [34] | Kang, S.; Zhang, H.; Wang, G.; Zhang, Y.; Zhao, H.; Zhou, H.; Cai, W. Inorg. Chem. Front. 2019, 6, 1432. |

/

| 〈 |

|

〉 |