氮掺杂碳纳米笼固载钌纳米粒子的费托合成性能

收稿日期: 2022-03-31

网络出版日期: 2022-05-26

基金资助

国家重点研发计划(2018YFA0209100); 国家重点研发计划(2017YFA0206500); 国家重点研发计划(2021YFA1500900); 国家自然科学基金(21972061); 国家自然科学基金(21832003); 国家自然科学基金(52071174); 江苏省前沿引领技术研究专项(BK20212005)

Ruthenium Nanoparticles Anchored on Nitrogen-Doped Carbon Nanocages for Fischer-Tropsch Synthesis

Received date: 2022-03-31

Online published: 2022-05-26

Supported by

National Key Research and Development Program of China(2018YFA0209100); National Key Research and Development Program of China(2017YFA0206500); National Key Research and Development Program of China(2021YFA1500900); National Natural Science Foundation of China(21972061); National Natural Science Foundation of China(21832003); National Natural Science Foundation of China(52071174); Natural Science Foundation of Jiangsu Province, Major Project(BK20212005)

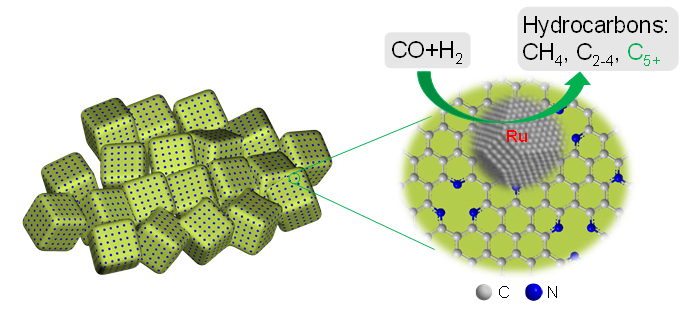

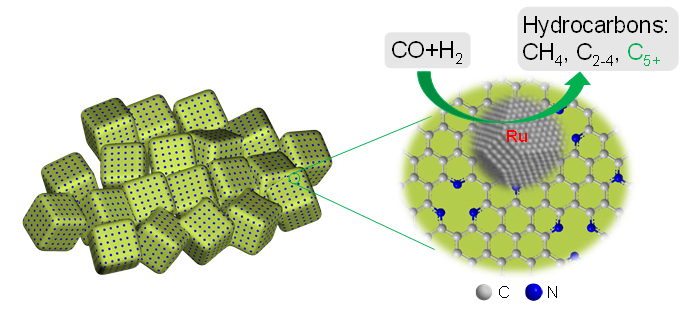

费托合成可以将来源广泛的合成气转化为低碳烯烃和燃油等高附加值化学品, 是后石油时代的重要化工过程, 而发展高性能的催化剂是该工程产业化的关键. 以具有高比表面积和高氮含量的氮掺杂碳纳米笼(NCNC)为载体, 采用等体积浸渍法制备了Ru的质量分数为20%的Ru/NCNC催化剂, 所得Ru纳米颗粒均匀分散, 相比于未掺杂碳纳米笼负载的Ru催化剂(Ru/CNC), Ru纳米粒子尺寸更小且分布更集中. Ru/NCNC催化剂展现出优异的费托合成催化性能, 在0.5 MPa和220 ℃的温和条件下, 具有高的催化活性、高的C5+选择性(55.7%)、低的CH4选择性(13.5%)和高的催化稳定性(60 h, CO转化率保持在≈33%), 显著优于Ru/CNC. 这可归因于N掺杂提高了Ru活性中心的数量和电子态密度以及表面碱性, 增强了金属-载体相互作用, 进而提高Ru/NCNC的催化活性、长链产物(C5+)选择性、抗烧结能力和催化稳定性. 本研究提供了一条通过掺杂碳载体设计提升费托合成催化剂性能的有效策略.

齐志豪 , 高福杰 , 周常楷 , 曾誉 , 吴强 , 杨立军 , 王喜章 , 胡征 . 氮掺杂碳纳米笼固载钌纳米粒子的费托合成性能[J]. 化学学报, 2022 , 80(8) : 1100 -1105 . DOI: 10.6023/A22030139

Fischer-Tropsch synthesis (FTS) is an important heterogeneous catalytic process in post-petroleum era, which can convert syngas from natural gas, coals and biomass into high value-added chemicals such as low-carbon olefins and fuel oil. In general, the target products have low selectivity owing to the limitation of Anderson-Schulz-Flory distribution law. The selectivity of target products can be adjusted by controlling the composition and structure of catalysts, supports and promotors. Carbon materials have been used as the remarkable supports due to the merits of rich morphological structure, high specific surface area, easily-regulated surface properties by doping and modification, good stability and so forth. Herein, taking advantage of the high specific surface area and high N content of N-doped carbon nanocages (NCNC), Ru/NCNC catalysts is prepared by equal volume impregnation method. As compared, Ru/CNC catalyst is prepared using undoped carbon nanocages (CNC) as support. Ru nanoparticles with ca. 3.9 nm in size were homogeneously dispersed on NCNC. The Ru nanoparticles on NCNC have the smaller sizes and more narrow distribution than those on CNC owing to the anchoring effect of nitrogen dopants for the former. The Ru/NCNC catalyst showed excellent catalytic performance, including good catalytic activity, high selectivity of C5+ products (55.7%), low selectivity of CH4 (13.5%) and high stability (60 h, CO conversion maintained at the level of ≈33%), evidently surpassing Ru/CNC. Such excellent FTS performance of Ru/NCNC can be attributed to the following reasons. (i) N doping increases the number of catalytic centers and density of electronic states of metallic Ru, and subsequently improving the catalytic activity, inhibiting the hydrogenation of intermediate products, increasing the chain growth possibility, and finally producing more long-chain products (C5+). (ii) N doping enhances the surface alkalinity of nanocages and then is conducive to inhibiting the formation of CH4. (iii) The metal-support interaction is enhanced due to the participation of N, leading to significantly improved anti-sintering ability and catalytic stability. This finding provides a promising strategy for developing high-performance FTS catalysts via designing N-doped carbon supports.

| [1] | Galvis, H. M. T.; Bitter, J. H.; Khare, C. B.; Ruitenbeek, M.; Dugulan, A. I.; de Jong, K. P. Science 2012, 335, 835. |

| [1] | Bao, J.; Yang, G.; Yoneyama, Y.; Tsubaki, N. ACS Catal. 2019, 9, 3026. |

| [2] | Zhou, W.; Cheng, K.; Kang, J.; Zhou, C.; Subramanian, V.; Zhang, Q.; Wang, Y. Chem. Soc. Rev. 2019, 48, 3193. |

| [3] | Chen, Y.; Wei, J.; Duyar, M. S.; Ordomsky, V. V.; Khodakov, A. Y.; Liu, J. Chem. Soc. Rev. 2021, 50, 2337. |

| [4] | Martinez, L.; Merino, P.; Santoro, G.; Martinez, J. I.; Katsanoulis, S.; Ault, J.; Mayoral, A.; Vazquez, L.; Accolla, M.; Dazzi, A.; Mathurin, J.; Borondics, F.; Blazquez-Blazquez, E.; Shauloff, N.; Lebron-Aguilar, R.; Quintanilla-Lopez, J. E.; Jelinek, R.; Cernicharo, J.; Stone, H. A.; de la Pena O'Shea, V. A.; de Andres, P. L.; Haller, G.; Ellis, G. J.; Martin-Gago, J. A. Nat. Commun. 2021, 12, 5937. |

| [5] | Galvis, H. M. T.; de Jong, K. P. ACS Catal. 2013, 3, 2130. |

| [6] | Khodakov, A. Y.; Chu, W.; Fongarland, P. Chem. Rev. 2007, 107, 1692. |

| [7] | Meng, G.; Sun, J.; Tao, L.; Ji, K.; Wang, P.; Wang, Y.; Sun, X.; Cui, T.; Du, S.; Chen, J.; Wang, D.; Li, Y. ACS Catal. 2021, 11, 1886. |

| [8] | van Ravenhorst, I. K.; Vogt, C.; Oosterbeek, H.; Bossers, K. W.; Moya-Cancino, J. G.; van Bavel, A. P.; van der Eerden, A. M. J.; Vine, D.; de Groot, F. M. F.; Meirer, F.; Weckhuysen, B. M. Angew. Chem., nt. Ed. 2018, 57, 11957. |

| [9] | Hernandez Mejia, C.; van der Hoeven, J. E. S.; de Jongh, P. E.; de Jong, K. P. ACS Catal. 2020, 10, 7343. |

| [10] | Yang, X.; Guo, X.; Zhang, C.; Wang, X.; Yang, Y.; Li, Y. Acta Chim. Sinica 2017, 75, 360. (in Chinese) |

| [10] | (杨向平, 郭晓雪, 张成华, 王小萍, 杨勇, 李永旺, 化学学报, 2017, 75, 360.) |

| [11] | Sun, D.; Sun, B.; Pei, Y.; Yan, S.; Fan, K.; Qiao, M.; Zhang, X.; Zong, B. Acta Chim. Sinica 2021, 79, 771. (in Chinese) |

| [11] | (孙冬, 孙博, 裴燕, 闫世润, 范康年, 乔明华, 张晓昕, 宗保宁, 化学学报, 2021, 79, 771.) |

| [12] | de Smit, E.; Weckhuysen, B. M. Chem. Soc. Rev. 2008, 37, 2758. |

| [13] | Okonye, L. U.; Yao, Y.; Hildebrandt, D.; Meijboom, R. Sustainable Energy Fuels 2021, 5, 79. |

| [14] | Lü, J.; Hu, R.; Zhuo, O.; Xu, B.; Yang, L.; Wu, Q.; Wang, X.; Fan, Y.; Hu, Z. Acta Chim. Sinica 2014, 72, 1017. (in Chinese) |

| [14] | (吕金钊, 胡仁之, 卓欧, 许波连, 杨立军, 吴强, 王喜章, 范以宁, 胡征, 化学学报, 2014, 72, 1017.) |

| [15] | Yang, J.; Zhao, B.; Zhao, H.; Lu, A.; Ma, D. Acta Chim. Sinica 2013, 71, 1365. (in Chinese) |

| [15] | (杨敬贺, 赵博, 赵华博, 陆安慧, 马丁, 化学学报, 2013, 71, 1365.) |

| [16] | Gao, R.; Li, G.; Chen, Y.; Zeng, Y.; Zhao, J.; Wu, Q.; Yang, L.; Wang, X.; Hu, Z. Acta Chim. Sinica 2021, 79, 755. (in Chinese) |

| [16] | (高润洲, 李国昌, 陈轶群, 曾誉, 赵杰, 吴强, 杨立军, 王喜章, 胡征, 化学学报, 2021, 79, 755.) |

| [17] | Zeng, Y.; Lyu, P.; Cai, Y.; Gao, F.; Zhuo, O.; Wu, Q.; Yang, L.; Wang, X.; Hu, Z. Acta Chim. Sinica 2021, 79, 539. (in Chinese) |

| [17] | (曾誉, 吕品, 蔡跃进, 高福杰, 卓欧, 吴强, 杨立军, 王喜章, 胡征, 化学学报, 2021, 79, 539.) |

| [18] | Kang, J.; Zhang, S.; Zhang, Q.; Wang, Y. Angew. Chem., nt. Ed. 2009, 48, 2565. |

| [19] | Lu, J.; Yang, L.; Xu, B.; Wu, Q.; Zhang, D.; Yuan, S.; Zhai, Y.; Wang, X.; Fan, Y.; Hu, Z. ACS Catal. 2014, 4, 613. |

| [20] | Zhuo, O.; Yang, L.; Gao, F.; Xu, B.; Wu, Q.; Fan, Y.; Zhang, Y.; Jiang, Y.; Huang, R.; Wang, X.; Hu, Z. Chem. Sci. 2019, 10, 6083. |

| [21] | Zhang, Y.; Yang, X.; Yang, X.; Duan, H.; Qi, H.; Su, Y.; Liang, B.; Tao, H.; Liu, B.; Chen; Su, X.; Huang, Y.; Zhang, T. Nat. Commun. 2020, 11, 3185. |

| [22] | Yan, L.; Liu, J.; Wang, X.; Ma, C.; Zhang, C.; Wang, H.; Wei, Y.; Wen, X.; Yang, Y.; Li, Y. Appl. Surface Sci. 2020, 526. |

| [23] | Chen, S.; Bi, J.; Zhao, Y.; Yang, L.; Zhang, C.; Ma, Y.; Wu, Q.; Wang, X.; Hu, Z. Adv. Mater. 2012, 24, 5593. |

| [24] | Wu, Q.; Yang, L.; Wang, X.; Hu, Z. Acc. Chem. Res. 2017, 50, 435. |

| [25] | Zhao, J.; Lai, H.; Lyu, Z.; Jiang, Y.; Xie, K.; Wang, X.; Wu, Q.; Yang, L.; Jin, Z.; Ma, Y.; Liu, J.; Hu, Z. Adv. Mater. 2015, 27, 3541. |

| [26] | Cai, Y.; Liu, C.; Zhuo, O.; Wu, Q.; Yang, L.; Chen, Q.; Wang, X.; Hu, Z. Acta Chim. Sinica 2017, 75, 686. (in Chinese) |

| [26] | (蔡跃进, 刘晨霞, 卓欧, 吴强, 杨立军, 陈强, 王喜章, 胡征, 化学学报, 2017, 75, 686.) |

| [27] | Macheli, L.; Carleschi, E.; Doyle, B. P.; Leteba, G.; van Steen, E. J. Catal. 2021, 395, 70. |

| [28] | Xiong, H.; Motchelaho, M. A.; Moyo, M.; Jewell, L. L.; Coville, N. J. Appl. Catal. A: Gen. 2014, 482, 377. |

| [29] | Ralston, W. T.; Melaet, G.; Saephan, T.; Somorjai, G. A. Angew. Chem.,Int. Ed. 2017, 56, 7415. |

| [30] | Qiu, C.; Wu, B.; Meng, S.; Li, Y. Acta Chim. Sinica 2015, 73, 690. (in Chinese) |

| [30] | (邱成武, 吴宝山, 孟劭聪, 李永旺, 化学学报, 2015, 73, 690.) |

| [31] | Goodwin, J. G.; Goa, D. O.; Erdal, S.; Rogan, F. H. Appl. Catal. 1986, 24, 199. |

/

| 〈 |

|

〉 |