羧基功能化Fe3O4固定化酶反应器的构筑及性能研究

收稿日期: 2023-01-18

网络出版日期: 2023-03-28

基金资助

陕西省教育厅科研计划(16JK1827); 陕西省教育厅科研计划(22JK0605); 陕西省自然科学基础研究计划(2023-JC-QN-0173)

Study on Construction and Performance of Immobilized Enzyme Reactors by Carboxyl-functionalized Fe3O4

Received date: 2023-01-18

Online published: 2023-03-28

Supported by

Scientific Research Program Funded by Shaanxi Provincial Education Department(16JK1827); Scientific Research Program Funded by Shaanxi Provincial Education Department(22JK0605); Natural Science Basic Research Program of Shaanxi(2023-JC-QN-0173)

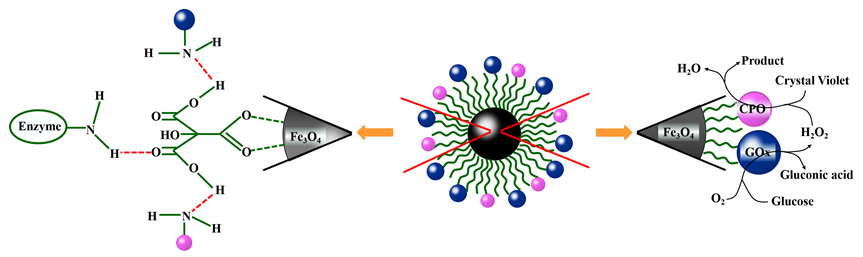

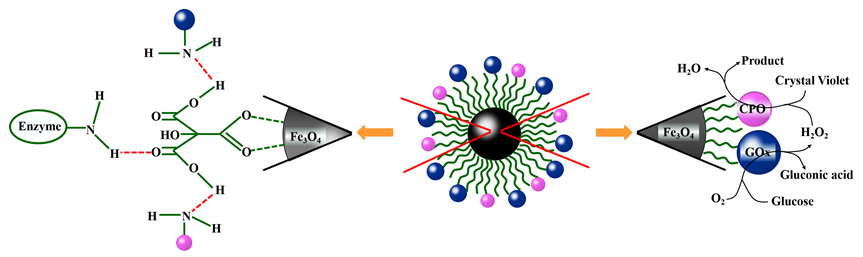

对固定化酶的载体进行功能化修饰, 通过改善载体和酶的界面连接可使酶分子在载体表面形成高度有序的二维排列, 从而提高酶的催化活性和操作稳定性. 用柠檬酸修饰的Fe3O4磁性纳米粒子(CA-Fe3O4)易于磁性分离且表面富含羧基, 可作为一种优良载体通过吸附法固定化氯过氧化物酶(CPO)构筑CPO@CA-Fe3O4酶反应器、共固定化CPO和葡萄糖氧化酶(GOx)构筑GOx&CPO@CA-Fe3O4级联酶反应器. 将酶反应器应用于催化氧化结晶紫染料的脱色时, 两种酶反应器均显示出良好的催化活性、对底物的亲和性与专一性、热稳定性, 在实际水样中也有良好的应用效果. 与CPO@CA-Fe3O4相比, GOx&CPO@CA-Fe3O4酶反应器因级联反应中H2O2的原位产生而表现出更优异的催化性能.

高丰琴 , 刘洋 , 张引莉 , 蒋育澄 . 羧基功能化Fe3O4固定化酶反应器的构筑及性能研究[J]. 化学学报, 2023 , 81(4) : 338 -344 . DOI: 10.6023/A23010015

The interface connection between carrier and enzyme can be improved by functionalizing the carrier of immobilized enzyme. This facilitates the formation of highly ordered two-dimensional arrangement of enzyme molecules on the surface of the carrier, thus improving the catalytic activity and operational stability of the enzymes. The surface of Fe3O4 modified with citric acid (CA-Fe3O4) is rich in carboxyl groups, which can be used as an excellent carrier due to its magnetic and easy separation characteristics. In this work, the adsorption method was more suitable for constructing enzyme reactors on the carrier of CA-Fe3O4, compared with covalent method. The CPO@CA-Fe3O4 reactor was constructed to immobilize chloroperoxidase (CPO) and the cascade enzyme reactor of GOx&CPO@CA-Fe3O4 was constructed by co-immobilization of CPO and glucose oxidase (GOx). In catalytic reaction, H2O2 was used as oxidant for CPO@CA-Fe3O4, while for GOx&CPO@CA-Fe3O4, the in-situ formation of H2O2 was caused by the oxidation of β-D-glucose by GOx. When the molar ratio of CPO to GOx was 3∶4 for immobilization, the effect of the cascade reaction can reach the best. When the enzyme reactors were applied to catalyze the oxidation of the decolorization of crystal violet, both enzyme reactors showed good catalytic activity, affinity and specificity for substrate. The thermal stabilities of the immobilized enzyme reactors were significantly improved. Both the enzyme reactors retained more than 55% of the activity at 70 ℃ for 1 h and more than 60% of the activity at 50 ℃ for 8 h, while the free enzyme was almost completely inactivated under the same reaction conditions. In contrast with CPO@CA-Fe3O4, the GOx&CPO@CA-Fe3O4 reactor showed better catalytic performance due to the in-situ generation of H2O2 in the cascade reaction. And this advantage was particularly reflected in the application of thermal stability and actual water samples. The important application potential has been shown about the immobilization of CPO enzyme reactors on CA-Fe3O4 carrier as a catalyst.

| [1] | Rana, H.; Sharma, A.; Dutta, S.; Goswami, S. J. Polym. Environ. 2022, 30, 4936. |

| [2] | Wu, H.; Mu, W.-M. Curr. Opin. Food Sci. 2022, 47, 100909. |

| [3] | Gao, X.; Pan, H.-B.; He, Z.-X.; Yang, K.; Qiao, C.-F.; Liu, Y.-L.; Zhou, C.-S. Acta Chim. Sinica 2021, 79, 1502. (in Chinese) |

| [3] | (高霞, 潘会宾, 贺曾贤, 杨柯, 乔成芳, 刘永亮, 周春生, 化学学报, 2021, 79, 1502.) |

| [4] | Lyu, F.-J.; Zhang, Y. F.; Zare, R. N.; Ge, J.; Liu, Z. Nano Lett. 2014, 14, 5761. |

| [5] | Li, S.-F.; Chen, Y.; Wang, Y.-S.; Mo, H.-L.; Zang, S.-Q. Sci. China: Chem. 2022, 65, 1122. |

| [6] | Xiong, Y.; Tsitkov, S.; Hess, H.; Gang, O.; Zhang, Y.-F. ACS Nano 2022, 16, 10383. |

| [7] | Wu, X. L.; Ge, J.; Yang, C.; Hou, M.; Liu, Z. Chem. Commun. 2015, 51, 13408. |

| [8] | Qiao, J.; Zhang, X.-Y.; Qi, L. ACS Appl. Bio Mater. 2022, 5, 4264. |

| [9] | Matera, A.; Dulak, K.; Sordon, S.; Wa?niewski, K.; Huszcza, E.; Pop?oński, J. Appl. Microbiol. Biotechnol. 2022, 106, 7763. |

| [10] | Xia, H.; Li, N.; Huang, W.-Q.; Song, Y.; Jiang, Y.-B. ACS Appl. Mater. Interfaces 2021, 13, 22240. |

| [11] | Wang, Y.; Zhang, X.; Wei, Z.-H.; Jiao, Y.-J.; An, D. Y.; Huang, Y. P.; Liu, Z.-S.; Yan, C. J. Chromatogr. A 2022, 1666, 462848. |

| [12] | Tvorynska, S.; Barek, J.; Josypcuk, B. Bioelectrochemistry 2022, 148, 108223. |

| [13] | Bahadur, A.; Saeed, A.; Shoaib, M.; Iqbal, S.; Bashir, M. I.; Waqas, M.; Hussain, M. N.; Abbas, N. Mater. Chem. Phys. 2017, 198, 229. |

| [14] | Mukhortova, Y. R.; Pryadko, A. S.; Chernozem, R. V.; Pariy, I. O.; Akoulina, E. A.; Demianova, I. V.; Zharkova, I. I.; Ivanov, Y. F.; Wagner, D. V.; Bonartsev, A. P.; Surmenev, R. A.; Surmeneva, M. A. Nano-Struct. Nano-Objects 2022, 29, 100843. |

| [15] | Zhao, Y.; Yuan, L.; Bai, X.-L.; Jiang, X.-X.; Zhang, Y.; Fang, Q.; Zhang, Q.; Liao, X. J. Sep. Sci. 2022, 45, 3635. |

| [16] | Sarno, M.; Iuliano, M.; Polichetti, M.; Ciambelli, P. Process Biochem. 2017, 56, 98. |

| [17] | Lv, C.-H.; Yang, X.-W.; Wang, Z.-K.; Ying, M.; Han, Q.-G.; Li, S.-F. Nanomaterials 2021, 11, 3086. |

| [18] | Zhang, Y.; He, S.; Simpson, B. K. Curr. Opin. Food Sci. 2018, 19, 30. |

| [19] | Verma, K.; Saha, G.; Kundu, L. M.; Dubey, V. K. Int. J. Biol. Macromol. 2019, 121, 1011. |

| [20] | Cheng, H.-P; Hu, M.-C.; Zhai, Q.-G.; Li, S.-N.; Jiang, Y.-C. Chem. Eng. J. 2018, 347, 703. |

| [21] | Jin, X.-Y.; Li, S.-S.; Long, N.-B.; Zhang, R.-F. Appl. Biochem. Biotechnol. 2018, 184, 1009. |

| [22] | Lu, J.; Cheng, L.; Wang, Y.; Ding, Y.; Hu, M.-C.; Li, S.-N.; Zhai, Q.-G.; Jiang, Y.-C. Mater. Des. 2017, 129, 219. |

| [23] | Wang, S.-J.; Ding, Y.; Chen, R.; Hu, M.-C.; Li, S.-N.; Zhai, Q.-G.; Jiang, Y.-C. Chem. Eng. Res. Des. 2018, 134, 52. |

| [24] | Cui, R.; Bai, C.-H.; Jiang, Y.-C.; Hu, M.-C.; Li, S.-N.; Zhai, Q.-G. Chem. Eng. J. 2015, 259, 640. |

| [25] | Nikazar, M.; Alizadeh, M.; Lalavi, R.; Rostami, M. H. J. Environ. Health Sci. 2014, 12, 21. |

| [26] | Wang, G.-S.; Geng, J.-H.; Guo, T.-L.; Qi, X.-W.; Yu, R.-T.; Zhang, Z.-X.; Wang, Y.-M.; Wang, Z.-H.; Li, Z.-Q.; Li, P.; Li, D.; Chang, G.-Q. Ceram. Int. 2022, 48, 29031. |

| [27] | Bahadur, A.; Saeed, A.; Shoaib, M.; Iqbal, S.; Bashir, M. I.; Waqas, M.; Hussain, M. N.; Abbas, N. Mater. Chem. Phys. 2017, 198, 229. |

| [28] | Jin, R.-X.; Li, C.-N.; Zhi, L.-F.; Jiang, Y.-C.; Hu, M.-C.; Li, S.-N.; Zhai, Q.-G. Carbohydr. Res. 2013, 370, 72. |

| [29] | Zhang, J.-F.; Li, Y.-J.; Zhang, Y.-X.; Wu, Y.-H.; Ju, J.-L.; He, W.; Li, C.-C. Nano 2022, 17, 2250062. |

| [30] | Li, C.-F.; Jiang, S.-H.; Zhao, X.-Y.; Liang, H. Molecules 2017, 22, 179. |

| [31] | Zhang, J.; Wang, Z.-J.; He, C.; Liu, X.-L.; Zhao, W.-F.; Sun, S.-D.; Zhao, C.-S. ACS Omega 2019, 4, 2853. |

| [32] | Zhao, R.-N.; Hu, M.-C.; Li, S.-N.; Zhai, Q.-G.; Jiang, Y.-C. Acta Chim. Sinica 2017, 75, 293. (in Chinese) |

| [32] | (赵睿南, 胡满成, 李淑妮, 翟全国, 蒋育澄, 化学学报, 2017, 75, 293.) |

/

| 〈 |

|

〉 |