基于PtAu阳极催化剂的柔性生物燃料电池的性能研究

Performance Study of Flexible Biofuel Cell Based on PtAu Anode Catalysts

Received date: 2024-06-15

Online published: 2024-09-02

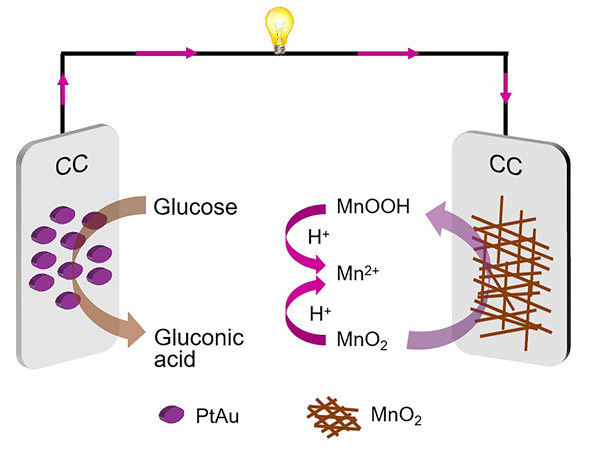

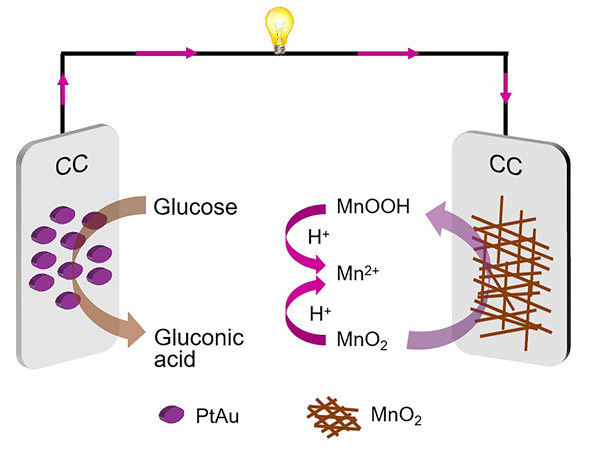

葡萄糖生物燃料电池(GFC)是一种能够将葡萄糖燃料中的化学能转换为电能的装置, 在自供电可穿戴医疗设备领域有着广泛的应用. 本工作采用一种简单的超声辅助法制备了PtAu纳米颗粒催化剂, 在中性环境下作为柔性GFC的阳极催化剂用于催化葡萄糖. PtAu催化剂对葡萄糖催化具有较高的活性和稳定性. 此外, 本工作还引入了消耗性固态二氧化锰(MnO2)电极替代O2还原阴极, 避免溶液中低氧溶解度和缓慢的O2还原动力学等问题. 通过采用PtAu催化剂修饰的碳布(PtAu/CC)阳极和MnO2/CC阴极制备的无膜柔性GFC的最大功率密度(Pmax)为22.61 μW•cm−2, 开路电压(EOCV)为0.439 V, 这为可穿戴设备领域的研究提供了新思路.

关键词: PtAu催化剂; 固态二氧化锰电极; 柔性葡萄糖生物燃料电池; 葡萄糖电催化氧化

许廷强 . 基于PtAu阳极催化剂的柔性生物燃料电池的性能研究[J]. 化学学报, 2024 , 82(10) : 1022 -1030 . DOI: 10.6023/A24060196

The rapid growth of flexible electronics has led to various wearable sensors, circuit, and storage devices. The glucose biofuel cell (GFC) is a device capable of converting the chemical energy from glucose fuel into electrical energy, with a wide range of applications in self-powered wearable medical devices. In this study, a PtAu nanoparticle catalyst was synthesized for the catalysis of glucose in a neutral environment through an ultrasound-assisted method. This method offers the advantages of simple operation, short reaction time, and environmental friendliness. In the synthesis of PtAu catalyst, drying is unnecessary, but the catalyst concentration must be carefully controlled to maintain its catalytic effectiveness. The morphology and structure of the PtAu catalysts were analyzed using transmission electron microscopy (TEM), X-ray diffraction (XRD), and X-ray photoelectron spectrum (XPS). The PtAu catalysts were immobilized on a carbon cloth (CC) to construct the anode of flexible GFC. The study investigated the impact of electrochemically active area, varying sweep rates, and pH values on the catalytic performance, demonstrating the PtAu catalyst’s commendable activity and durability for glucose catalysis. Furthermore, a solid manganese dioxide (MnO2) material was synthesized through a simple hydrothermal method. The morphology and structure MnO2 were characterized using scanning electron microscopy (SEM) and XRD. The prepared solid MnO2 material was applied to the CC as the cathode of flexible GFC to address issues such as low oxygen solubility and slow O2 reduction kinetics in solution. Linear scanning voltammetry (LSV) was employed to examine the influence of glucose on MnO2. In addition, the effects of various mechanical deformations on the anode and cathode were studied, demonstrating their strong mechanical strain capacity. A membrane-less flexible GFC prepared using a PtAu/CC anode and a MnO2/CC cathode achieved a maximum power density (Pmax) of 22.61 μW•cm−2 and an open circuit voltage (EOCV) of 0.439 V, surpassing previous reports in the literature, demonstrating its potential for wearable applications. Notably, the flexible GFC maintains consistent power density and EOCV even after repeated bending, highlighting its stability.

| [1] | Kim, J.; Campbell, A. S.; de ávila, B. E.-F.; Wang, J. Nat. Biotechnol. 2019, 37 389. |

| [2] | Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. Nat. Commun. 2014, 5 3132. |

| [3] | Liang, H.-R.; Ma, H.-X.; Duan, X.-R.; Yu, J.; Wang, H.-M.; Li, S.; Zhu, M.-J.; Chen, A.-B.; Zheng, H.; Zhang, Y.-Y. Acta Chim. Sinica 2023, 81 1402 (in Chinese). |

| [3] | (梁华润, 马浩轩, 段新荣, 于洁, 王灏珉, 李硕, 朱梦嘉, 陈爱兵, 郑晖, 张莹莹, 化学学报, 2023, 81 1402.) |

| [4] | Liu, Y.-X.; Cao, C. AET 2023, 49 75 (in Chinese). |

| [4] | (刘宇轩, 曹超, 电子技术应用, 2023, 49 75.) |

| [5] | Wang, J.; Sun, M.; Pei, X.; Zheng, L.; Ma, C.; Liu, J.; Cao, M.; Bai, J.; Zhou, M. Adv. Funct. Mater. 2022, 32 2209697. |

| [6] | Guan, S.; Wang, J.; Yang, Y.; Zhu, X.; Zhou, J.; Ye, D.; Chen, R.; Dai, H.; Liao, Q. Adv. Funct. Mater. 2023, 33 2303134. |

| [7] | Zou, Q.; Liu, J.; Zhu, G.-B.; Zhang, X.-H.; Chen, J.-H. Acta Chim. Sinica 2013, 71 1154 (in Chinese). |

| [7] | (邹琼, 刘娟, 朱刚兵, 张小华, 陈金华, 化学学报, 2013, 71 1154.) |

| [8] | Miao, K.-P.; Yan, L.; Ma, P.-C.; Ma, X.-Y. Chinese J. Power Sources 2021, 45 406 (in Chinese). |

| [8] | (苗昆鹏, 闫龙, 马鹏程, 马晓燕, 电源技术, 2021, 45 406.) |

| [9] | Santiago, ó.; Navarro, E.; Raso, M. A.; Leo, T. J. Appl. Energy 2016, 179 497. |

| [10] | Santoro, C.; Babanova, S.; Erable, B.; Schuler, A.; Atanassov, P. Bioelectrochemistry 2016, 108 1. |

| [11] | Pletcher, D. J. Appl. Electrochem. 1984, 14 403. |

| [12] | Mello, G. A. B.; Cheuquepán, W.; Briega-Martos, V.; Feliu, J. M. Electrochim. Acta 2020, 354 136765. |

| [13] | Tian, K.; Baskaran, K.; Tiwari, A. Vacuum 2018, 155 696. |

| [14] | Wei, W.; Hui, W.-Y.; Shan, C.-S. J. Hubei Univ., Nat. Sci. 2023, 45 18 (in Chinese). |

| [14] | (魏文, 惠文宇, 单长胜, 湖北大学学报(自然科学版), 2023, 45 18.) |

| [15] | Chu, T.-F.; Lin, F.-Y.; Kuznetsova, I.; Wang, G.-J. J. Power Sources 2021, 486 229374. |

| [16] | Huang, J.; Simons, P.; Sunada, Y.; Rupp, J. L. M.; Yagi, S. J. Electrochem. Soc. 2021, 168 064511. |

| [17] | Zuo, C.; Chao, F.; Li, M.; Dai, Y.; Wang, J.; Xiong, F.; Jiang, Y.; An, Q. Adv. Energy Mater. 2023, 13 2301014. |

| [18] | Deng, R.; Chen, J.; Chu, F.; Qian, M.; He, Z.; Robertson, A. W.; Maier, J.; Wu, F. Adv. Mater. 2024, 36 2311153. |

| [19] | Shen, X.-F.; Wang, X.-N.; Yu, N.-S.; Yang, W.; Zhou, Y.-R.; Shi, Y.-H.; Wang, Y.-L.; Dong, L.-Z.; Di, J.-T.; Li, Q.-W. Acta Phys.-Chim. Sin. 2022, 38 58 (in Chinese). |

| [19] | (沈晓帆, 王晓娜, 俞能晟, 杨薇, 周雨融, 石艳红, 王玉莲, 董立忠, 邸江涛, 李清文, 物理化学学报, 2022, 38 58.) |

| [20] | Xia, D.; Gao, H.; Li, M.; Holoubek, J.; Yan, Q.; Yin, Y.; Xu, P.; Chen, Z. SmartMat 2023, 4, e1208. |

| [21] | Pan, Z.; Jin, L.; Yang, C.; Ji, X.; Liu, M. Chem. Eng. J. 2023, 470 144084. |

| [22] | Chi, G.; Gong, W.; Xiao, G.; Pan, J.; Chen, J.; Su, L.; Fugetsu, B.; Sakata, I.; Zhang, X. Nano Energy 2023, 117 108887. |

| [23] | Hou, Z.-X.; Wang, X.-H.; Qu, C.-Y.; Wang, J. Energy Storage Sci. Technol. 2020, 9 797 (in Chinese). |

| [23] | (侯朝霞, 王晓慧, 屈晨滢, 王健, 储能科学与技术, 2020, 9 797.) |

| [24] | Zheng, J. H.; Zhang, J. L.; Li, G.; Zhang, J. M.; Zhang, B. W.; Jiang, Y. X.; Sun, S. G. Mater. Today Energy 2022, 27 101028. |

| [25] | Lv, Z.; Luo, Y.; Tang, Y.; Wei, J.; Zhu, Z.; Zhou, X.; Li, W.; Zeng, Y.; Zhang, W.; Zhang, Y.; Qi, D.; Pan, S.; Loh, X. J.; Chen, X. Adv. Mater. 2018, 30 1704531. |

| [26] | Wang, F.; Cai, R.; Tan, W. Anal. Chem. 2023, 95 6046. |

| [27] | Burke, L. D. Electrochim. Acta 1994, 39 1841. |

| [28] | Tian, K.; Prestgard, M.; Tiwari, A. Mater. Sci. Eng. C 2014, 41 100. |

| [29] | Gao, H.; Xiao, F.; Ching, C. B.; Duan, H. ACS Appl. Mater. Interfaces 2011, 3 3049. |

| [30] | Do, U. P.; Seland, F.; Wang, K.; Johannessen, E. A. J. Mater. Sci. 2019, 54 14143. |

| [31] | Kerzenmacher, S.; Kr?ling, U.; Metz, T.; Zengerle, R.; von Stetten, F. J. Power Sources 2011, 196 1264. |

| [32] | Zhao, Y.; Tian, L.; Fan, Y.; Zhang, M.; Wang, X. J. Mater. Sci. 2021, 56 13066. |

| [33] | Chu, T.-F.; Rajendran, R.; Kuznetsova, I.; Wang, G.-J. J. Power Sources 2020, 453 227844. |

/

| 〈 |

|

〉 |