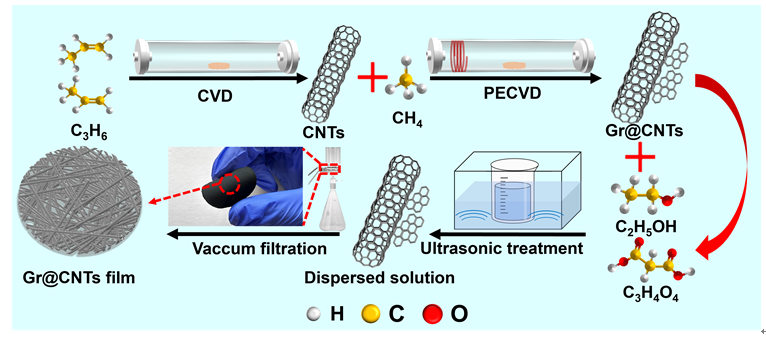

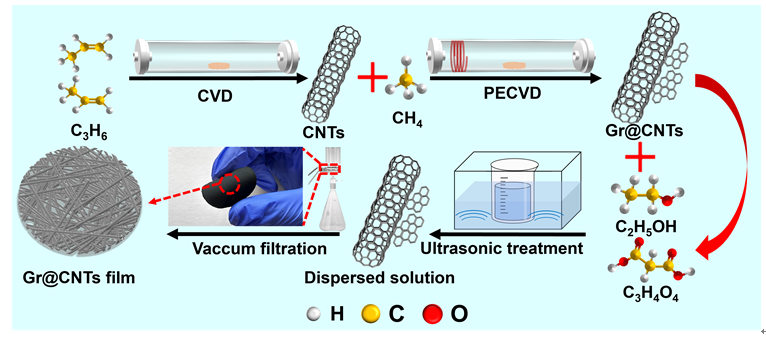

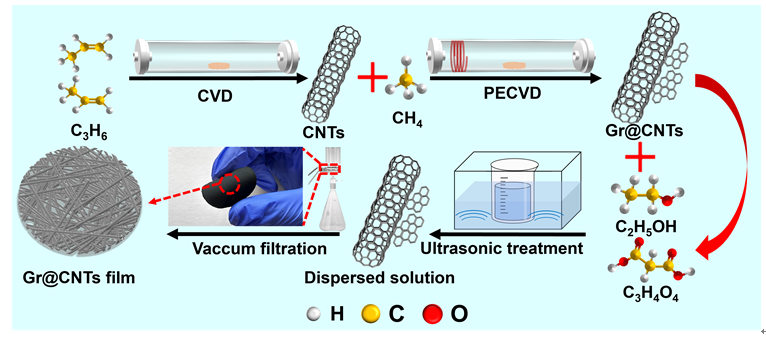

随着全球经济的快速发展和人口规模的持续增长,水资源短缺问题日益严峻。开发新型高效水净化材料以实现水资源可持续利用,已成为当前研究的热点。太阳能界面蒸发技术因能够高效利用可再生能源进行水处理而备受关注,其中光热材料的设计与构筑是其关键所在。碳基纳米材料因具有宽光谱吸收、高光热转化效率、优良的稳定性及可调控的结构特性,被认为是极具潜力的新一代光热材料。基于此,本文采用等离子体增强化学气相沉积(PECVD)技术,在碳纳米管(CNTs)基体上原位生长石墨烯(Gr)纳米片,构筑了三维Gr@CNTs异质结材料。该材料具有高比表面积和大孔隙结构,在3 Sun光照强度(3 kW/m2)下,材料的表面温度在30 s内可迅速升至138.8 ℃。经过碱化处理后获得强亲水性自支撑薄膜,并与聚氨酯海绵复合形成蒸发器,可应用于太阳能蒸发系统,其水蒸发速率可达3.62 kg/(m2·h),光热转化效率高达84.0%。相比于纯CNTs材料,Gr@CNTs材料展现出更加优异的光热性能和快速光响应特性,为碳基光热材料在高效太阳能蒸发与水处理领域的进一步优化与应用提供了借鉴方向。

With the rapid growth of the global economy and the continuous increase in population, freshwater scarcity has become an increasingly critical global challenge. Consequently, the development of efficient and sustainable water purification materials has attracted considerable research interest. Solar-driven interfacial evaporation technology has emerged as a promising approach for water treatment owing to its effective utilization of renewable solar energy, in which the rational design and fabrication of photothermal materials are of paramount importance. Carbon-based nanomaterials are widely recognized as promising next-generation photothermal materials due to their broadband light absorption, high photothermal conversion efficiency, excellent stability, and tunable structural characteristics. However, the photothermal performance of conventional carbon materials is often limited by insufficient light harvesting, restricted water transport, or slow thermal response. Therefore, constructing advanced carbon-based architectures with synergistic structural and functional characteristics remains a critical challenge. In this study, a graphene@carbon nanotubes (Gr@CNTs) hybrid photothermal material was rationally designed and fabricated by in situ growing Gr nanosheets on a CNT scaffold via plasma-enhanced chemical vapor deposition (PECVD). This hybrid architecture integrates the large specific surface area of two-dimensional Gr with the porous, interconnected framework of one-dimensional CNTs, forming a unique three-dimensional network structure with high surface area and microporosity. Under 3 Sun illumination (3 kW/m2), the surface temperature of the Gr@CNTs material rapidly increased to 138.8 °C within 30 s, indicating an ultrafast photothermal response. After alkaline treatment, a strongly hydrophilic free-standing Gr@CNTs film was obtained and subsequently integrated with a polyurethane sponge to construct a composite solar evaporator. The resulting system achieved a high water evaporation rate of 3.62 kg/(m2·h) and a photothermal conversion efficiency of up to 84.0%. Compared with pristine CNTs materials, the Gr@CNTs hybrid exhibits significantly enhanced photothermal performance, faster light-response behavior, and improved operational stability. This study provides valuable insights into the rational design of advanced carbon-based photothermal materials and offers a promising strategy for efficient solar-driven evaporation and sustainable water purification applications.

[1] Meng H.; Zhang L.; Fan L. W.; Lv Y.; Hai L.; Yu Z. T.; Cen, K. F. Energy Convers. Manage.2015, 91. 101—109.

[2] Chandrashekara M.; Avadhesh, Yadav. Renew. Sust. Energy Rev. 2017, 67.1308—1330.

[3] Long Y.; Jiao X. C.; Meng Z.; Zhang S. Q.; Yao H. F.; Zhao W. C.; Xia A. D.; Harald Ade.; Hou, J. H. Adv. Mater.2015, 27. 6046—6054.

[4] Jibran Khan.; Mudassar, H. Arsalan. Renew. Sust. Energy Rev.2016, 55. 414—425.

[5] Md. Nahian, Al. Subri. Ivan.; Shuvra Saha.; Ahmed Mortuza. Saleque.; Safayet Ahmed.; Amrit Kumar. Thakur.; Bai G. X.; Zhang M.; R. Saidur.; Yuen, Hong. Tsong. Nano Energy.2024, 120. 109176.

[6] Ingjerd Haddeland.; Jens Heinke.; Hester Biemans.; Dominik, Wisser. Proc. Natl. Acad. Sci.2013, 111. 3251—3256.

[7] Tao F. J.; Michael Green.; Alma Valenzuela. Garcia.; Xiao T.; Anh Thi. Van. Tran.; Zhang Y. L.; Yin Y. S.; Chen, X. B. Appl. Mater. Today.2019, 17. 45—84.

[8] Zhu L. L.;G, M. M.; Connor, Kang. Nuo. Peh.; Ghim, W. H.Mater. Horiz. 2018, 5. 323—343.

[9] Wen S.; Deng T. Nat. Energy.2016, 1. 16133.

[10] Oara Neumann.; Alexander S. Urban.; Jared, Day.; Peter, Nordlander.; Surbhi, Lai. ACS Nano. 2013, 7. 42—49.

[11] Jing X. X.; Wang W. D.; Mo H. S.; Tan P.; Chen Z. G.; Wu Z. Y.; Sun, L. B. Inorganica. Chimica. Acta.2024, 40. 1033—1064 (in Chinese).

(景欣欣,王伟铎,莫何苏,谈朋,陈志刚,吴正颖,孙林兵,无机化学学报, 2024, 40. 1033—1064.)

[12] Yang, D.; Shi, X. F.; Zhang, J. J.; Bu, X. H. Acta. Chimica. Sinica. 2023, 81. 1052—1063 (in Chinese).

(杨地,史潇凡,张冀杰,卜显和,化学学报, 2023, 81. 1052—1063.)

[13] Hao C. X.; Li M.; Yang J. H.; Wang X. D.; Xia Y. H.; Chu C. Q.; Liu Z. M.; He Y.; Ci, H. N. Small Methods.2025, 9. 2401101.

[14] Peng M.; Zhang Z.; Wei B.; He J. X.; Sun H. X.; Zhu Z. Q.; Liang W. D.; An, L. Adv. Energy Mater.2019, 9. 1802158.

[15] Wang Y. C.; Wang C. Z.; Song X. J.; Suresh Kumar. Megarajan.; Jiang, H. Q. J. Mater. Chem. A.2018, 6. 963—071.

[16] Shuo Q.; Tao J.; Zhang Y. Y.; Zhao Y. J.; Xing Y. T.; Zhang M.; Wang F.; Chen C. X.; Wong, W. Y. Adv. Funct. Mater.2025, 35. 2503234.

[17] Hu A. W.; Zhao Y.; Hu Q.; Chen C. H.; Lu X.; Cui S. L.; Liu B. Nat. Commun.2024, 15. 9484.

[18] Wang, S.; Niu, Y.; Yan, L. J.; Chan, W. J.; Zhu, Z. Q.; Sun, H. X.; Li, J. Y.; Liang, W. D.; Li, A. Compos. Sci. Technol. 2022, 228. 109683.

[19] Ren H. Y.; Tang M.; Guan B. L.; Wang K. X.; Yang J. W.; Wang F. Y.; Wang M. Z.; Shan J. Y.; Chen Z. L.; Wei D.; Peng H. L.; Liu, Z. F. Adv. Mater.2017, 29. 1702590.

[20] Zhang P. P.; Li J.; Lv L. X.; Zhao Y.; Qu, L. T. ACS Nano. 2017, 11.5087—5093.

[21] Daniel, Peter. Storer.; Jack, Leslie. Phelps.; Xuan, Wu.; Gary, Owens.; Nasreen, Islam. Khan.; Xu, H. L. ACS Appl. Mater. Interfaces. 2020, 12. 15279—15287.

[22] Beom Soo. Joo.; Woo-Young Lee.; Seongyu Lee.; Jin Hong. Kim.; JoonHyun Kang.; Hyungduk Ko.; Gumin, Kang. Chem. Eng. J.2025, 505. 159733.

[23] Fan Z. F.; Liu J.; Liu H. J.; Liu L. J.; She Y.; Wen X. Y.; Wang H. Y.; Hu G. X.; Niu R.; Gong, J. J. Energy Chem.2024, 94. 527—540.

[24] Cheng C.; Fang J. W.; Chai Y. Q.; Yuan R.; Liu, H. Y. Chem. Eng. J.2024, 498. 155665.

[25] Xi, S. B.; Wang, M.; Wang, L. L.; Xie, H. Q.; Wei, Y. Sol. Energy Mater. Sol. Cells. 2021, 226. 111068.

[26] Wang, W. T.; Geng, W. W.; Guo, X. L.; Wang, K. H.; Yao, Y. Y.; Ding, L. M. Acta. Chimica. Sinica. 2023, 81. 595—603 (in Chinese).

(王文涛,耿伟纬,郭小龙,王康辉,姚玉元,丁黎明,化学学报, 2023, 81. 595—603.)

[27] Chen Y. B.; Zheng D. X.; Wang N.; Liu J. S.; Yu F. Y.; Wu S. J.; Liu S. Z.; Li, Z. P. Acta. Chimica. Sinica.2024, 82. 987—1000 (in Chinese).

(陈宇波,郑德旭,王楠,刘吉双,于凤阳,吴飒建,刘生忠,李志鹏,化学学报, 2024, 82. 987—1000.)

[28] Liu M. T.; Zhu P. P.; Lai S. T.; Zhang X. G.; Yuan F.; Ling X.; Liu D.; Kui F.; Lu X. H.; Guo X. G.; Liao X. F.; Chen, Y. W. Chin. J. Chem.2025, 43. 13—22.

[29] Li X. R.; Zhu J.; Cao L. Y.; Zhang H. Y.; Du X. Y.; Lin H.; Zheng C. J.; Tao, S. L. Chin. J. Chem.2025, 43. 2433—2440.

[30] Zhao Z. X.; Li J. Q.; Wang F.; Tan P. X.; Wang L.; Wang B.; Jin J. J.; Wang X. X.; Zhang W. H.; Wang, C. B. J. Energy Chem.2025, 104. 540—550.

[31] Yang H.; Wang X.; Li S. H.; Zhao B.; Liu C.; Li D.; Liang Z. Q.; Ibrahim Abdulhalim.; Peng M. W.; Sun Y. H.; Jiang L.Adv. Funct. Mater. 2025, e20083.

[32] Wang L.; Wu D. C.; Zhu X. C.; Hang S. H.; Gu N.; Geng W. P.; Fan X. Q.; Imran Shakir.; Xu Y. X.; Sun Y. Y.Adv. Funct. Mater. 2025, e28068.