对苯二甲酰氯与N-甲基吡咯烷酮反应机理以及对聚对苯二甲酰对苯二胺聚合的影响

收稿日期: 2013-12-06

修回日期: 2014-01-17

网络出版日期: 2014-03-03

基金资助

国家重点基础研究发展计划(973计划,No. 2011CB606102)资助项目.

Reaction Mechanism of Terephthaloyl Chloride/N-Methyl-2-pyrrolidone and the Effect on Poly(p-phenylene terephthalamide) Polymerization

Received date: 2013-12-06

Revised date: 2014-01-17

Online published: 2014-03-03

Supported by

Project supported by the National Basic Research Program of China (973 Program, No. 2011CB606102).

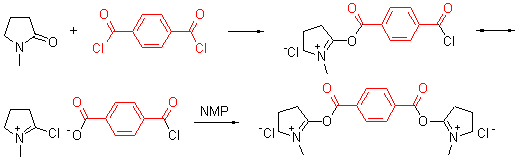

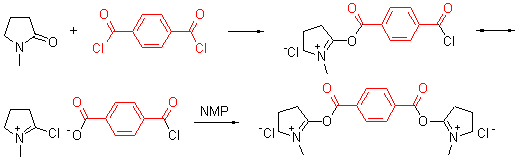

稳定合成高分子量聚对苯二甲酰对苯二胺(PPTA)树脂是生产高性能芳纶纤维的基础. 在PPTA聚合过程中,以单体对苯二甲酰氯(TPC)/N-甲基吡咯烷酮(NMP)溶液与单体对苯二胺(PPD)/NMP溶液进行溶液缩聚反应是最理想高效的方式,但是因为TPC/NMP间未知的相互作用导致这种聚合方式难以实现. 通过实验与计算模拟相结合的方式,利用红外光谱(FTIR)、核磁共振(1H NMR)、飞行时间质谱及示差扫描量热分析对TPC/NMP间的反应进行了分析,并通过分子模拟计算证明TPC与NMP会发生类似Vilsmeier-Haack反应,导致TPC上的酰氯基团失活,从而严重影响其聚合反应活性. 最后,通过PPTA聚合实验验证了该结论的正确性.

关键词: PPTA; TPC/NMP; Vilsmeier-Haack反应; 分子模拟

郭澄龙 , 许甲 , 王力慧 , 庹新林 , 王罗新 . 对苯二甲酰氯与N-甲基吡咯烷酮反应机理以及对聚对苯二甲酰对苯二胺聚合的影响[J]. 有机化学, 2014 , 34(6) : 1132 -1137 . DOI: 10.6023/cjoc201312006

Stable synthesis of high molecular weight of poly(p-phenylene terephthalamide) (PPTA) resin is the basis for the production of high-performance aramid fibers. In PPTA polymerization process, the feeding method of the monomer terephthaloyl chloride (TPC) has important influence on the molecular weight. In theory, using TPC/N-methyl-2-pyrrolidone (NMP) solution and monomer p-phenylene diamine (PPD)/NMP solution for solution polycondensation is the most ideal and effective way, but in real polymerization process, it is difficult to synthesize high molecular weight PPTA due to some unknown interaction between TPC and NMP. This article combines experiments and molecular stimulation together, using Frontier infrared spectroscopy (FTIR), 1H NMR, the time of flight mass spectrometer (TOF-MS) and differential scanning calorimetric analysis (DSC), analyzing the reaction between TPC and NMP, and verified that TPC and NMP has obvious reaction similar to Vilsmeier-Haack reaction through molecular stimulation, which may cause the chloride group on the TPC deactivating, and seriously influence its reactivity. And the conclusion is verified through PPTA polymerization experiments, and the longer TPC/NMP solution is prepared, the worse of the polymerization effect is. These observations and experiments suggest that it is not feasible to synthesize high molecular weight PPTA in industry using TPC/NMP solution feeding method.

Key words: PPTA; TPC/NMP; Vilsmeier-Haack reaction; molecular simulation

[1] Kwolek, S. L. US 3671542, 1972 [Chem. Abstr. 1970, 72, 122796]

[2] Yang, H. H. Kevlar Aramid Fiber, Wiley-Interscience, New York, 1992.

[3] Chae, H. G.; Kumar, S. J. Appl. Polym. Sci. 2006, 100(1), 791.

[4] Tanner, D.; Fitzgerald, J. A.; Phillips, B. R. Angew. Chem., Int. Ed. Engl. 1989, 28, 649. [5] Rao, Y.; Waddon, A. J.; Ferris, R. J. Polymer 2001, 42, 5937.

[6] Morgan, P. W. Condensation Polymers: By Interfacial and Solution Method, Interscience, New York, 1965.

[7] Yamazaki, N.; Matsumoto, M.; Higashi, F. J. Polym. Sci., Polym. Chem. 1975, 13, 1373.

[8] Hearle, J. W. S. High Performance Fiber, Woodhead Press, Cambridge, 2001.

[9] Yotsumoro, T.; Imai, I. JP 62131804, 1987 [Chem. Abstr. 1988, 108, 23200].

[10] Shin, H.; Del, W. US 4009153, 1977 [Chem. Abstr. 1977, 86, 141532].

[11] Pan, Y. Y.; Cai, B. L.; Zhou, Z. S.; Xu, J. S. CN 1048710, 1991 [Chem. Abstr. 1991, 115, 161123].

[12] Cao, Y. T.; Zhou, Z. S.; You, X. L.; Liu, Z. F. CN 101220148, 2008 [Chem. Abstr. 2008, 149, 224768].

[13] Panar, M.; Beste, L. F. Macromolecules 1977, 10(6), 1401.

[14] Sun, L. L.; Xu, J.; Luo, W.; Guo, C. L.; Tuo, X. L.; Wang, X. G. Acta Polym. Sinica 2012, 1, 70 (in Chinese).

(孙力力, 许甲, 罗文, 郭澄龙, 庹新林, 王晓工, 高分子学报, 2012, 1, 70.)

[15] Frisch, M. J.; Trucks, G. W.; Schlegel, H. B.; Scuseria, G. E. Gaussian 03, Revision E.01, Gaussian, Inc., Wallingford, CT, 2005.

[16] Zhang, S. F.; Han, B. Z.; Bao, J. S. Polym. Commun. 1983, 2, 88 (in Chinese).

(张树范, 韩宝珍, 宝净生, 高分子通讯, 1983, 2, 88.)

[17] Campaigne, E.; Archer, W. L. Org. Synth. Coll. 1963, 4, 331.

[18] Meth-Cohn, O.; Stanforth, S. P. Compd. Org. Synth. 1991, 2, 777.

[19] Higashi, F.; Nishi, T. J. Polym. Sci. 1986, 24, 701.

[20] Özp?nar, G. A.; Kaufmann, D. E.; Clark, T. J. Mol. Model 2011, 17, 3209.

[21] Guo, X.; Cheng, Y. W.; Li, X. Acta Crystallogr. 2005, 61, 3410.

/

| 〈 |

|

〉 |