聚合离子液体在催化转化果糖制备乳酸中的应用

收稿日期: 2014-08-28

修回日期: 2014-09-26

网络出版日期: 2014-10-30

基金资助

国家自然科学基金(No. 21476021)和国家重点基础研究发展计划(No. 2010CB226902)资助项目.

Application of Polymeric Ionic Liquids in the Catalytic Conversion of Fructose to Lactic Acid

Received date: 2014-08-28

Revised date: 2014-09-26

Online published: 2014-10-30

Supported by

Project supported by the National Natural Science Foundation of China (No. 21476021) and the National Basic Research Program of China (No. 2010CB226902).

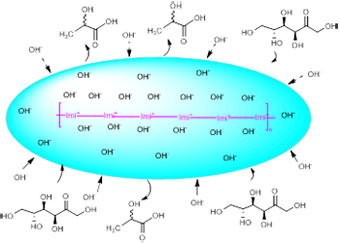

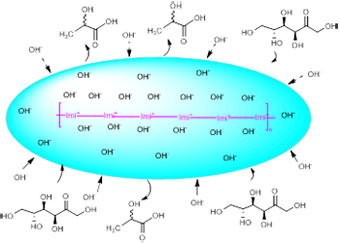

化学法分解糖类制备乳酸大都需要苛刻的反应条件, 如高浓度强碱、较高的反应温度等. 介绍了一种以聚合离子液体([IMEP]Cl)为催化剂, 采用水热法直接催化转化果糖制备乳酸的方法, 并对聚合离子液体类型、碱类型、反应温度、[IMEP]Cl与NaOH相对量以及底物浓度等实验条件进行了优化. 结果表明, 在100 ℃条件下, 底物浓度为25 mmol/L时, 反应30 min乳酸达到最高收率65%, [IMEP]Cl与NaOH浓度分别为100和50 mmol/L. 该方法有效降低了水热法合成乳酸的反应温度和碱浓度, 并且[IMEP]Cl经过5次循环利用仍有较好的催化效果, 乳酸收率仍保持在55%以上. 对该体系催化转化果糖制备乳酸的反应机理进行了初步的推测. 表明以聚合离子液体为催化剂催化转化碳水化合物制备乳酸有着较好的前景.

汪亚美 , 王新承 , 李顺杰 , 黄崇品 , 宋彦磊 , 陈标华 . 聚合离子液体在催化转化果糖制备乳酸中的应用[J]. 有机化学, 2015 , 35(2) : 404 -410 . DOI: 10.6023/cjoc201408034

Preparation of lactic acid via chemical transformation of carbohydrates requires rigorous reaction conditions, such as high concentrations of alkali, high temperature, etc. This paper reports the use of polymeric ionic liquids ([IMEP]Cl) as catalyst for the hydrothermal conversion of fructose to lactic acid; the main variables of the reaction, temperature, substrate concentration, as well as the relative amount of [IMEP]Cl and NaOH were optimized. Results showed that, at 100 ℃, substrate concentration of 25 mmol/L, reaction time of 30 min, the highest yield of lactic acid was 65% with [IMEP]Cl and NaOH concentrations of 100 and 50 mmol/L respectively. This method reduces the reaction temperature and alkali concentration compared to traditional hydrothermal method, additionally it was found that [IMEP]Cl can be used during 5 catalytic cycles without losing its catalytic effect with a lactic acid yield of 55% in the 5th reuse cycle. This demonstrates that the use of polymer ionic liquids as catalysts has a better prospect for future developments. A possible reaction mechanism has been proposed, but further investigation is required.

Key words: polymeric ionic liquids; fructose; lactic acid

[1] Keshwani, D. R.; Cheng, J. J. Bioresour. Technol. 2009, 100(4), 1515.

[2] Sims, R. E. H.; Mabee, W.; Saddler, J. N.; Taylor, M. Bioresour. Technol. 2010, 101(6), 1570.

[3] Rom, L. Y.; Barrettc, J.; Liu, Z. Y. Nat. Biotechnol. 2007, 447, 982.

[4] Chang, C. Ph.D. Dissertation, Institute of Bioengineering, Zhejiang University, Hangzhou, 2006 (in Chinese). (常春, 博士论文, 浙江大学生物工程研究所, 杭州, 2006.)

[5] Zhu, G.-Y.; Ma, Y.-H.; Zhu, X. Chin. J. Org. Chem. 2010, 30, 142 (in Chinese). (朱广用, 马艳华, 朱宪, 有机化学, 2010, 30, 142.)

[6] Huber, G. W.; Iborra, S.; Corma, A. Chem. Rev. 2006, 106, 4044.

[7] Demirbas, M. F.; Balat, M. Energy Convers. Manage. 2006, 47(15~16), 2371.

[8] Gallezot, P. Chem. Soc. Rev. 2012, 41, 1538.

[9] Chandel, A. K.; da Silva, S. S.; Carvalho, W.; Singh, O. V. J. Chem. Technol. Biotechnol. 2012, 87(1), 11.

[10] Liu, Z. Ph.D. Dissertation, Zhejiang University, Hangzhou, 2012 (in Chinese). (刘镇, 博士论文, 浙江大学, 杭州, 2012.)

[11] San-Martin, M.; Pazos, C.; Coca, J. J. Chem. Technol. Biotechnol. 1992, 54, 1e6.

[12] Epane, G.; Laguerre, J. C.; Wadouachi, A.; Marek, D. Green Chem. 2010, 12(3), 502.

[13] Gao, C.; Ma, C.; Xu, P. Biotechnol. Adv. 2011, 29(6), 930.

[14] Bai, D.; Zhao, X.; Li, X.; Xu, S. Biochem. Eng. J. 2004, 18(1), 41.

[15] Salminen, S.; Ouwehand, A.; Wright, A. V.; Daly, C. Ann. N. Y. Acad. Sci. 1993, 429.

[16] Zeng, W.; Chen, F.-Q.; Zhan, X.-L; Chem. Ind. Eng. Progr. 2006, 25(7), 744 (in Chinese). (曾炜, 陈丰秋, 詹晓力, 化工进展 2006, 25(7), 744.)

[17] Wasewar, K. L.; Yawalkar, A. A.; Moulijn, J. A.; Pangarkar, V. G. Ind. Eng., Chem. Res. 2004, 43(19), 5969.

[18] Aida, T. M.; Tajima, K.; Watanabe, M.; Saito, Y.; Kuroda, K.; Nonaka, T.; Hattori, H.; Smith, R. L.; Arai, K. J. Supercrit. Fluids 2007, 42(1s), 110.

[19] Onda, A.; Ochi, T.; Kajiyoshi, K.; Yanagisawa, K. Catal. Commol.2008, 9(6), 1050.

[20] Onda, A.; Ochi, T.; Kajiyoshi, K.; Yanagisawa, K. Appl. Catal. A 2008, 343(1~2), 49.

[21] Yan, X.-Y.; Jin, F.-M.; Tohji, K.; Kishita, A.; Enomoto, H. AIChE J. 2010, 56, 2727.

[22] Zhang, S.-P.; Jin, F. -M.; Hu, J.-J.; Huo, Z.-B. Bioresour. Technol. 2010, 102(2011), 1998.

[23] Rasrendra, C. B.; Makertihartha, I.; Adisasmito, S.; Heeres, H. J. Top. Catal. 2010, 53(15~18), 1241.

[24] Hayashi, Y.; Sasaki, Y. Chem. Commol/Lun. 2005, 41(21), 2716。

[25] Holm, M. S.; Saravanamurugan, S.; Taarning, E. Science 2010, 328, 602.

[26] Chambon, F.; Rataboul, F.; Pinel, C.; Cabiac, A.; Guillon, E.; Essayem, N. Appl. Catal. B 2011, 105, 171.

[27] (a) Aslanov, L. A.; Zakharov, V. N.; Savilov, S. V. RU 2471709, 2013 [Chenm. Abstr. 2013, 158, 162458].

(b) Patil, A. B.; Pathak, P.; Shinde, V. S.; Godbole, S. V.; Mohahapatra, P. K. Dalton Trans. 2013, 42(5), 1519.

(c) Luo, S.-Z.; Mi, X.-L.; Zhang, L.; Liu, S.; Xu, H.; Cheng, J.-P. Tetrahedron 2007, 1923.

[28] Song, Y.-L.; Wang, X.-C.; Huang, C.-P.; Liang, F.-B.; Chen, B.-H. Chin. J. Org. Chem. 2013, 33, 1715 (in Chinese). (宋彦磊, 王新承, 黄崇品, 梁凤兵, 毓志超, 陈标华, 有机化学, 2013, 33, 1715.)

[29] Gao, Y.-J. M.S. Thesis, Zhejiang Normal University, Jinhua, 2009 (in Chinese). (高尤剑, 硕士论文, 浙江师范大学, 金华, 2009.)

[30] Wei, Z.-Z. M.S. Thesis, Shandong University, Jinan, 2012 (in Chinese). (韦珍珍, 硕士论文, 山东大学, 济南, 2012.)

[31] Li, J.; Sun, H.; Cai, X.-C.; Dai, L.-Y. Chin. J. Org. Chem. 2007, 27, 1296 (in Chinese). (李娟, 孙辉, 蔡晓晨, 戴立益, 有机化学, 2007, 27, 1296.)

[32] Hirao, M.; Ito, K.; Ohno, H. Electrochim. Acta 2000, 45, 1291.

[33] Shaplov, A. S.; Lozinskaya, E. I.; Ponkratov, D. O.; Malyshkina, I. A.; Vidal, F.; Aubert, P. H.; Okatova, O. V.; Pavlov, G. M.; Komarova, L. I.; Wandrey, C.; Vygodskii, Y. S. Electrochim. Acta 2011, 57, 74.

[34] Ohno, H.; Ito, K. Chem. Lett. 1998, 27, 751.

[35] Hirao, M.; Ito, K.; Ohno, H. Polym. Adv. Technol. 2000, 11, 534.

[36] Zhang, H.; Zhou, Z. -B.; Nie, J. Prog. Chem. 2013, 25(5), 761 (in Chinese). (张恒, 周志彬, 聂进, 化学进展, 2013, 25(5), 761.)

[37] He, H.-Y.; Zhang, S.-J.; Liu, X.-M.; Wang, J.-W.; Yao, X.-Q.; Zhang, X.-P. Fluid Phase Equilib. 2013, 169.

[38] Yan, R.-Y.; Yang, P.; Li, Z.-X.; Wang, H.; Diao, Y.-Y.; Wang, L.; Zhang, S.-J. Adv. Mater. Res. 2011, 1146.

[39] Dong, K.; Song, Y.-T.; Liu, X.-M.; Cheng, W.-G.; Yao, X. -Q.; Zhang, S.-J. J. Phys. Chem. B 2011, 1007.

[40] Kanazawa, A.; Ikeda, T.; Endo, T. J. Polym. Sci., Part A: Polym. Chem. 1993, 31, 1099.

[41] Bicker, M.; Endres, S.; Ott, L.; Vogel, H. Mol. J. Catal. A: Chem.2005, 239, 151.

[42] Ellis, A. V.; Wilson, M. A. J. Org. Chem. 2002, 67, 8469.

[43] Rasrendra, C. B.; Fachri, B. A.; Makertihartha, I. G. B. N.; Adisasmito, S.; Heeres, H. J. ChemSusChem 2011, 4, 768.

/

| 〈 |

|

〉 |