铁催化硬脂酸选择性氢化制硬脂醇

收稿日期: 2019-02-26

网络出版日期: 2019-07-03

基金资助

国家自然科学基金(21702227);中国石油大学(北京)校启动基金(2462014YJRC037)

Iron-Catalyzed Selective Hydrogenation of Stearic Acid to Stearyl Alcohol

Received date: 2019-02-26

Online published: 2019-07-03

Supported by

the National Natural Science Foundation of China(21702227);the Science Foundation of China University of Petroleum (Beijing)(2462014YJRC037)

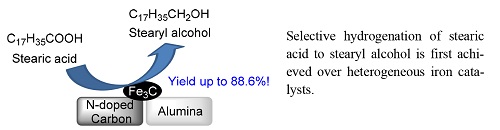

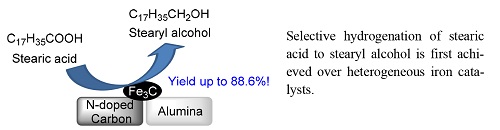

长链脂肪酸是一种重要的生物质原料,其氢化制备的脂肪醇由于用途广泛以及市场价值不断增长,近年来引起了人们的广泛关注.报道了一例使用非均相铁催化硬脂酸选择性加氢制备硬脂醇的实例.与其他非贵金属元素(如钴和镍)相比,铁在地壳中的丰度高出3000~30000倍,价格仅为20~150分之一,因此该方法更经济,更有吸引力.催化剂是通过将铁和氮掺杂碳前驱体同时热解到氧化铝载体上制备的.制备催化剂时最佳热解温度为900℃,最佳铁的质量分数为20%.反应最佳反应温度为320℃,最佳氢气压力为4 MPa.产物随时间分布曲线表明硬脂酸在0.5 h内迅速转化为硬脂醇,收率为88.6%.4 h后逐渐转化为十八烷,收率为90%.

李江 , 万童 , 张俊杰 , 傅尧 . 铁催化硬脂酸选择性氢化制硬脂醇[J]. 有机化学, 2019 , 39(11) : 3258 -3263 . DOI: 10.6023/cjoc201902031

The utilization of sustainable resources such as biomass to produce fuels and chemicals has recently attracted significant attention due to the depletion of fossil reserves, increasing energy demand, and growing environmental concerns. Long-chain fatty acids, which are major constituents of plant oil, are important feedstock for biorefinery. Besides producing well-known biodiesels, the hydrogenation of fatty acids to fatty alcohols has recently drawn significant attention due to the versatility and growing market value of fatty alcohols. An example of heterogenous iron-catalyzed selective hydrogenation of stearic acid to stearyl alcohol is reported. Comparing with other reported non-noble metal centers, such as Co and Ni, Fe is 3000~30000 times more abundant and 20~150 times cheaper, thus making our method more economic and attractive. The iron catalyst was prepared by simultaneous pyrolysis of iron precursor[Fe(acac)3] and nitrogen-doped carbon precursor (melamine) onto alumina, bearing Fe3C active phase and nitrogen-doped carbon-alumina hybrid support. The optimization of preparation parameter showed that the optimal pyrolysis temperature is 900℃, while the best mass fraction of iron is 20%. The replacement of Fe(acac)3 with Fe(NO3)3 led to inferior catalytic performance, which was due to undesired redox reaction between NO3- and melamine during pyrolysis that hampered the reaction between Fe and melamine to form Fe3C active phase. Instead, hercynite phase became the predominant phase. The exploration of reaction parameter showed that the optimal reaction temperature is 320℃, and the best H2 pressure is 4 MPa. The time course for stearic acid conversion shows that stearic acid was rapidly converted into stearyl alcohol with yield of 88.6% within 0.5 h, and then gradually converted into octadecane with yield of 90% at 4 h. The unsatisfactory stability of the iron catalyst is probably due to the decomposition of Fe3C active phase to metallic Fe phase during recycling tests.

Key words: biomass conversion; hydrogenation; iron; fatty acid; fatty alcohol

| [1] | Huber G. W. Iborra S. Corma A. Chem. Rev. 2006 106 4044. |

| [2] | Corma A. Iborra S. Velty A. Chem. Rev. 2007 107 2411. |

| [3] | Yang Z. Fu Y. Guo Q. Chin. J. Org. Chem. 2015 35 273. |

| [3] | 杨 珍 傅 尧 郭 庆祥 有机化学 2015 35 273. |

| [4] | Jamil F. Al-Haj L. Al-Muhtaseb A. H. Al-Hinai M. A. Baawain M. Rashid U. Ahmad M. N. M. Rev. Chem. Eng. 2018 34 267. |

| [5] | Besson, M.; Gallezot, P.; Pinel, C. Chem. Rev. 2014, 114, 1827. |

| [6] | Gupta S. Frost and Sullivan Market Insight 2004 11075449. |

| [7] | Adkins H. Folkers K. J. Am. Chem. Soc. 1931 53 1095. |

| [8] | Toba M. Tanaka S.-I. Niwa S.-I. Mizukami F. Koppa?ny Z. Guczi L. Cheah K.-Y. Tang T.-S. Appl. Catal., A 1999 189 243. |

| [9] | Mendes M. Santos O. Jordao E. Silva A. Appl. Catal., A 2001 217 253. |

| [10] | Takeda Y. Nakagawa Y. Tomishige K. Catal. Sci. Technol. 2012 2 2221. |

| [11] | Takeda Y. Tamura M. Nakagawa Y. Okumura K. Tomishige K. ACS Catal. 2015 5 7034. |

| [12] | Ullrich J. Breit B. ACS Catal. 2018 8 785. |

| [13] | Manyar H. G. Paun C. Pilus R. Rooney D. W. Thompson J. M. Hardacre C. Chem. Commun. 2010 46 6279. |

| [14] | Rozmys?owicz B. Kirilin A. Aho A. Manyar H. Hardacre C. Wa?rn J. Salmi T. Murzin D. Y. J. Catalysis 2015 328 197. |

| [15] | Toyao T. Siddiki S. M. Touchy A. S. Onodera W. Kon K. Morita Y. Kamachi T. Yoshizawa K. Shimizu K. I. Chem.-Eur. J. 2017 23 1001. |

| [16] | Kandel K. Chaudhary U. Nelson N. C. Slowing I. I. ACS Catal. 2015 5 6719. |

| [17] | Wu L. Li L. Li B. Zhao C. Chem. Commun. 2017 53 6152. |

| [18] | Onyestya?k G. Harnos S. Kallo? D. Catal. Commun. 2011 16 184. |

| [19] | Gao X. Tong D. Zhong H. Jin B. Jin F. Zhang H. RSC Adv. 2016 6 27623. |

| [20] | Kong X. Fang Z. Bao X. Wang Z. Mao S. Wang Y. J. Catalysis 2018 367 139. |

| [21] | Jia W. Xu G. Liu X. Zhou F. Ma H. Zhang Y. Fu Y. Energy Fuels 2018 32 8438. |

| [22] | Song S. Wang D. Di L. Wang C. Dai W. Wu G. Guan N. Li L. Chin. J. Catal. 2018 39 250. |

| [23] | Li J. Zhang J. Wang S. Xu G. Wang H. Vlachos D. G. ACS Catal. 2019 9 1564. |

| [24] | Jagadeesh R. V. Surkus A. Junge H. Pohl M. Radnik J. Rabeah J. Huan H. Schunemann V. Bruckner A. Beller M. Science 2013 342 1073. |

| [25] | Cui X. Li Y. Bachmann S. Scalone M. Surkus A. Junge K. Topf C. Beller M. J. Am. Chem. Soc. 2015 137 10652. |

| [26] | Natte K. Neumann H. Jagadeesh R. V. Beller M. Nat. Commun. 2017 8 1344. |

| [27] | Li J. Liu J. Zhou H. Fu Y. ChemSusChem 2016 9 1339. |

| [28] | Li J. Liu J. Liu H. Xu G. Zhang J. Liu J. Zhou G. Li Q. Xu Z. Fu Y. ChemSusChem 2017 10 1436. |

| [29] | Li J. Zhang J. Liu H. Liu J. Xu G. Liu J. Sun H. Fu Y. ChemistrySelect 2017 2 11062. |

| [30] | Li J. Sun H. Liu J. X. Zhang J. J. Li Z. X. Fu Y. Mol. Catal. 2018 452 36. |

| [31] | Leveneur J. Waterhouse G. I. N. Kennedy J. Metson J. B. Mitchell D. R. G. J. Phys. Chem. C 2011 115 20978. |

/

| 〈 |

|

〉 |