化学学报 ›› 2022, Vol. 80 ›› Issue (7): 946-955.DOI: 10.6023/A22020093 上一篇 下一篇

研究论文

牛犇a,b, 翟振宇a,b, 郝肖柯a,b, 任婷莉a,b, 李从举a,b,*( )

)

投稿日期:2022-02-27

发布日期:2022-05-05

通讯作者:

李从举

基金资助:

Ben Niua,b, Zhenyu Zhaia,b, Xiaoke Haoa,b, Tingli Rena,b, Congju Lia,b( )

)

Received:2022-02-27

Published:2022-05-05

Contact:

Congju Li

Supported by:文章分享

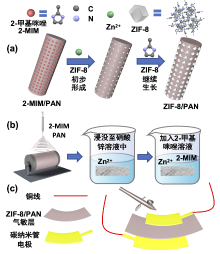

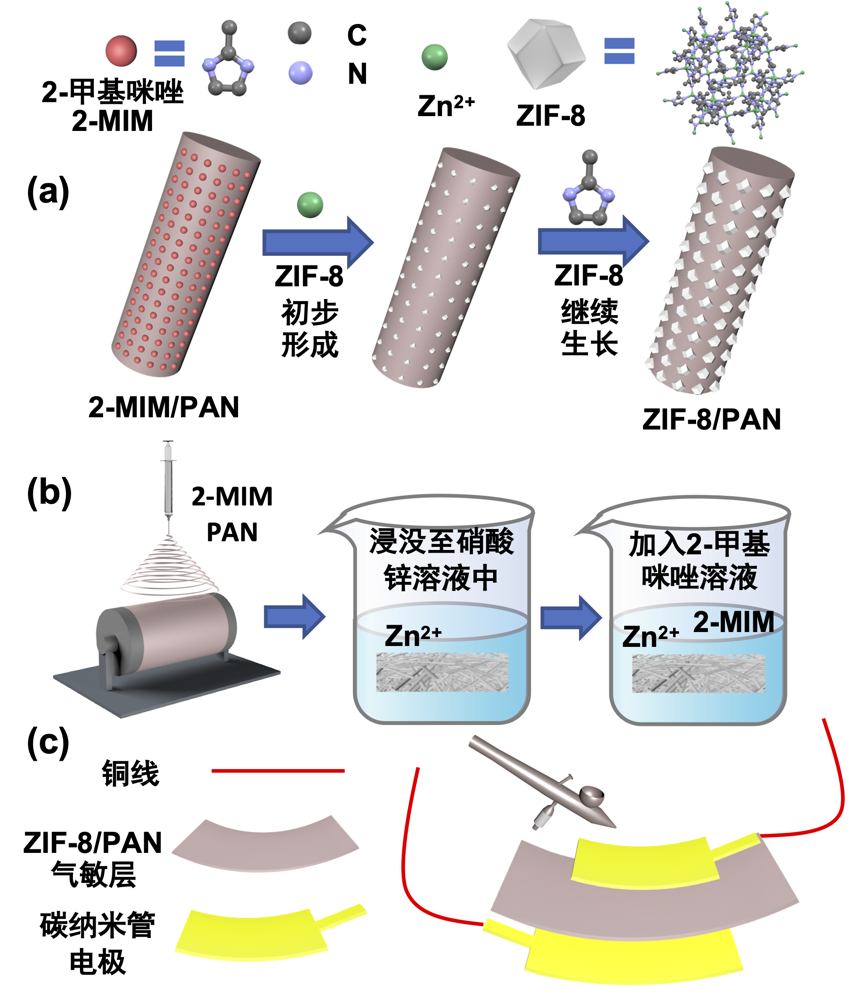

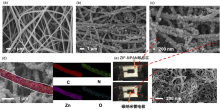

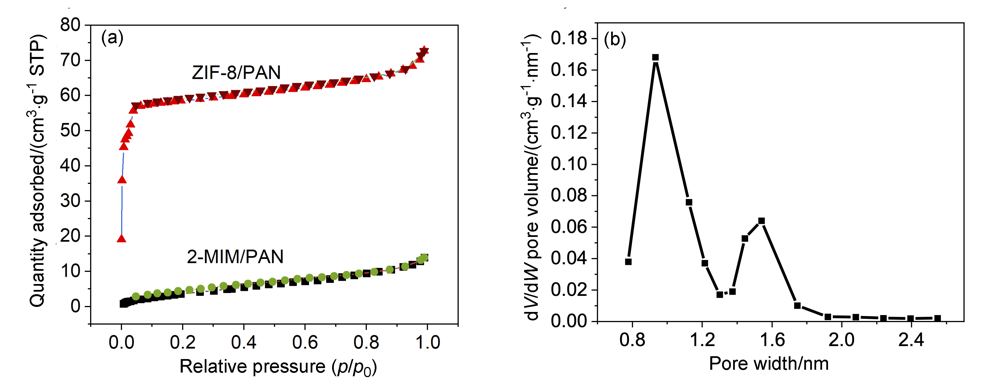

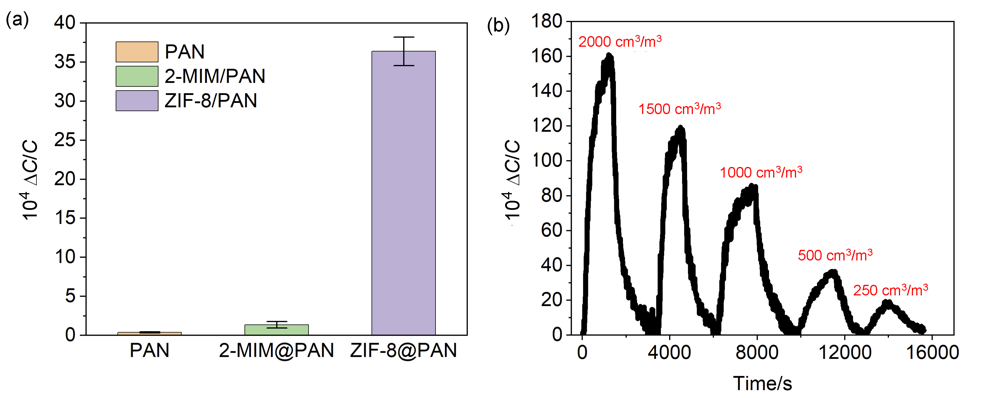

ZIF-8是一种Zn基金属有机骨架材料, 可以吸附丙酮气体从而作为电容式丙酮传感器的气敏材料, 然而ZIF-8的传统使用形式为粉末态, 这导致其不能成为具备柔性的整体, 从而限制了传感器的柔性. 结合包埋种子和二次生长法将ZIF-8与纳米纤维结合成纤维型柔性材料, 并将其作为气敏层制备了柔性电容式丙酮气体传感器. 该传感器在9种常见挥发性有机化合物中表现出良好的选择性, 对250~2000 cm3/m3的丙酮气体具有灵敏的响应、良好的循环响应及长期稳定性. 值得注意的是该柔性传感器不仅在室温下进行传感, 而且在弯折180°的状态下对丙酮气体的响应值与不弯折(0°)状态下几乎一致, 在200次以内的180°弯折-恢复后同样表现出了传感性能的稳定, 表明了其在柔性传感器方面的潜力.

牛犇, 翟振宇, 郝肖柯, 任婷莉, 李从举. 基于ZIF-8/PAN复合薄膜的柔性丙酮气体传感器[J]. 化学学报, 2022, 80(7): 946-955.

Ben Niu, Zhenyu Zhai, Xiaoke Hao, Tingli Ren, Congju Li. Flexible Acetone Gas Sensor based on ZIF-8/Polyacrylonitrile (PAN) Composite Film[J]. Acta Chimica Sinica, 2022, 80(7): 946-955.

| [1] |

Li, X. Q.; Zhang, L.; Yang, Z. Q.; Wang, P.; Yan, Y. F.; Ran, J. Y. Sep. Purif. Technol. 2020, 235, 116213.

doi: 10.1016/j.seppur.2019.116213 |

| [2] |

Yang, C. T.; Miao, G.; Pi, Y. H.; Xia, Q. B.; Wu, J. L.; Li, Z.; Xiao, J. Chem. Eng. J. 2019, 370, 1128.

doi: 10.1016/j.cej.2019.03.232 |

| [3] |

Gardner, J. W.; Shin, H. W.; Hines, E. L. Sens. Actuators, B 2000, 70, 19.

|

| [4] |

Liu, D.; Pervaiz, E.; Adimi, S.; Thomas, T.; Qu, F.; Huang, C.; Wang, R.; Jiang, H.; Yang, M. Appl. Surf. Sci. 2021, 566, 150642.

doi: 10.1016/j.apsusc.2021.150642 |

| [5] |

Wang, C. X.; Cai, D. P.; Liu, B.; Li, H.; Wang, D. D.; Liu, Y.; Wang, L. L.; Wang, Y. R.; Li, Q. H.; Wang, T. H. J. Mater. Chem. A 2014, 2, 10623.

doi: 10.1039/c4ta00844h |

| [6] |

Cavallari, M. R.; Izquierdo, J. E. E.; Braga, G. S.; Dirani, E. a. T.; Pereira-Da-Silva, M. A.; Rodríguez, E. F. G.; Fonseca, F. J. Sensors 2015, 15, 9592.

doi: 10.3390/s150409592 pmid: 25912354 |

| [7] |

Cao, R.; Zhao, S. Y.; Li, C. J. ACS Appl. Electron. Mater. 2019, 1, 2301.

doi: 10.1021/acsaelm.9b00483 |

| [8] |

Zhang, X. L.; Na, J. W.; Xing, Y.; Li, C. J. Glob. Chall. 2019, 3, 1900070.

|

| [9] |

Surya, S. G.; Bhanoth, S.; Majhi, S. M.; More, Y. D.; Teja, V. M.; Chappanda, K. N. CrystEngComm 2019, 21, 7303.

doi: 10.1039/C9CE01323G |

| [10] |

Impeng, S.; Junkaew, A.; Maitarad, P.; Kungwan, N.; Zhang, D.; Shi, L.; Namuangruk, S. Appl. Surf. Sci. 2019, 473, 820.

doi: 10.1016/j.apsusc.2018.12.209 |

| [11] |

Hazra, A.; Das, S.; Kanungo, J.; Sarkar, C. K.; Basu, S. Sens. Actuators, B 2013, 183, 87.

|

| [12] |

Paliwal, A.; Sharma, A.; Tomar, M.; Gupta, V. Sens. Actuators, B 2017, 250, 679.

|

| [13] |

Li, Z.; Zhang, Y.; Zhang, H.; Yi, J. X. Sens. Actuators, B 2021, 344, 130182.

|

| [14] |

Andrés, M. A.; Vijjapu, M. T.; Surya, S. G.; Shekhah, O.; Salama, K. N.; Serre, C.; Eddaoudi, M.; Roubeau, O.; Gascón, I. ACS Appl. Mater. Interfaces 2020, 12, 4155.

doi: 10.1021/acsami.9b20763 |

| [15] |

Zeinali, S.; Homayoonnia, S.; Homayoonnia, G. Sens. Actuators, B 2019, 278, 153.

|

| [16] |

Scott, A. J.; Majdabadifarahani, N.; Stewart, K. M. E.; Duever, T. A.; Penlidis, A. Macromol. React. Eng. 2020, 14, 2000004.

doi: 10.1002/mren.202000004 |

| [17] |

Lan, K. B.; Wang, Z.; Yang, X. D.; Wei, J. Q.; Qin, Y. X.; Qin, G. X. Nanotechnology 2022, 33, 155502.

doi: 10.1088/1361-6528/ac46b3 |

| [18] |

Andrysiewicz, W.; Krzeminski, J.; Skarżynski, K.; Marszalek, K.; Sloma, M.; Rydosz, A. Electron. Mater. Lett. 2020, 16, 146.

doi: 10.1007/s13391-020-00199-z |

| [19] |

Zhang, L.; Guo, Y. Y. H.; Liu, G. Y.; Tan, Q. L. IEEE Access 2020, 8, 171568.

doi: 10.1109/ACCESS.2020.3023028 |

| [20] |

Zhang, J. W.; Li, P.; Zhang, X. N.; Ma, X. J.; Wang, B. Acta Chim. Sinica 2020, 78, 597. (in Chinese)

doi: 10.6023/A20050153 |

|

(张晋维, 李平, 张馨凝, 马小杰, 王博, 化学学报, 2020, 78, 597.)

doi: 10.6023/A20050153 |

|

| [21] |

Li, C.; Li, N.; Chang, L. M.; Gu, Z. G.; Zhang, J. Acta Chim. Sinica 2022, 80, 340. (in Chinese)

doi: 10.6023/A21120545 |

|

(李崇, 李娜, 常立美, 谷志刚, 张健, 化学学报, 2022, 80, 340.)

doi: 10.6023/A21120545 |

|

| [22] |

Qi, Y.; Ren, S. S.; Che, Y.; Ye, J. W.; Ning, G. L. Acta Chim. Sinica 2020, 78, 613. (in Chinese)

doi: 10.6023/A20040126 |

|

(齐野, 任双颂, 车颖, 叶俊伟, 宁桂玲, 化学学报, 2020, 78, 613.)

doi: 10.6023/A20040126 |

|

| [23] |

Zeng, J. Y.; Wang, X. S.; Zhang, X. Z.; Zhuo, R. X. Acta Chim. Sinica 2019, 77, 1156. (in Chinese)

doi: 10.6023/A19070259 |

|

(曾锦跃, 王小双, 张先正, 卓仁禧, 化学学报, 2019, 77, 1156.)

doi: 10.6023/A19070259 |

|

| [24] |

Zhai, Z. Y.; Zhang, X. L.; Wang, J. N.; Li, H. Y.; Sun, Y. X.; Hao, X. K.; Qin, Y.; Niu, B.; Li, C. J. Chem. Eng. J. 2022, 428, 131720.

doi: 10.1016/j.cej.2021.131720 |

| [25] |

Zhang, X. L.; Hao, X. K.; Zhai, Z. Y.; Wang, J. N.; Li, H. Y.; Sun, Y. X.; Qin, Y.; Niu, B.; Li, C. Appl. Surf. Sci. 2022, 573, 151446.

doi: 10.1016/j.apsusc.2021.151446 |

| [26] |

Szilágyi, P. Á.; Westerwaal, R. J.; Van De Krol, R.; Geerlings, H.; Dam, B. J. Mater. Chem. C 2013, 1, 8146.

doi: 10.1039/c3tc31749h |

| [27] |

Chen, B. L.; Yang, Z. X.; Zhu, Y. Q.; Xia, Y. D. J. Mater. Chem. A 2014, 2, 16811.

doi: 10.1039/C4TA02984D |

| [28] |

Peng, L, C.; Zhang, X, L..; Sun, Y, X.; Xing, Y.; Li, C, J. Environ. Res. 2020, 188, 109742.

doi: 10.1016/j.envres.2020.109742 |

| [29] |

Venkatesh, M. R.; Sachdeva, S.; El Mansouri, B.; Wei, J.; Bossche, A.; Bosma, D.; De Smet, L. C. P. M.; Sudhölter, E. J. R.; Zhang, G. Q. Sensors 2019, 19, 888.

doi: 10.3390/s19040888 |

| [30] |

Sun, Y. X.; Zhang, X. L.; Xi, H. L.; Li, C. J. Fine Chem. 2020, 37, 1334. (in Chinese)

|

|

(孙亚昕, 张秀玲, 习海玲, 李从举, 精细化工, 2020, 37, 1334.)

|

|

| [31] |

Yao, A.; Jiao, X.; Chen, D.; Li, C. ACS Appl. Mater. Interfaces 2020, 12, 18437.

doi: 10.1021/acsami.9b22242 |

| [32] |

Ma, K. K.; Wang, Y. F.; Chen, Z. J.; Islamoglu, T.; Lai, C. L.; Wang, X. W.; Fei, B.; Farha, O. K.; Xin, J. H. ACS Appl. Mater. Interfaces 2019, 11, 22714.

doi: 10.1021/acsami.9b04780 |

| [33] |

Ma, K.; Idrees, K. B.; Son, F. A.; Maldonado, R.; Wasson, M. C.; Zhang, X.; Wang, X.; Shehayeb, E.; Merhi, A.; Kaafarani, B. R.; Islamoglu, T.; Xin, J. H.; Farha, O. K. Chem. Mater. 2020, 32, 7120.

doi: 10.1021/acs.chemmater.0c02379 |

| [34] |

Hao, X. K.; Zhai, Z. Y.; Sun, Y. X.; Li, C. J. Acta Chim. Sincia 2022, 80, 49. (in Chinese)

|

|

(郝肖柯, 翟振宇, 孙亚昕, 李从举, 化学学报, 2022, 80, 49.)

doi: 10.6023/A21080402 |

|

| [35] |

Zhang, X. L.; Fan, W.; Li, H.; Zhao, S. Y.; Wang, J. N.; Wang, B.; Li, C. J. J. Mater. Chem. A 2018, 6, 21458.

doi: 10.1039/C8TA07884J |

| [36] |

Cao, R.; Wang, J. N.; Zhao, S. Y.; Yang, W.; Yuan, Z. Q.; Yin, Y. Y.; Du, X. Y.; Li, N. W.; Zhang, X. L.; Li, X. Y.; Wang, Z. L.; Li, C. J. Nano Res. 2018, 11, 3771.

doi: 10.1007/s12274-017-1951-2 |

| [37] |

Lee, S.; Franklin, S.; Hassani, F. A.; Yokota, T.; Someya, T. Science 2020, 370, 966.

doi: 10.1126/science.abc9735 |

| [38] |

Homayoonnia, S.; Zeinali, S. Sens. Actuators, B 2016, 237, 776.

|

| [39] |

Tung, T. T.; Tran, M. T.; Feller, J.-F.; Castro, M.; Van Ngo, T.; Hassan, K.; Nine, M. J.; Losic, D. Carbon 2020, 159, 333.

doi: 10.1016/j.carbon.2019.12.010 |

| [40] |

Bahri, M.; Haghighat, F.; Kazemian, H.; Rohani, S. Chem. Eng. J. 2017, 313, 711.

doi: 10.1016/j.cej.2016.10.004 |

| [41] |

Huang, X. C.; Lin, Y. Y.; Zhang, J. P.; Chen, X. M. Angew. Chem., Int. Ed. 2006, 45, 1557.

doi: 10.1002/anie.200503778 |

| [42] |

Shekhah, O.; Eddaoudi, M. Chem. Commun. 2013, 49, 10079.

doi: 10.1039/c3cc45343j |

| [1] | 刘佳, 陈光海, 陈轶群, 江杰涛, 肖霄, 吴强, 杨立军, 王喜章, 胡征. 碳热还原活化扩孔提升介观结构碳纳米笼超级电容器性能★[J]. 化学学报, 2023, 81(7): 709-716. |

| [2] | 王文涛, 耿伟纬, 郭小龙, 王康辉, 姚玉元, 丁黎明. 光/电-热转换柔性相变复合膜的制备及性能[J]. 化学学报, 2023, 81(6): 595-603. |

| [3] | 贾洋刚, 陈诗洁, 邵霞, 程婕, 林娜, 方道来, 冒爱琴, 李灿华. 高性能无钴化钙钛矿型高熵氧化物负极材料的制备及储锂性能研究[J]. 化学学报, 2023, 81(5): 486-495. |

| [4] | 李西安, 李孝坤. 基于温度诱导相转变共聚物和导电聚合物的自隔断超级电容器[J]. 化学学报, 2023, 81(5): 511-519. |

| [5] | 蒋江民, 郑欣冉, 孟雅婷, 贺文杰, 陈亚鑫, 庄全超, 袁加仁, 鞠治成, 张校刚. 氟氮共掺杂多孔碳纳米片的制备及其储钾性能研究[J]. 化学学报, 2023, 81(4): 319-327. |

| [6] | 梁华润, 马浩轩, 段新荣, 于洁, 王灏珉, 李硕, 朱梦嘉, 陈爱兵, 郑晖, 张莹莹. 柔性电化学传感器及其在无创医学检测中的应用★[J]. 化学学报, 2023, 81(10): 1402-1419. |

| [7] | 张国强, 霍京浩, 王鑫, 郭守武. 基于P掺杂TiO2/C纳米管负极的高性能锂离子电容器[J]. 化学学报, 2023, 81(1): 6-13. |

| [8] | 李小娟, 叶梓瑜, 谢书涵, 王永净, 王永好, 吕源财, 林春香. 氮氯共掺杂多孔碳活化过一硫酸盐降解苯酚的性能及机理研究[J]. 化学学报, 2022, 80(9): 1238-1249. |

| [9] | 孙嘉贤, 刘禹廷, 尹志刚, 郑庆东. 基于吸收互补有机半导体本体复合薄膜的高性能柔性光突触晶体管[J]. 化学学报, 2022, 80(7): 936-945. |

| [10] | 王志琴, 项博, 黄晓宇, 陆国林, 冯纯. 磷钨酸对对苯撑乙烯撑寡聚物-b-聚(2-乙烯基吡啶)自晶种行为的影响※[J]. 化学学报, 2022, 80(3): 297-302. |

| [11] | 王雨柔, 王国琪, 李想, 尹君, 朱剑. 溶液法制备柔性压阻式传感器的研究进展[J]. 化学学报, 2022, 80(2): 214-228. |

| [12] | 龚政, 张意, 吕华, 崔树勋. 脯氨酸聚酯的单链力学性质[J]. 化学学报, 2022, 80(1): 7-10. |

| [13] | 郝肖柯, 翟振宇, 孙亚昕, 李从举. 柔性可水洗的Zr-MOFs复合纳米纤维薄膜的制备和性能表征[J]. 化学学报, 2022, 80(1): 49-55. |

| [14] | 翟耀, 辛国祥, 王佳琦, 张邦文, 宋金玲, 刘晓旭. 微波辅助合成具有优异电化学性能的rGO/CeO2超级电容器电极材料[J]. 化学学报, 2021, 79(9): 1129-1137. |

| [15] | 郭彩霞, 马小杰, 王博. 金属有机框架基复合材料的制备及其光热性能研究[J]. 化学学报, 2021, 79(8): 967-985. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||