[1] Osman M. B.; Tierney J. E.; Zhu J.; Tardif R.; Hakim G. J.; King J.; Poulsen C. J.,Nature 2021, 599, 239-244.

[2] Allen M. R.; Frame D. J.; Huntingford C.; Jones C. D.; Lowe J. A.; Meinshausen M.; Meinshausen N.,Nature 2009, 458, 1163-1166.

[3] Duan H.; Zhou S.; Jiang K.; Bertram C.; Harmsen M.; Kriegler E.; van Vuuren, D. P.; Wang, S.; Fujimori, S.; Tavoni, M.; Ming, X.; Keramidas, K.; Iyer, G.; Edmonds, J.,Science 2021, 372, 378-385.

[4] Rogelj J.; den Elzen, M.; Höhne, N.; Fransen, T.; Fekete, H.; Winkler, H.; Schaeffer, R.; Sha, F.; Riahi, K.; Meinshausen, M.,Nature 2016, 534, 631-639.

[5] Li H.; Zick M. E.; Trisukhon T.; Signorile M.; Liu X.; Eastmond H.; Sharma S.; Spreng T. L.; Taylor J.; Gittins J. W.; Farrow C.; Lim S. A.; Crocellà V.; Milner P. J.; Forse A. C.,Nature 2024, 630, 654-659.

[6] Sanz-Pérez, E. S.; Murdock, C. R.; Didas, S. A.; Jones, C. W.,Chem. Rev. 2016, 116, 11840-11876.

[7] Ren S.; Joulié D.; Salvatore D.; Torbensen K.; Wang M.; Robert M.; Berlinguette C. P.,Science 2019, 365, 367-369.

[8] Nitopi S.; Bertheussen E.; Scott S. B.; Liu X.; Engstfeld A. K.; Horch S.; Seger B.; Stephens I. E.L.; Chan, K.; Hahn, C.; Nørskov, J. K.; Jaramillo, T. F.; Chorkendorff, I.,Chem. Rev. 2019, 119, 7610-7672.

[9] Huang L.; Gao G.; Zhao J.; Roberts W. L.; Lu X.,Nat. Catal. 2025, 8, 968-976.

[10] García de Arquer, F. P.; Dinh, C.-T.; Ozden, A.; Wicks, J.; McCallum, C.; Kirmani, A. R.; Nam, D.-H.; Gabardo, C.; Seifitokaldani, A.; Wang, X.; Li, Y. C.; Li, F.; Edwards, J.; Richter, L. J.; Thorpe, S. J.; Sinton, D.; Sargent, E. H.,Science 2020, 367, 661-666.

[11] Yang Y.; Louisia S.; Yu S.; Jin J.; Roh I.; Chen C.; Fonseca Guzman, M. V.; Feijóo, J.; Chen, P.-C.; Wang, H.; Pollock, C. J.; Huang, X.; Shao, Y.-T.; Wang, C.; Muller, D. A.; Abruña, H. D.; Yang, P.,Nature 2023, 614, 262-269.

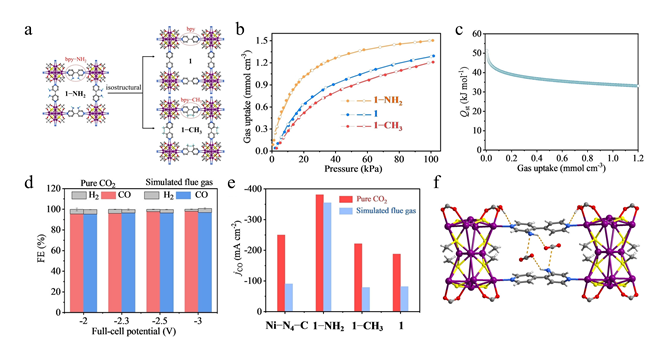

[12] Huang D.-S.; Wang Y.; Tang Y.; Huang J.-R.; Li P.-X.; Liang C.-P.; Zhao Z.-H.; Liao P.-Q.; Chen X.-M.,Natl. Sci.Rev. 2025, 12, nwaf329.

[13] Song Y.; Musgrave C. B.; Su J.; Huang L.; Guo W.; Liu Y.; Li G.; Xin Y.; Zhang Q.; Feng X.; Liao C.; Liu S.; Kwok R. T.K.; Lam, J. W. Y.; He, M.; Choong, K. S.; Feng, Z.; Tang, B. Z.; Goddard, W. A.; Ye, R.,Nat. Nanotechnol. 2025, 21, 78-86.

[14] Dai Y.; Li H.; Wang C.; Xue W.; Zhang M.; Zhao D.; Xue J.; Li J.; Luo L.; Liu C.; Li X.; Cui P.; Jiang Q.; Zheng T.; Gu S.; Zhang Y.; Xiao J.; Xia C.; Zeng J.,Nat. Commun. 2023, 14, 3382.

[15] Huang D.-S.; Zhu H.-L.; Zhao Z.-H.; Huang J.-R.; Liao P.-Q.; Chen X.-M.,ACS Catal. 2022, 12, 8444-8450.

[16] Ding J.;Bin Yang, H.; Ma, X.-L.; Liu, S.; Liu, W.; Mao, Q.; Huang, Y.; Li, J.; Zhang, T.; Liu, B.,Nat. Energy 2023, 8, 1386-1394.

[17] Huang D.-S.; Qiu X.-F.; Huang J.-R.; Mao M.; Liu L.; Han Y.; Zhao Z.-H.; Liao P.-Q.; Chen X.-M.,Nat. Synth. 2024, 3, 1404-1413.

[18] Zhang H.; Li D.; Chen Z.; Wang Y.; Sun H.; Liu F.; Liu M.; Zheng Y.; Huang H.,Chin. J. Chem. 2024, 42, 1846-1852.

[19] Lu J.; Wang Q.; Jin Z.; Xiao Y.; Huang B.-H.; Zhang C.-H.; Yang G.-Z.; Zhou Y.; Ke F.-S.,Chin. J. Chem. 2024, 42, 2788-2794.

[20] Jin S.; Hao Z.; Zhang K.; Yan Z.; Chen J.,Angew. Chem. Int. Ed. 2021, 60, 20627-20648.

[21] Guan Y.; Li Y.; Li Z.; Hou Y.; Lei L.; Yang B.,Adv. Mater. 2025, 37, 2417567.

[22] Belsa B.; Xia L.; Golovanova V.; Polesso B.; Pinilla-Sánchez, A.; San Martín, L.; Ye, J.; Dinh, C.-T.; García de Arquer, F. P.,Nat. Rev. Mater. 2024, 9, 535-549.

[23] Lai W.; Qiao Y.; Zhang J.; Lin Z.; Huang H.,Energy Environ. Sci. 2022, 15, 3603-3629.

[24] Jia S.; Ma X.; Sun X.; Han B.,CCS Chem. 2022, 4, 3213-3229.

[25] Goeppert A.; Czaun M.; Surya Prakash, G. K.; Olah, G. A.,Energy Environ. Sci. 2012, 5, 7833-7853.

[26] Chu S.,Science 2009, 325, 1599-1599.

[27] Keith D. W.; Holmes G.; St. Angelo,D.; Heidel, K.,Joule 2018, 2, 1573-1594.

[28] Wei W.; Li D.; Yan X.; Mu X.; Li Z.; Liu Z.,Carbon Capture Sci. Technol. 2024, 13, 100235.

[29] Buckingham J.; Reina T. R.; Duyar M. S.,Carbon Capture Sci. Technol. 2022, 2, 100031.

[30] Wang M.; Joel A. S.; Ramshaw C.; Eimer D.; Musa N. M.,Appl. Energy 2015, 158, 275-291.

[31] Gouedard C.; Picq D.; Launay F.; Carrette P. L.,Int. J. Greenh. Gas Control 2012, 10, 244-270.

[32] Bui M.; Adjiman C. S.; Bardow A.; Anthony E. J.; Boston A.; Brown S.; Fennell P. S.; Fuss S.; Galindo A.; Hackett L. A.; Hallett J. P.; Herzog H. J.; Jackson G.; Kemper J.; Krevor S.; Maitland G. C.; Matuszewski M.; Metcalfe I. S.; Petit C.; Puxty G.; Reimer J.; Reiner D. M.; Rubin E. S.; Scott S. A.; Shah N.; Smit B.; Trusler J. P.M.; Webley, P.; Wilcox, J.; Mac Dowell, N.,Energy Environ. Sci. 2018, 11, 1062-1176.

[33] Dutcher B.; Fan M.; Russell A. G.,ACS Appl. Mater. Interfaces 2015, 7, 2137-2148.

[34] Yang Q.; Wang X.; Zhang J.; Mao Y.; Xi S.; Liu Y.-C.; Hsu Y.-H.; Zhang L.; Bin Dolmanan, S.; Wang, M.; Wang, B.; Zang, Y.; Zhang, M.; Leow, W. R.; Hung, S.-F.; Wang, Z.; Lum, Y.,Nat. Synth. 2025, 4, 1396-1407.

[35] Jouny M.; Luc W.; Jiao F.,Ind. Eng. Chem. Res. 2018, 57, 2165-2177.

[36] Jin J.; Wicks J.; Min Q.; Li J.; Hu Y.; Ma J.; Wang Y.; Jiang Z.; Xu Y.; Lu R.; Si G.; Papangelakis P.; Shakouri M.; Xiao Q.; Ou P.; Wang X.; Chen Z.; Zhang W.; Yu K.; Song J.; Jiang X.; Qiu P.; Lou Y.; Wu D.; Mao Y.; Ozden A.; Wang C.; Xia B. Y.; Hu X.; Dravid V. P.; Yiu Y.-M.; Sham T.-K.; Wang Z.; Sinton D.; Mai L.; Sargent E. H.; Pang Y.,Nature 2023, 617, 724-729.

[37] Luo J.-P.; Zhang J.; Yin N.; Wang T.-P.; Tan Z.-C.; Han W.; Shi Q.,Chem. Eng. J. 2022, 442, 136210.

[38] Hou P.; Song W.; Wang X.; Hu Z.; Kang P.,Small 2020, 16, 2001896.

[39] Jiao L.; Yang W.; Wan G.; Zhang R.; Zheng X.; Zhou H.; Yu S.-H.; Jiang H.-L.,Angew. Chem. Int. Ed. 2020, 59, 20589-20595.

[40] Ding M.; Liu X.; Ma P.; Yao J.,Coord. Chem. Rev. 2022, 465, 214576.

[41] Zhang Y.; Ding L.; Xie Z.; Zhang X.; Sui X.; Li J.-R.,Chin. Chem. Lett. 2025, 36, 109676.

[42] Zhao Z.-H.; Huang J.-R.; Huang D.-S.; Zhu H.-L.; Liao P.-Q.; Chen X.-M.,J. Am. Chem. Soc. 2024, 146, 14349-14356.

[43] Liu Y.-Y.; Huang J.-R.; Zhu H.-L.; Liao P.-Q.; Chen X.-M.,Angew. Chem. Int. Ed. 2023, 62, e202315579.

[44] Kim C.; Bui J. C.; Luo X.; Cooper J. K.; Kusoglu A.; Weber A. Z.; Bell A. T.,Nat. Energy 2021, 6, 1026-1034.

[45] Li H.-Y.; Kong X.-J.; Han S.-D.; Pang J.; He T.; Wang G.-M.; Bu X.-H.,Chem. Soc. Rev. 2024, 53, 5626-5676.

[46] Lees E. W.; Bui J. C.; Romiluyi O.; Bell A. T.; Weber A. Z.,Nat. Chem. Eng. 2024, 1, 340-353.

[47] Liu W.; Lv Z.; Li X.; Wang C.; Tian C.; Feng X.; Wang B.; Yang W.,J. Am. Chem. Soc. 2025, 147, 24023-24031.

[48] Mukhopadhyay S.; Naeem M. S.; Shiva Shanker, G.; Ghatak, A.; Kottaichamy, A. R.; Shimoni, R.; Avram, L.; Liberman, I.; Balilty, R.; Ifraemov, R.; Rozenberg, I.; Shalom, M.; López, N.; Hod, I.,Nat. Commun. 2024, 15, 3397. |