化学学报 ›› 2021, Vol. 79 ›› Issue (6): 787-793.DOI: 10.6023/A21030098 上一篇 下一篇

研究论文

投稿日期:2021-03-19

发布日期:2021-05-13

通讯作者:

苑世领

基金资助:

Yingzhe Du, Heng Zhang, Shiling Yuan( )

)

Received:2021-03-19

Published:2021-05-13

Contact:

Shiling Yuan

Supported by:文章分享

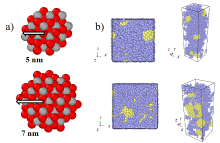

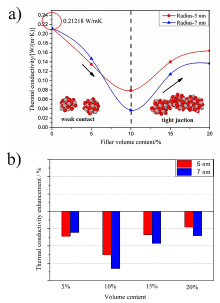

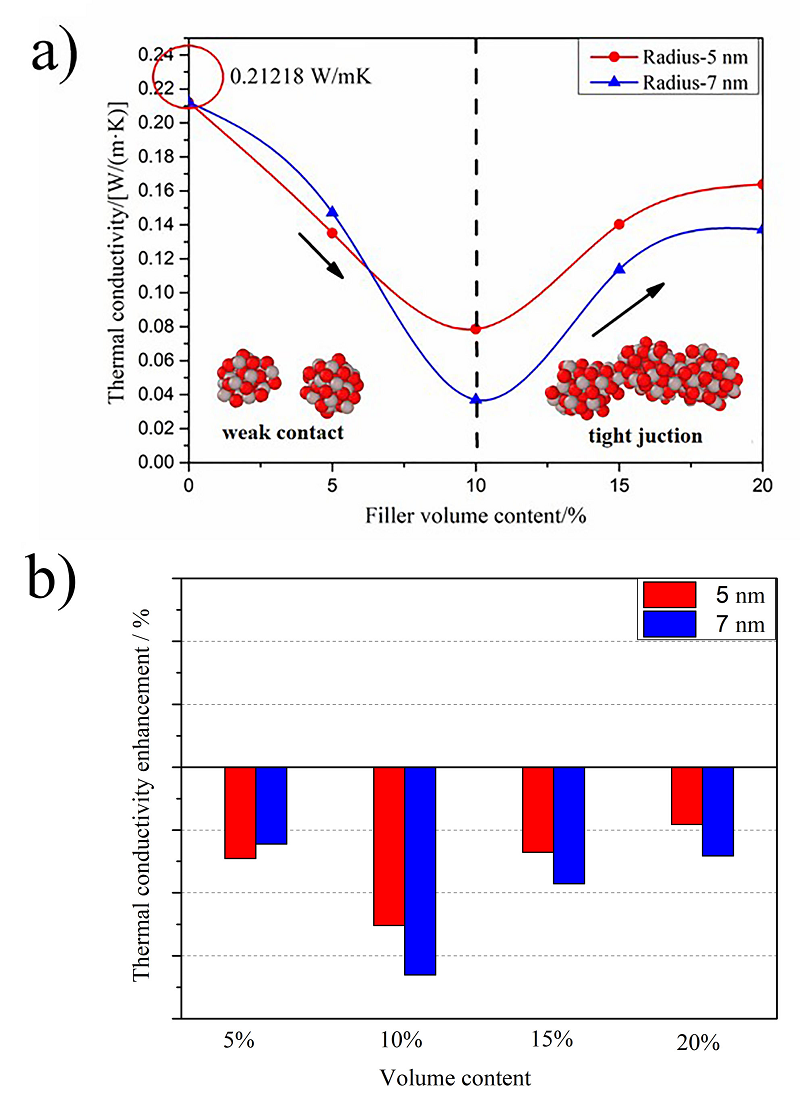

采用分子动力学模拟方法研究了Al2O3/聚甲基二硅氧烷(PDMS)复合材料在300 K时的传热行为, 通过分析热传导、温度梯度以及导热增强等理论数据, 讨论了不同半径以及不同浓度的Al2O3填料粒子对PDMS传热的影响. 结果表明随着体积分数的增大, Al2O3/PDMS复合材料的热传导先减小后增加. 并且当Al2O3填充粒子的半径为5 nm时, Al2O3/PDMS复合材料的热传导达到最大值. 通过考察传热过程中的Al2O3填料和Al2O3/PDMS复合材料的温度和结构变化, 添加有小半径Al2O3填料的Al2O3/PDMS复合材料在传热的过程中主要以声子的形式进行传热, 此时决定热导率的主要因素有热容c、声子的平均速度v和声子的平均自由程l. 同时, 当体积分数为15%时, 传导链形成, 热量可以顺利通过Al2O3填料形成的传导链传播, 有助于热传导的增加.

杜英喆, 张恒, 苑世领. Al2O3/PDMS复合材料热传导的分子动力学模拟[J]. 化学学报, 2021, 79(6): 787-793.

Yingzhe Du, Heng Zhang, Shiling Yuan. Molecular Dynamics Simulation of Thermal Conductivity of Al2O3/PDMS Composites[J]. Acta Chimica Sinica, 2021, 79(6): 787-793.

| [1] |

Fu, G. C.; Gao, Z. X.; Fang, Z. Q.; Zou, H. Electro-mechanical Engineering 2004, 103, 13. (in Chinese)

|

|

(付桂翠, 高泽溪, 方志强, 邹航, 电子机械工程, 2004, 103, 13.)

|

|

| [2] |

Gohy, J. F.; Vanhoorne, A.; Jérôme, R. Macromolecules 1996, 29, 3376.

doi: 10.1021/ma951303u |

| [3] |

Park, W.; Guo, Y.; Li, X. J. Phys. Chem. C 2015, 119, 26753.

doi: 10.1021/acs.jpcc.5b08816 |

| [4] |

Ralphs, M. I.; Kemme, N.; Vartak, P. B.; Joseph, E.; Tipnis, S.; Turnage, S.; Solanki, K. N.; Wang, R. Y.; Rykaczewski, K. ACS Appl. Mater. Interfaces 2018, 10, 2083.

doi: 10.1021/acsami.7b15814 |

| [5] |

Zhang, R.; Cai, J.; Wang, Q.; Li, J.; Hu, Y.; Du, H.; Li, L. J. Electron. Packag. 2014, 136, 011012.

doi: 10.1115/1.4026616 |

| [6] |

Chung, D. D. Appl. Therm. Eng. 2001, 21, 1593.

doi: 10.1016/S1359-4311(01)00042-4 |

| [7] |

Sim, L. C.; Ramanan, S. R.; Ismail, H.; Seetharamu, K. N.; Goh, T. J. Thermochim. Acta 2005, 430, 155.

doi: 10.1016/j.tca.2004.12.024 |

| [8] |

Goel, P.; Choudhury, M. D.; Bin Aqeel, A.; Li, X. Y.; Shao, L. H.; Duan, H. L. Langmuir 2019, 35, 6916.

doi: 10.1021/acs.langmuir.9b00799 |

| [9] |

Yao, Y. M.; Ye, Z. Q.; Huang, F. Y.; Zeng, X. L. ACS Appl. Mater. Interfaces 2020, 12, 2892.

doi: 10.1021/acsami.9b19280 |

| [10] |

Pan, C. F.; Ohm, Y.; Wang, J. X.; Ford, M. J.; Kumar, K.; Kumar, S.; Majidi, C. ACS Appl. Mater. Interfaces 2019, 11, 42561.

doi: 10.1021/acsami.9b13266 |

| [11] |

Yu, H. T.; Feng, Y. Y.; Gao, L.; Chen, C. Macromolecules 2020, 53, 7161.

doi: 10.1021/acs.macromol.9b02544 |

| [12] |

Yang, C. R.; Chen, C. D.; Cheng, C.; Shi, W. H.; Chen, P. H.; Teng, T. P. Int. J. Therm. Sci. 2020, 155, 106431.

doi: 10.1016/j.ijthermalsci.2020.106431 |

| [13] |

Sim, L. C.; Lee, C. K.; Ramanan, S. R.; Ismall, H.; Seetharamu, K. N. Polym.-Plast. Technol. Eng. 2006, 45, 301.

doi: 10.1080/03602550500373683 |

| [14] |

Huang, Z. Q.; Wu, W.; Drummer, D.; Liu, C.; Wang, Y.; Wang, Z. Y. Polymers 2021, 13, 248.

doi: 10.3390/polym13020248 |

| [15] |

Yang, J. K.; Yang, Y. Small 2011, 7, 2334.

doi: 10.1002/smll.v7.16 |

| [16] |

Zhou, W. Y.; Zhang, Y. T. China Synthetic Resin and Plastics 2010, 27, 69. (in Chinese)

|

|

(周文英, 张亚婷, 合成树脂及材料, 2010, 27, 69.)

|

|

| [17] |

Socher, R.; Krause, B.; Hermasch, S.; Wursche, R.; Potschke, P. Compos. Sci. Technol. 2011, 71, 1053.

doi: 10.1016/j.compscitech.2011.03.004 |

| [18] |

Cai, S. Y.; Chang, C. H.; Huang, Y. F.; Lin, W. J. ACS Appl. Mater. Interfaces 2018, 10, 17393.

doi: 10.1021/acsami.8b04950 |

| [19] |

Pak, S. Y.; Kim, H. M.; Kim, S. Y.; Youn, J. R. Carbon 2012, 50, 4830.

doi: 10.1016/j.carbon.2012.06.009 |

| [20] |

Xie, B. H.; Huang, X.; Zhang, G. J. Compos. Sci. Technol. 2013, 85, 98.

doi: 10.1016/j.compscitech.2013.06.010 |

| [21] |

Yang, S. Q.; Li, W. Z.; Bai, S. B. ACS Appl. Mater. Interfaces 2019, 11, 3388.

doi: 10.1021/acsami.8b16209 |

| [22] |

Lin, F.; Bhatia, G. S.; Ford, J. D. J. Appl. Polym. Sci. 1993, 49, 1869.

doi: 10.1002/app.1993.070491101 |

| [23] |

Nielsen, L. E. J. Appl. Polym. Sci. 1973, 17, 3819.

doi: 10.1002/app.1973.070171224 |

| [24] |

Agari, Y.; Uno, T. J. Appl. Polym. Sci. 1986, 32, 5705.

doi: 10.1002/app.1986.070320702 |

| [25] |

Plimpton, S. J. Comput. Phys. 1995, 117, 1.

|

| [26] |

Mu, Q. H.; Feng, S. Y.; Diao, G. Z. Polym. Composite. 2010, 28, 125.

doi: 10.1002/(ISSN)1548-0569 |

| [27] |

Aktulga, H. M.; Fogarty, J. C.; Pandit, A. Y. Parallel Comput. 2012, 38, 245.

doi: 10.1016/j.parco.2011.08.005 |

| [28] |

Yuan, S. D.; Wang, X. Y.; Zhang, H. J. Phys. Chem. C 2020, 124, 1932.

doi: 10.1021/acs.jpcc.9b08702 |

| [29] |

Moradi, H.; Azizpour, H.; Bahmanyar, H. Heliyon 2020, 6, e05383.

doi: 10.1016/j.heliyon.2020.e05383 |

| [30] |

Wang, Z. T.; Li, H.; Yan, S. C.; Fang, Q. R. Acta Chim. Sinica 2020, 78, 63. (in Chinese)

doi: 10.6023/A19110397 |

|

(王志涛, 李辉, 颜士臣, 方千荣, 化学学报, 2020, 78, 63.)

doi: 10.6023/A19110397 |

|

| [31] |

Yu, H.; Guo, J.; Wang, J.; Long, Y. C. Acta Chim. Sinica 2012, 70, 1543. (in Chinese)

doi: 10.6023/A1203041 |

|

(余辉, 郭娟, 汪靖, 龙英才, 化学学报, 2012, 70, 1543.)

doi: 10.6023/A1203041 |

|

| [32] |

Xu, W. X.; Wu, Y. Y.; Zhu, Y.; Liang, X. G. Chin. Phys. B 2020, 29, 046601. (in Chinese)

doi: 10.1088/1674-1056/ab7743 |

|

(徐文雪, 吴雁艳, 祝渊, 梁新刚, 中国物理B, 2020, 29, 046601.)

|

|

| [33] |

Mark, J. J. Am. Chem. Soc. 2009, 131, 16330.

|

| [34] |

Castejon, H. J. J. Phys. Chem. B 2003, 107, 826.

doi: 10.1021/jp021189z |

| [35] |

Ikeshoji, T.; Hafskjold, B. Mol. Phys. 1994, 81, 251.

doi: 10.1080/00268979400100171 |

| [36] |

Sundstrom, D. W.; Lee, Y. D. J. Appl. Polym. Sci. 1972, 16, 3159.

doi: 10.1002/app.1972.070161210 |

| [37] |

Si, W. Y.; He, X. X.; Huang, Y.; Gao, X. L.; Zheng, X. T.; Zheng, X. P.; Leng, C.; Su, F. C.; Wu, D. M. RSC Adv. 2018, 8, 36007.

doi: 10.1039/C8RA07229A |

| [38] |

Li, A.; Zhang, C.; Zhang, Y. F. Polymers 2017, 9, 437.

|

| [39] |

Zhou, W. Y.; Qi, S. H.; Tu, C. C.; Zhao, H. Z.; Wang, C. F.; Kou, J. L. J. Appl. Polym. Sci. 2010, 104, 1312.

doi: 10.1002/(ISSN)1097-4628 |

| [40] |

Hao, L. Y.; Wen, B. Y.; Zhang, Y. P. China Plastics 2017, 31, 1994. (in Chinese)

|

|

(郝鲁阳, 温变英, 张宜鹏, 中国塑料, 2017, 31, 1994.)

|

|

| [41] |

Liu, J.; Yang, R. G. Phys. Rev. B 2012, 86, 104307.

doi: 10.1103/PhysRevB.86.104307 |

| [42] |

Schelling, P. K.; Phillpot, S. R.; Keblinski, P. Phys. Rev. B 2002, 65, 144306.

doi: 10.1103/PhysRevB.65.144306 |

| [1] | 王华高, 程群峰. 冰模板技术仿生构筑层状高分子纳米复合材料的研究进展★[J]. 化学学报, 2023, 81(9): 1231-1239. |

| [2] | 王海朋, 蔡文生, 邵学广. 抗冻剂抗冻机制的近红外光谱与分子模拟研究★[J]. 化学学报, 2023, 81(9): 1167-1174. |

| [3] | 袁瑞琳, 陈龙, 吴长征. 二维纳米材料热传导行为及其界面调控※[J]. 化学学报, 2022, 80(6): 839-847. |

| [4] | 宋亚瑞, 王凯升, 安广宇, 赵法军, 门彬, 杜昭兮, 王东升. 粉末活性炭基复合材料制备及净化含油污水的性能和机制[J]. 化学学报, 2022, 80(12): 1592-1599. |

| [5] | 朱鹏飞, 娄晨思, 史雨翰, 王传义. Ag/AgCl/ZIF-8复合材料的制备及其对NO光催化氧化性能的研究[J]. 化学学报, 2022, 80(10): 1385-1393. |

| [6] | 刘汉鼎, 贾国栋, 朱胜, 盛建, 张则尧, 李彦. 功能碳基复合材料在锂硫电池正极中的应用[J]. 化学学报, 2022, 80(1): 89-97. |

| [7] | 郭彩霞, 马小杰, 王博. 金属有机框架基复合材料的制备及其光热性能研究[J]. 化学学报, 2021, 79(8): 967-985. |

| [8] | 李旭飞, 闫保有, 黄维秋, 浮历沛, 孙宪航, 吕爱华. 金属有机骨架及其复合材料基于筛分复合效应的C2分离的研究进展[J]. 化学学报, 2021, 79(4): 459-471. |

| [9] | 王宁, 庞宏伟, 于淑君, 顾鹏程, 宋爽, 王宏青, 王祥科. 层状双金属氢氧化物及复合材料对放射性元素铀的吸附及机理研究[J]. 化学学报, 2019, 77(2): 143-152. |

| [10] | 马超, 武佳炜, 朱琳, 韩晓霞, 阮伟东, 宋薇, 王旭, 赵冰. g-C3N4/Ag纳米复合材料表面增强拉曼基底对婴幼儿糖果中的罗丹明B的痕量检测[J]. 化学学报, 2019, 77(10): 1024-1030. |

| [11] | 郭宇, 姚远, 李慧, 赫兰兰, 朱尊伟, 杨忠志, 宫利东, 刘翠, 赵东霞. 光合释氧机理的ABEEM/MM/MD和BS-DFT理论研究[J]. 化学学报, 2017, 75(9): 903-913. |

| [12] | 陈海军, 黄舒怡,张志宾, 刘云海, 王祥科. 功能性纳米零价铁的构筑及其对环境放射性核素铀的富集应用研究进展[J]. 化学学报, 2017, 75(6): 560-574. |

| [13] | 郑媛, 罗静, 魏玮, 刘晓亚. Pickering乳液法制备聚苯胺-石墨烯空心微球[J]. 化学学报, 2017, 75(4): 391-397. |

| [14] | 黄佳琦, 孙滢智, 王云飞, 张强. 锂硫电池先进功能隔膜的研究进展[J]. 化学学报, 2017, 75(2): 173-188. |

| [15] | 王蕾, 赵冬冬, 刘旭, 于鹏, 付宏刚. 水热法合成氧化亚钴纳米粒子/石墨烯复合材料及其储锂性能研究[J]. 化学学报, 2017, 75(2): 231-236. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||